Method for preparing methane by catalyzing and gasifying coal

A technology of gas methane and coal methane, which is applied in the field of coal gasification to produce substitute natural gas, which can solve the problems of long pre-oxidation time, large calorific value loss, and difficulty in maintaining the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

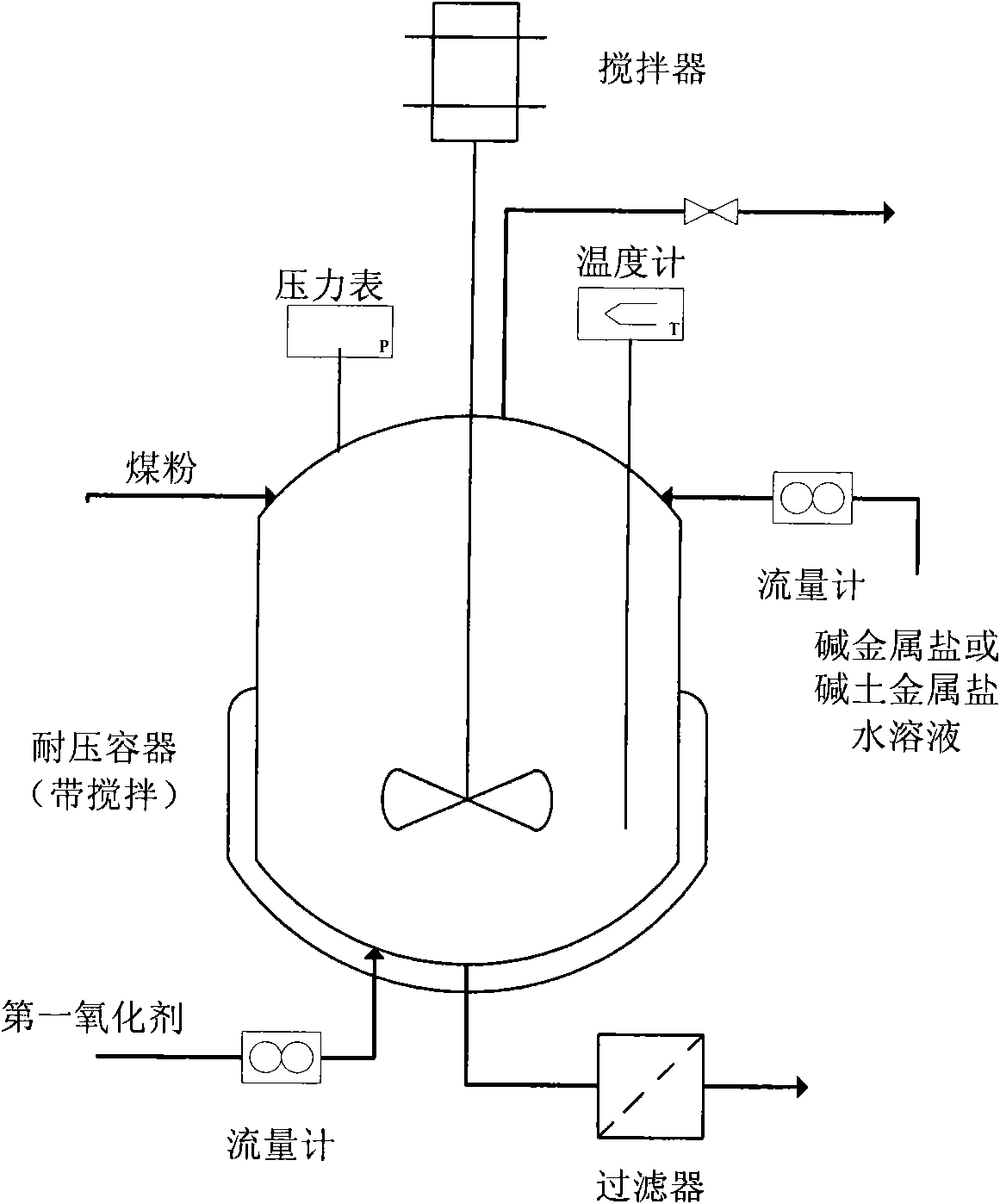

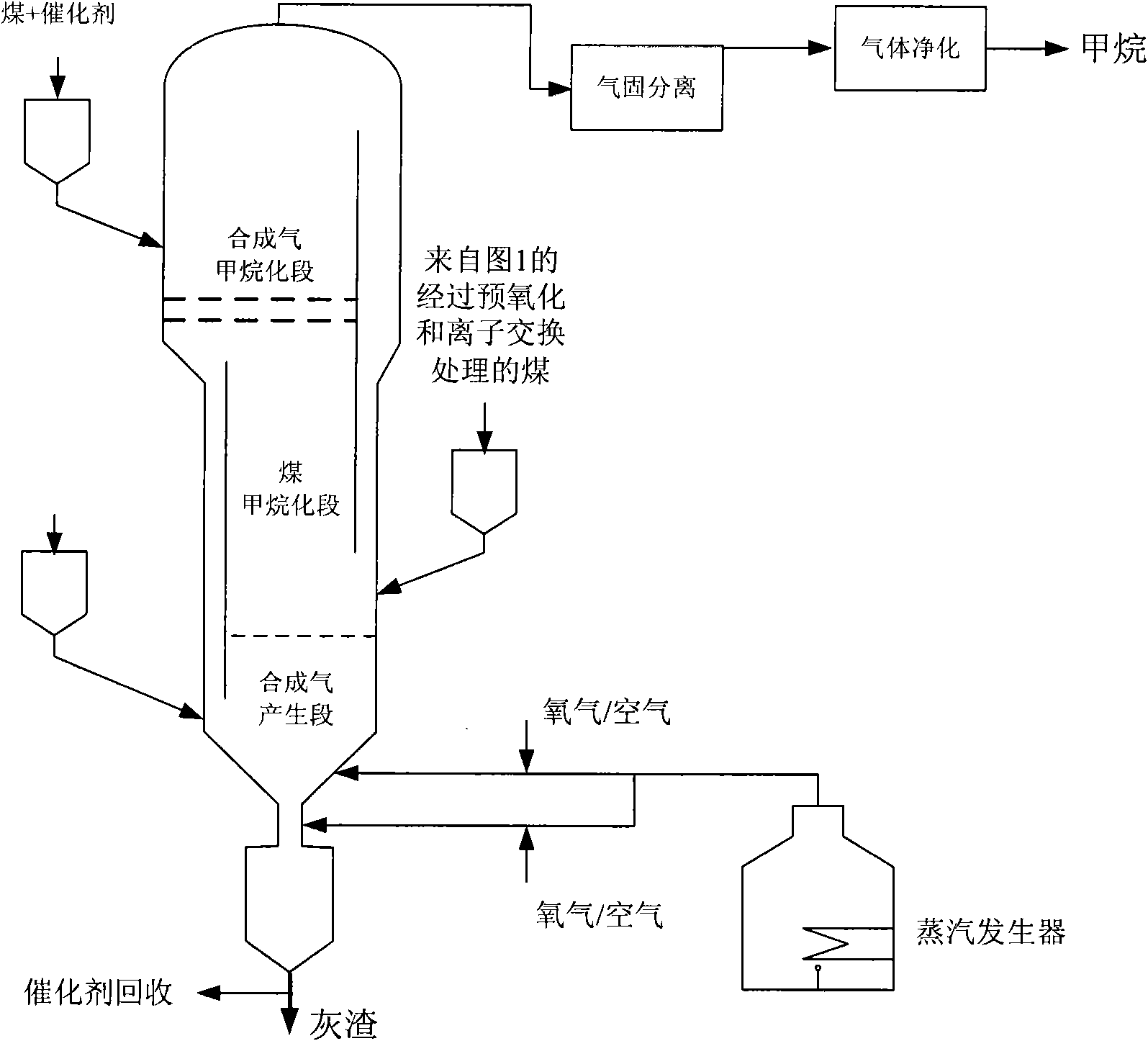

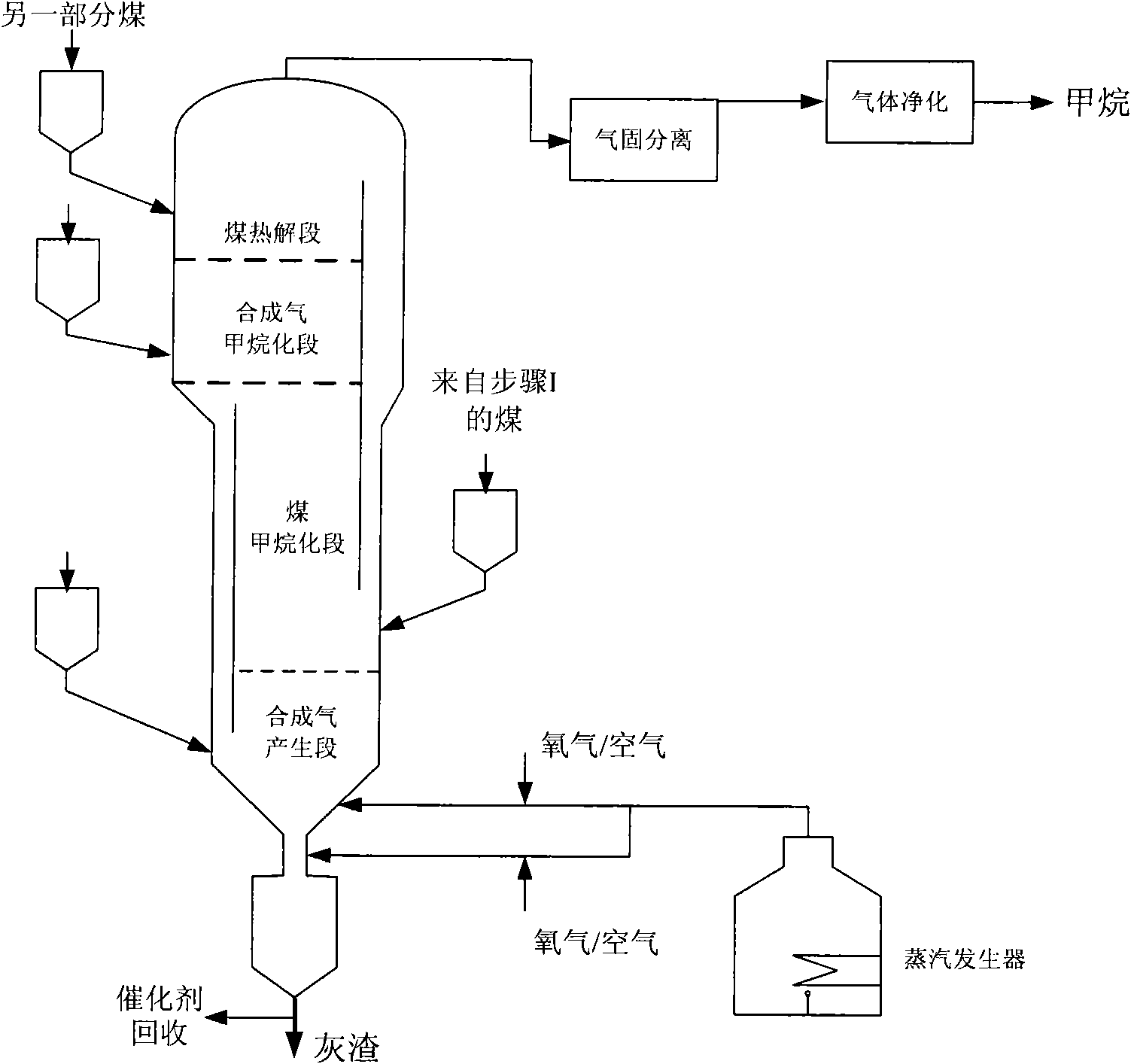

Method used

Image

Examples

Embodiment 1

[0066] The coal used in this example is Ordos bituminous coal in Inner Mongolia. It was crushed and sieved to obtain coal powder with a particle size of 20-80 meshes. Samples were taken respectively, and the following pretreatments were carried out respectively: Coal sample 1 was directly ion-exchanged without pre-oxidation treatment. Coal sample 2 undergoes pre-oxidation treatment and ion exchange treatment in sequence. The pre-oxidation reaction conditions were: temperature 200 °C, oxygen partial pressure 3.5 MPa, oxidation time 3 h; the total acid content on the surface of the two coal samples was measured by the Schafer method before the ion exchange treatment, and the results are shown in Table 1 below. The two coal samples were mixed with potassium carbonate aqueous solution (the K in the solution + The quality of the coal sample is 15% of the mass of the coal sample) mixed for ion exchange, the pH is controlled to be 12, fully stirred for 8 hours, and then the potassium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com