Method for preparing activated carbon from kernel of common macrocarpium fruit

A technology for preparing activated carbon and dogwood fruit stones, which is applied in the field of preparing activated carbon, can solve problems that have not been reported, and achieve the effects of reducing manufacturing costs, saving costs, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

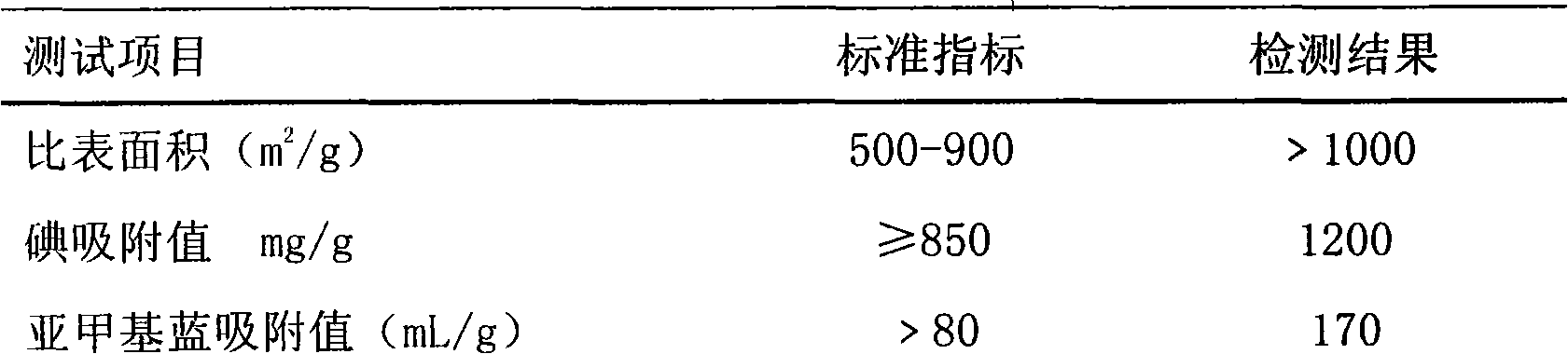

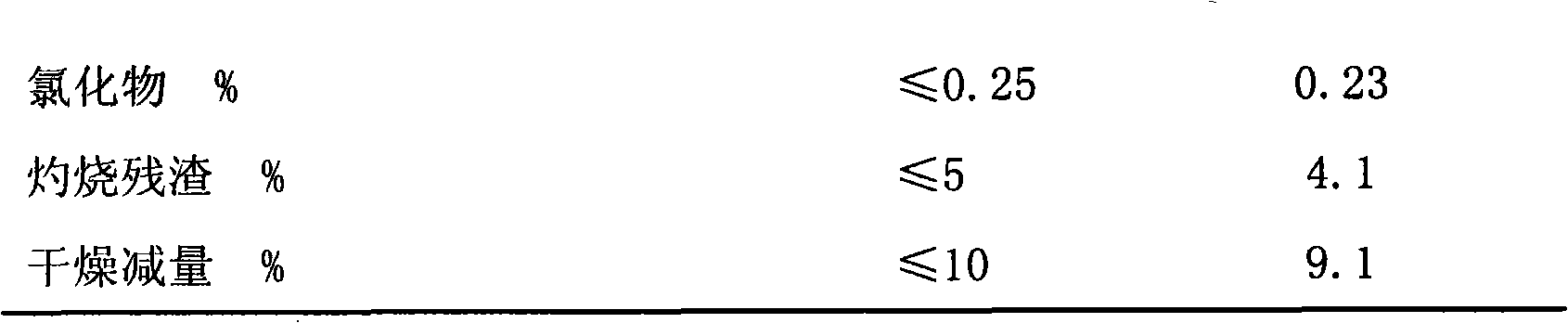

Examples

Embodiment 1

[0027] Drying: remove impurities from the fruit cores of Cornus officinalis, and dry them at 105±5°C for 12 hours for dehydration.

[0028] Pulverization: pulverize the dried raw materials through a 20-mesh sieve.

[0029] Impregnation: mix with 60% zinc chloride solution according to the weight ratio of material to liquid ratio 1:1.5, use the intermittent tank reactor treated with corrosion-resistant materials for two-way stirring, impregnate for 3 hours, and accelerate kneading. Then filter it out and set aside.

[0030] Charcoal activation reaction: put the impregnated raw material into a rotary furnace, pass through a protective gas, such as nitrogen, and activate the charcoal at a temperature of 550°C for 4 hours, so that the pore structure of the raw material is gradually developed and finally becomes activated carbon.

[0031] Pickling: After the activation material is cooled, boil it with 1mol / L hydrochloric acid solution for 30-60 minutes.

[0032] Washing: Rinse th...

Embodiment 2

[0035] Drying: remove impurities from the fruit cores of Cornus officinalis, and dry them at 105±5°C for 12 hours for dehydration.

[0036] Pulverization: pulverize the dried raw materials through a 20-mesh sieve.

[0037] Impregnation: Mix with 50% zinc chloride solution according to the weight ratio of material to liquid ratio 1:3, use the batch tank reactor treated with corrosion-resistant materials to stir in both directions, impregnate for 6 hours, the speed is 4r / min, every 2min, turn 1 time in the opposite direction to speed up kneading. Then filter it out and set aside.

[0038] Charcoal activation reaction: put the impregnated raw material into a rotary furnace, pass through a protective gas, such as nitrogen, and activate the charcoal at a temperature of 650°C for 3 hours, so that the pore structure of the raw material will gradually develop and finally become activated carbon.

[0039] Pickling: After the activation material is cooled, boil it with 1mol / L hydrochl...

Embodiment 3

[0043] Drying: remove impurities from the fruit cores of Cornus officinalis, and dry them at 105±5°C for 12 hours for dehydration.

[0044] Pulverization: pulverize the dried raw materials through a 20-mesh sieve.

[0045] Impregnation: mix with 35% zinc chloride solution according to the weight ratio of material to liquid ratio 1:4.5, use the batch tank reactor treated with corrosion-resistant materials to stir in both directions, impregnate for 9 hours, the speed is 4r / min, every 2min, turn 1 time in the opposite direction to speed up kneading. Then filter it out and set aside.

[0046] Charcoal activation reaction: put the impregnated raw material into a rotary furnace, pass through a protective gas, such as nitrogen, and activate the charcoal at a temperature of 800°C for 2 hours, so that the pore structure of the raw material is gradually developed and finally becomes activated carbon.

[0047] Pickling: After the activation material is cooled, boil it with 1mol / L hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com