Red coke quenching method and quenching device

A red coke and coke quenching technology, applied in the coking field, can solve the problems of affecting the air permeability of the screening blast furnace, increasing the amount of coke used in the blast furnace, increasing the heat consumption, etc., and achieving the effect of reducing the soaking time, reducing the water content, and reducing the fluctuation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

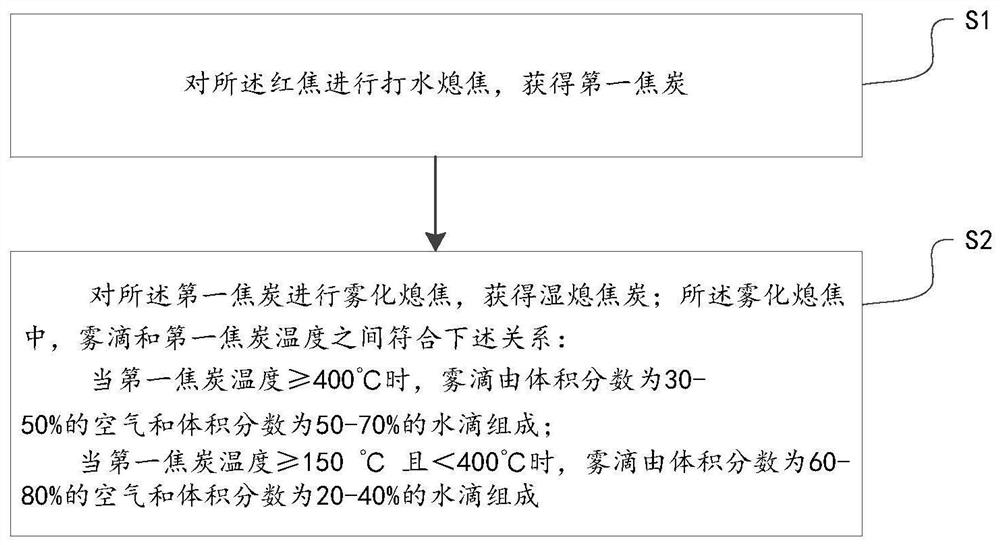

Method used

Image

Examples

Embodiment approach

[0047] As an implementation manner of the embodiment of the present invention, the water coke quenching also includes high-pressure water coke quenching, the high-pressure water coke quenching time is 40-50s, and the water pressure of the high-pressure water coke quenching is 43-80KPa, The high-pressure water coke quenching water flow rate is 1.06-2.42M 3 / s.

[0048] The role of high-pressure water quenching is to enable water to penetrate the entire coke layer, forming rising steam at the bottom of the compartment to extinguish coke. Too long high-pressure water quenching time will lead to increased water consumption for coke quenching. Coke soaked in water for a long time will eventually affect Wet quenching moisture will also lead to long quenching cycle time (coke quenching cycle time = low pressure time + high pressure time), affecting the daily coke quenching output; at the same time, high pressure water is also matched with low pressure water to make coke from top to b...

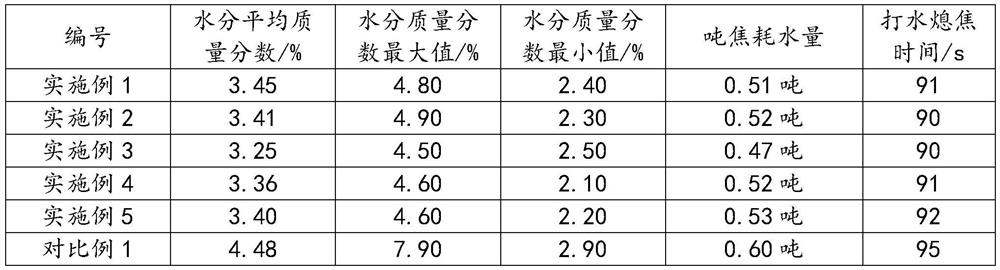

Embodiment 1

[0084] Embodiment 1 provides a kind of coke quenching method of red coke, take the coke oven of 6 meters high carbonization chamber of a certain coking company as example, specifically as follows:

[0085] 1. Overhaul and replace the body sealing system of the coke quenching car to reduce water leakage of the body, save coke quenching water, and ensure that the red coke is not soaked by too much water.

[0086] 2. Put the red coke smelted in the coke oven into the coke quenching car in step 1, measure the coke thickness of each part in the coke quenching car at the same time, and adjust the valve opening according to the following formula.

[0087] The valve opening of each part = the thickness of coke in each part ÷ the maximum coke thickness in the quenching car × 100%

[0088] The coke thicknesses of the 4 points where the coke is evenly distributed from one side to the other on the center line of the quenching car are 0.48m, 2.40m, 2.40m, and 0.72m respectively, and the ma...

Embodiment 2

[0099] Embodiment 2 provides a kind of coke quenching method of red coke, take the coke oven of 4.3 meters high carbonization chamber of a certain coking company as example, specifically as follows:

[0100] 1. Overhaul and replace the body sealing system of the coke quenching car to reduce water leakage of the body, save coke quenching water, and ensure that the red coke is not soaked by too much water.

[0101] 2. Put the red coke smelted in the coke oven into the coke quenching car in step 1, measure the coke thickness of each part in the coke quenching car at the same time, and adjust the valve opening according to the following formula.

[0102] The valve opening of each part = the thickness of coke in each part ÷ the maximum coke thickness in the quenching car × 100%

[0103] The coke thicknesses of the 4 points where the coke is evenly distributed from one side to the other on the center line of the quenching car are 0.46, 2.30m, 2.25m, and 0.81m respectively, and the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com