Preparation method of bandgap longitudinal gradient distributed Ga2O3 thin film co-doped with Al and Fe

A gradient distribution and co-doping technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of uneven electric field distribution, large leakage current, unstable electrical performance, etc., achieving superior performance, dense film, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

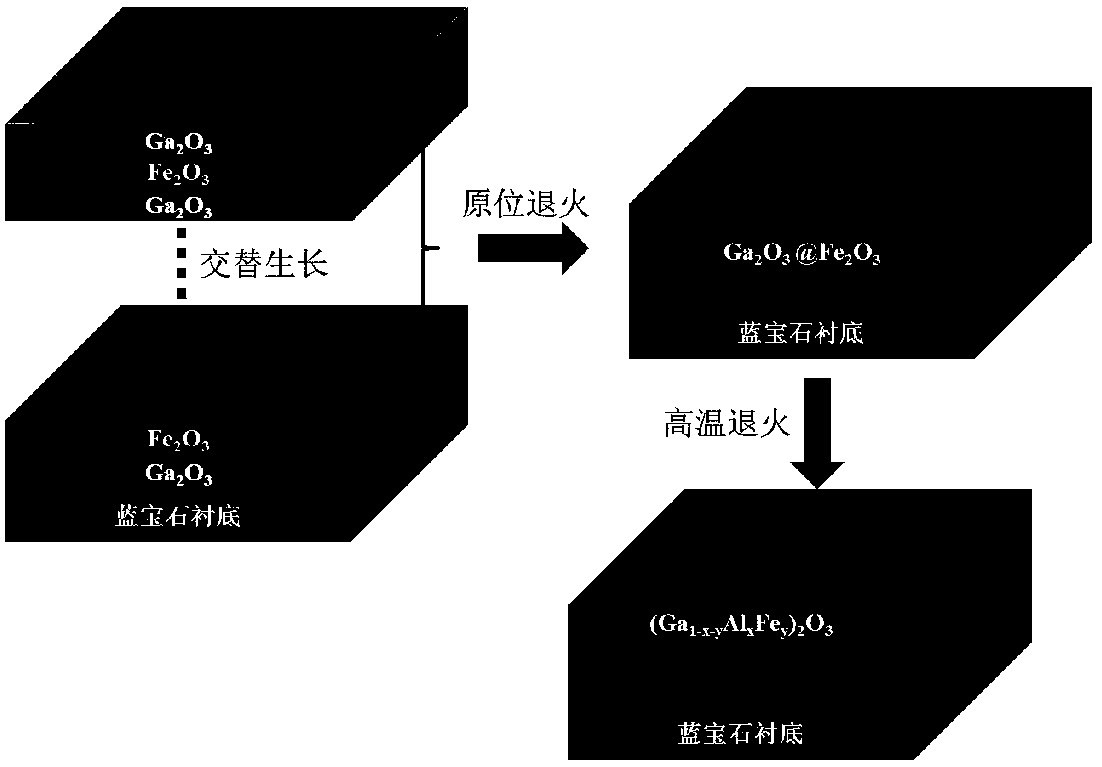

[0055] This embodiment provides a longitudinal gradient distribution of bandgap Al and Fe co-doped Ga 2 o 3 The preparation method of thin film, comprises the following steps:

[0056] 1) With the cleaned c-plane sapphire as the substrate, a layer of Ga was first deposited on the substrate by laser molecular beam epitaxy 2 o 3 ultra-thin layer, and then deposited a layer of Fe 2o 3 Ultra-thin layer, deposited Ga 2 o 3 with Fe 2 o 3 The number of laser pulses for ultra-thin layers is selected: 200 / 20, 200 / 40, 200 / 60, 200 / 80, 200 / 100; alternate growth, so cycle 20 times;

[0057] Among them, the specific conditions for laser molecular beam epitaxy are: the background vacuum is 1×10 -6 Pa, substrate temperature is 750℃, oxygen pressure is 5×10 -1 Pa, the laser energy is 400mJ, the laser pulse frequency is 1Hz, and the distance between the target and the substrate is 4.5cm;

[0058] 2) Deposit Ga 2 o 3 and Fe 2 o 3 After the ultra-thin layer, in-situ annealing at 75...

Embodiment 2

[0065] This embodiment provides a longitudinal gradient distribution of bandgap Al and Fe co-doped Ga 2 o 3 The preparation method of thin film, comprises the following steps:

[0066] 1) With the cleaned c-plane sapphire as the substrate, a layer of Ga was first deposited on the substrate by laser molecular beam epitaxy 2 o 3 ultra-thin layer, and then deposited a layer of Fe 2 o 3 Ultra-thin layer, deposited Ga 2 o 3 with Fe 2 o 3 The number of laser pulses for the ultra-thin layer is selected: 100 / 30 alternate growth, so that the cycle is 100 cycles;

[0067] Among them, the specific conditions for laser molecular beam epitaxy are: the background vacuum is 1×10 -6 Pa, substrate temperature is 750℃, oxygen pressure is 5×10 -1 Pa, the laser energy is 400mJ, the laser pulse frequency is 1Hz, and the distance between the target and the substrate is 4.5cm;

[0068] 2) Deposit Ga 2 o 3 and Fe 2 o 3 After the ultra-thin layer, in-situ annealing at 750°C for 30 minut...

Embodiment 3

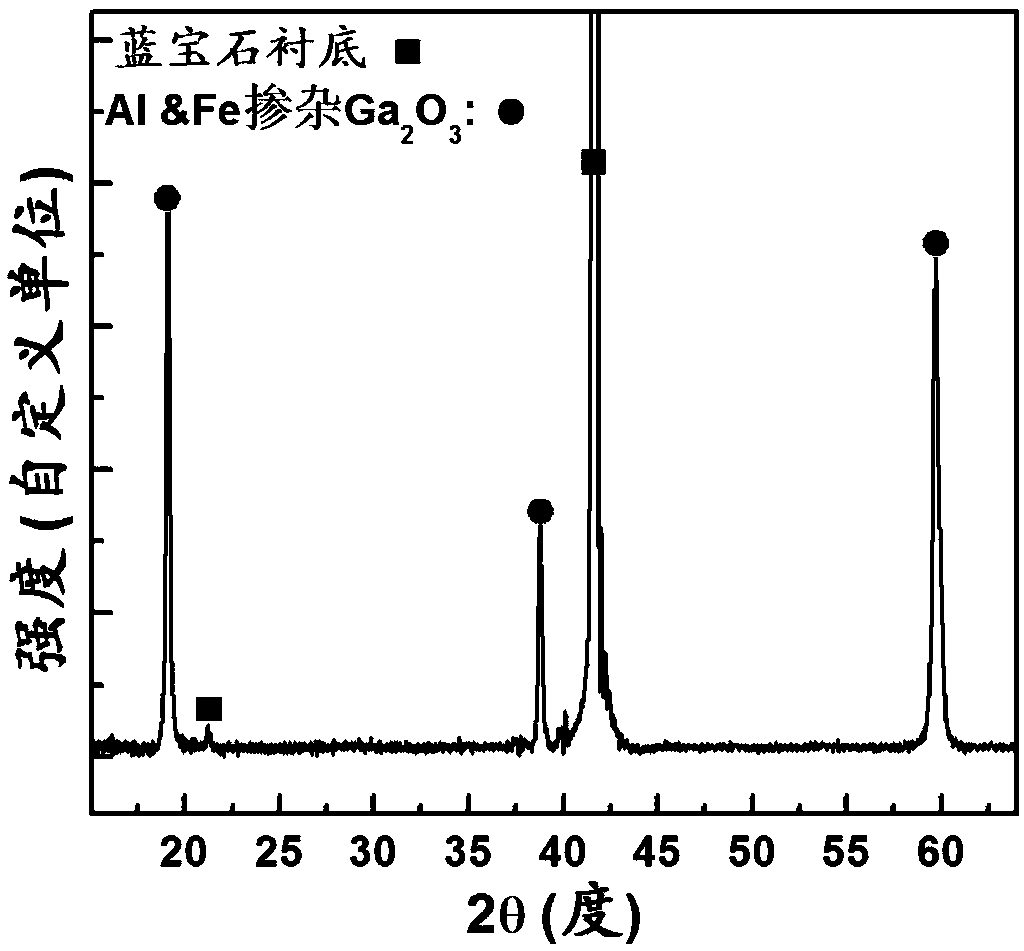

[0071] This embodiment provides a longitudinal gradient distribution of bandgap Al and Fe co-doped Ga 2 o 3 The difference between the method of making the film and Example 2 is that the annealing temperature in step 3) is 800°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com