Method of cooperatively regulating and improving crystal seed decomposition of sodium aluminate solution

A sodium aluminate and seed crystal technology, applied in the field of aluminum metallurgy, can solve the problems of insignificant economy, high operating cost, large equipment investment, etc., achieve high decomposition rate, less new equipment, improve output rate and cycle efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of highly active seed crystal slurry: take 50mL sodium bicarbonate slurry (NaHCO 3 120g / L), added to a 500mL beaker, heated to 45°C in a water bath; added 70mL sodium aluminate solution (Na 2 O155.01g / L, Al 2 o 3 179.59g / L, α K 1.42), induce nucleation for 30 minutes; then add 20 mL of sodium aluminate solution, decompose quickly for 60 minutes, and prepare a slurry of highly active aluminum hydroxide seed crystals. The particle size of aluminum hydroxide is fine (average particle size d501.4μm, less surface-to-surface superimposition, mainly intersecting or perpendicular to each other, particle edges are jagged, poor crystallization), and the stirring time is 4 hours at 45°C.

[0029] (2) Solution seeding enhancement: Take 900mL of sodium aluminate solution and add it to a 2000mL stainless steel bucket, heat it in a water bath to a temperature of 60°C, and add aluminum hydroxide circulating seeds at 1000g / L (average particle size d5060.13μm, - The n...

Embodiment 2

[0032] (1) Preparation of highly active seed crystal slurry: take 50mL sodium bicarbonate slurry (NaHCO 3 120g / L), added to a 500mL beaker, heated in a water bath to 40°C; added 50mL of sodium aluminate solution (Na 2 O160.23g / L, Al 2 o 3 185.64g / L, α K 1.42), induce nucleation for 30 minutes; then add 50 mL of sodium aluminate solution, decompose quickly for 60 minutes, and prepare a slurry of highly active aluminum hydroxide seed crystals. The particle size of aluminum hydroxide is fine (average particle size d502.5μm, the particles are mainly vertical or intersecting), and the stirring time is 3.5 hours at 40°C.

[0033] (2) Solution seeding enhancement: Take 900mL of sodium aluminate solution and add it to a 2000mL stainless steel bucket, heat it in a water bath to a temperature of 60°C, and add aluminum hydroxide circulating seeds at 1000g / L (average particle size d5060.13μm, - The number of 45 μm particles accounted for 18.21% of the total), and 15 mL of highly activ...

Embodiment 3

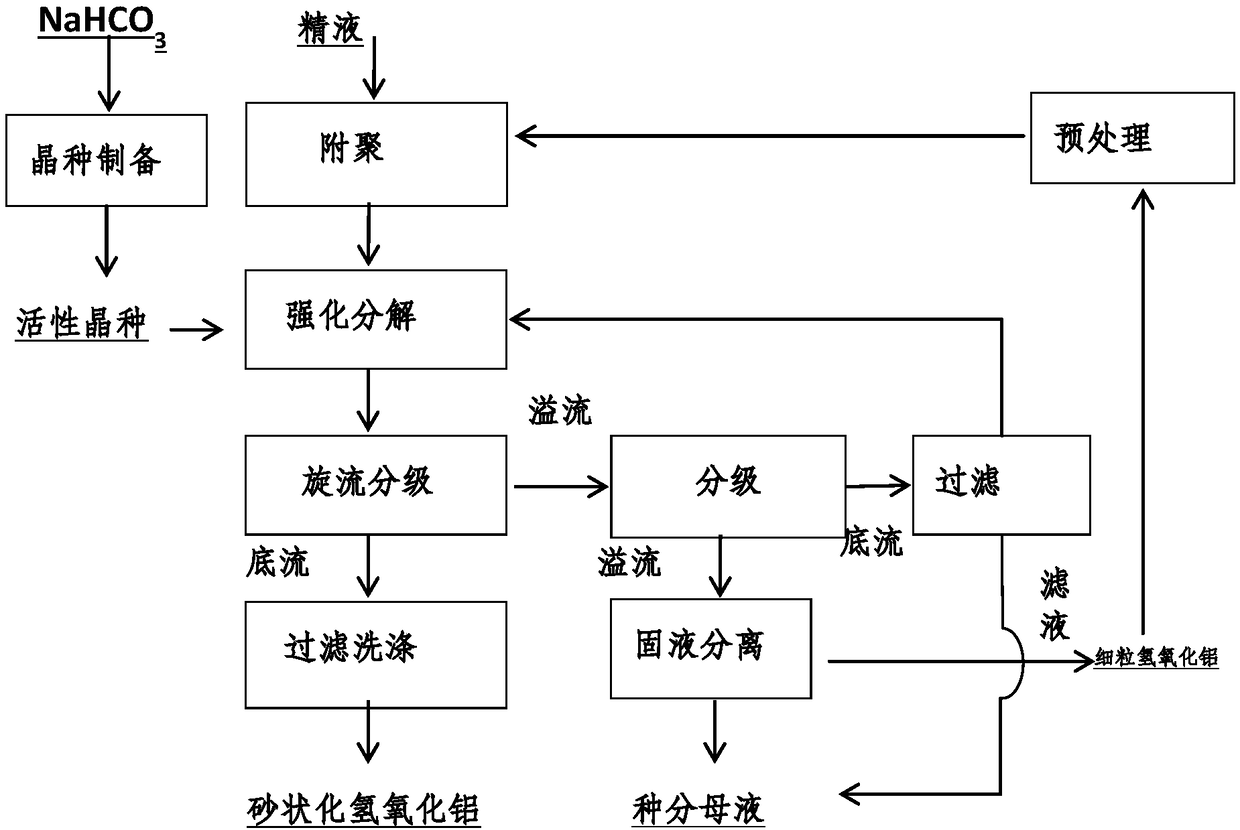

[0036] Adopt technological process of the present invention ( figure 1 ):

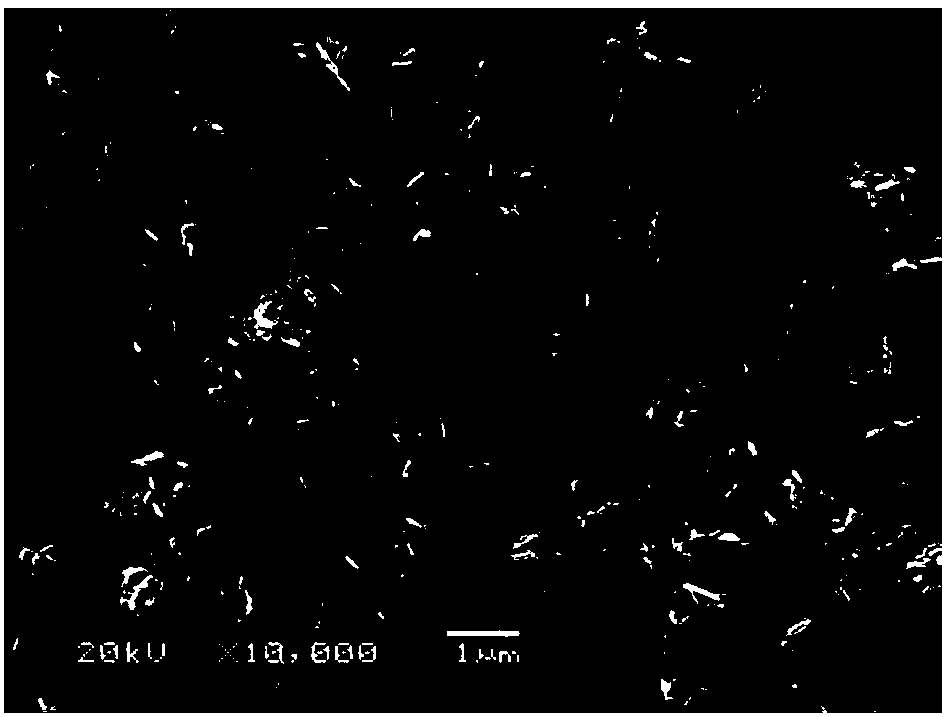

[0037] (1) Preparation of highly active seed crystal slurry: take 50mL sodium bicarbonate slurry (NaHCO 3 100g / L), added to a 500mL beaker, heated to 40°C in a water bath; 50mL of sodium aluminate solution (Na 2 O162.10g / L, Al 2 o 3 189.31g / L, α K 1.41), induce nucleation for 10 minutes; then add 50mL of sodium aluminate solution, decompose quickly for 60 minutes, and prepare a slurry of highly active aluminum hydroxide seed crystals. Highly active aluminum hydroxide seed crystals have fine particle size (average particle size d501.4μm, vertical or intersecting surfaces, irregular and jagged edges, figure 2 ), 40°C residence stirring time is less than 2 hours.

[0038] (2) Solution seeding enhancement: Take 900mL of sodium aluminate solution and add it to a 2000mL stainless steel bucket, heat it in a water bath to a temperature of 60°C, and add the aluminum hydroxide seed crystals (average Part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com