Control method for blast furnace top material distribution

A control method and material distribution technology, applied in blast furnaces, blast furnace details, comprehensive factory control, etc., can solve problems such as unstable gas distribution, large adjustment range, and difficulty in stabilizing furnace conditions, so as to improve gas utilization and change gas distribution , the effect of increasing the output of molten iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

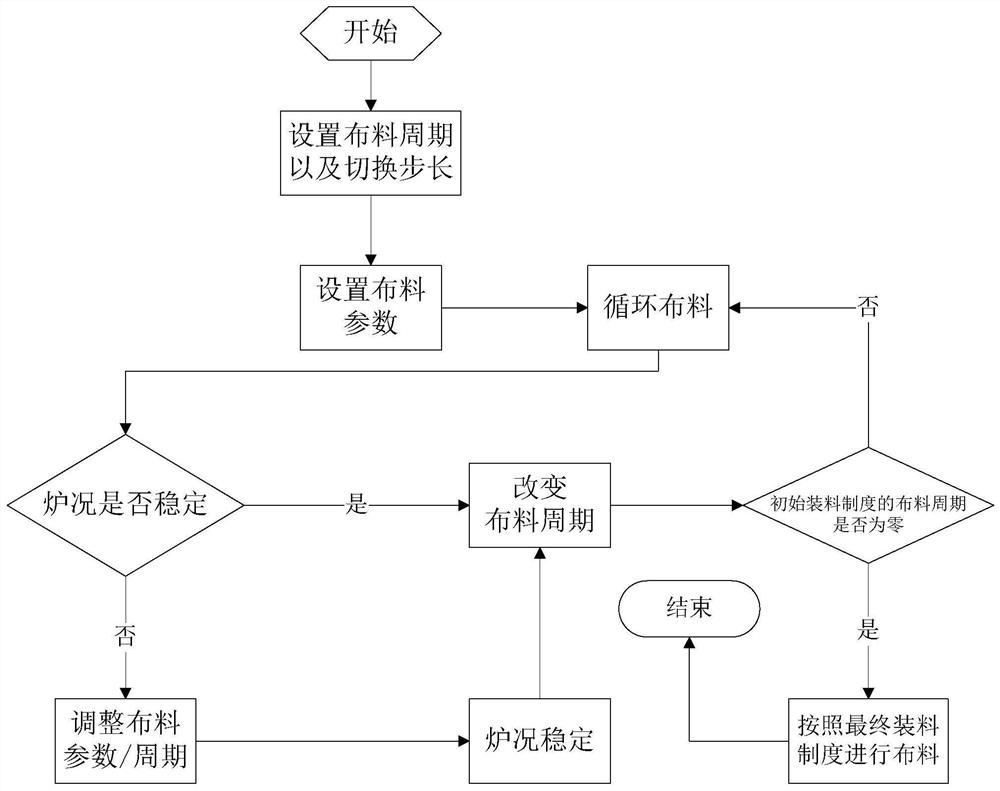

[0018] Such as Figure 1 to Figure 2 As shown, a control method for blast furnace roof distribution, including the following steps:

[0019] 1) Set the cloth cycle of the initial charging system, the cloth cycle of the final charging system, and set the switching step of the cloth cycle;

[0020] The material distribution cycle of the initial charging system, the material distribution cycle of the final charging system, and the switching step of the material distribution cycle are all obtained in continuous material distribution experiments on the basis of stable furnace conditions, that is, the initial charging system The cloth cycle of , the cloth cycle of the final loading system, and the switching step of the cloth cycle are all empirical values or calibration values.

[0021] In this embodiment, it is assumed that the cloth cycle of the initial charging system is T 初 , the cloth cycle of the final charging system is T 终 , the switching step of cloth cycle is T 步长 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com