Oriented ZnO nanorod or nanowire film and preparation process thereof

A technology of nanorods and zinc oxide, which is applied in the field of thin film preparation of low-dimensional nanomaterials, can solve the problems that are not conducive to large-scale industrial production, complex and expensive equipment, and harsh preparation conditions, and achieve low cost, good orientation, and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

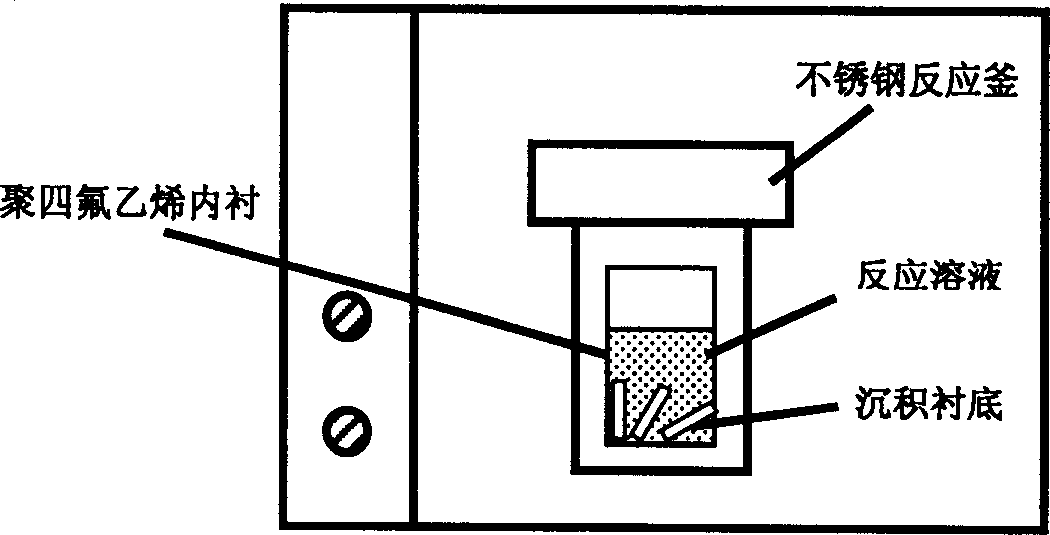

Embodiment 1

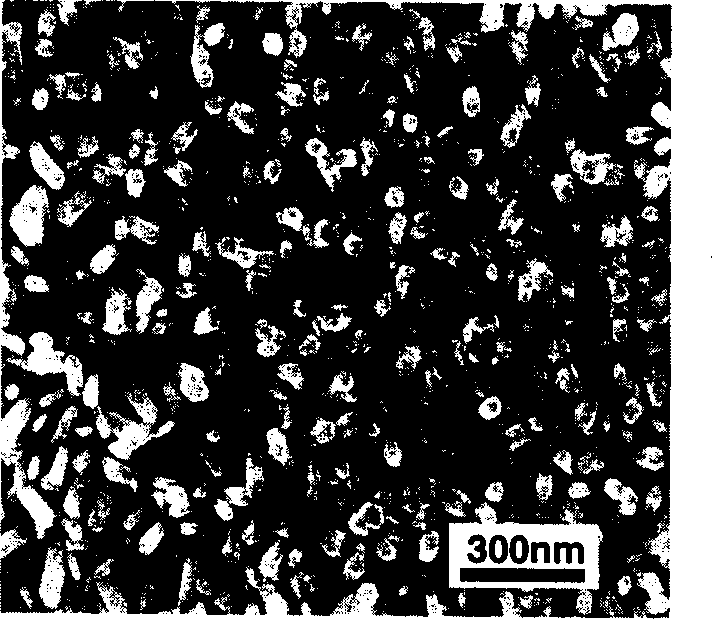

[0016] After the zinc nitrate solution with a molar concentration of 1mM and the hexamethylenetetramine solution with a molar concentration of 2mM were evenly mixed, they were placed in a stainless steel reaction kettle lined with polytetrafluoroethylene, and at the same time, the ZnO(002) oriented The silicon wafer substrate with the textured seed crystal was placed inside the PTFE lining, and the surface of the deposition substrate seed crystal was at an angle of 90° to the surface of the PTFE inner substrate. The ZnO nano-rod (wire) array thin film with directional growth and good crystallinity is grown on the substrate, and the diameter of the nano-rod (wire) is about 10-30nm.

Embodiment 2

[0018] After the zinc acetate solution with a molar concentration of 6mM and the hexamethylenetetramine solution with a molar concentration of 5mM were evenly mixed, they were placed in a stainless steel reaction kettle lined with polytetrafluoroethylene, and at the same time, the ZnO(002) oriented The plastic substrate of the textured seed crystal was placed inside the PTFE lining, and the surface of the deposition substrate seed crystal was at an angle of 70° to the surface of the PTFE inner substrate. The ZnO nano-rod (wire) array thin film with good crystallinity grows directional growth on the bottom, and the diameter of the nano-rod (wire) is about 40-60nm.

Embodiment 3

[0020] After uniformly mixing the zinc citrate solution with a molar concentration of 10mM and the cyclodextrin-hexamethylenetetramine solution with a molar concentration of 10mM, they were placed in a stainless steel reaction kettle lined with polytetrafluoroethylene. The glass substrate of the ZnO(002) oriented textured seed crystal was placed inside the PTFE lining, and the surface of the deposition substrate seed crystal was at an angle of 50° to the surface of the PTFE inner substrate, kept at 90°C for 2 hours, and then cooled naturally Finally, grow directional growth on the substrate, ZnO nanorod (wire) array thin film with good crystallinity, the diameter of nanorod (wire) is about 50-80nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com