Continuous production method of transition metal amido complex

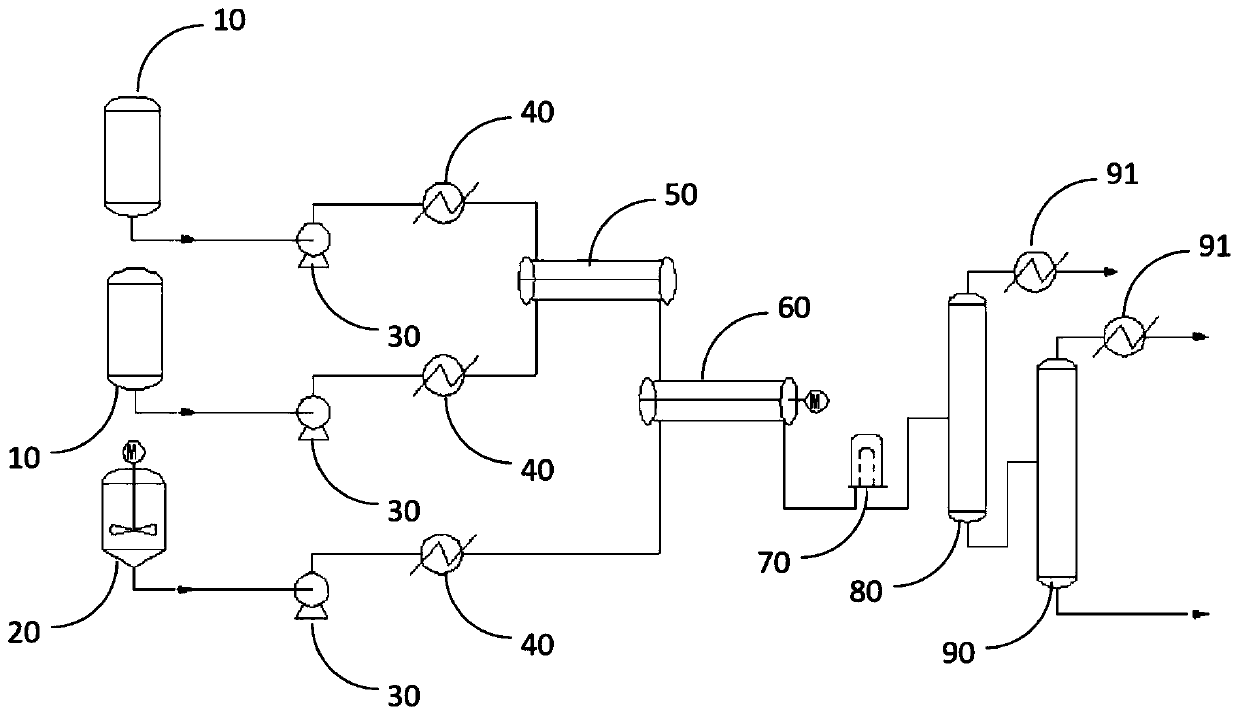

A metal amine-based, production method technology, applied in the field of continuous production of transition metal amine-based complexes, can solve the problems of unsatisfactory industrial continuous production, low reaction efficiency, slow reaction speed, etc., and achieve short reaction time and high conversion rate High, stable and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] The continuous production method of tetra(methylethylamino) hafnium:

[0081] 1) Mix n-butyllithium and n-hexane in proportion to form liquid A, and the volume concentration of n-butyllithium is 15%; mix ethylmethylamine (purity ≥ 99%) and n-hexane to form liquid B, and The molar concentration of methylamine is 15%; hafnium chloride (purity ≥ 99%) and n-hexane are mixed to prepare liquid C, and the mass concentration of hafnium chloride is 23%;

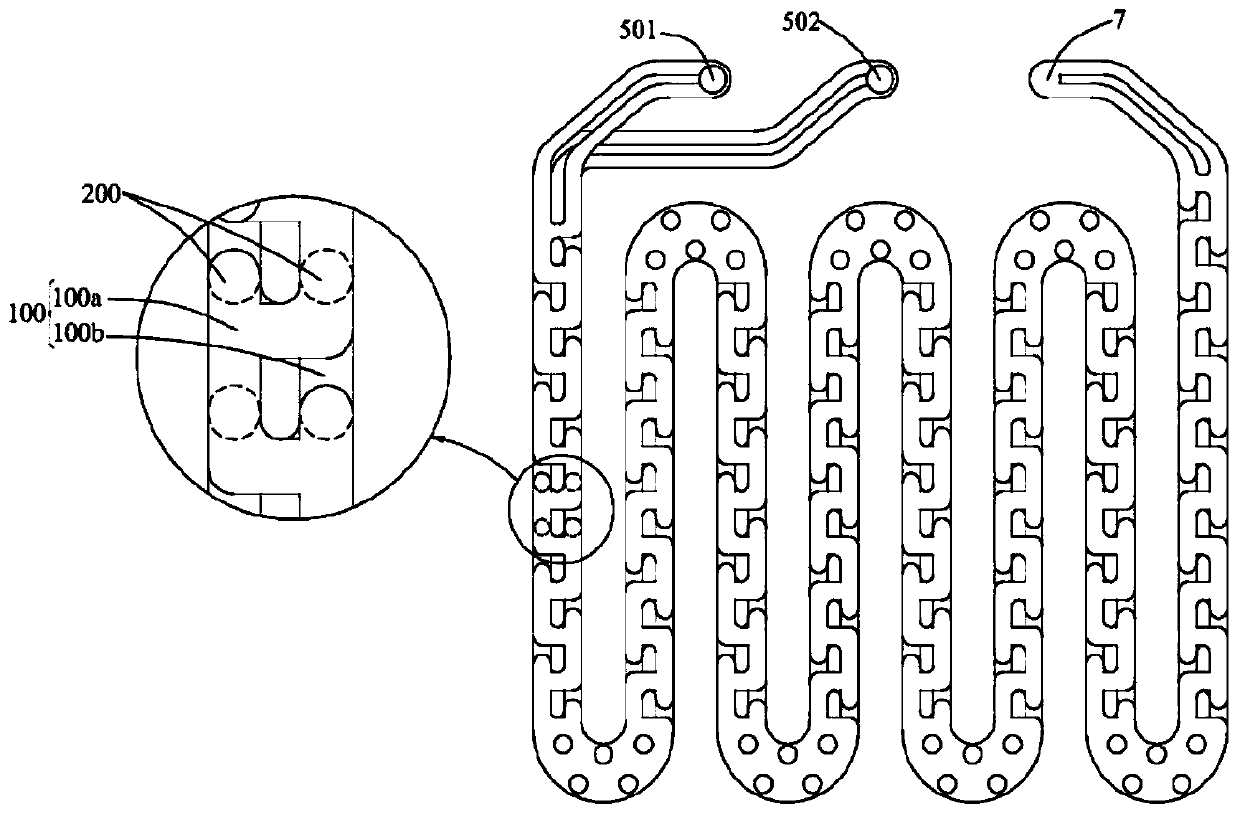

[0082] 2) Liquid A and Liquid B are respectively cooled to -15°C by a plunger pump and a precooler, and injected into a continuous flow reactor at a temperature of -15°C at a certain flow rate for 5-30 seconds to generate a solid containing The intermediate mixed solution of the product; the flow ratio of A liquid and B liquid is preferably 1:1, more preferably 40-50mL / min;

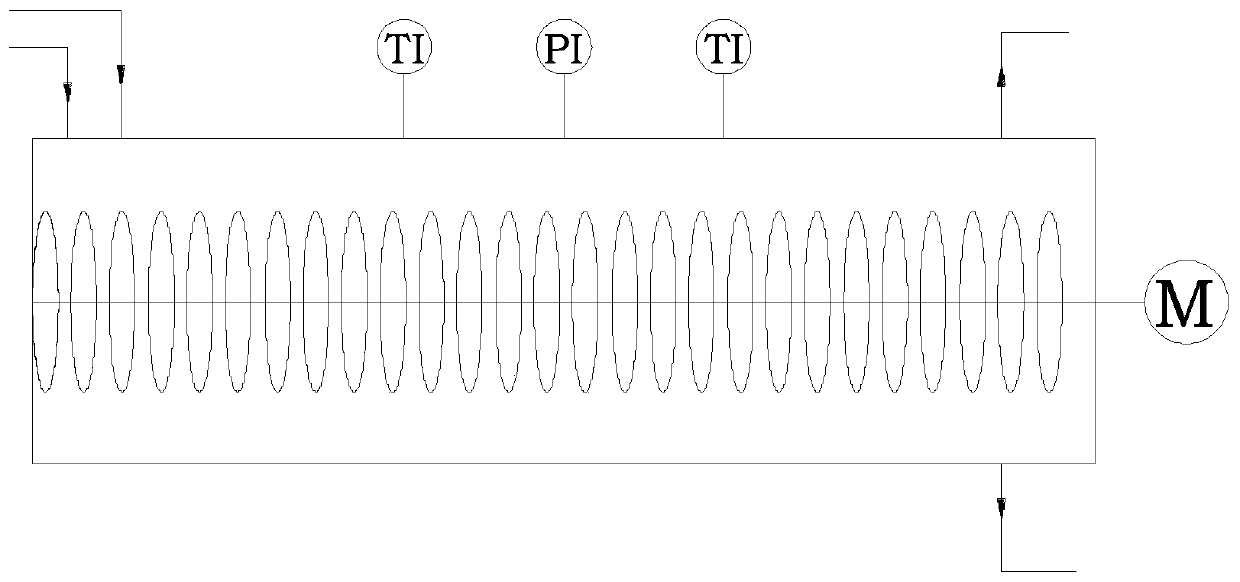

[0083] 3) The intermediate mixed liquid flows out from the outlet of the continuous flow reactor, and enters a dynamic tubular reactor with a temperature...

Embodiment 2

[0088] Continuous production method of penta(diethylamino)tantalum:

[0089] 1) Prepare tert-butyllithium and n-hexane in proportion to form liquid A, the volume concentration of tert-butyllithium is 12%; mix diethylamine (purity ≥ 99%) and n-hexane to form liquid B, ethyl methyl The molar concentration of amine is 12%; tantalum pentachloride (purity ≥ 99%) is mixed with n-hexane to prepare liquid C, and the mass concentration of tantalum pentachloride is 20.6%;

[0090] 2) Liquid A and liquid B are respectively cooled to -10°C by a plunger pump and a precooler, and injected into a continuous flow reactor at a temperature of -10°C at a certain flow rate to react for 5-30s to form a solid containing The intermediate mixed solution of the product; the flow ratio of A liquid and B liquid is preferably 1:1, more preferably 40-50mL / min;

[0091] 3) The intermediate mixed liquid flows out from the outlet of the continuous flow reactor, and enters the dynamic tubular reactor with a ...

Embodiment 3

[0096] The continuous production method of tetrakis (methyl ethyl amino) zirconium:

[0097] 1) Mix n-butyllithium and toluene solvent in proportion to prepare liquid A, and the volume concentration of n-butyllithium is 13%; mix ethylmethylamine (purity ≥ 99%) and toluene to prepare liquid B, ethyl The molar concentration of methylamine is 13%; ZrCl 4 (purity ≥ 99%) mixed with toluene to prepare liquid C, ZrCl 4 The mass concentration is 16.7%;

[0098] 2) Liquid A and Liquid B are respectively cooled to -15°C by a plunger pump and a precooler, and injected into a continuous flow reactor at a temperature of -15°C at a certain flow rate for 5-30 seconds to generate a solid containing The intermediate mixed solution of the product; the flow ratio of A liquid and B liquid is preferably 1:1, more preferably 40-50mL / min;

[0099] 3) The intermediate mixed liquid flows out from the outlet of the continuous flow reactor, and enters a dynamic tubular reactor with a temperature of -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com