Roller type top-net forming device and its dewatering method

A former and top wire technology, applied in the direction of textiles and papermaking, paper machine, paper machine wet end, etc., can solve the problems of sacrificing the dehydration efficiency of the top wire former, small curvature radius, and large extrusion force of the two wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

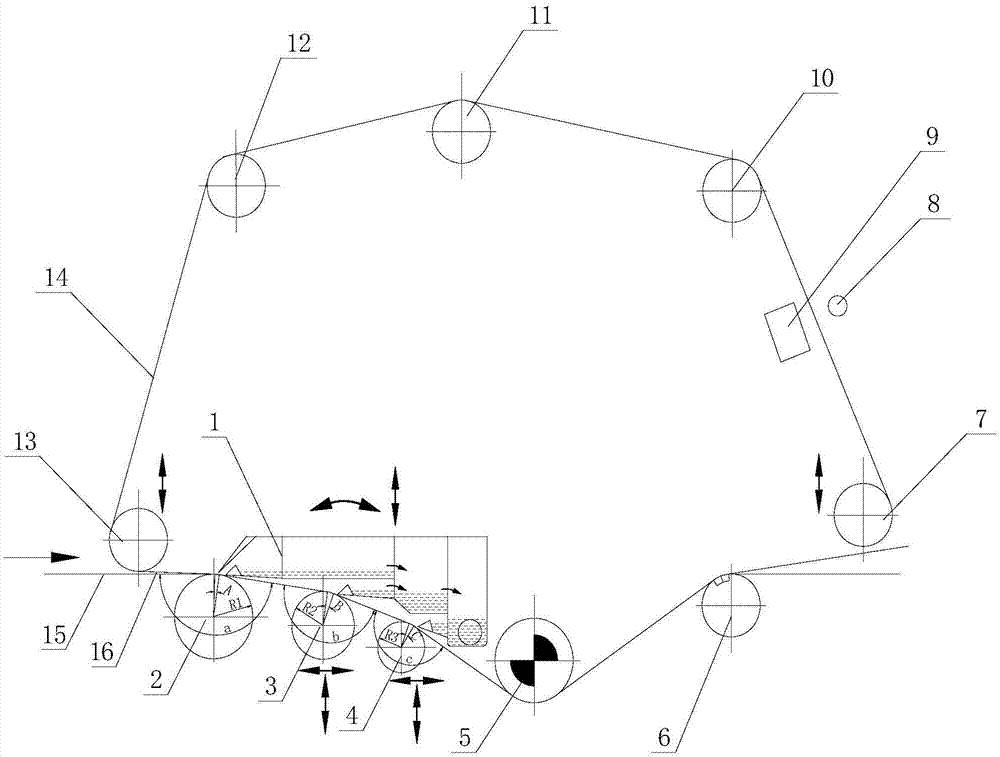

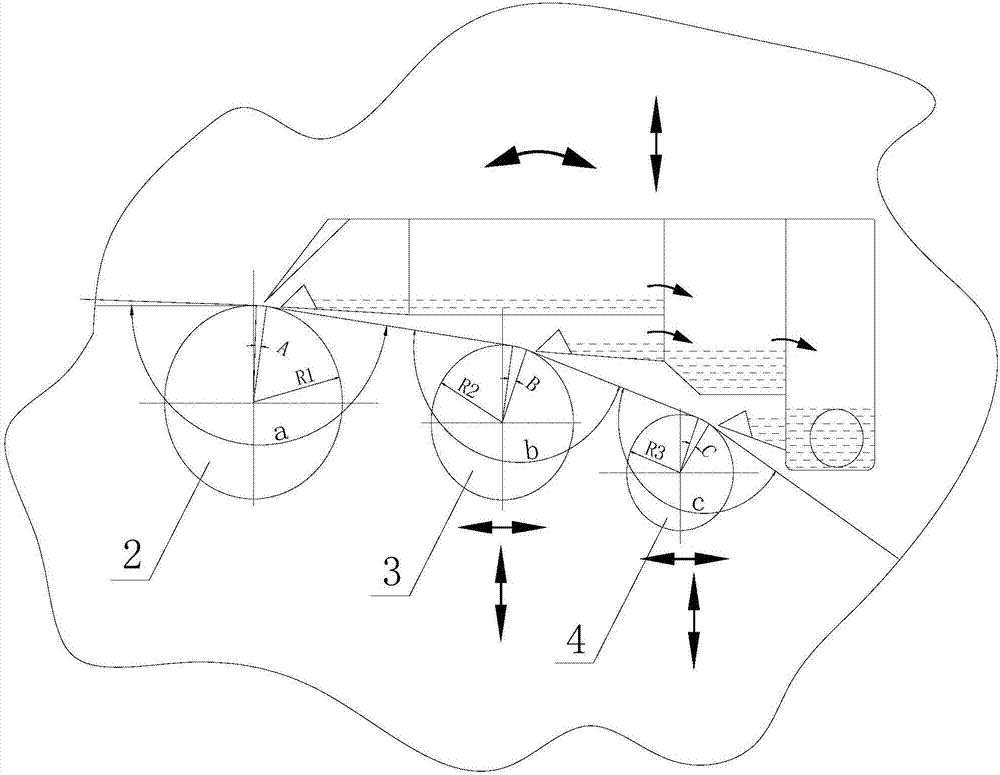

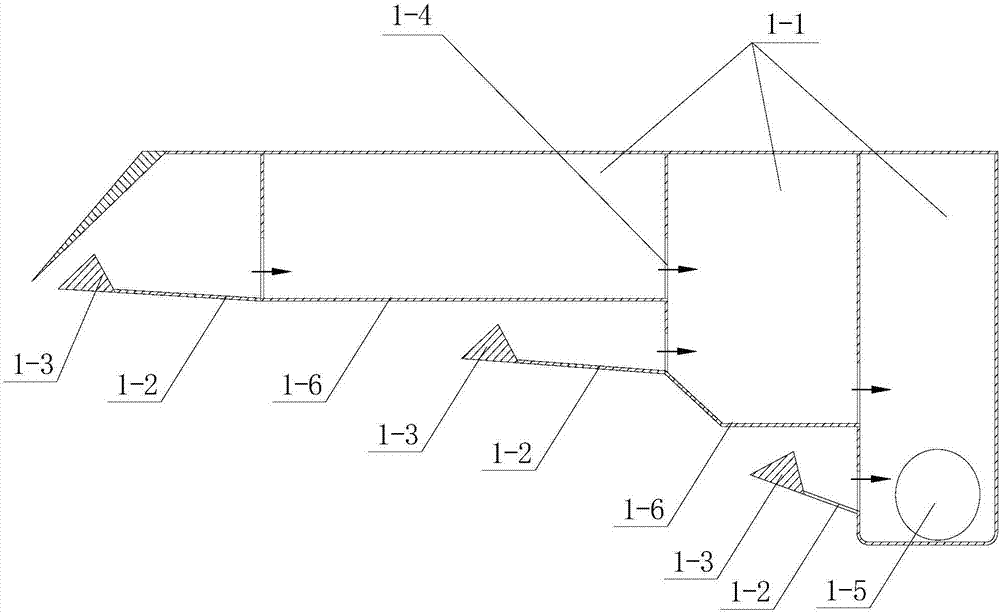

[0035] A kind of roller type top net shaper of present embodiment, as figure 1 As shown, it includes top net 14, main forming roll 5 and three pre-forming rolls (respectively entrance and forming roll 2, first intermediate forming roll 3 and second intermediate forming roll 4), and top net is arranged above bottom net 15 , and form the wet paper sheet delivery channel 16 between the top wire and the bottom wire; along the conveying direction of the wet paper sheet (such as figure 1 shown by the single arrow in ), the three preforming rollers and the main forming rollers are arranged in sequence, the three preforming rollers are arranged under the bottom wire, and the main forming rollers are arranged above the top wire; the corresponding top wire of the three preforming rollers A water suction box 1 is provided, and a plurality of scrapers are arranged on the water suction box, and each scraper is set corresponding to a preforming roller, and each scraper is in contact with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com