Ternary-cycle cascade refrigeration natural gas liquefaction system and method thereof

A natural gas, cascading technology, applied in the direction of refrigeration and liquefaction, liquefaction, gas fuel, etc., can solve the problem that the construction cost of large-scale liquefaction plants cannot be effectively controlled, and achieve rich system adjustment methods, no heat transfer bottlenecks, procurement convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

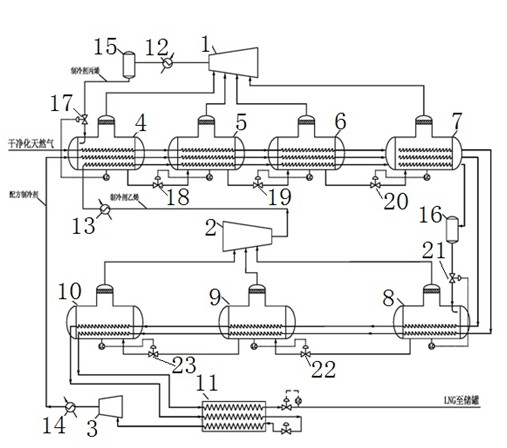

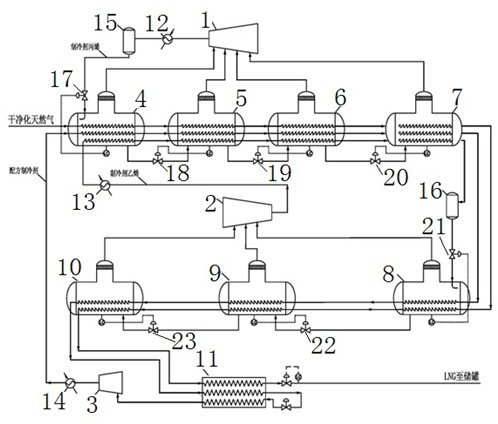

[0030] A three-cycle cascade refrigeration natural gas liquefaction system, such as figure 1As shown, including: propylene compressor 1, ethylene compressor 2, formula refrigerant compressor 3, high-pressure propylene evaporator 4, medium-pressure propylene evaporator 5, low-pressure propylene evaporator 6, low-pressure propylene evaporator 7, high-pressure ethylene Evaporator 8, medium pressure ethylene evaporator 9, low pressure ethylene evaporator 10, natural gas subcooler 11, propylene cooler 12, ethylene cooler 13, formula refrigerant cooler 14, propylene storage tank 15, ethylene storage tank 16, The first-stage J-T valve 17, the second-stage J-T valve 18, the third-stage J-T valve 19, the fourth-stage J-T valve 20, the fifth-stage J-T valve 21, the sixth-stage J-T valve 22, and the seventh-stage J-T valve 23, among which:

[0031] Propylene compressor 1, propylene cooler 12, propylene storage tank 15, primary J-T valve 17, high-pressure propylene evaporator 4, medium-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com