Novel air preheater system for coal-fired power plant and work method thereof

A technology of air preheater and coal-fired power plant, which is applied in the direction of combustion method, combustion air/fuel supply, non-combustible liquid/gas transportation, etc. It can solve the problems of low air leakage rate, zero mixing of cold air, reduced boiler efficiency, Problems such as the rise of exhaust gas temperature, to achieve the effect of reducing exhaust gas temperature, reducing power consumption, and improving boiler efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

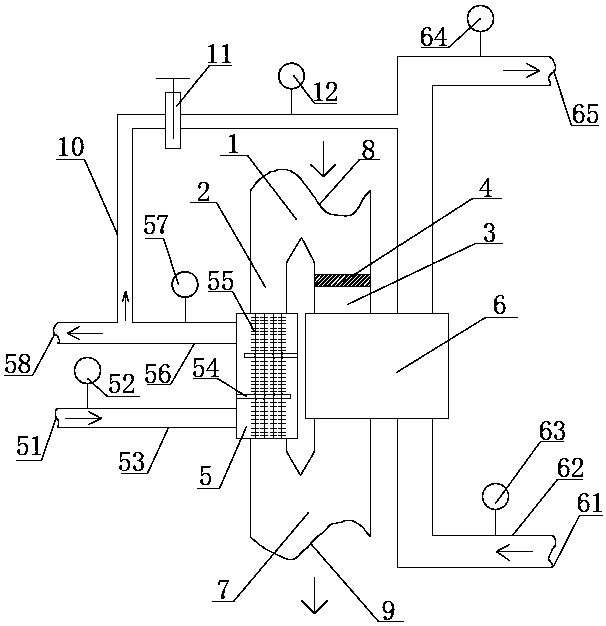

[0022] see figure 1 , the new air preheater system of the coal-fired power plant in this embodiment includes the main inlet flue 1, the tubular air preheater 5, the rotary air preheater 6, the main outlet flue 7, and the primary air bypass 10 , primary air inlet pipe 53, primary air outlet pipe 56 and secondary air pipe 62.

[0023] The main inlet flue 1 communicates with the side-by-side A sub-flue 2 and B sub-flue 3, wherein the A sub-flue 2 is provided with a tubular air preheater 5 for heating the cold primary air, and the B sub-flue 3 passes through The rotary air preheater 6 used for rotary heating of the cold secondary air is passed through, and an adjusting baffle 4 is arranged inside the B branch flue 3; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com