Marine diesel engine fuel oil filter with ultrasonic cleaning device and filtering method

A technology for marine diesel engines and fuel filters, which is applied to machines/engines, charging systems, mechanical equipment, etc., can solve problems such as incomplete filter cleaning, improve cleaning efficiency and cleaning quality, ensure cleaning, and solve cleaning problems. thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

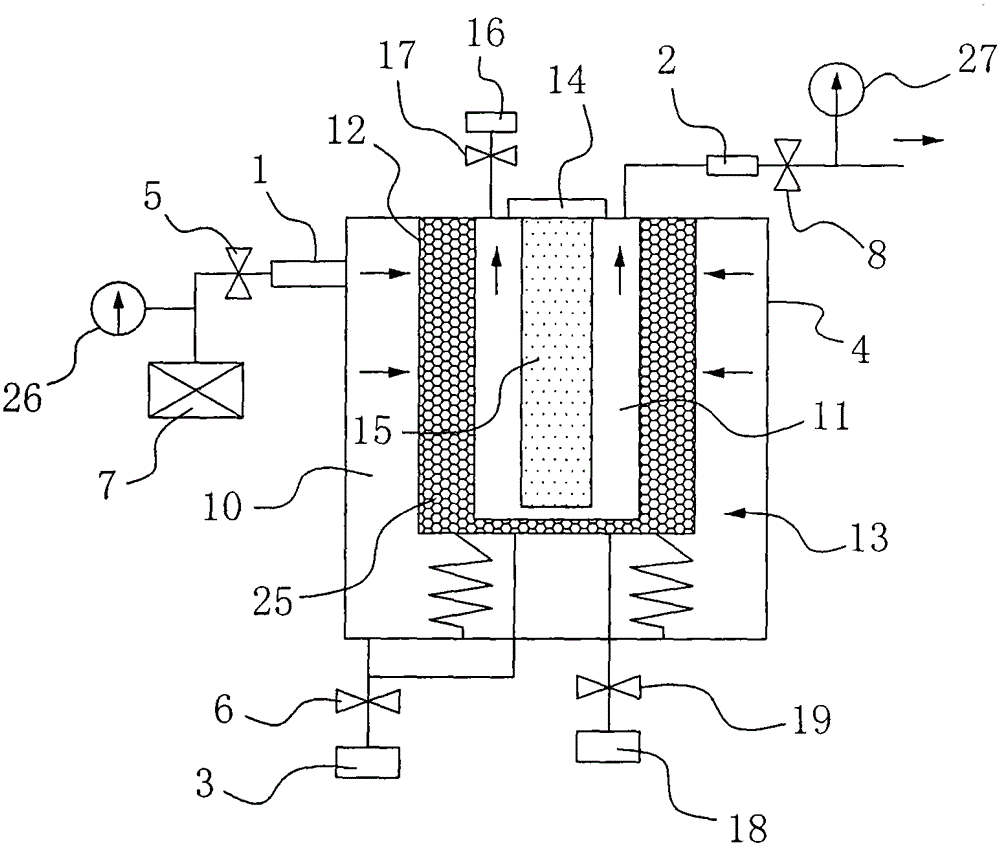

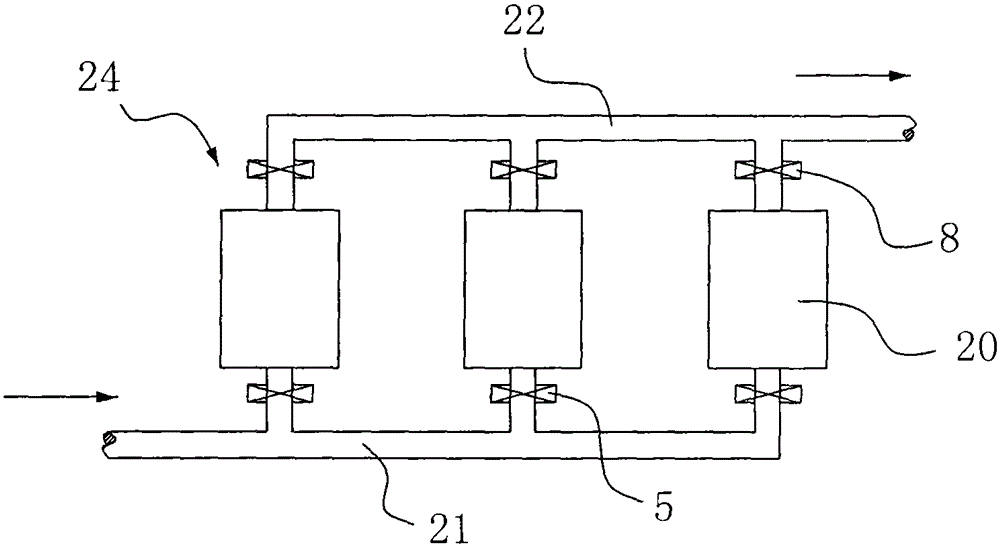

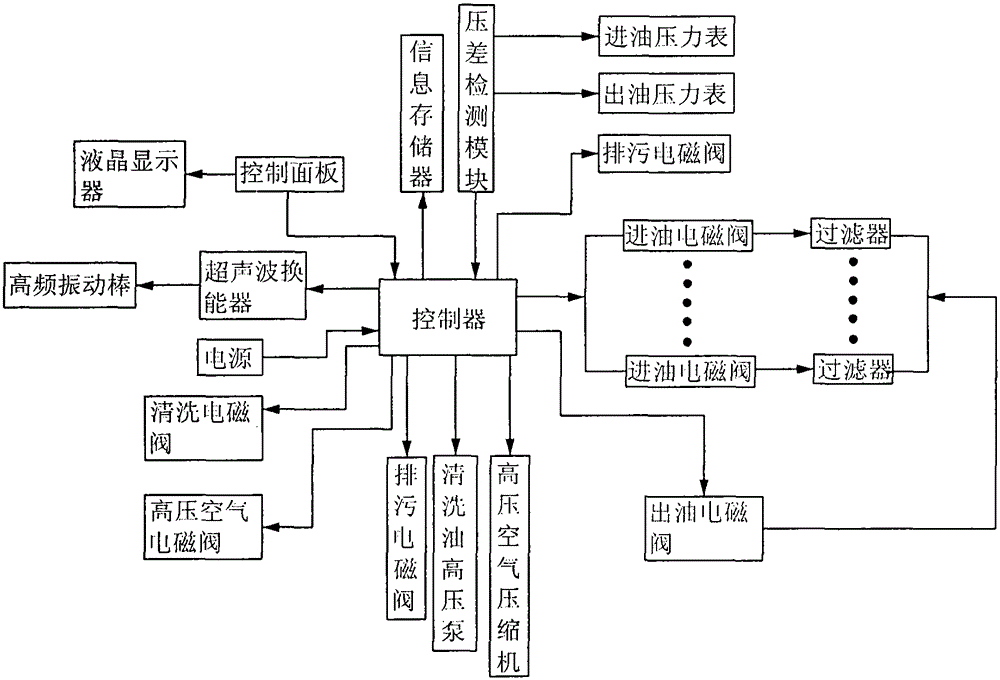

[0032] like figure 1 , 2 , shown in 3, a kind of marine diesel engine fuel filter with ultrasonic cleaning device, comprises a filter housing 4 that has oil inlet 1, oil outlet 2 and the blowdown outlet 3 that is used for impurity discharge, enters Oil inlet 1, oil outlet 2 and sewage outlet 3 are respectively equipped with oil inlet solenoid valve 5, oil outlet solenoid valve 8 and sewage discharge solenoid valve 6 to control their opening and closing. Oil inlet 1 is connected to the oil tank 7 on the ship , the oil outlet 2 is connected with the engine oil supply pipeline, and an accommodating chamber 10 for accommodating heavy oil is formed inside the filter housing 4, and a filter chamber 11 for filtering heavy oil is provided in the accommodating chamber 10 A filter element 12, the surface of the filter element 12 is evenly distributed with a plurality of filter holes 25 communicating with the accommodation chamber 10 and the filter chamber 11, and the sewage outlet 3 is...

Embodiment 2

[0048] The same part of this embodiment and embodiment 1 will not be repeated, and its difference is:

[0049] 1. In order to thoroughly clean the dirt remaining in the filter after deep cleaning, regular cleaning can be performed after deep cleaning to achieve the best effect.

[0050] 2. In the cleaning process of the high-pressure oil of the present invention, the heavy diesel oil used by the diesel engine itself can be used, and light oil with a smaller viscosity can also be used. When other light oils are used for cleaning, the cleaning solenoid valve can be opened to enter the oil for cleaning. When the heavy diesel oil of the marine diesel engine itself is used for cleaning, it is not necessary to open the cleaning solenoid valve to feed the oil, and the heavy diesel oil that enters the oil inlet can be directly used.

[0051] 3. In the setting of the cleaning program, this embodiment can adopt the pressure difference control method, that is, an oil inlet for detecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com