A kind of non-oriented silicon steel for driving motor and its production method

A technology of oriented silicon steel and drive motor, which is applied in the direction of improving process efficiency, can solve the problems of high cost and complicated process, and achieve the effects of low production cost, simple process and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

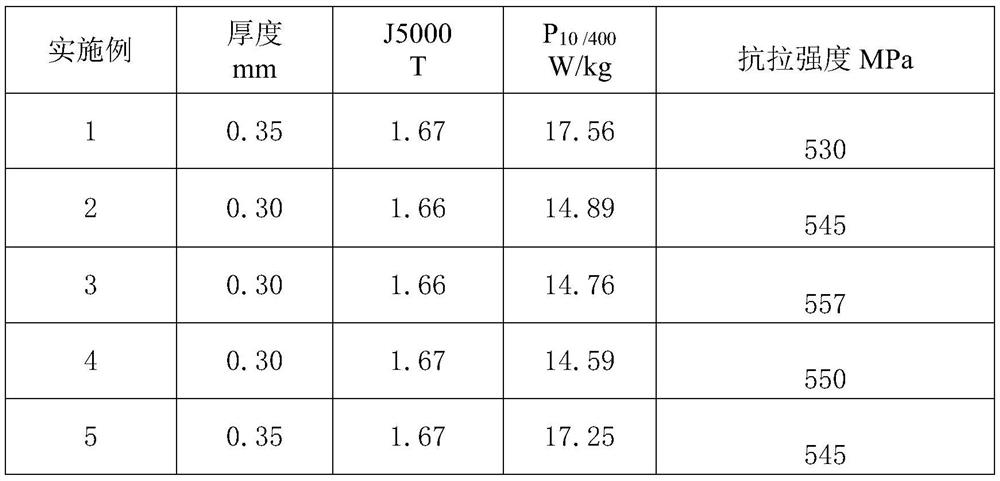

[0043] According to the chemical composition shown in Table 1, it is smelted, billet cast, and hot rolled. Adjust normalization, cold rolling, and annealing processes to achieve stable and smooth production.

[0044]Normalization: the temperature rise rate of the steel strip is 315°C / min, the normalization holding time is 1.5min, the grain size after normalization is 118.3μm, and the soaking section temperature is 945°C.

[0045] Cold rolling: the reduction rate of the first pass is 38%, the rolling force is 458t, and the unit tension of the entry side of the second pass is 28Kg / mm 2 , the outlet side unit tension is 30Kg / mm 2 .

[0046] Annealing: the speed is 80m / min, and the temperature is 925°C.

[0047] According to the chemical composition design in Table 1, and adopting the above control process, the mechanical properties of the 0.27-0.35mm cold-rolled non-oriented silicon steel products for driving motors produced are shown in Table 2.

Embodiment 2

[0049] According to the chemical composition shown in Table 1, it is smelted, billet cast, and hot rolled. Adjust normalization, cold rolling, and annealing processes to achieve stable and smooth production.

[0050] Normalization: The temperature rise rate of the steel strip is 320°C / min, the normalization holding time is 1.2min, the grain size after normalization is 127.5μm, and the soaking section temperature is 965°C.

[0051] Cold rolling: the reduction rate of the first pass is 36%, the rolling force is 425t, and the unit tension of the entry side of the second pass is 29Kg / mm 2 , the unit tension on the outlet side is 33Kg / mm 2 .

[0052] Annealing: the speed is 70m / min, and the temperature is 905°C.

[0053] According to the chemical composition design in Table 1, and adopting the above control process, the mechanical properties of the 0.27-0.35mm cold-rolled non-oriented silicon steel products for driving motors produced are shown in Table 2.

Embodiment 3

[0055] According to the chemical composition shown in Table 1, it is smelted, billet cast, and hot rolled. Adjust normalization, cold rolling, and annealing processes to achieve stable and smooth production.

[0056] Normalization: the temperature rise rate of the steel strip is 330°C / min, the normalization holding time is 1.4min, the grain size after normalization is 135.4μm, and the soaking section temperature is 959°C.

[0057] Cold rolling: the reduction rate of the first pass is 40%, the rolling force is 489t, and the unit tension of the entry side of the second pass is 26Kg / mm 2 , the unit tension on the outlet side is 31Kg / mm 2 .

[0058] Annealing: the speed is 75m / min, and the temperature is 910°C.

[0059] According to the chemical composition design in Table 1, and adopting the above control process, the mechanical properties of the 0.27-0.35mm cold-rolled non-oriented silicon steel products for driving motors produced are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com