Test device and test method for pure water point flux of external pressure hollow fiber ultrafiltration membrane

An external pressure hollow fiber and testing device technology, applied in ultrafiltration, chemical instruments and methods, membrane technology, etc., can solve the problem that it is not suitable to use the membrane fiber along the process parameter change, it is not suitable to quantitatively explain the membrane fiber law, and the operating characteristic distribution is not suitable. Uniformity and other problems, to achieve the effect of efficient and fast testing process, low power, and small amount of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

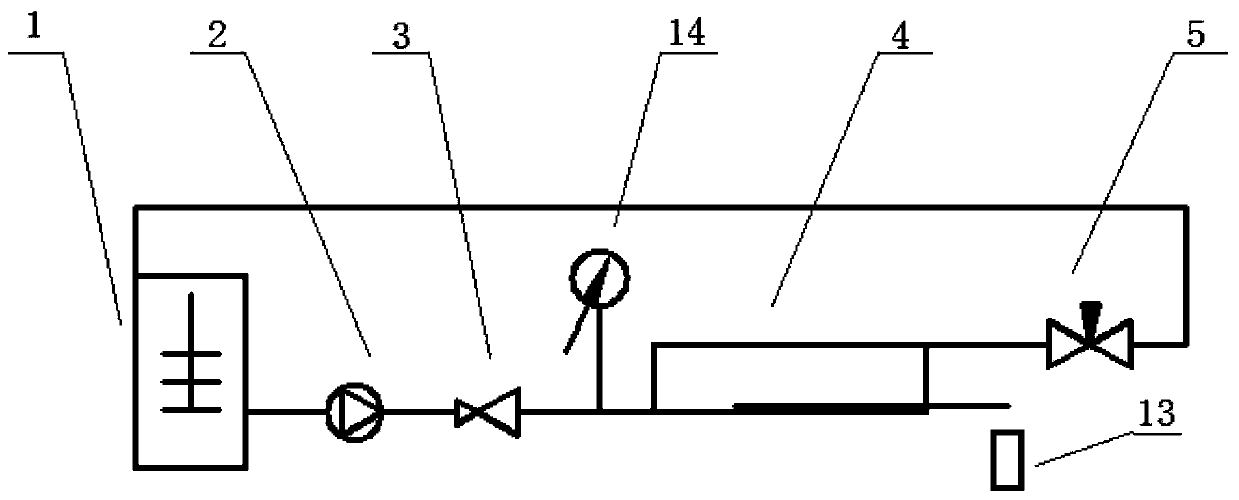

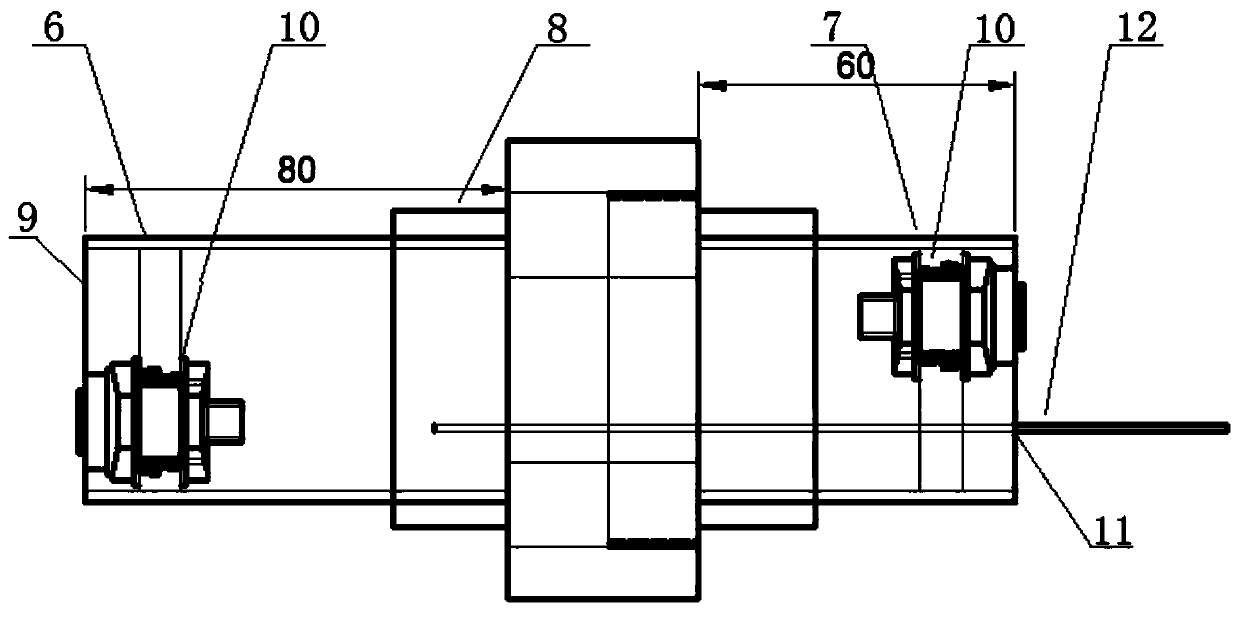

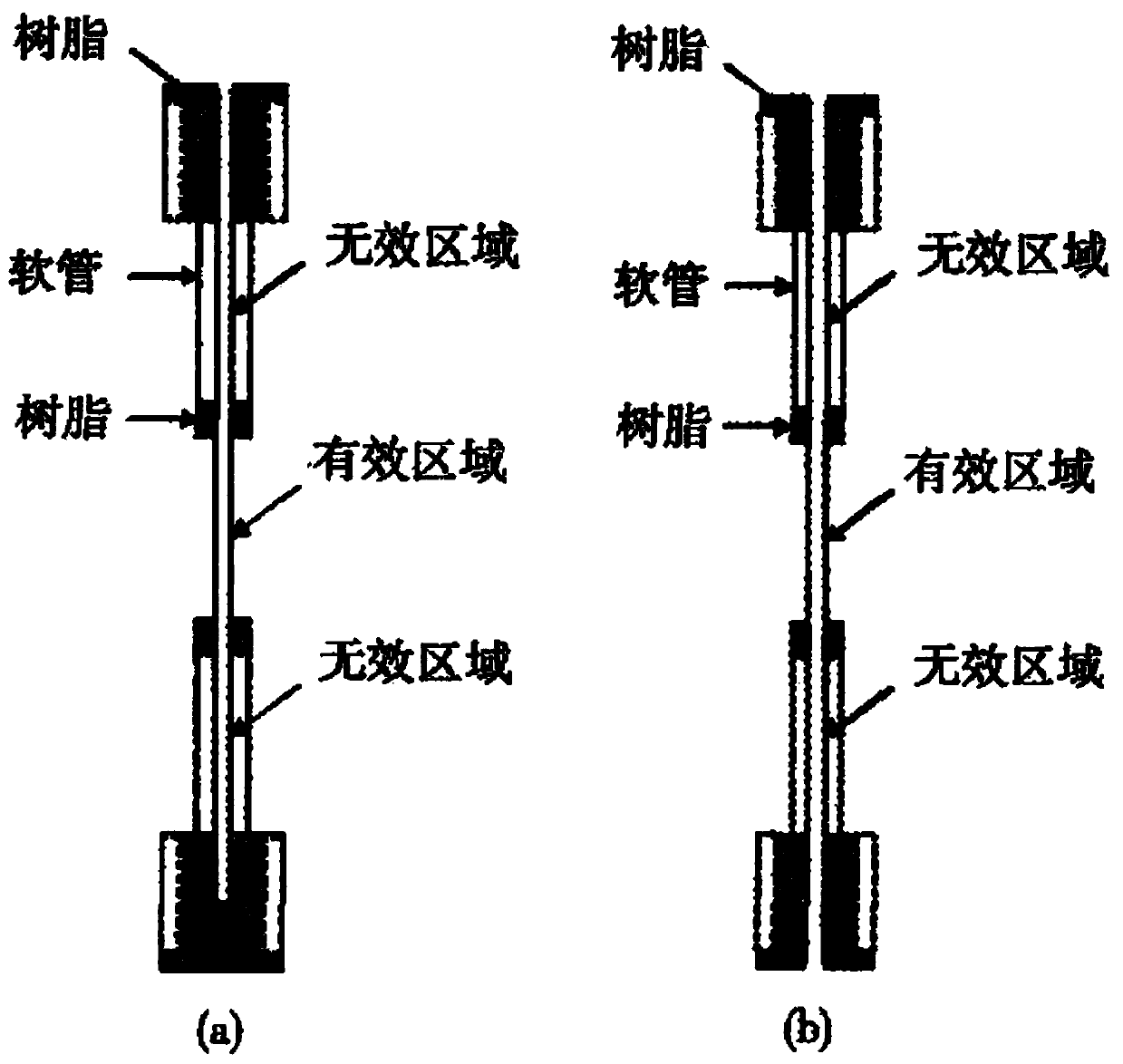

[0040] figure 1 It is a schematic structural diagram of the test device for the pure water point flux of the external pressure hollow fiber ultrafiltration membrane silk provided in the embodiment of the present invention; figure 2 is a schematic diagram of the structure of the membrane module to be tested; such as Figures 1 to 2 As shown in the figure, the test device for the pure water point flux of the external pressure hollow fiber ultrafiltration membrane silk provided in this embodiment includes a constant temperature tank 1, a water pump 2, a pressure reducing valve 3, a membrane to be measured that are connected in sequence through pipelines and form a loop Component 4, throttle valve 5; the membrane module 4 to be tested includes a first water supply pipe 6, a second water supply pipe 7, a joint 8, an end sealing disc 9, the first water supply pipe 6 and the second water supply pipe One end of 7 is detachably connected to both ends of the live connection 8, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com