Double-layer medical infusion bottle and manufacturing method thereof

A manufacturing method and technology for infusion bottles, which are applied in the directions of medical containers, medical packaging, transportation and packaging, etc., can solve the problems of mixing medicine, medicine liquid migration, and difficulty in coloring and printing of blended polypropylene materials, and achieve easy coloring and isolation. Good, safe and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

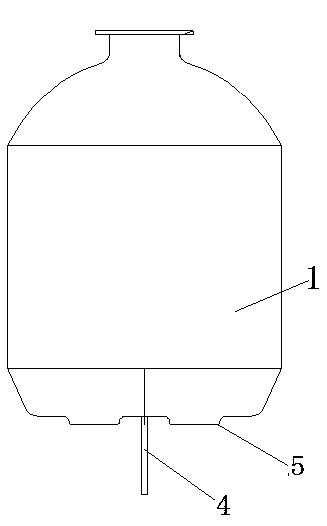

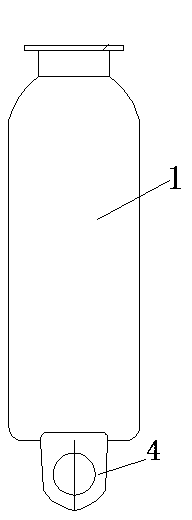

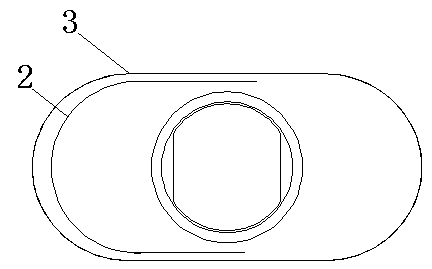

[0025] Such as figure 1 , 2 As shown in and 3, this embodiment provides a double-layer medical infusion bottle and a manufacturing method thereof. A double-layer medical infusion bottle is mainly a flat-shaped infusion bottle body 1 with a double-layer structure, and the shoulder of the infusion bottle body 1 stands up , The bottleneck is trapezoidal; the double-layer structure is the inner layer 2 of polypropylene and the outer layer 3 of lipid copolymer. The bottom of the infusion bottle body 1 is provided with an integrated punching suspension ring 4 outside the bottom of the infusion bottle body 1. Four supporting feet 5 are arranged around the suspension ring 4; the mass ratio of the polypropylene of the inner layer 2 to the lipid copolymer of the outer layer 3 is 60:40, and the outer layer can be made of high-barrier materials for packaging amino acids and fat emulsions. Such as easy to oxidize infusion.

[0026] A method for manufacturing a double-layer medical infusion bo...

Embodiment 2

[0036] Such as figure 1 , 2 As shown in and 3, this embodiment provides a double-layer medical infusion bottle and a manufacturing method thereof. A double-layer medical infusion bottle is mainly a flat-shaped infusion bottle body 1 with a double-layer structure, and the shoulder of the infusion bottle body 1 stands up , The bottleneck is trapezoidal; the double-layer structure is the inner layer 2 of polypropylene and the outer layer 3 of lipid copolymer. The bottom of the infusion bottle body 1 is provided with an integrated punching suspension ring 4 outside the bottom of the infusion bottle body 1. Four supporting feet 5 are arranged around the suspension ring 4; the mass ratio of the polypropylene of the inner layer 2 to the lipid copolymer of the outer layer 3 is 70:30, and the outer layer can be made of high-barrier materials for packaging amino acids and fat emulsions Such as easy to oxidize infusion.

[0037] A method for manufacturing a double-layer medical infusion bot...

Embodiment 3

[0047] Such as figure 1 , 2 As shown in and 3, this embodiment provides a double-layer medical infusion bottle and a manufacturing method thereof. A double-layer medical infusion bottle is mainly a flat-shaped infusion bottle body 1 with a double-layer structure, and the shoulder of the infusion bottle body 1 stands up , The bottleneck is trapezoidal; the double-layer structure is the inner layer 2 of polypropylene and the outer layer 3 of lipid copolymer. The bottom of the infusion bottle body 1 is provided with an integrated punching suspension ring 4 outside the bottom of the infusion bottle body 1. Four supporting feet 5 are arranged around the suspension ring 4; the mass ratio of the polypropylene of the inner layer 2 to the lipid copolymer of the outer layer 3 is 80:20, and the outer layer can be made of high-barrier materials for packaging amino acids and fat emulsions. Such as easy to oxidize infusion.

[0048] A method for manufacturing a double-layer medical infusion bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com