An automatic jet-type dewatering cleaning device

A cleaning device and jet technology, which are applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc. Good effect and strong function expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

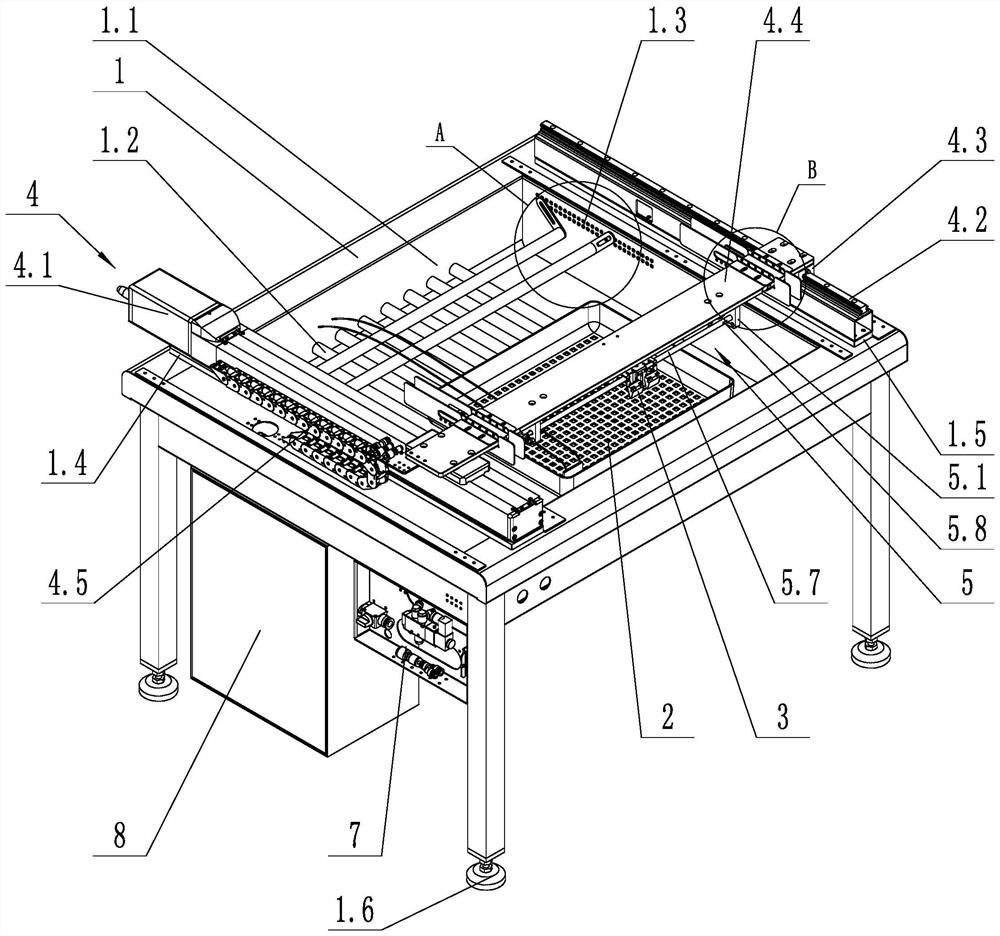

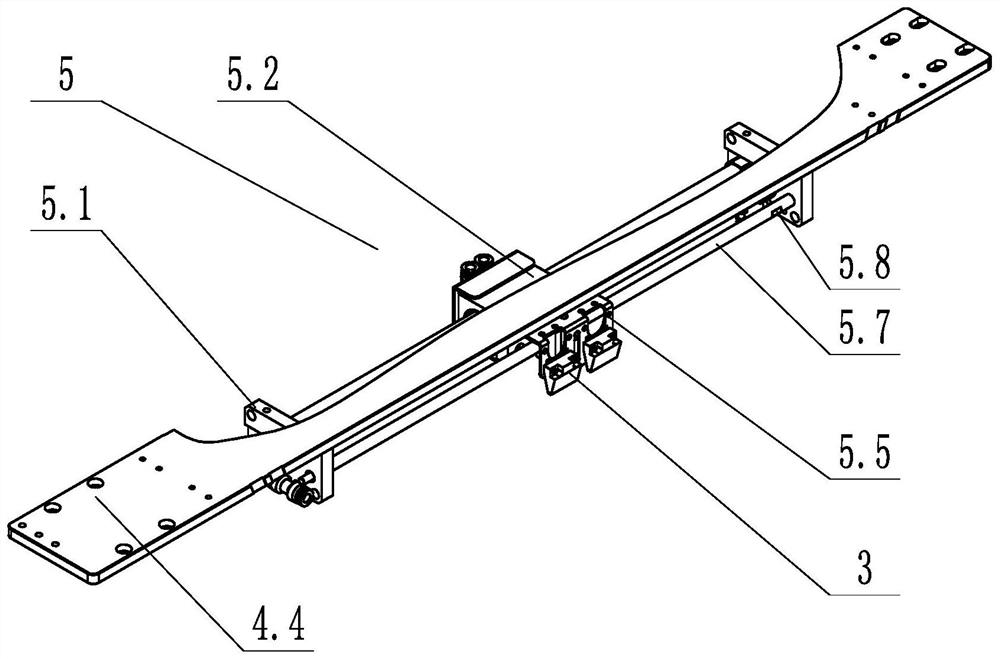

[0033] Such as figure 1 As shown, an automatic jet-type water removal and cleaning device includes a sink table 1, a cleaning basket 2, an air jet structure 3, an X-axis driving structure 4 and a Y-axis driving structure 5.

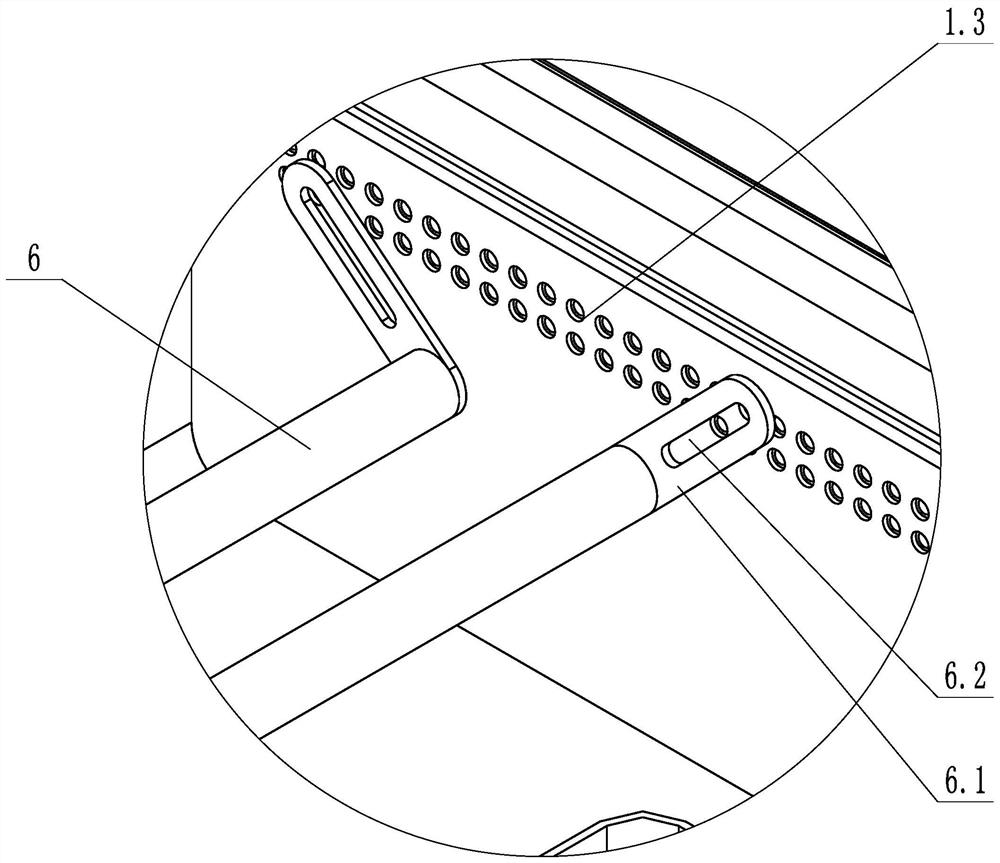

[0034] The middle position of the sink table 1 is provided with a water storage tank 1.1 for water storage; the inside of the water storage tank 1.1 is welded with a plurality of support tubes 1.2 along the X-axis direction, which are used to carry the cleaning basket 2 for stacking thermoelectric products, and have a certain distance from the bottom of the water storage tank 1.1. There is a positioning through hole near the operating end of the staff, and the fast positioning can be realized by inserting the bolt, such as figure 2 As shown, there are threaded holes 1.3 on both sides of the water storage tank 1.1, which are used to install the wire rod 6. The wire rod 6 is installed parallel to the inside of the sink table 1 along the Y-axis direction, a...

Embodiment 2

[0042] Such as Figure 4 As shown, on the basis of Embodiment 1, a waterproof structure 9 is also included. The waterproof structure 9 includes a protective cover 9.1, and the protective cover 9.1 is arranged above the X-axis driving structure 4. There is a strip avoidance hole 9.1.1, and one end of the bridge connecting plate 4.4 passes through the avoidance hole 9.1.1.

[0043] Such as Figure 5 As shown, the upper surface of the bridge connecting plate 4.4 is fixed with the first waterproof angle plate 9.2 and the third waterproof angle plate 9.4, and the lower surface of the bridge connecting plate 4.4 is fixed with the second waterproof angle plate 9.3 and the fourth waterproof angle plate 9.5 ; The first waterproof corner plate 9.2 and the second waterproof corner plate 9.3 are arranged on the outside of the protective cover 9.1, and the first waterproof corner plate 9.2 and the second waterproof corner plate 9.3 are arranged on the upper and lower corresponding positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com