Variable-heat-conductivity-coefficient vacuum environment liquid metal cooler

A liquid metal cooling and thermal conductivity technology, applied in indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., to achieve the effects of good regulation, changing heat exchange capacity, and many adjustment means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

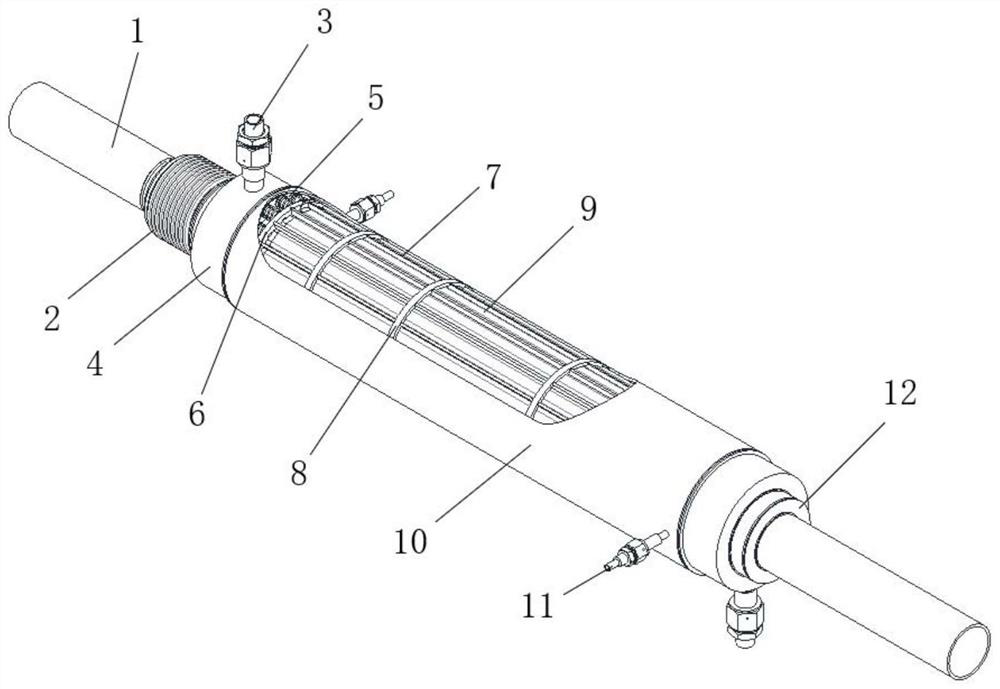

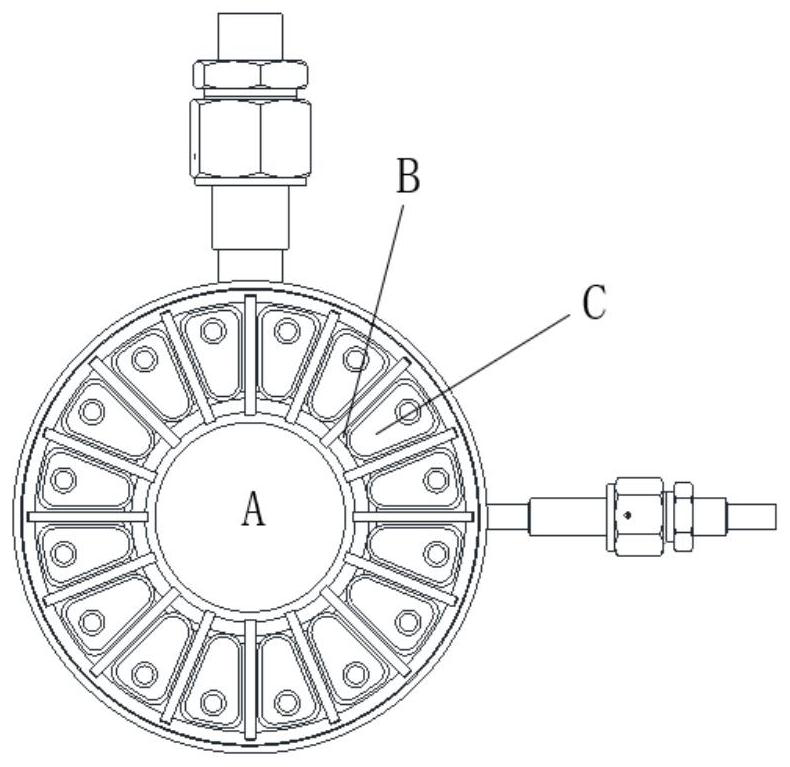

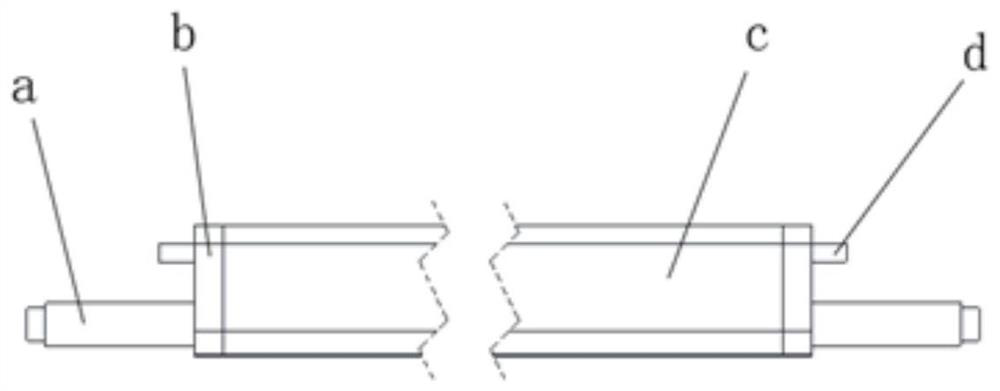

[0029] Such as figure 1 As shown, the present invention provides a liquid metal cooler in a vacuum environment with variable thermal conductivity, including a liquid metal pipeline 1, a heat-conducting air cavity and a cooling water assembly 9; the heat-conducting air cavity wraps at least a part of the liquid metal pipeline 1 to The heat dissipation of the liquid metal pipeline 1 is adjusted through the change of its own thermal conductivity; the cooling water assembly 9 is arranged in the heat conduction air chamber to adjust the background temperature. The heat conduction air chamber realizes the adjustment of its own thermal conductivity by adjusting the mixing ratio and / or gas pressure of the heat conduction gas. The cooler of the present invention adopts a reverse flow working form, that is, the flow direction of the cooling water is opposite t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com