Fully-automatic function testing equipment for earphone main board

A fully automated, functional testing technology, applied in electrical components, sorting, sensors, etc., can solve problems such as low product testing efficiency, and achieve the effect of fast and efficient testing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

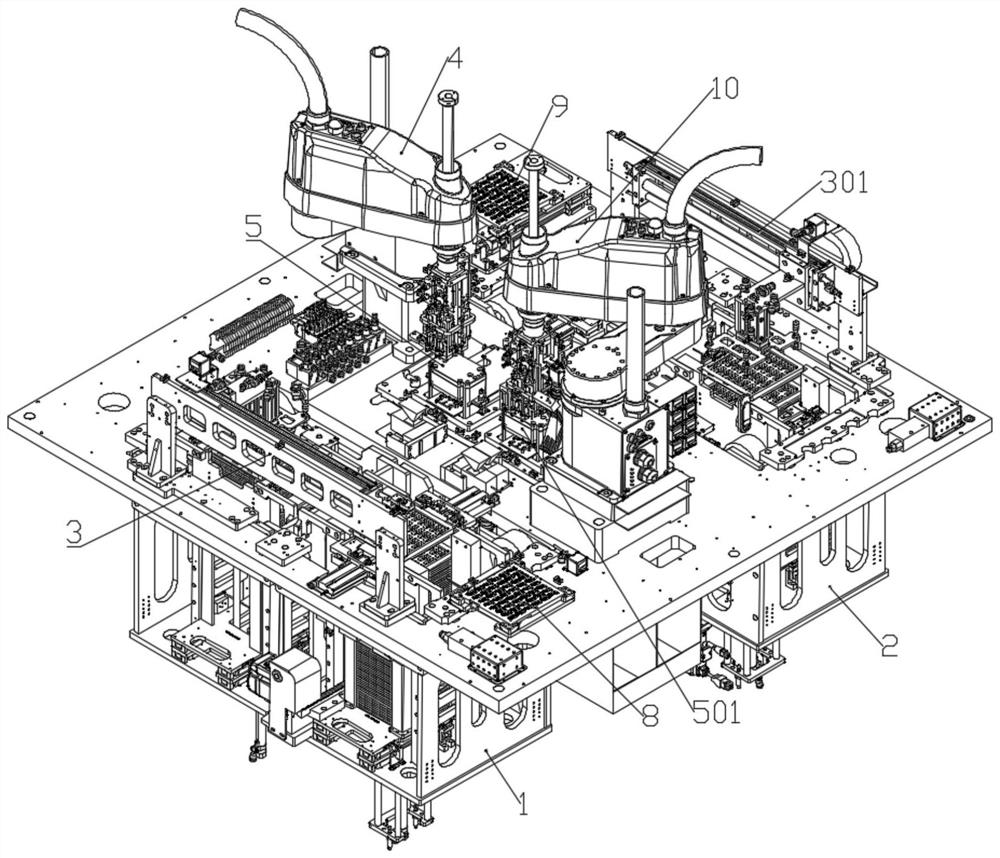

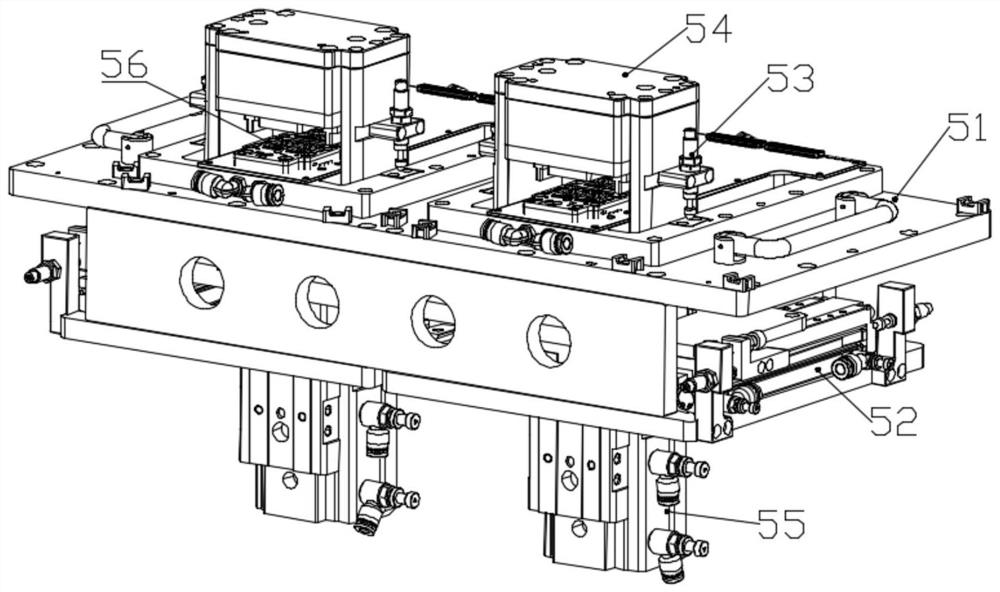

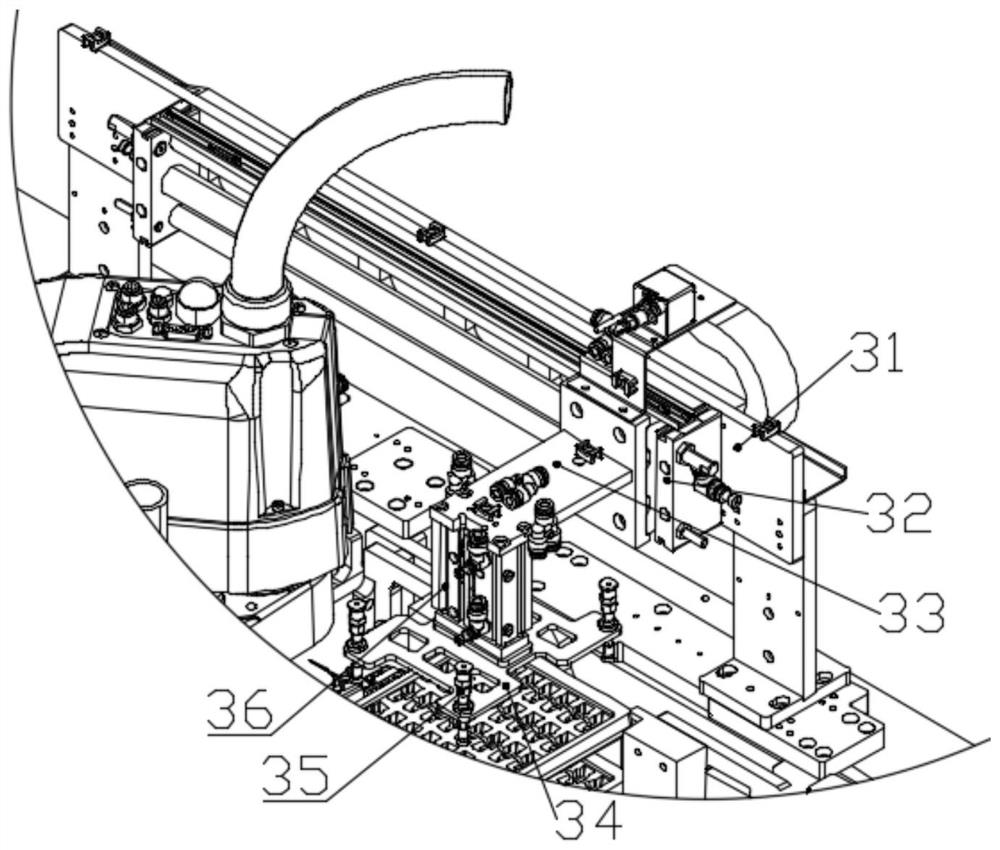

[0028] Such as figure 1 As shown: this embodiment discloses a fully automated functional testing device for earphone mainboards: including product feeding component 1, product discharging component 2, Cui pan grabbing component 1 3, Cui pan grabbing component 2 301, and a feeding manipulator 4. Feeding manipulator 10, NG material tray 9, test component 501 and retest component 5, product feeding component 1 is used to transport the product to the preset position, and tray grabbing component 1-3 is used to grab the product Go to the test component 501 or scan the abnormal tray 8, and grab the tested product to the empty tray, and the product output component 2 is used to output the tray with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com