Patents

Literature

137results about How to "Little impact on production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

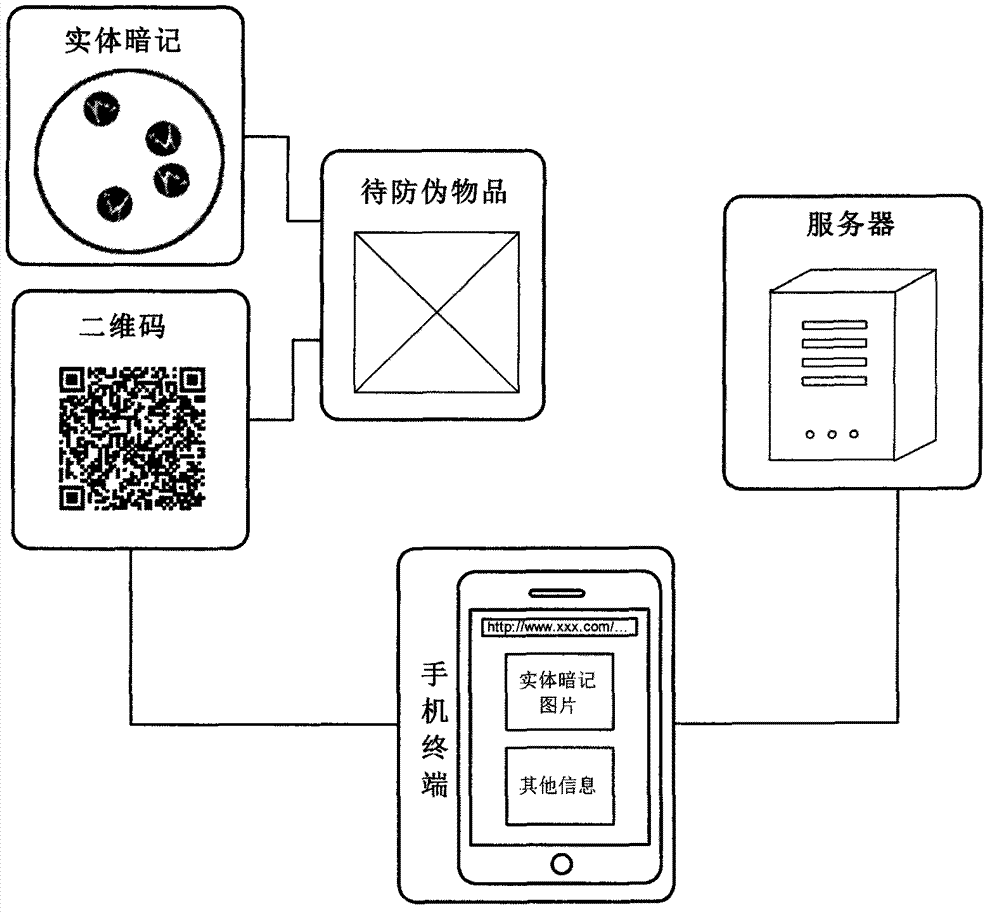

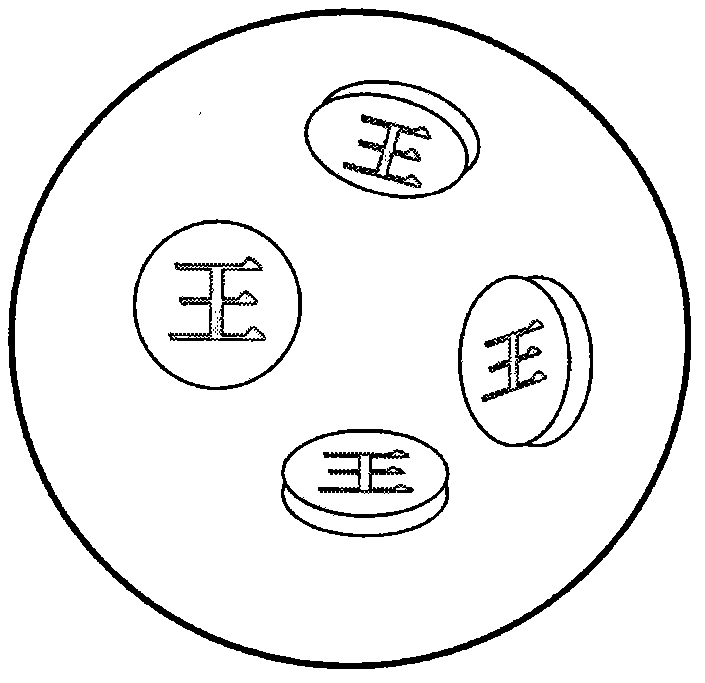

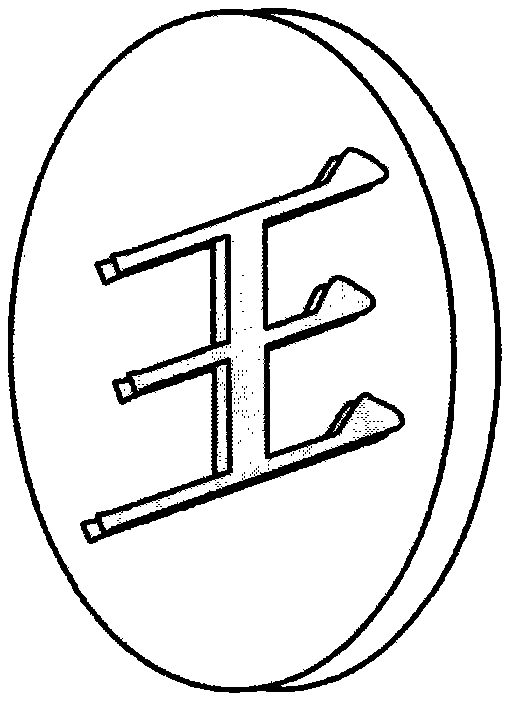

Three-dimensional entity secret mark anti-counterfeiting system and method

InactiveCN103489109AGuaranteed one-time useGood anti-counterfeiting effectStampsSensing record carriersComputer securityComputer network

The invention provides a three-dimensional entity secret mark anti-counterfeiting system and method. The anti-counterfeiting system comprises an object to be detected, an entity secret mark label fixed to any position of the object to be provided with an anti-counterfeiting mark, a two-dimensional code fixed to any position of the object to be provided with the anti-counterfeiting mark, a remote server and a mobile terminal, wherein the mobile terminal scans the two-dimensional code, is connected to the remote server and compares the entity secret mark label with a reference photo on the server so that counterfeiting prevention and identification can be achieved, and a random number of unique random three-dimensional hollow-out arrangement structures which are formed by a plurality of three-dimensional structure entity secret marks are arranged on the entity secrete mark label. The anti-counterfeiting system and method are easy to operate, good in interactivity and strong in anti-counterfeiting practicability, the effects of enabling an anti-counterfeiting structure to be hard to counterfeit, copy and crack are well guaranteed through the unique hollow-out three-dimensional anti-counterfeiting marks, and the extremely good counterfeiting prevention effect is achieved.

Owner:郑国义

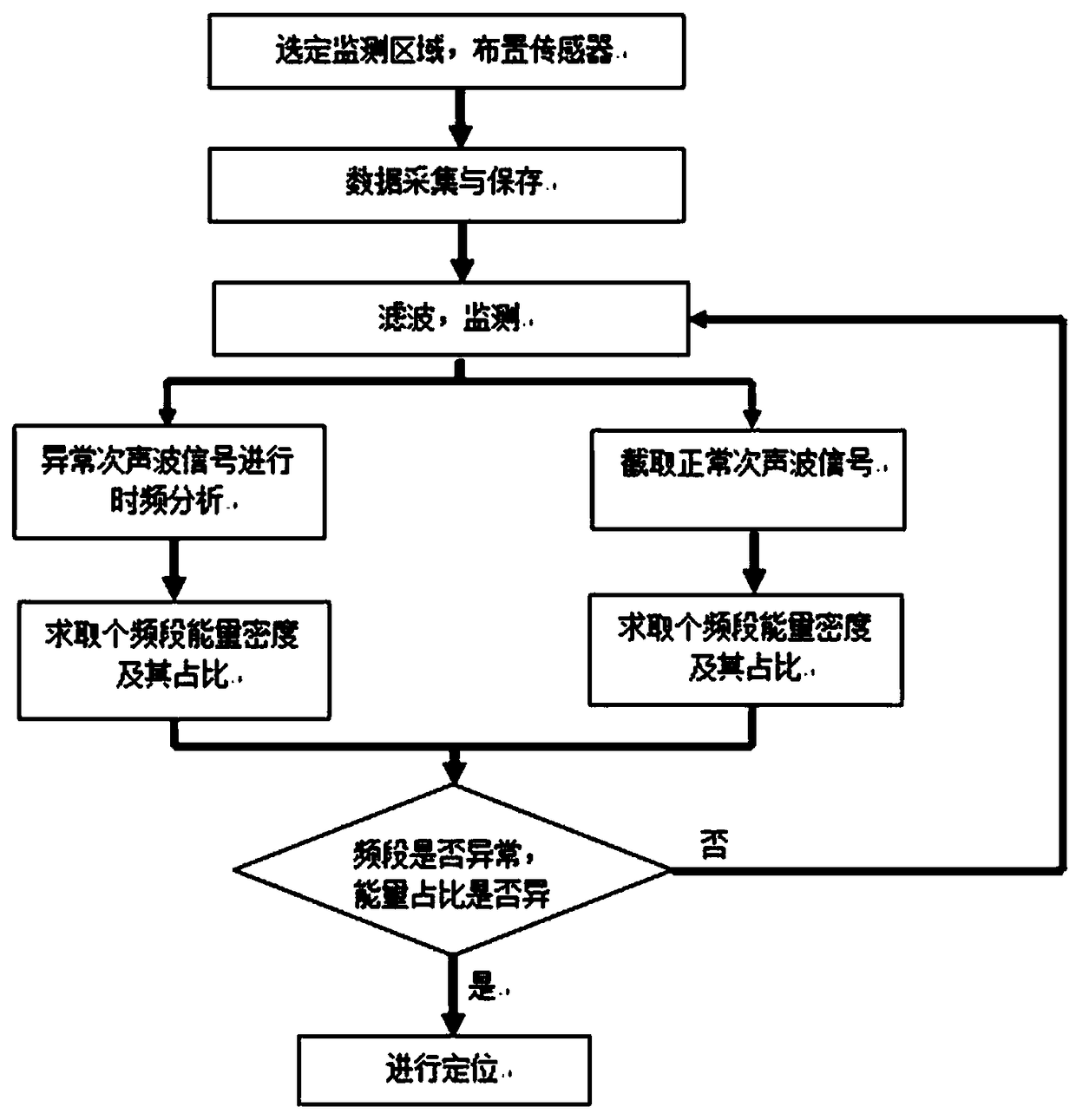

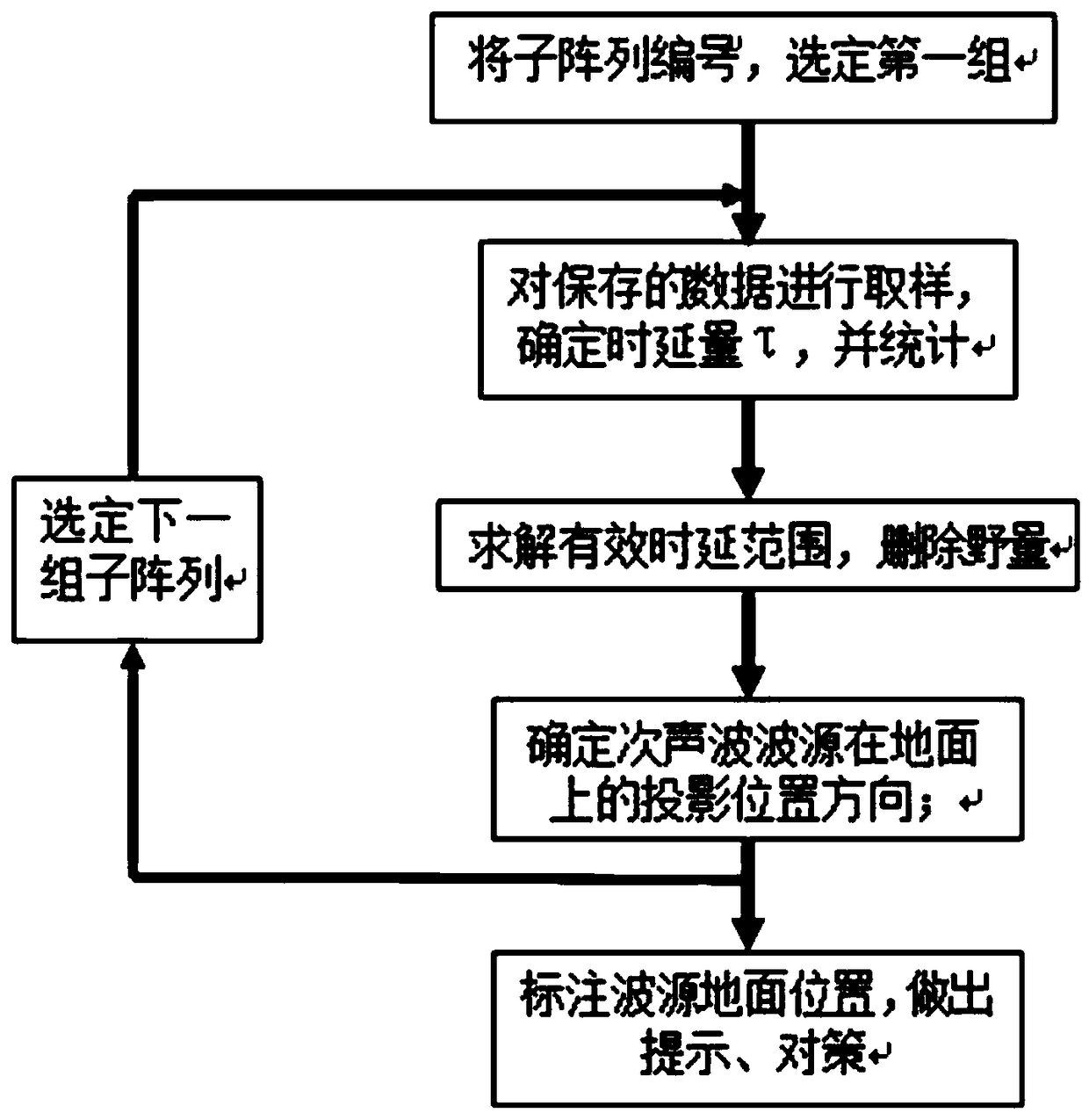

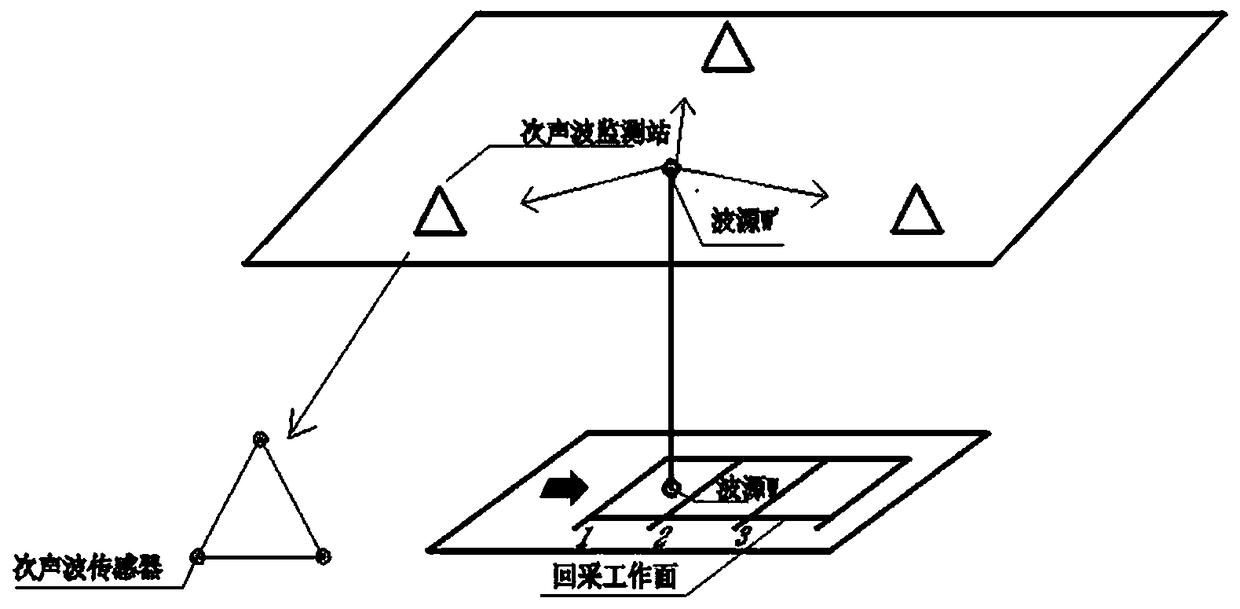

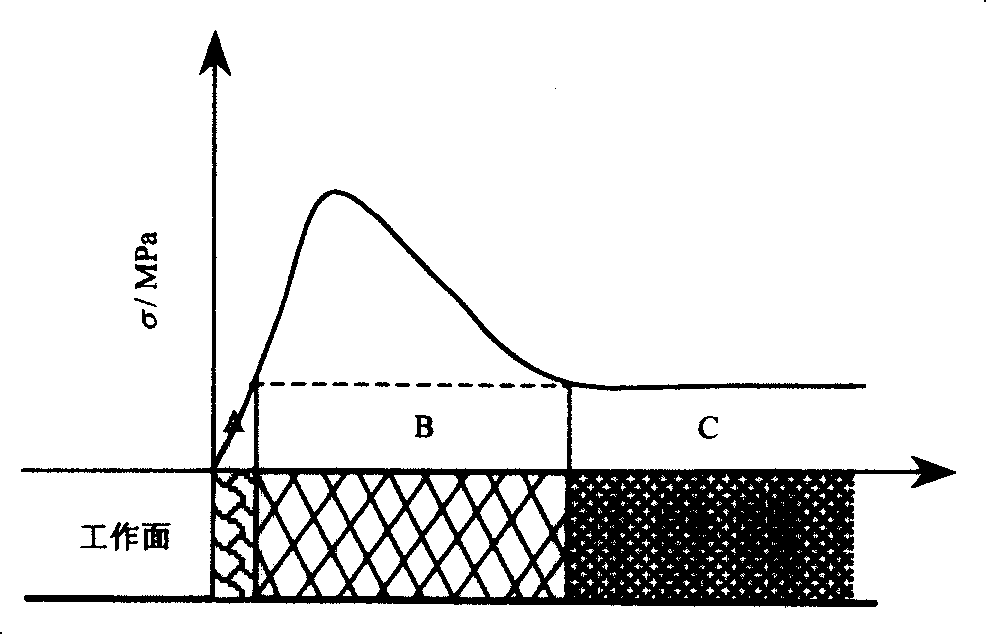

Method and system for positioning coal rock dynamic disaster through infrasonic wave monitoring

ActiveCN108802825AMonitor ruptureMonitoring and positioning functionSeismology for water-loggingStatistical analysisShort time fourier transformation

The invention discloses a method and a system for positioning coal rock dynamic disaster through infrasonic wave monitoring. The system comprises a monitoring main station and a plurality of monitoring substations, and the monitoring substations are connected with the monitoring main station through a fiber optic network; each monitoring substation is composed of three infrasonic wave sensors arranged in a triangular form, and the infrasonic wave sensors are connected with an infrasonic wave monitor; and the monitoring main station is provided with a computing server. The positioning method isthat the main station computing server filters collected data, the time-frequency analysis is performed on the data by the short-time Fourier transform (STFT), the frequency energy density is compared, signals of the main frequency band are extracted, and the calculation result is positioned through statistical analysis and time delay estimation theory. The system monitors the infrasonic wave signal generated by the fracture of the loaded coal rock. Through this method, the non-contact and regional tests are carried out on the stress distribution state of the surrounding rock of the tunnel ormines to determine the area of coal rock fracture and stress anomaly. The method is simple in installation and operation, has little impact on production, and has a large detection range and a long detection distance.

Owner:HENAN POLYTECHNIC UNIV

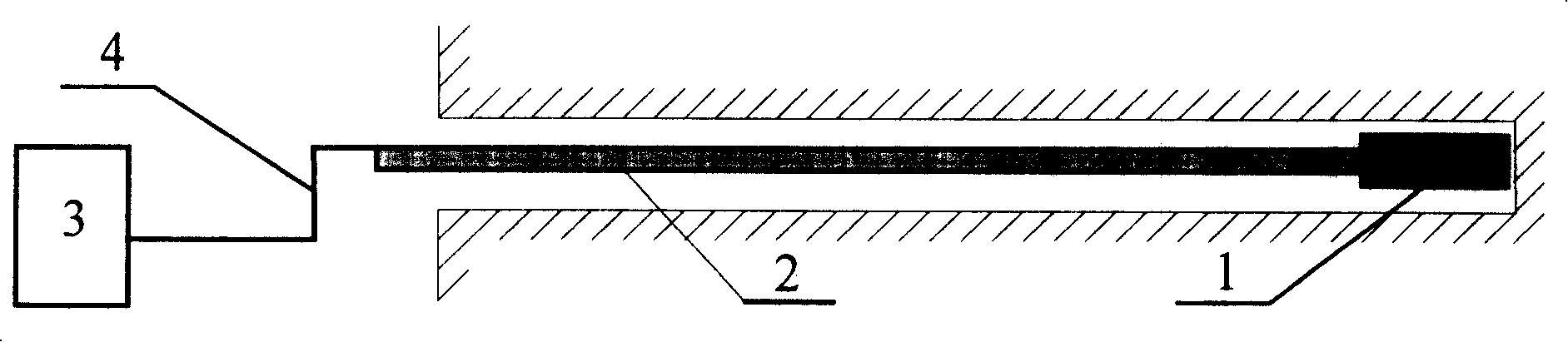

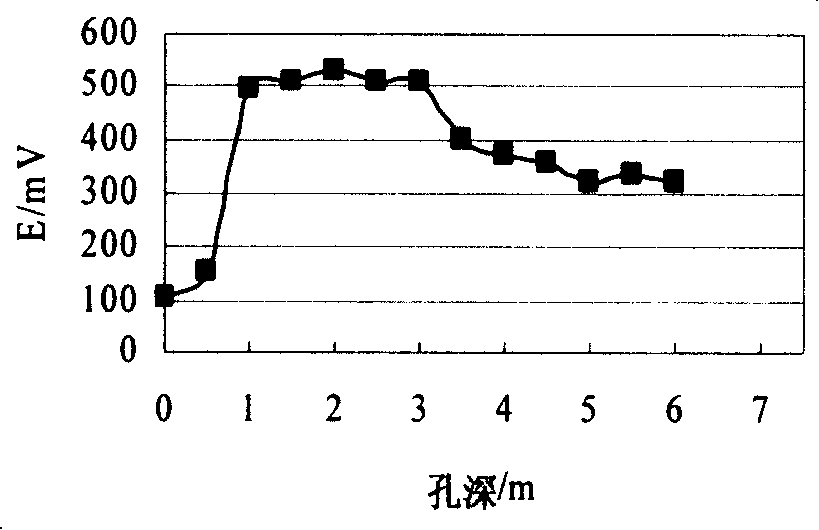

Method for monitoring mine rock stress state by electromagnetic radiation method

The present invention discloses electromagnetic radiation method for monitoring the stress status of mine. Electromagnetic radiation signal of rock stratum in mine is monitored with one electromagnetic radiation monitoring system and applied in analyzing the stress status of rock stratum in mine based on the corresponding relation between the electromagnetic radiation signal and the stress status of the rock stratum. The electromagnetic radiation monitoring system includes sensors, and one monitoring instrument. The sensor has one push-pull rod connected to detect the stress status in different area in the mine. The method is practical, accurate and suitable for various kinds of mine, especially coal mine.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

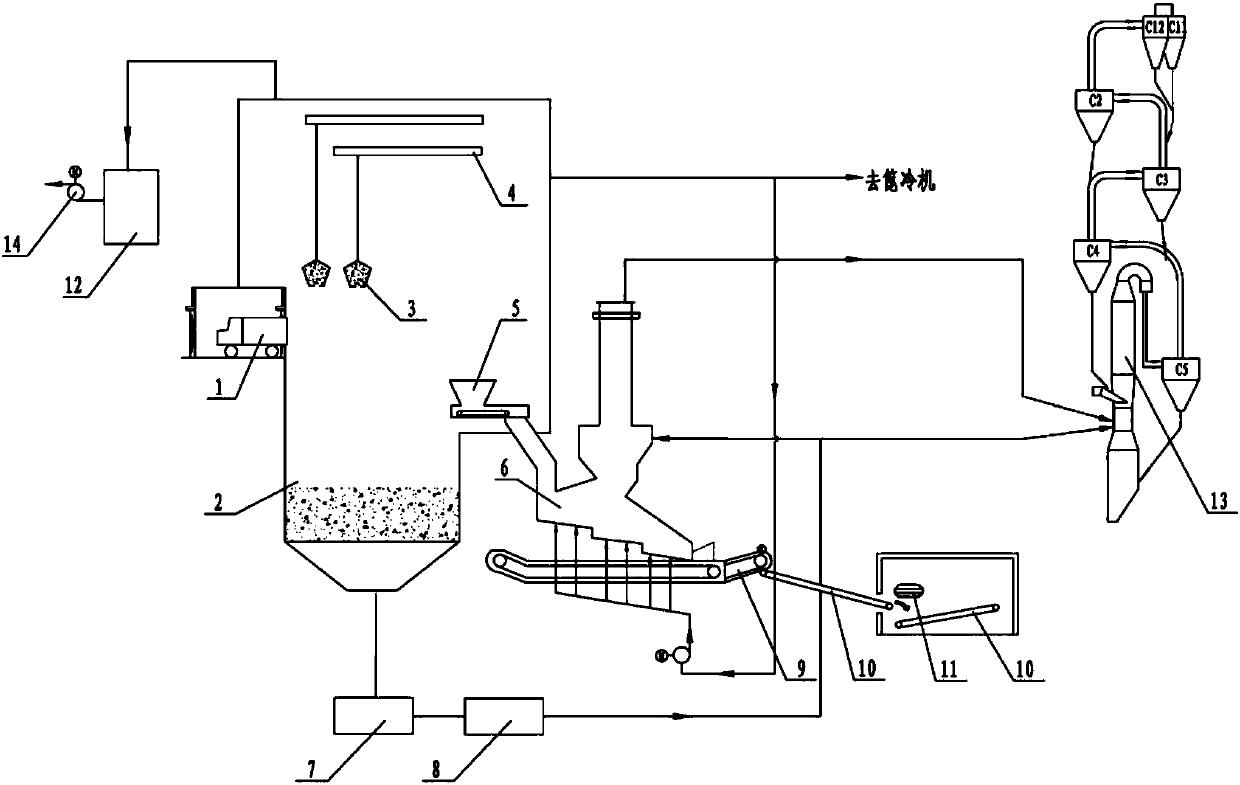

System for synergistically treating domestic garbage through cement kiln and method thereof

InactiveCN107917427AReduce the impactSimple and fast operationFurnace typesIncinerator apparatusProcess engineeringEnvironmental engineering

The invention discloses a system for synergistically treating domestic garbage through a cement kiln and a method thereof. The system comprises a feeding system, a gasification incineration system, adeslagging system, a smell treating system and a leachate treating system. According to the system, a grate furnace and a cement production process technology are combined, and waste gas produced by garbage incineration is lead into a decomposing furnace of a novel dry cement kiln system, and harmful gas such as dioxin produced by garbage can be further absorbed and treated under about 880 DEG C high temperature and alkaline conditions in the decomposing furnace, thus the garbage treatment meets the requirements of harmlessness, quantity reduction and recycling requirements. The system is simple and convenient to operate, stable to run, small in investment, and low in cements on cement lines and environment, and is an ideal domestic garbage treatment scheme.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

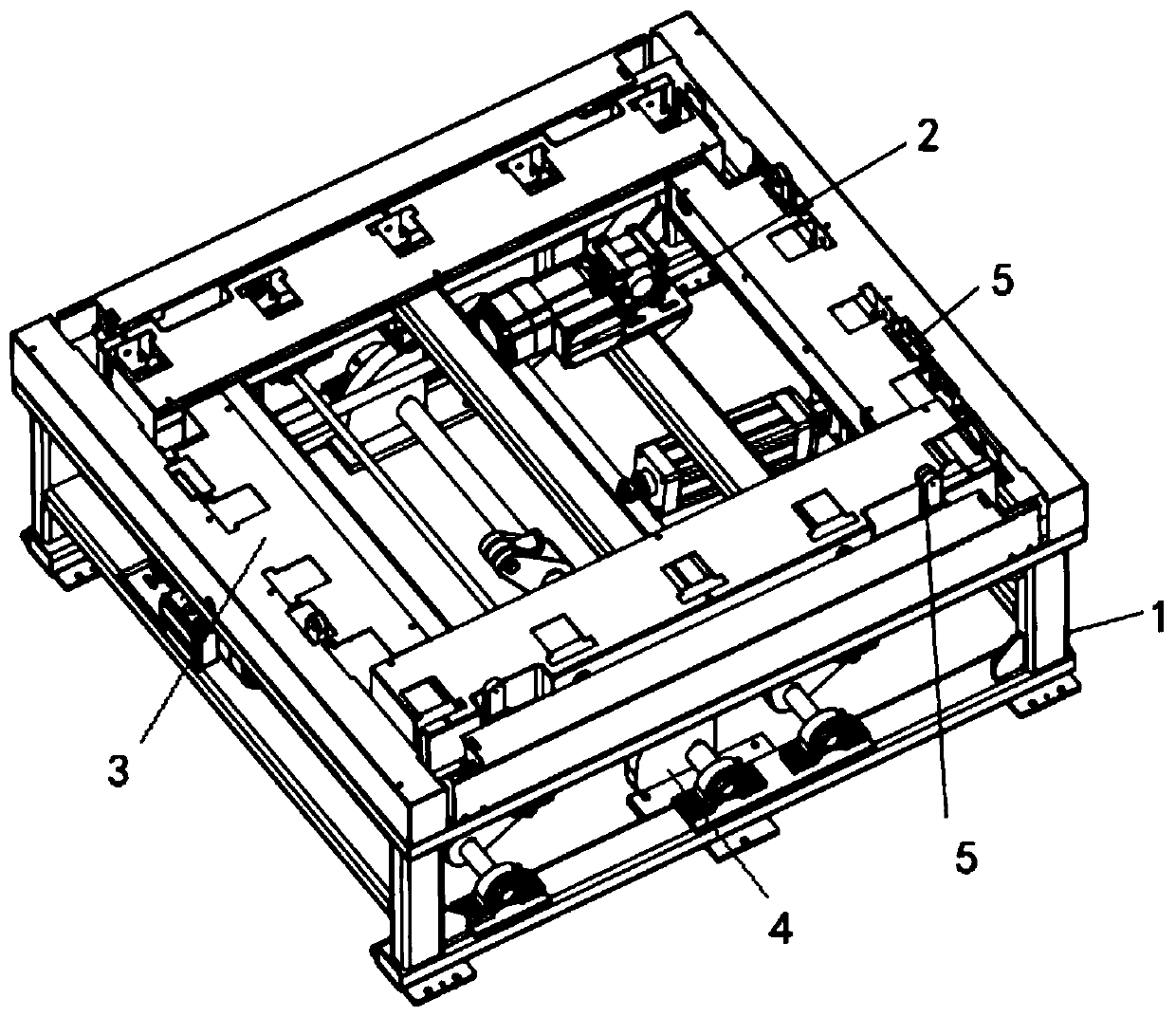

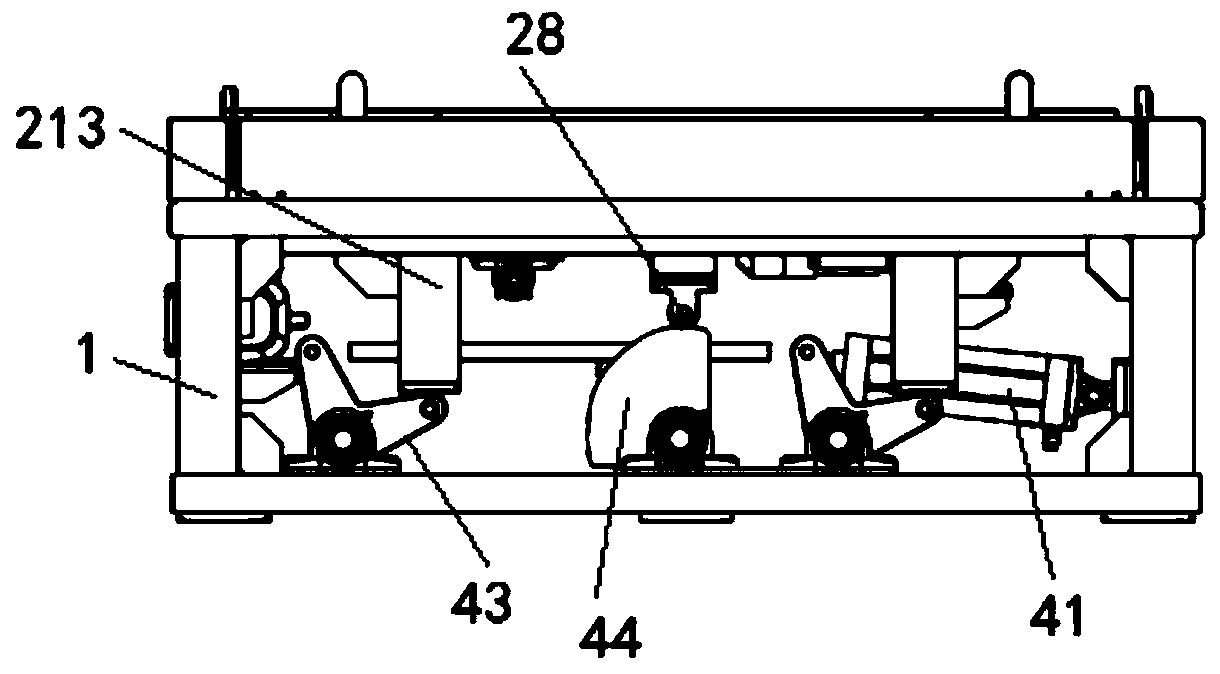

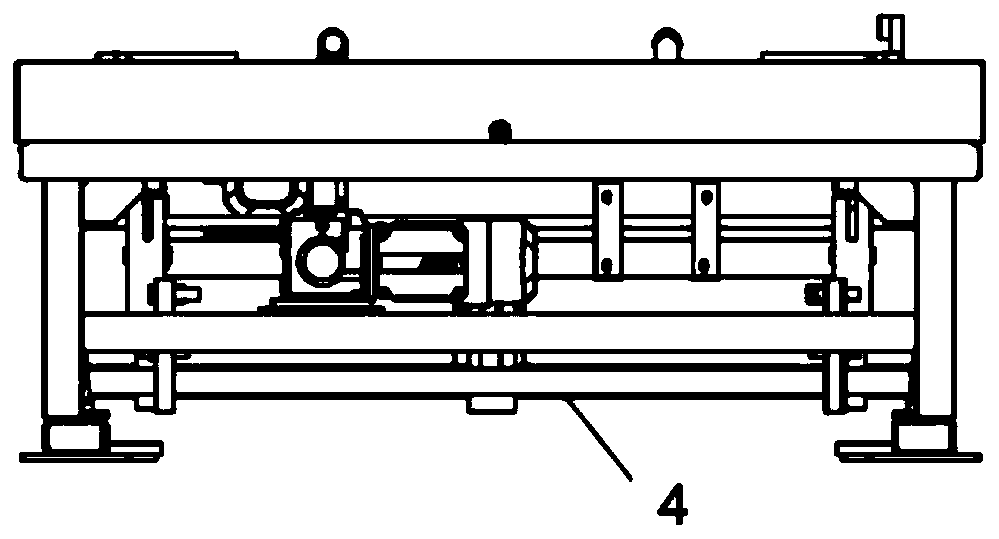

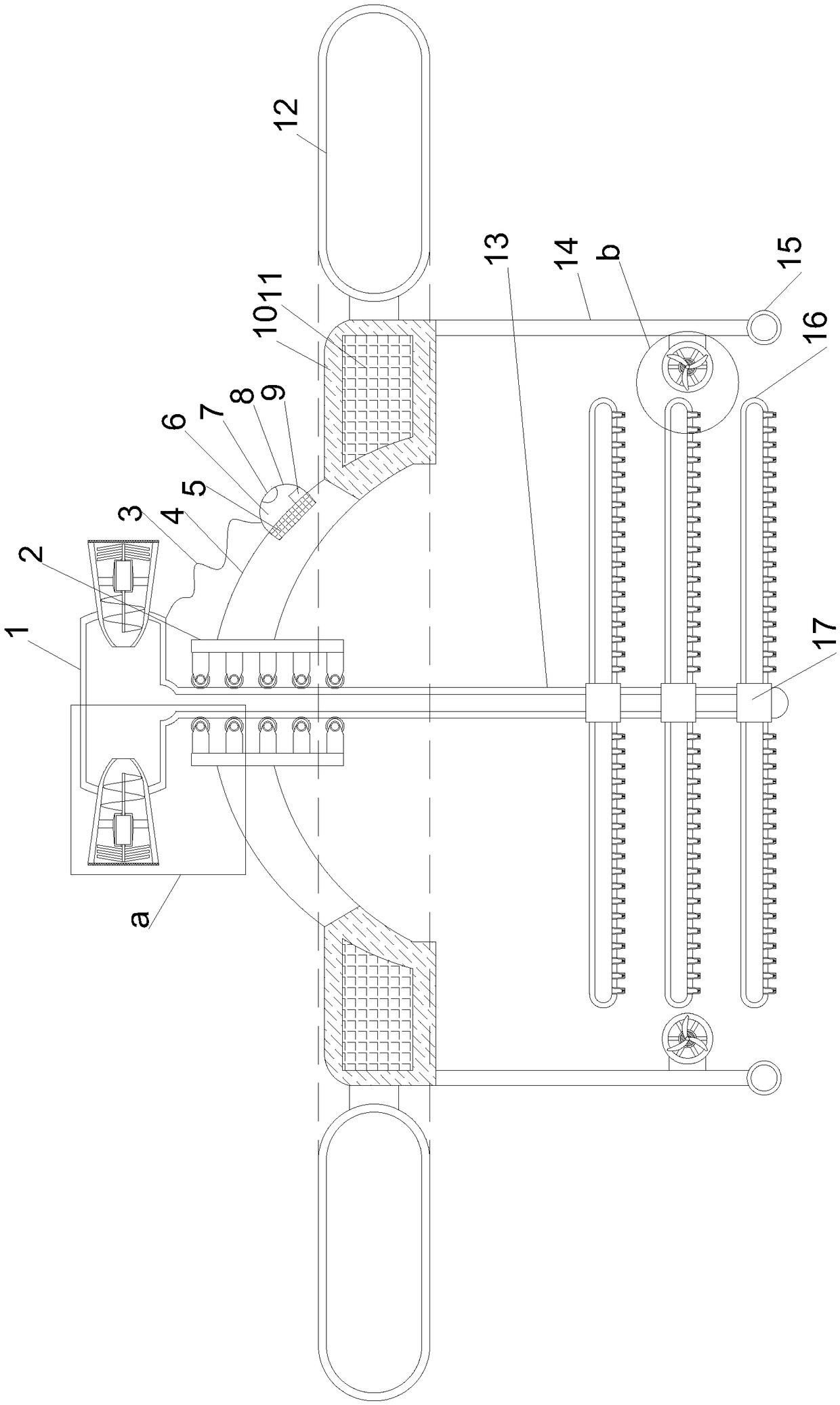

Reversing lifting conveyor and conveying system

PendingCN110356823AImprove transportation efficiencyCompact structureConveyor partsRoller-waysEngineeringMechanical engineering

The invention relates to a reversing lifting conveyor and a conveying system. The reversing lifting conveyor comprises a rack, a lifting mechanism which is arranged on the rack, a transverse conveyingmechanism which can transversely convey, is arranged on the lifting mechanism, and is driven by the lifting mechanism to perform lifting motion, a longitudinal conveying mechanism which is arranged on the rack and can perform longitudinal conveying, and blocking mechanisms which are separately arranged at the transverse side and the longitudinal side of the rack correspondingly and can be used for blocking transverse conveying and longitudinal conveying of material frames or material trays. The reversing lifting conveyor solves the technical problem that an existing conveying mode does not have functions of reversing, transporting and buffering the material frames or the material trays.

Owner:德屹智能科技(扬州)有限公司

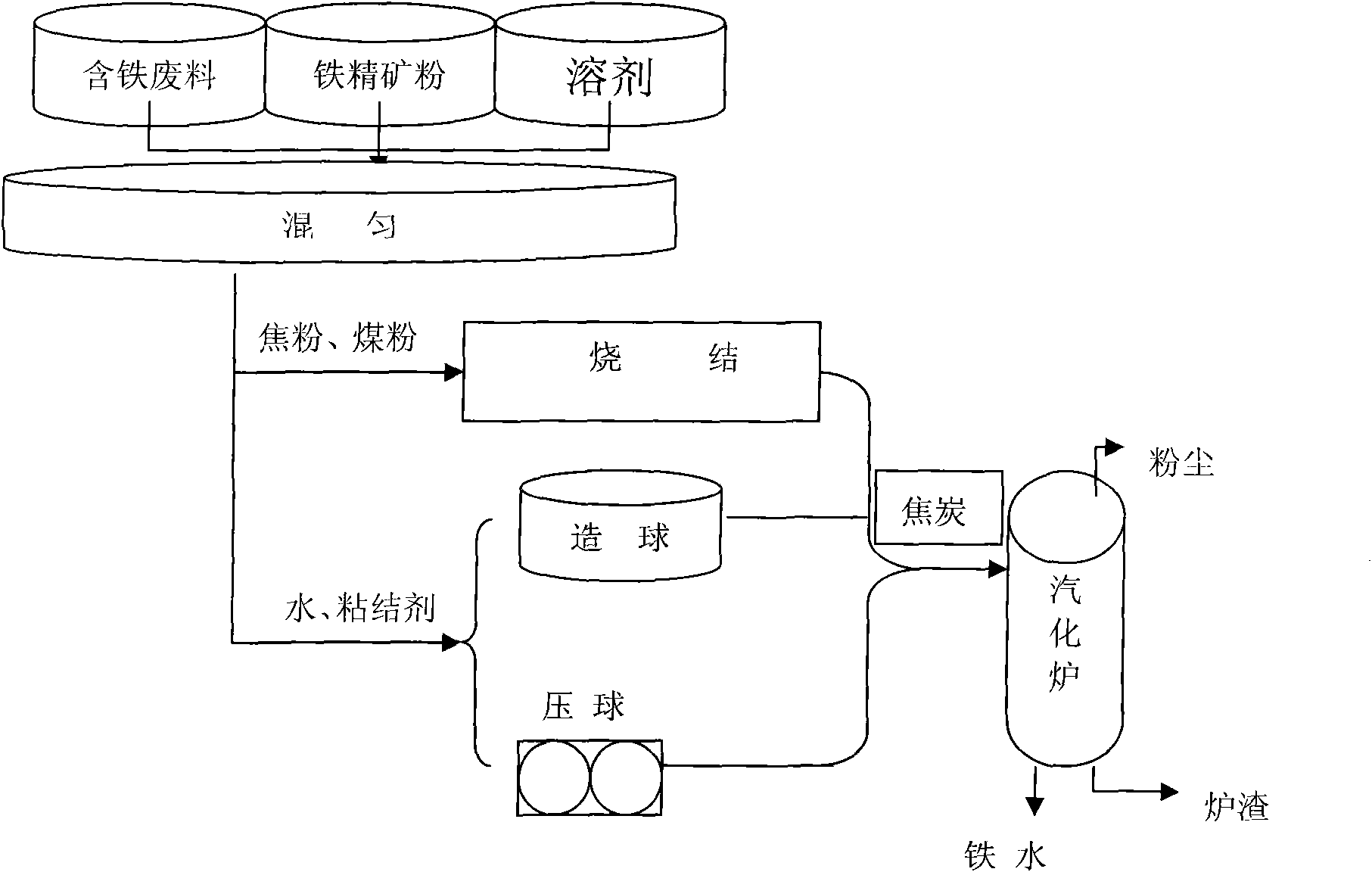

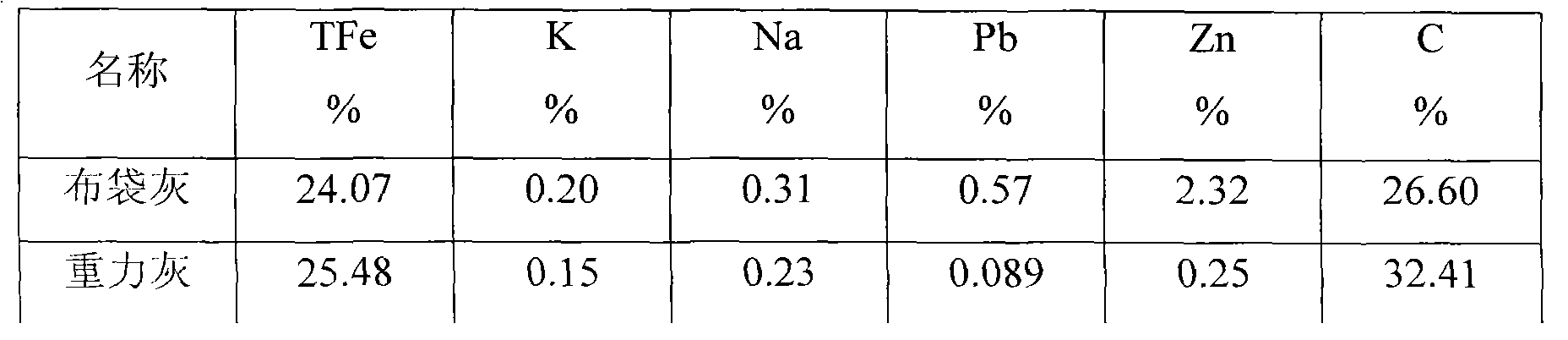

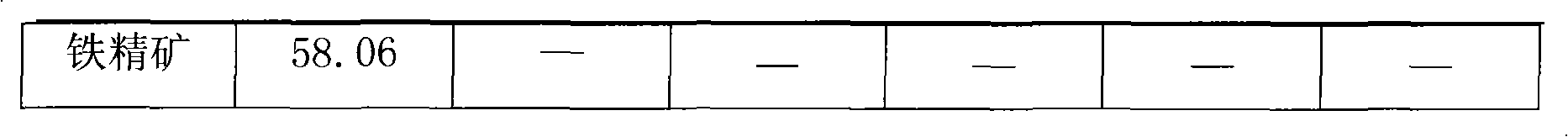

Method for treating iron-containing dusts in steel plant by using melting gasification furnace

The invention discloses a method for treating iron-containing dusts in a steel plant by using a melting gasification furnace, which comprises the following steps of: preparing uniformly mixed raw materials, namely mixing various iron-containing dusts in the steel plant, iron ore concentrate powder, adhesive and flux in a certain proportion to form the uniformly mixed raw materials; preparing lumps, namely preparing the uniformly mixed raw materials into the lumps by a cold bond agglomeration method or a hot-state agglomeration method; and smelting in a blast furnace, namely adding the prepared lumps and a certain amount of coke into the high-wind-temperature melting gasification furnace to perform melting, and finally obtaining molten iron by melting. The method for treating the iron-containing dusts in the steel plant can effectively solve the pollution problem of the iron-containing dusts, can obtain qualified molten iron, and makes full use of valuable elements such as carbon, iron and the like in wastes.

Owner:UNIV OF SCI & TECH BEIJING

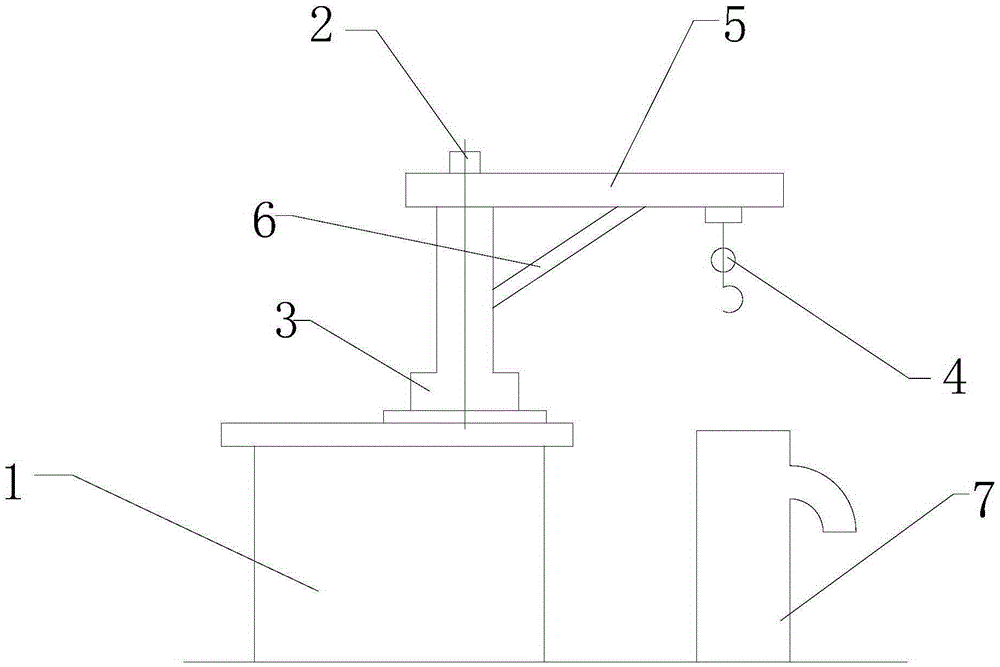

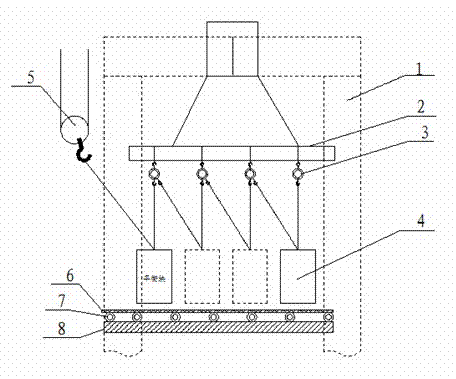

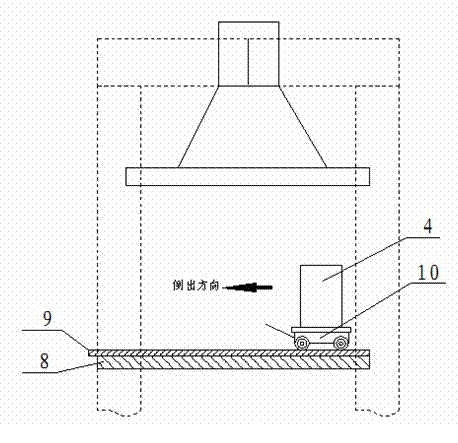

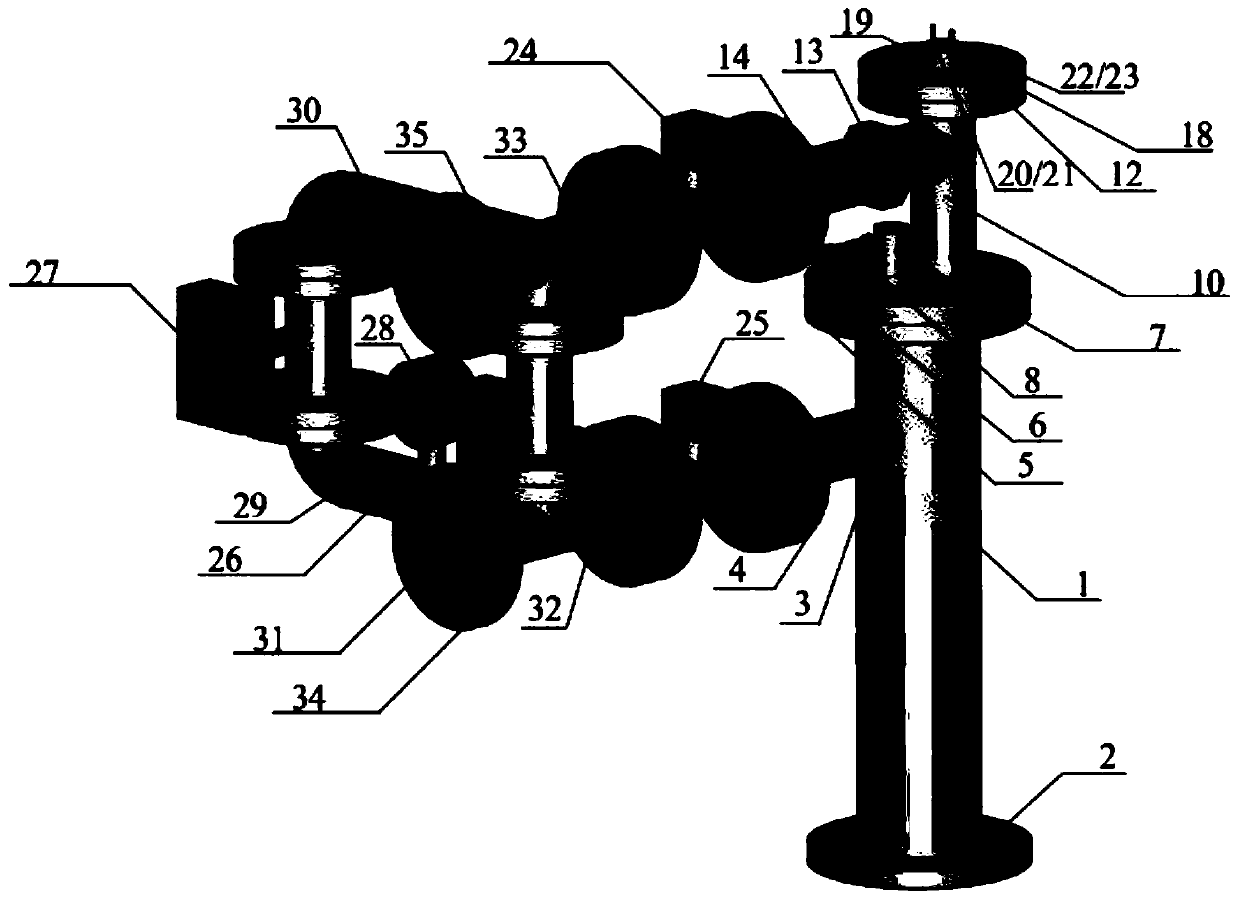

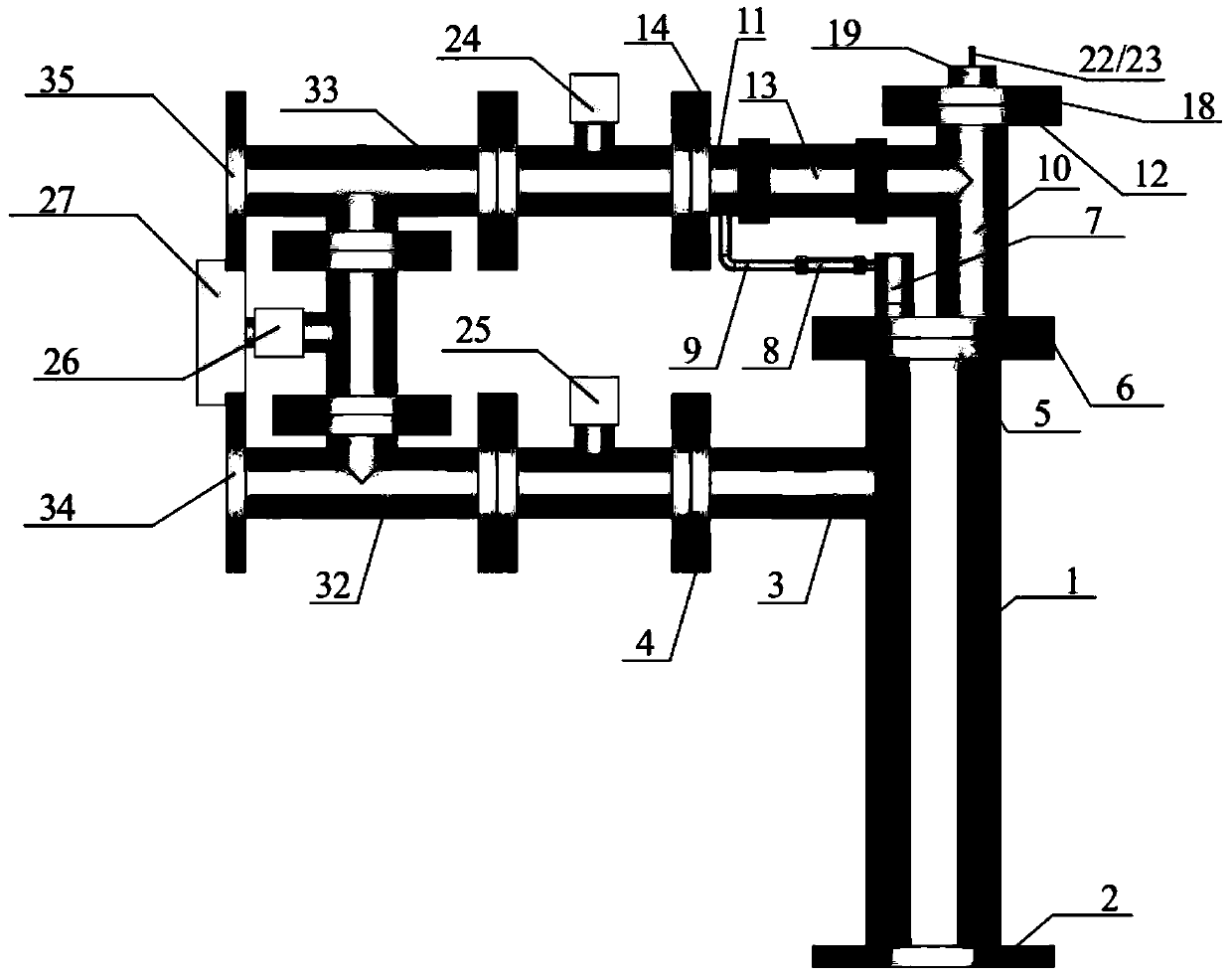

Coke oven riser tube replacement apparatus and coke oven riser tube replacement method

The invention provides a coke oven riser tube replacement apparatus and a coke oven riser tube replacement method, and especially relates to a coke oven riser tube replacement apparatus and a coke oven riser tube replacement method applied in the field of coke oven production. The coke oven riser tube replacement apparatus provided by the invention has the advantages of simple structure, shortening of the unkeeping time, and maintenance of the coke oven production continuity, and comprises a coal car, a fixed stand column, a rotating stand column, a crane and a transverse arm. The coke oven riser tube replacement method can reduce the danger of replacement working, and comprises the following steps: 1, rotating the transverse arm to a position above a riser tube to be replaced; 2, hoisting the riser tube to be replaced; 3, moving out the riser tube to be replaced; 4, moving a new riser tube to a position to be installed, and installing; 5, rotating the transverse arm to the initial position, and fixing. A rotatable cantilever crane in the invention has the advantages of simple structure, low cost, realization of no influences on the use performances of the coal car, coal car walking or normal production of a coke oven after installation, and flexible usage.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

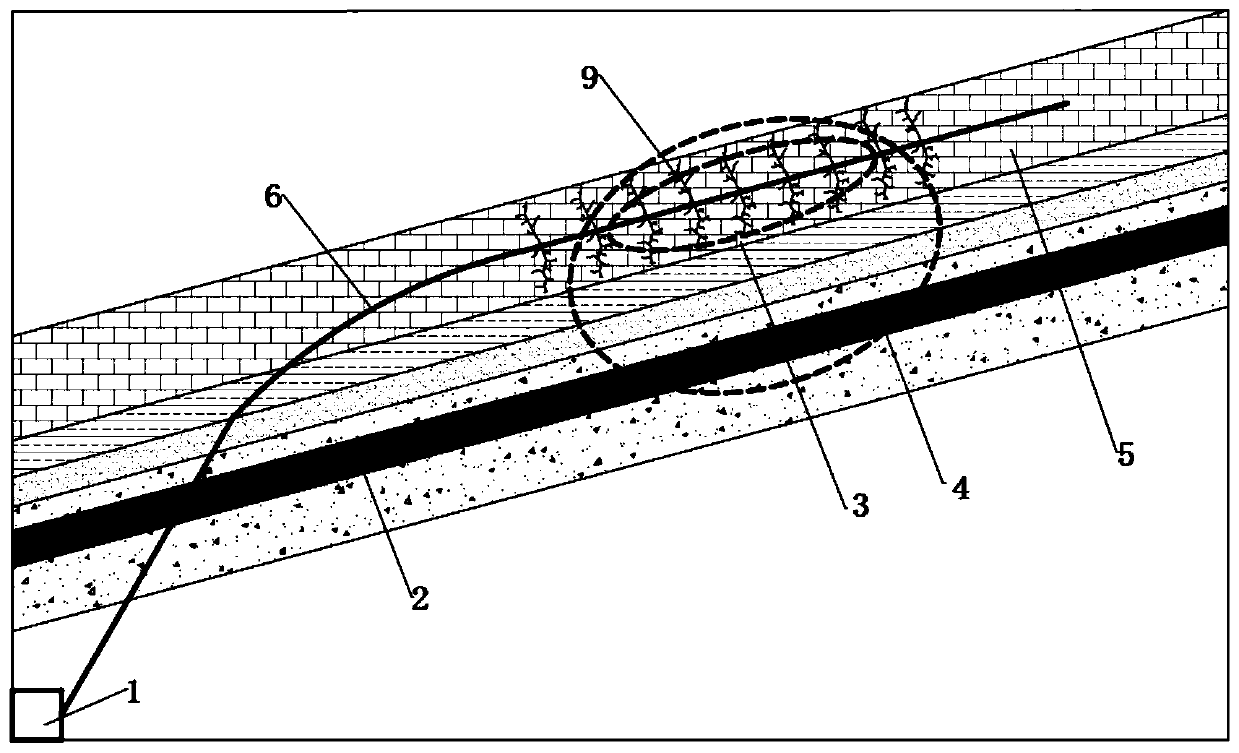

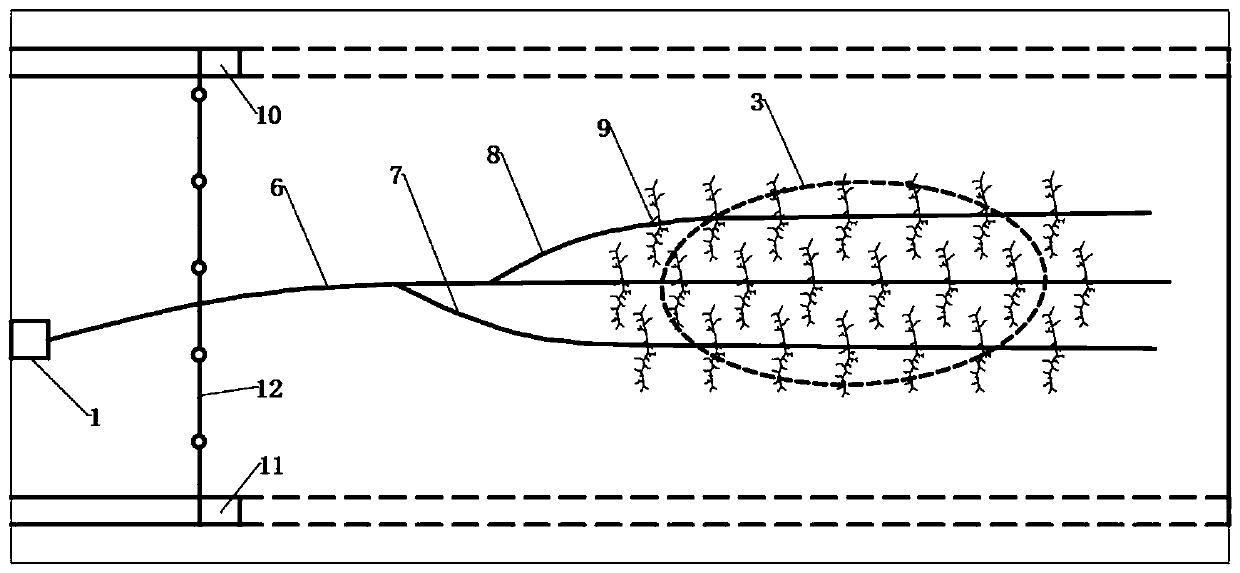

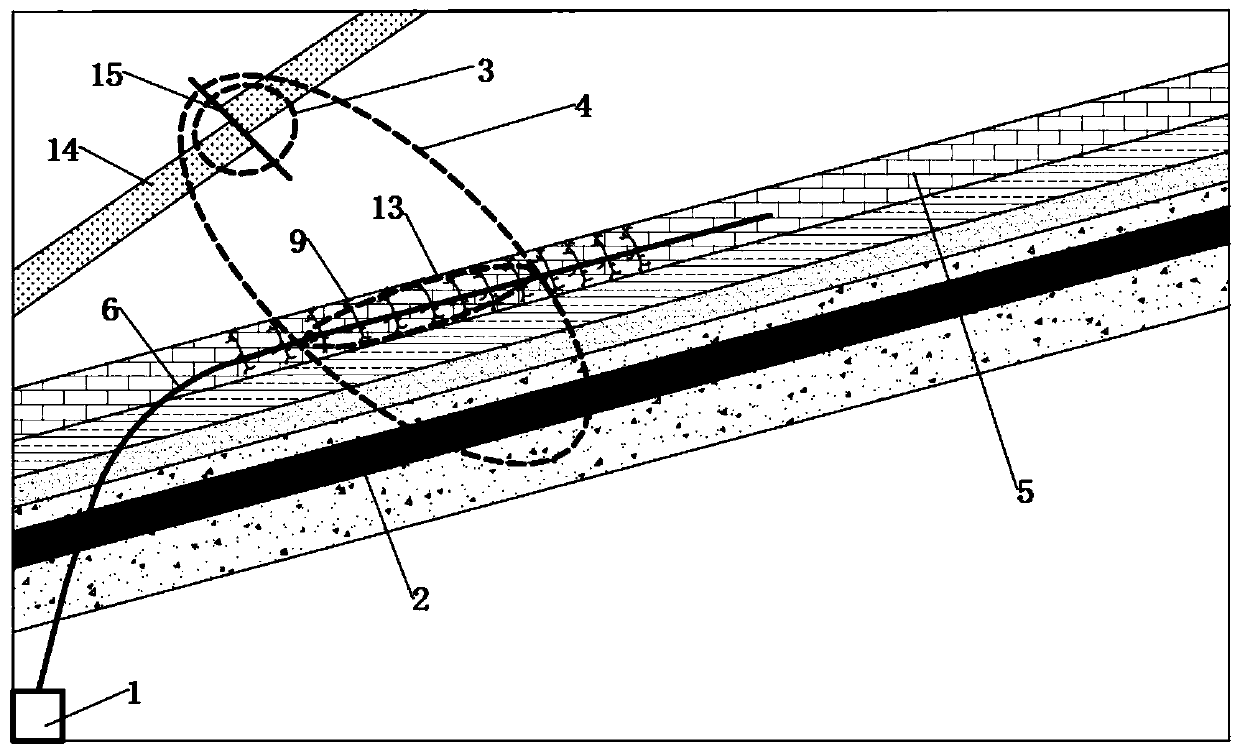

Method for precise prevention and control of rock burst in remote area under coal mine

ActiveCN111270987AImprove prevention efficiencyImprove efficiencySurveyFluid removalMining engineeringCoal

The invention discloses a method for precise prevention and control of rock burst in a remote area under a coal mine. The method comprises the following steps: analyzing and evaluating impact risks ofmining engineering and each adjacent area according to geological and mining conditions; determining impact vibration sources, stress wave spreading paths and rock burst risky areas; formulating keytechnological parameters of directional drilling and segmented controllable fracturing; conducting directional long drilling and branch drilling at the impact vibration sources or in areas of the impact stress wave spreading paths with a directional drilling machine; adopting retreating-type, step-by-step and segmented controllable fracturing; and conducting quantitative evaluation of accurate prevention and control effects in the remote area through monitoring and inverse analysis of effective influential areas of directional drilling and segmented fracturing. The method has the beneficial effects that bending energy, fracture energy, impact energy and structural activation energy of a high-altitude roof can be effectively reduced, or the impact stress wave spreading paths can be cut off,or stress wave spreading strength can be reduced; finally, accurate and efficient prevention and control of rock burst in a remote area can be realized; and the method is especially applicable to prevention and control of large rock burst of a roof-fracture type and a structural-activation type.

Owner:CHINA UNIV OF MINING & TECH

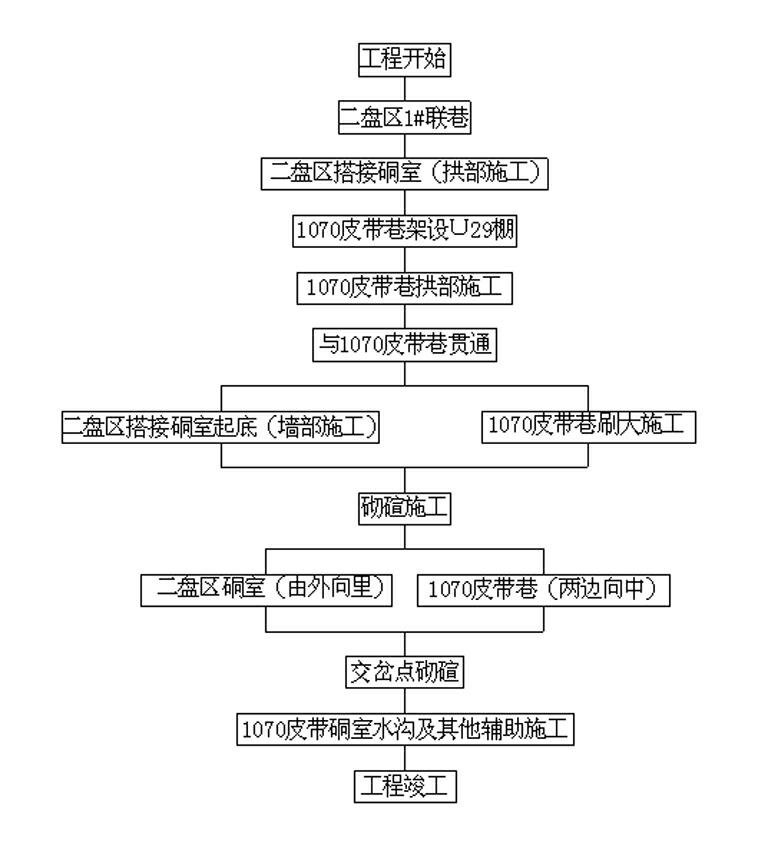

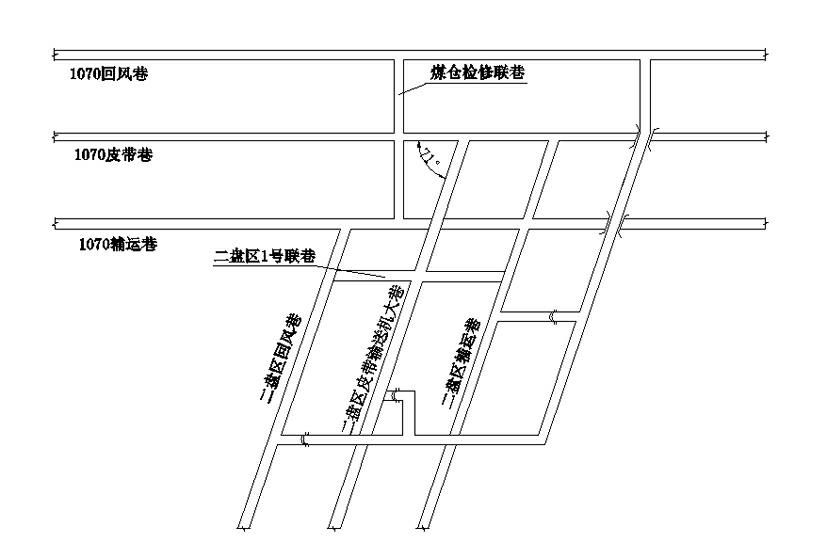

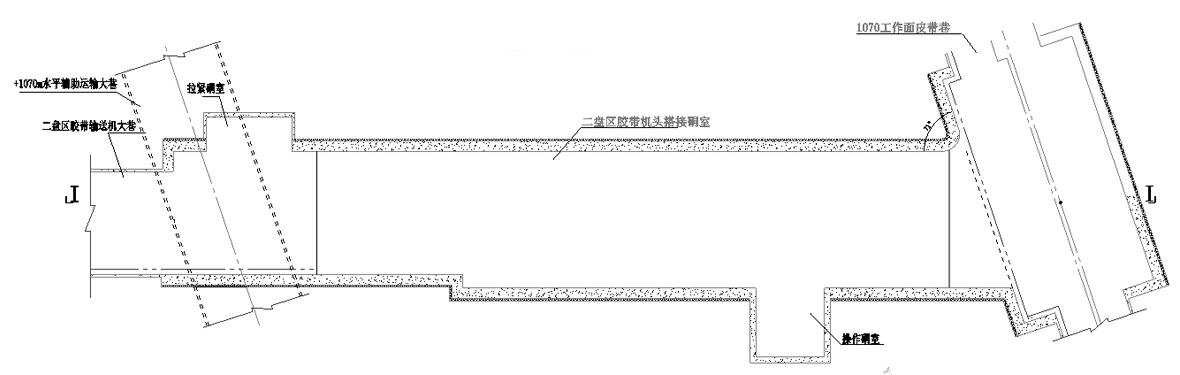

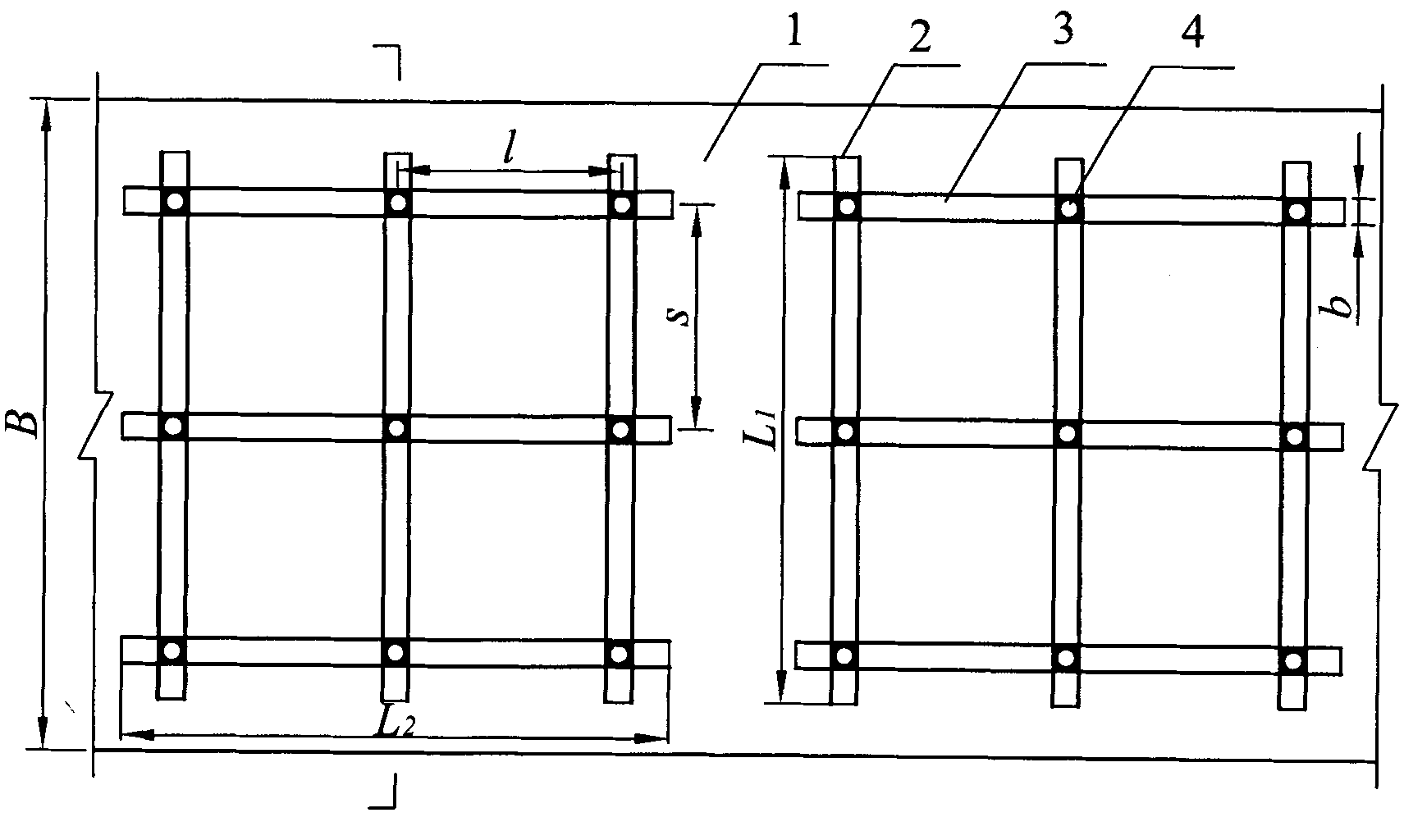

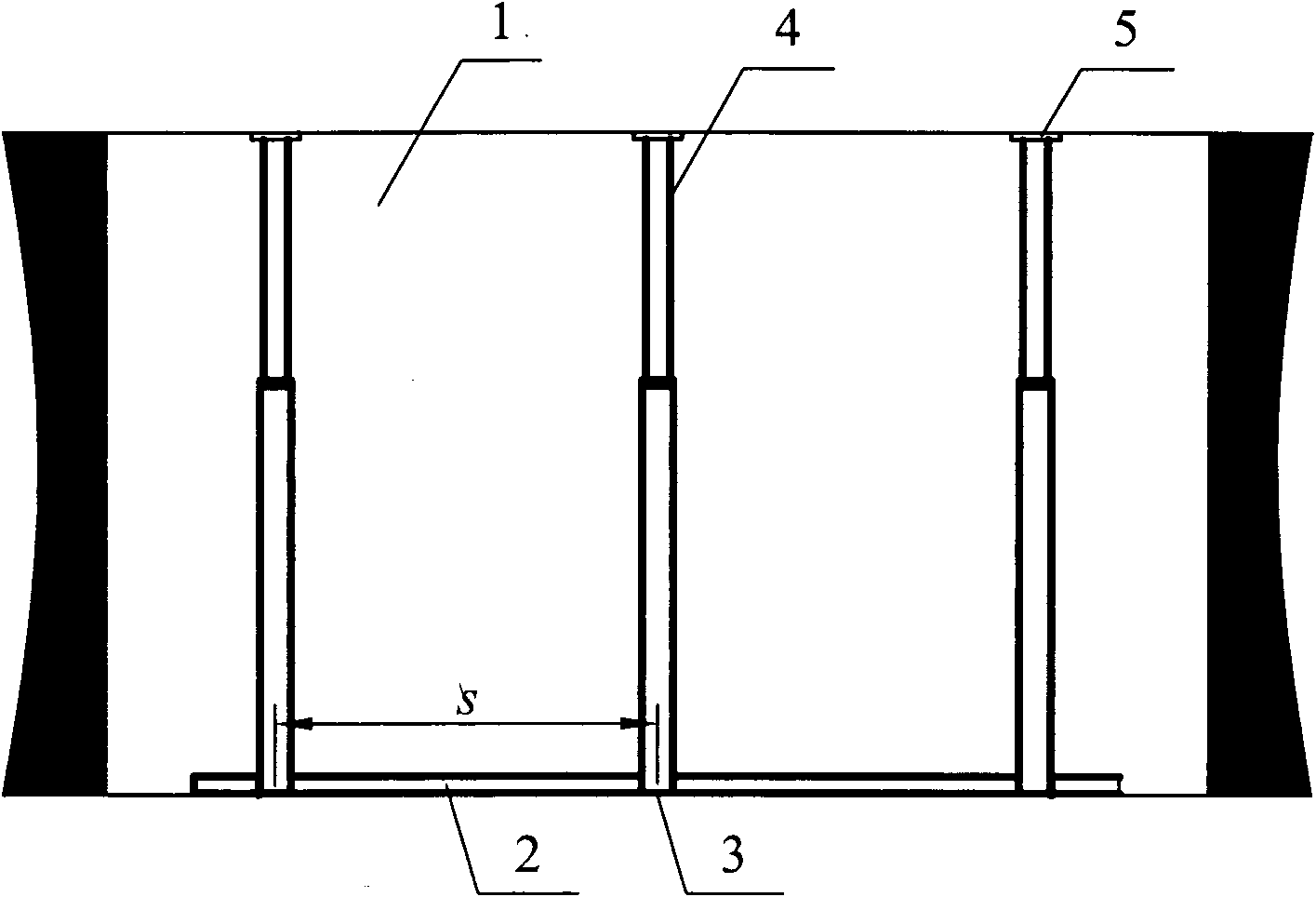

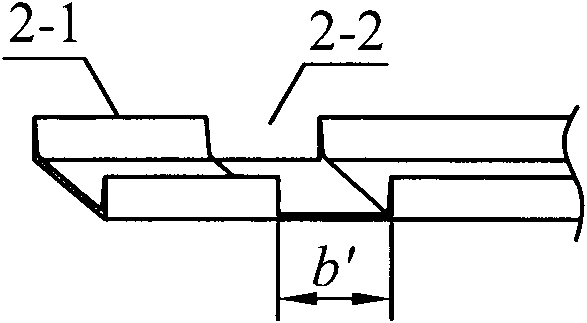

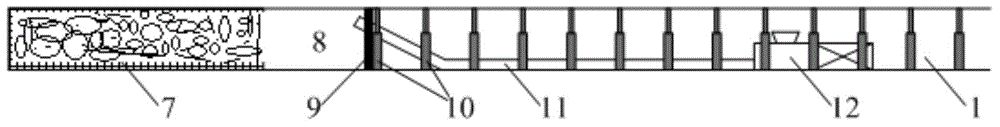

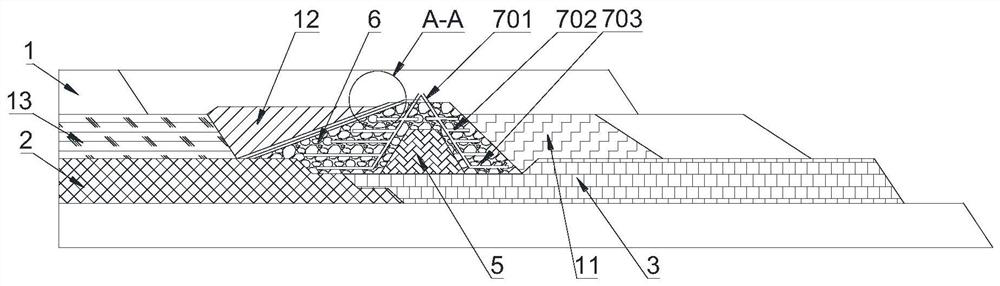

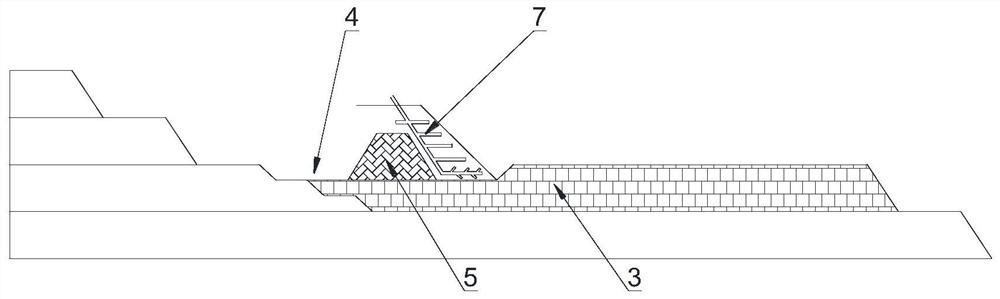

Method for constructing cross-over chambers with full-coal outsize cross section under host lane ceaseless transportation condition

ActiveCN102425422ALittle impact on productionShorten the construction periodTunnelsLap jointEngineering

The invention discloses a method for constructing cross-over chambers with a full-coal outsize cross section under a host lane ceaseless transportation condition. The method comprises the steps of: construction for lap joint between a panel adhesive tape machine head and a camber, construction for lap joint between a working face belt lane and a chamber and maintenance for the working face belt lane, and specifically comprises the steps of: (1) performing the lap joint construction on the panel adhesive tape machine head and the arc part of the chamber, (2) maintaining the working face belt lane and protecting auxiliary facilities and cables, (3) performing lap joint construction between the working face belt lane and the arc part of the chamber, (4) penetrating through the chamber in lap joint with the panel adhesive tape machine head and the chamber in lap joint with the working face belt lane, (5) performing wall part construction on the chamber in lap joint with the panel adhesive tape machine head and performing large brushing construction on the chamber in lap joint with the working face belt lane, (6) performing arch building on the chamber in lap joint with the panel adhesive tape machine head and the chamber in lap joint with the working face belt lane, and (7) performing arch building on a cross-over point between the chamber in lap joint with the panel adhesive tape machine head and the chamber in lap joint with the working face belt lane. According to the invention, the transportation of the working face belt lane is not influenced during construction, and the difficult in performing chamber construction under a full-coal-seal geological condition is eliminated.

Owner:DATONG COAL MINE GRP

Governance method of floor heave of mine roadway during mining

InactiveCN101936172AImprove support strengthThe supporting strength is sufficientProps/chocksEngineeringUltimate tensile strength

Owner:CHINA UNIV OF MINING & TECH

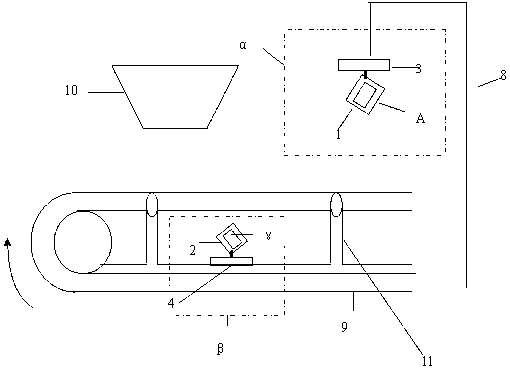

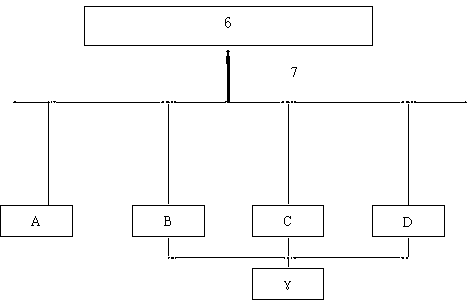

Visual inspection and pre-warning system for longitudinal tear of conveying belt and application method of conveying belt

InactiveCN103213823AAvoid damageEnsure transportation safetyControl devices for conveyorsVisual inspectionWorking environment

The invention discloses a visual inspection and pre-warning system for a longitudinal tear of a conveying belt and an application method of the conveying belt and belongs to the technical field of on-line testing of coal mining equipment. The visual inspection and pre-warning system for the longitudinal tear of the conveying belt is characterized in that inspection is performed in the manner that an infrared visual sensor system and advanced RISC machine (ARM) framework-based embedded system platform are combined to accurately judge an ongoing longitudinal tear fault and a hidden dangerous source of the conveying belt; and the conveying belt is inspected and pre-warned from two levels so as to guarantee the safe operation of the conveying belt. According to the system, image information is normally acquired under the dark condition, and therefore, the defect that auxiliary backlight needs to be adopted when a common industrial camera is used in traditional visual inspection is avoided, the defects that a traditional visual inspection instrument is complex to install, is serious in energy consumption, cannot be applied to complicated work environments and is not ideal in inspection effect are overcome, the damage degree of the conveying belt is reduced to the maximum limit, the possibility of accident occurrence and hazards brought after an accident occurs are fundamentally reduced, the safe transport of the conveying belt is comprehensively guaranteed, the work cost is reduced, and the work efficiency is effectively improved.

Owner:TAIYUAN UNIV OF TECH

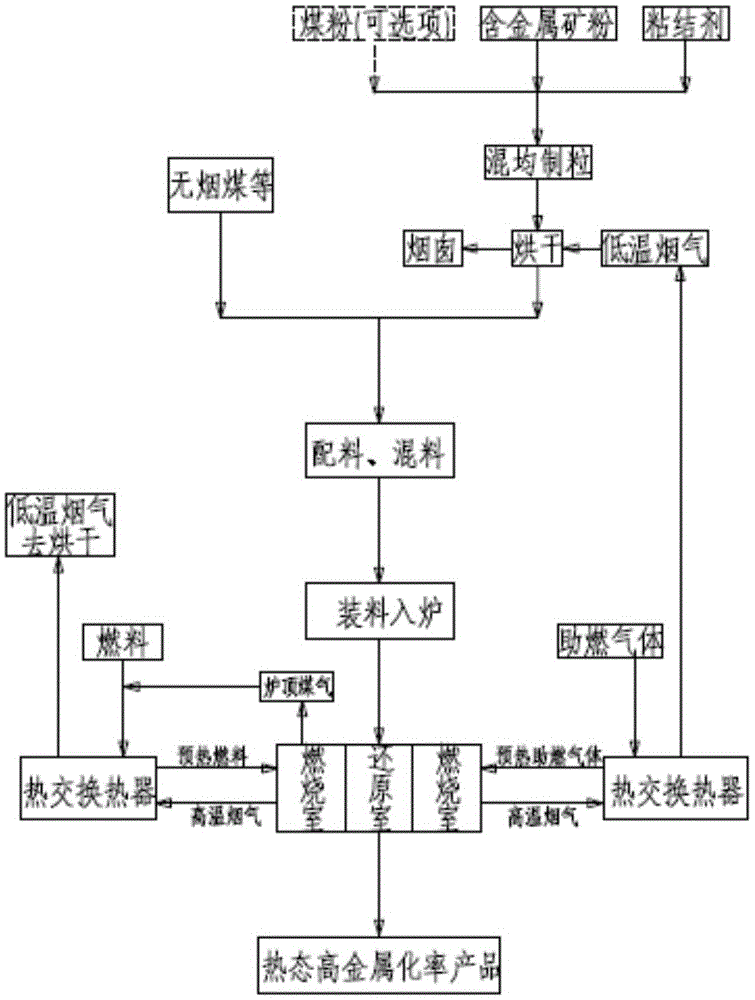

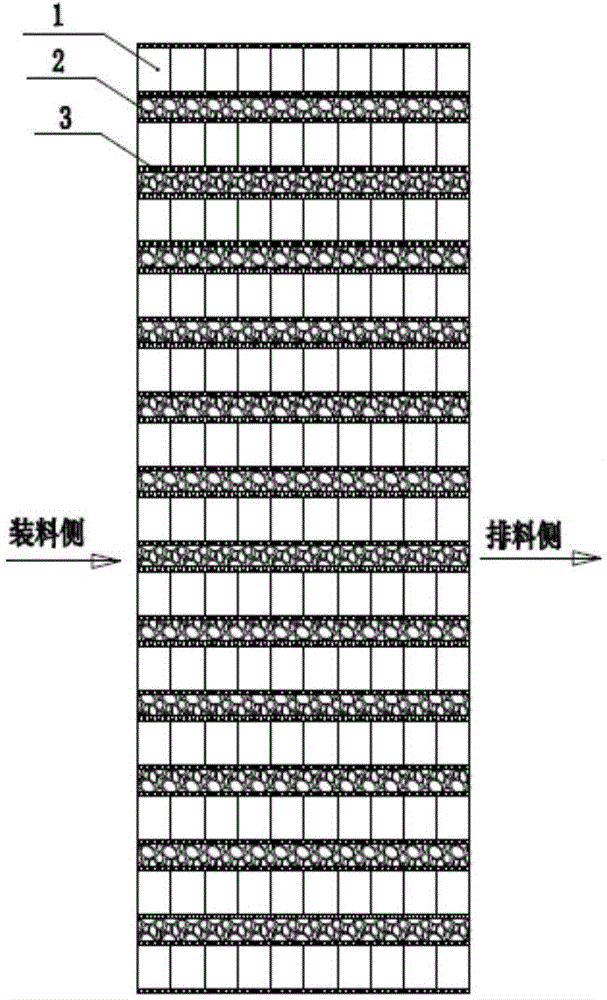

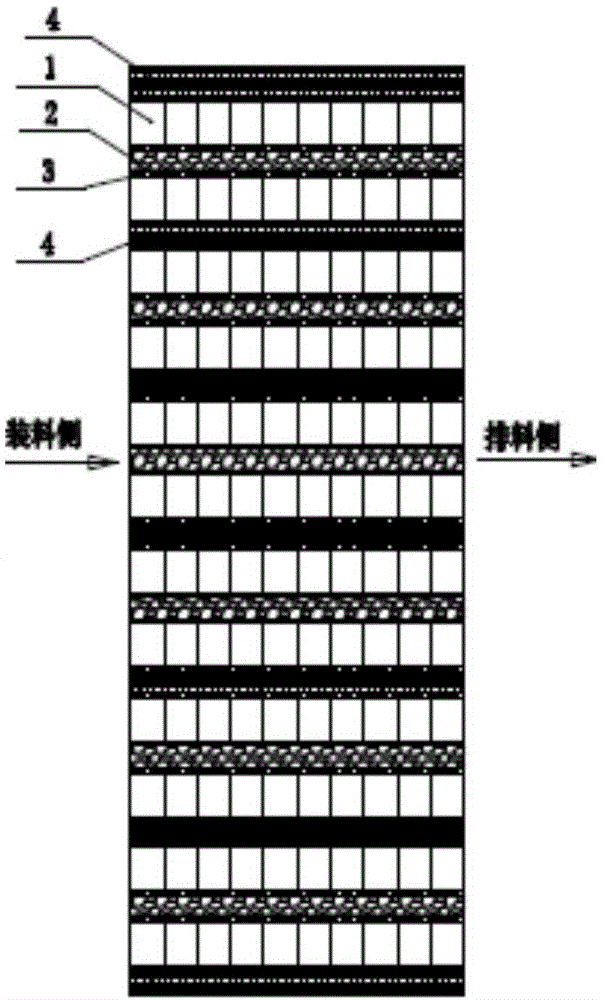

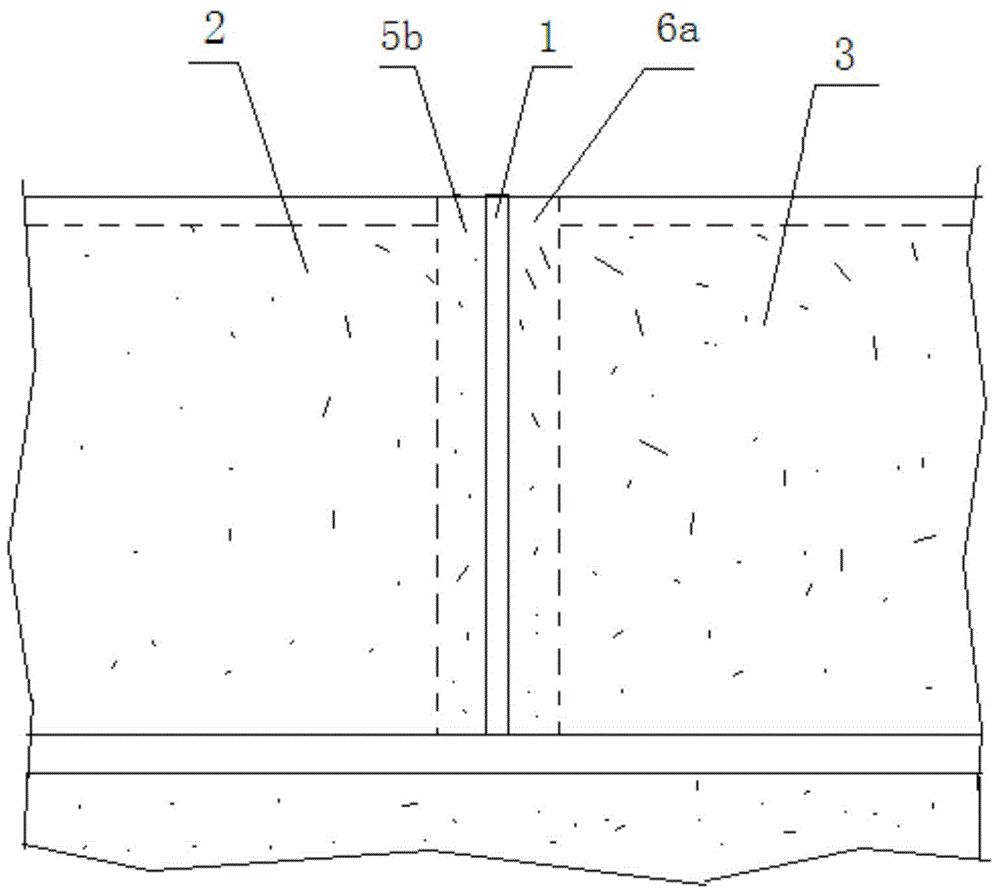

QDF (quiescent direct furnace) direct reduction technology

InactiveCN104630404AAchieve the desired effectReduced strength requirementsFluidised-bed furnacesCombustion chamberProduct gas

The invention relates to a QDF (quiescent direct furnace) direct reduction technology which comprises the following steps: uniformly mixing a metal-containing raw material and reducing agent powder, and putting into each reducing chamber, wherein in a reducing process, the reducing chambers and the reduced material are all kept in a stationary state; uniformly heating the materials in the reducing chambers by use of the heat generated by the combustion of the fuel in a combustion chamber and a combustion-supporting gas so as to perform a reduction reaction between the metal-containing raw material and the reducing agent, wherein each reducing chamber is a narrow long one-section reactor. According to the technology provided by the invention, the reducing chambers and the reduced material are all in a stationary state, the requirement on the strength of the granular raw material is reduced, and the production efficiency of a granulation process is improved; and the reducing time can be prolonged, and the metallization ratio of the reduction product is improved. The reducing chamber is not provided with a preheating area or a cooling area, the temperature is uniform, the atmosphere is uniform and consistent, and the overall quality of the reduction product is improved. The direct reduction technology has remarkable advantages of wide application range of raw materials, uniform temperature field, easy control on reduction process, high product metallization ratio, high yield and the like.

Owner:WISDRI ENG & RES INC LTD

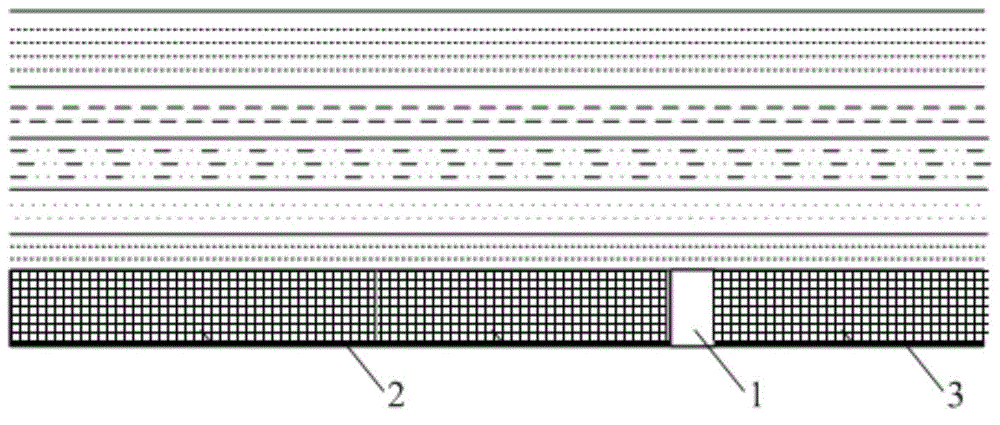

Side-supporting roadway forming method by pre-digging guide cavern and filling with artificial side wall for secondary use

ActiveCN104100271ASmall reduction in areaSimple processUnderground chambersMaterial fill-upSpelunkingEngineering

The invention discloses a side-supporting roadway forming method by pre-digging a guide cavern and filling with an artificial side wall for secondary use. Firstly, the guide cavern is dug in advance before mining roadway construction, and filling is performed to form the artificial side wall; then mining roadways are constructed in sequence respectively along two sides of the artificial side wall, and are filled with the artificial side wall which serves as a side support of the two mining roadways for mining of two working faces. Compared with a gob-side entry retaining technology in existing coal pillar-free roadway protection technologies, the side-supporting roadway forming method has the advantages that the mining roadways are directly caved without maintenance, the percentage reduction of area is small, and the method is also applicable under the complex conditions such as high seam full-mechanized caving mining and deep-part high-stress seam mining; the pre-dug guide cavern is used for filling, during filling, two sides of the guide cavern are both solid coal, and two side templates are not needed during filling, so the process is simple and the construction speed is high.

Owner:SHANDONG UNIV OF SCI & TECH

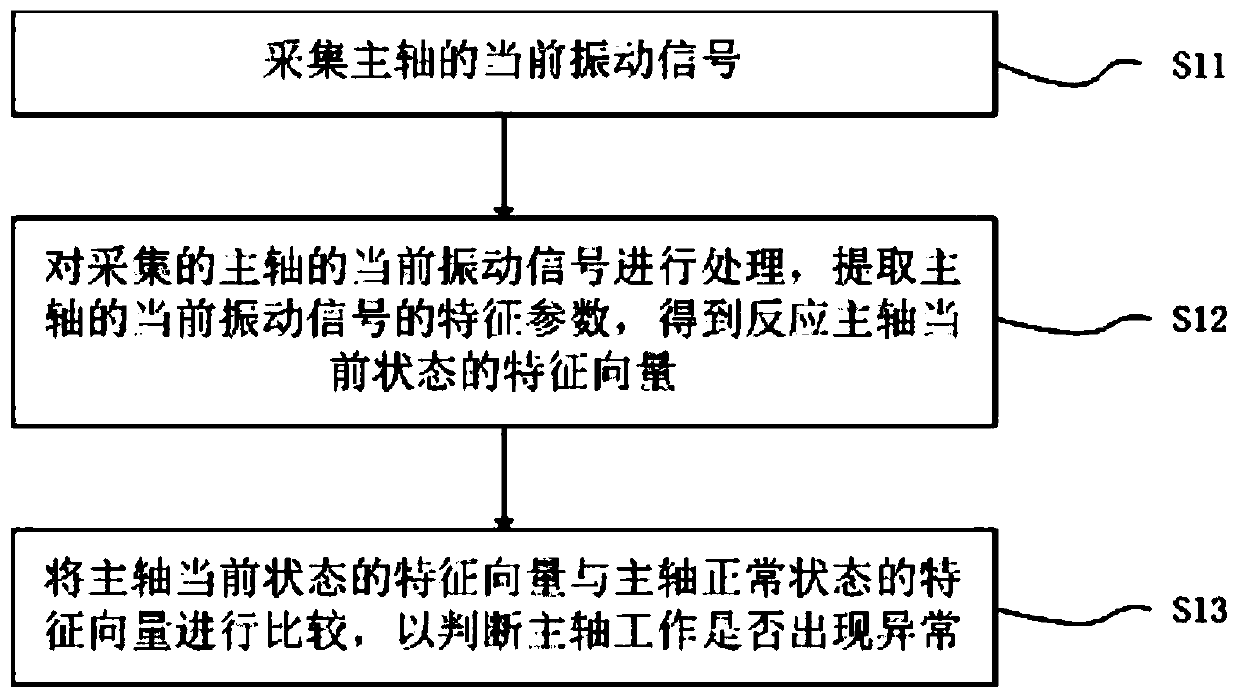

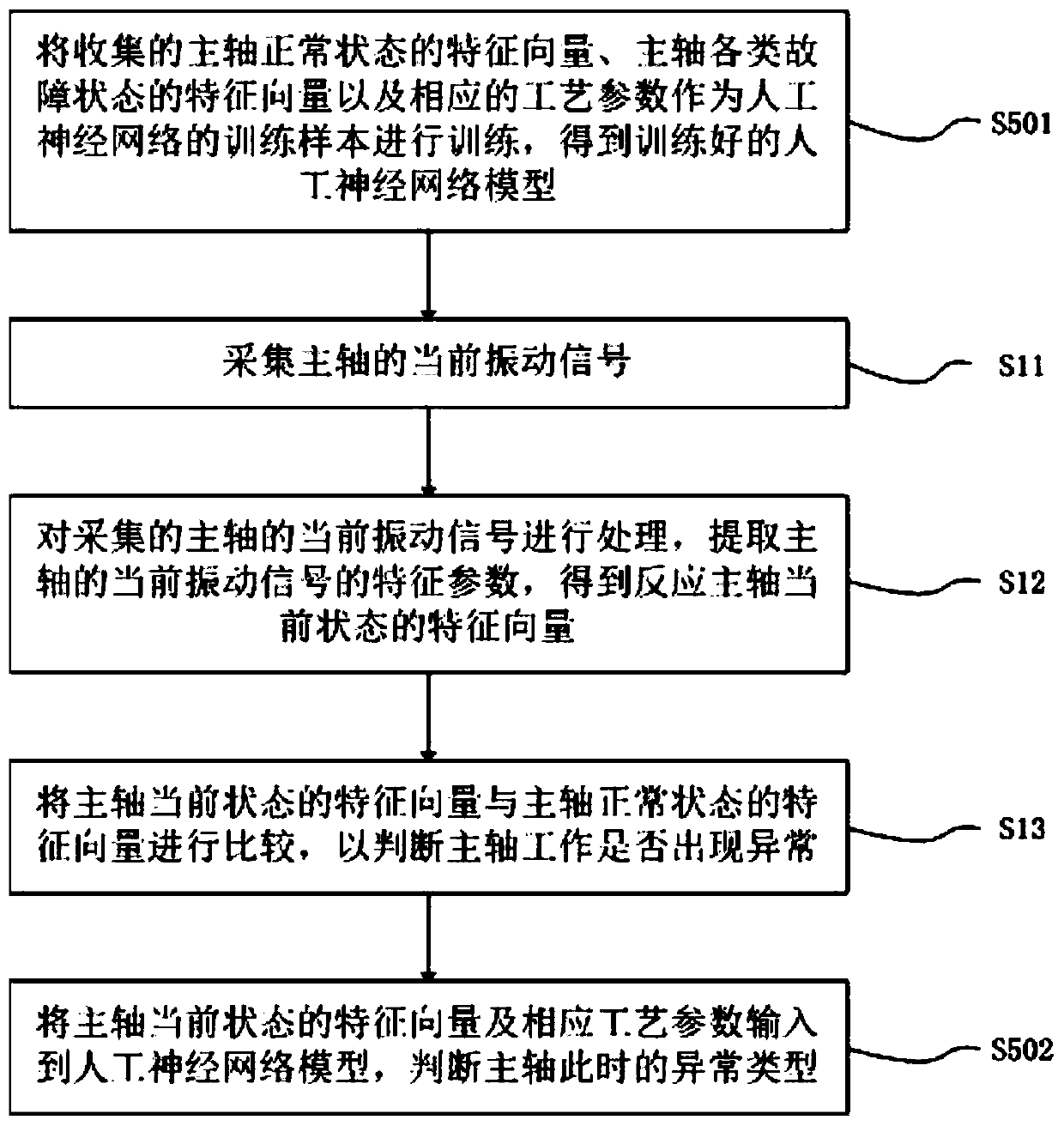

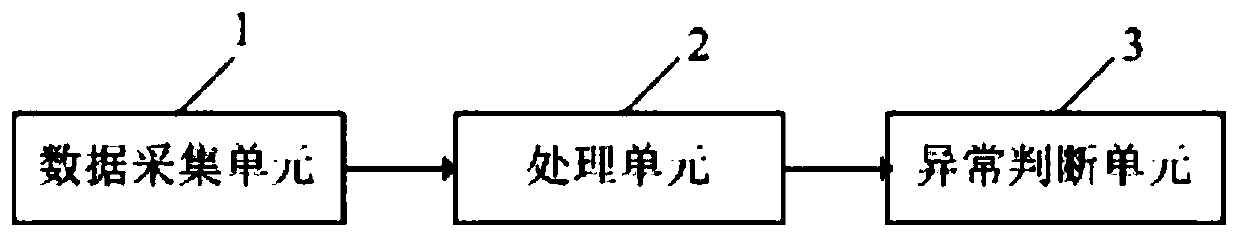

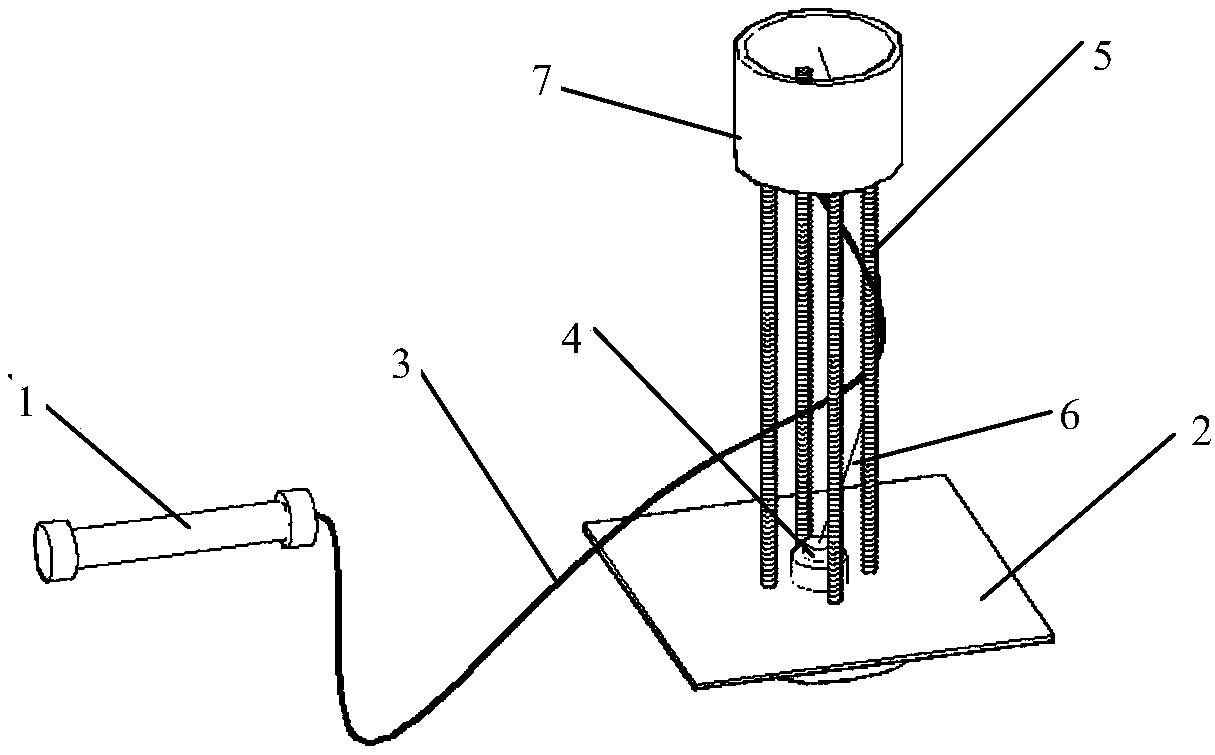

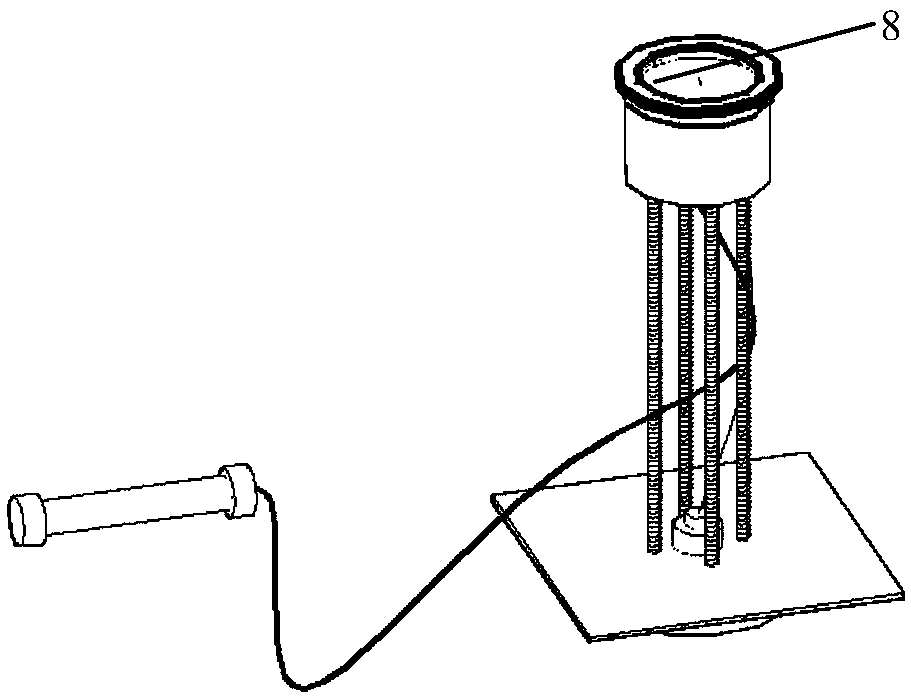

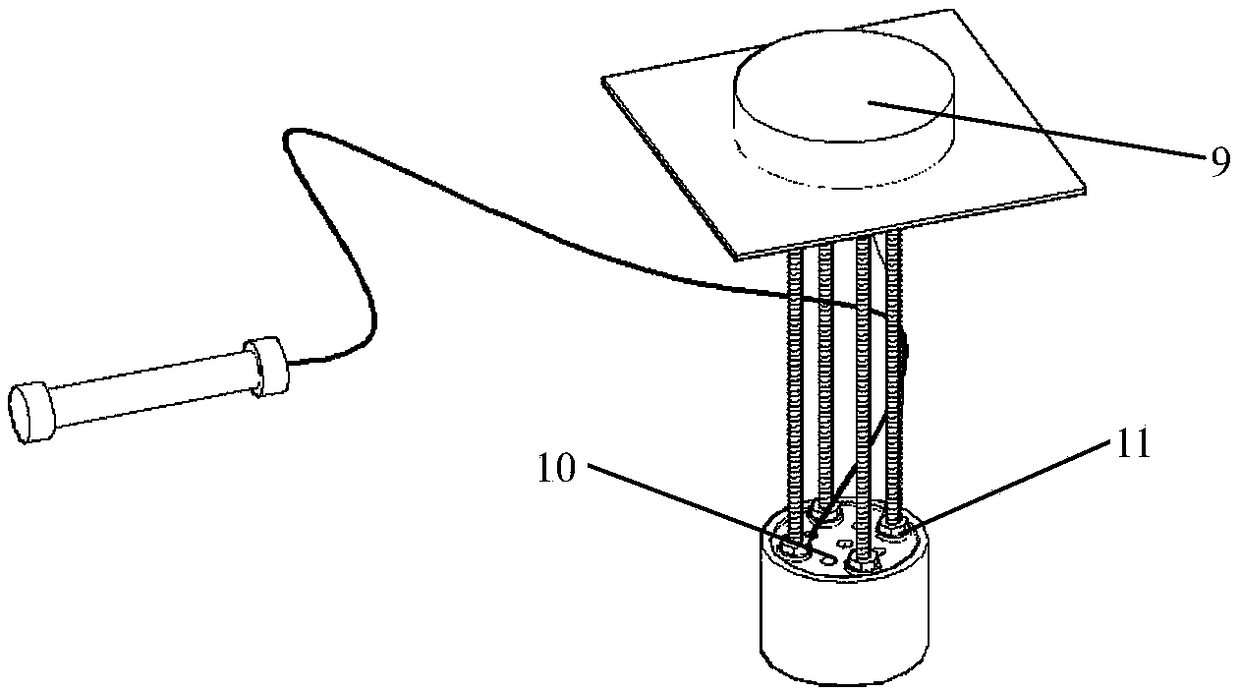

Intelligent diagnosis method and device for abnormal working state of spindle system of machining center

ActiveCN109857079AReduce maintenance costsAccurate diagnosisElectric testing/monitoringNumerical controlFeature vector

The invention discloses an intelligent diagnosis method and device for an abnormal working state of a spindle system of a machining center. The method includes the following steps: collecting a current vibration signal of a spindle; processing the collected current vibration signal of the spindle, extracting characteristic parameters, and obtaining a characteristic vector reflecting the current state of the spindle; comparing the characteristic vector of the current state of the spindle with the characteristic vector of the normal state of the spindle to judge whether the spindle is abnormal or not; and analyzing stored characteristic quantities reflecting the state of the spindle, and predicting the state change trend of the spindle. The device includes a data collection unit, a processing unit and an abnormality judgment unit connected in turn. The intelligent diagnosis method and device for an abnormal working state of a spindle system of a machining center are accurate in diagnosis, and can reduce the maintenance cost of the spindle of the numerical control machining center, shorten the maintenance time and improve the production efficiency.

Owner:SHANGHAI JIAO TONG UNIV +1

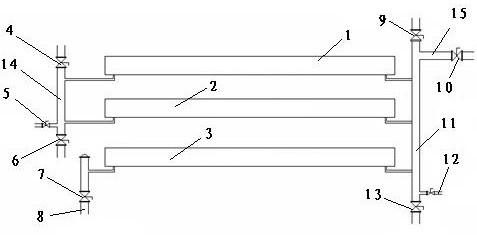

Device for jointly testing internal force and external force of shield tunnel duct piece and manufacturing and burying method

InactiveCN109505625AShorter laying timeLittle impact on productionUnderground chambersApparatus for force/torque/work measurementArchitectural engineeringRebar

The invention relates to a device for jointly testing an internal force and an external force of a shield tunnel duct piece. The device comprises a steel bar strain gauge, a soil pressure sensor, a water stop steel plate and a cable protection box and a connecting screw, wherein one end of the steel bar strain gauge is connected with a steel bar strain gauge cable and is connected with a duct piece steel bar cage through a galvanized wire binding method, the steel bar strain gauge cable penetrates through the cable protection box, the cable protection box is connected with the water stop steelplate through the connecting screw, an adjusting nut and a washer are arranged between the connecting screw and the cable protection box, a corresponding number of wiring holes are distributed in thebottom surface of the cable protection box, the top face of the cable protection box is provided with a cable protection box cover, the bottom of the cable protection box is provided with protectivesponge. The device has the advantages that the steel bar strain gauge of the device is connected with the duct piece steel bar cage through the galvanized wire binding method, accordingly the processes of steel bar cage cutting and welding of the steel bar strain gauge to a connecting rod are omitted, the embedding time of a duct piece prefabrication factory is greatly shortened, and the influenceon the production of the duct piece prefabrication factory is smaller.

Owner:NINGBO UNIV +1

U-PVC pipe with high impact resistant performance

The invention relates to a U-PVC pipe with a high impact resistant performance. The U-PVC pipe comprises the following components in parts by weight: 100 parts of PVC-SG8 resin, 1 to 10 parts of ABS resin powder, 1 to 10 parts of solubilizer, 1 to 10 parts of heat stabilizer, 0.1 to 5 parts of lubricant, 0 to 5 parts of processing modifier, 5 to 50 parts of filling agent, and 0.5 to 5 parts of titanium dioxide. The pipe comprises ABS powder, the chain sections of butadiene rubber of ABS can absorb the impact energy, and thus the pipe can well resist the impact. At the same time, the amount of added ABS powder is little, the influence on the processing property and product stability is small, and the production is barely affected. A proper amount of CPE is added to increase the capacity of the ABS / PVC system, in the microscopic view, the phase separation degree is decreased, and thus the impact resistant effect is enhanced.

Owner:ZHEJIANG TONGZHENG PIPE TECH

Quick replacement method of counterbalance of four-high mill

The invention discloses a quick replacement method of counterbalances of a four-high mill, which is as follows: when the counterbalance of the large four-high mill is overhauled, the counterbalance fixed in a housing frame of the mill is replaced by the following steps of: firstly, confirming the safety of three parties, and stopping a medium; secondly, paving steel plates of delta 20mm on a working roller replacing rail; thirdly, disassembling a counterbalance connection bolt; fourthly, utilizing a manufactured cross traveling trolley to reversely carry the counterbalance from the inner part of the mill; and fifthly, hoisting the disassembled counterbalance by a crane. The method disclosed by the invention is simple in steps, convenient in operation, short in construction period, small in influence to the production and high in production efficiency.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

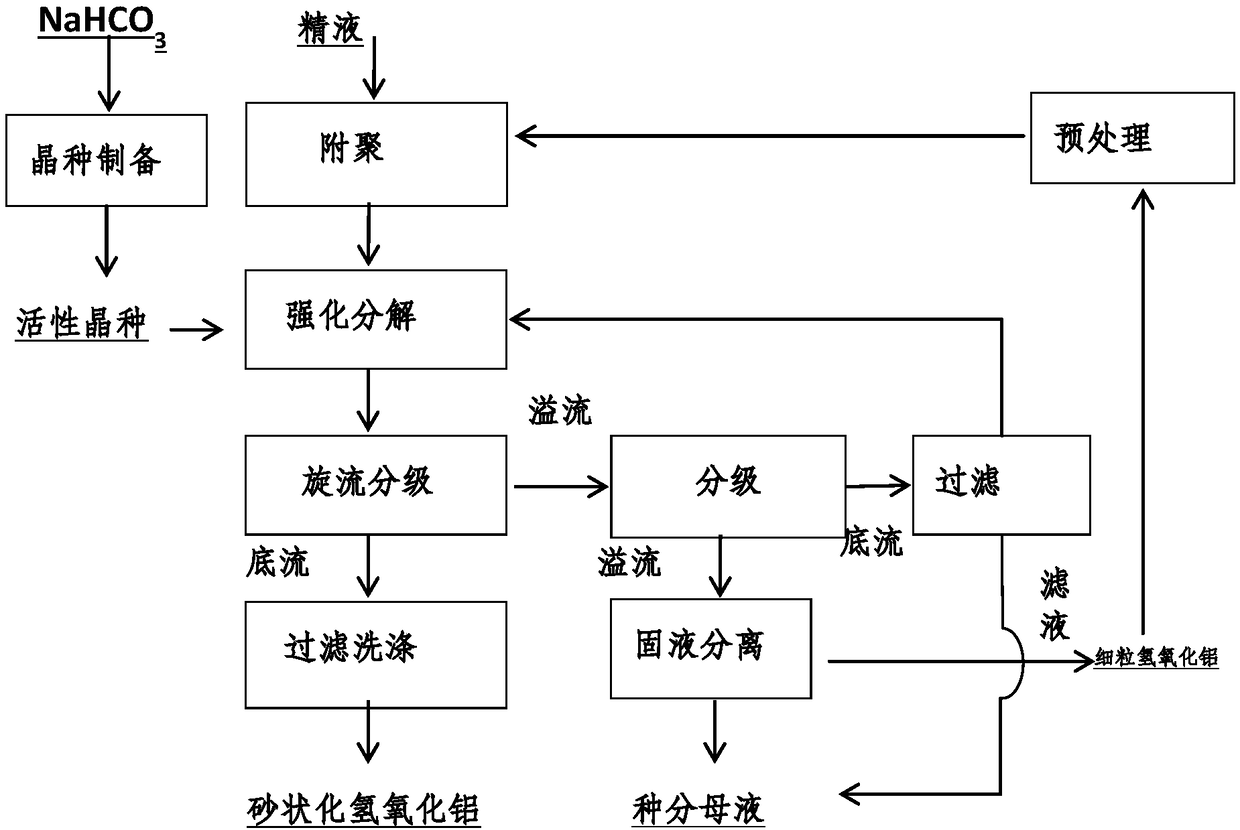

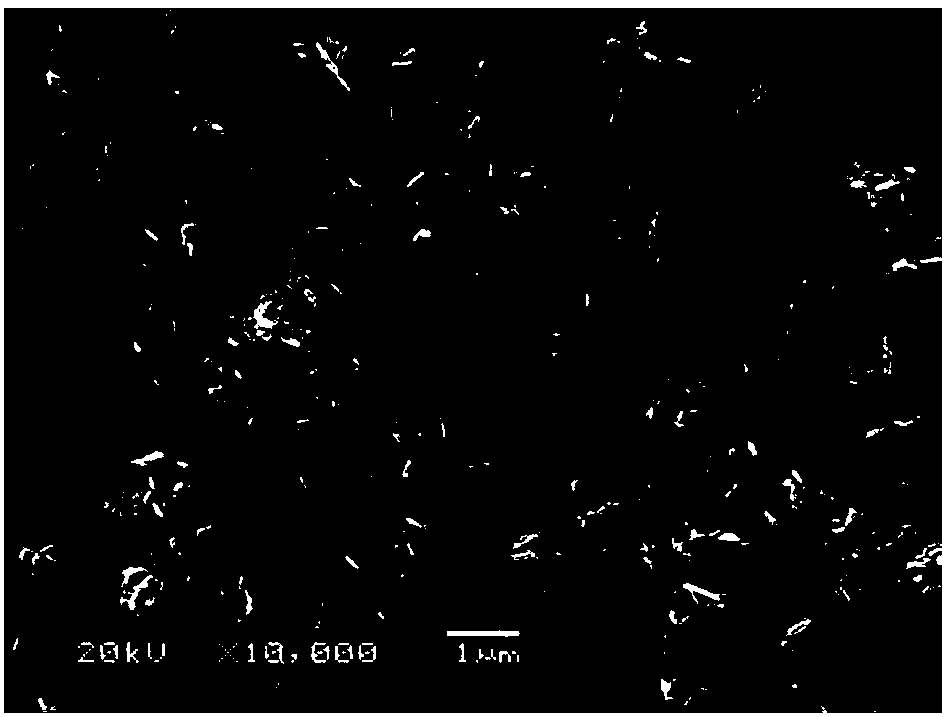

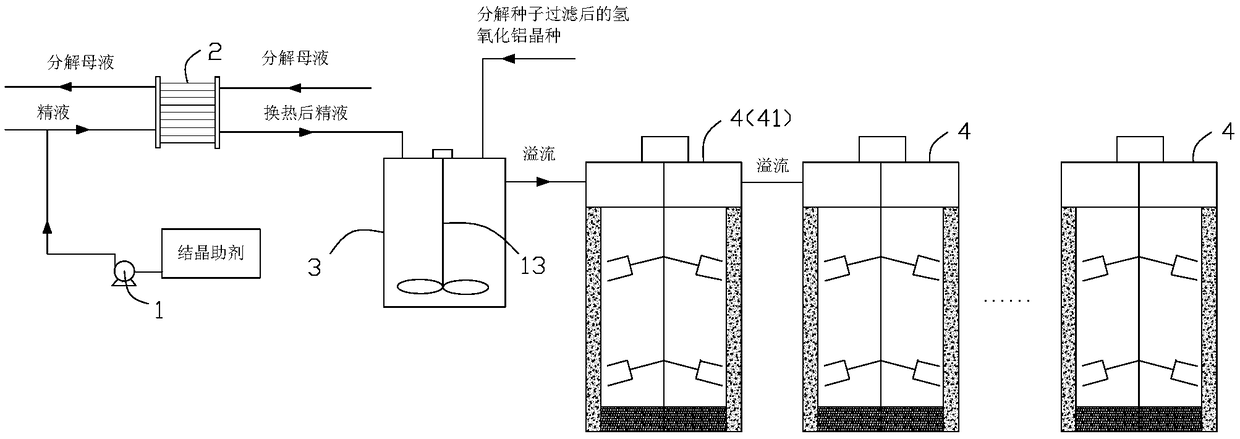

Method of cooperatively regulating and improving crystal seed decomposition of sodium aluminate solution

InactiveCN108585007ARich adjustment meansImprove decomposition rateAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationDecompositionSodium aluminate

A method of cooperatively regulating and improving crystal seed decomposition of sodium aluminate solution includes the steps of preparing high-activity crystal seed slurry, reinforcing seed precipitation, pretreating and agglomerating fine particles. In the method, solution decomposition and crystallization processes are regulated through multiple means, thus solving a contradictory problem of increasing decomposition rate and guaranteeing production quality. By means of the method, solution decomposition rate can reach more than 57%. The product has a sandy appearance and can satisfy first grade in national standard. The method is high in decomposition rate, can form the sandy product, has simple process and low investment, and has extensive application prospect.

Owner:CENT SOUTH UNIV

Visual detection method of longitudinal tear of conveying belt

ActiveCN102951426BEliminate the effects ofSave energyControl devices for conveyorsOptically investigating flaws/contaminationPyroelectric detectorsEngineering

The invention relates to a visual detection method of longitudinal tear of a conveying belt, which belongs to the technical field of on-line monitoring of coal mine automation. The visual detection method is characterized in that in the condition of dim light or no light, a pyroelectric detector is used for detecting the temperature variation of the conveying belt due to the longitudinal tear, an infrared CCD (Charge-coupled Device) camera is controlled to take a photo, an obtained image is processed, and then an accident of the conveying belt can be accurately judged. According to the visual detection method, the simultaneous working mode of timing photo taking and triggering photo taking is adopted, omitted judgment caused by failure of the pyroelectric detector is prevented, and great energy of the infrared CCD camera, which is consumed by continuously taking photos for a long time, is saved. Additionally, negative effects that the service life of the infrared CCD camera is shortened and the working efficiency is reduced are avoided, wherein the negative effects are caused by the fact that the infrared CCD camera is continuously operated for a long time. A sharp image can be obtained by the infrared CCD camera when the conveying belt is moved at high speed, the obtained image is a grayscale image and is easily processed at a later period, and the position and the degree of the longitudinal tear can be visually reflected through finally processed information. The visual detection method has the advantages of high precision and reliable performance.

Owner:TAIYUAN UNIV OF TECH +2

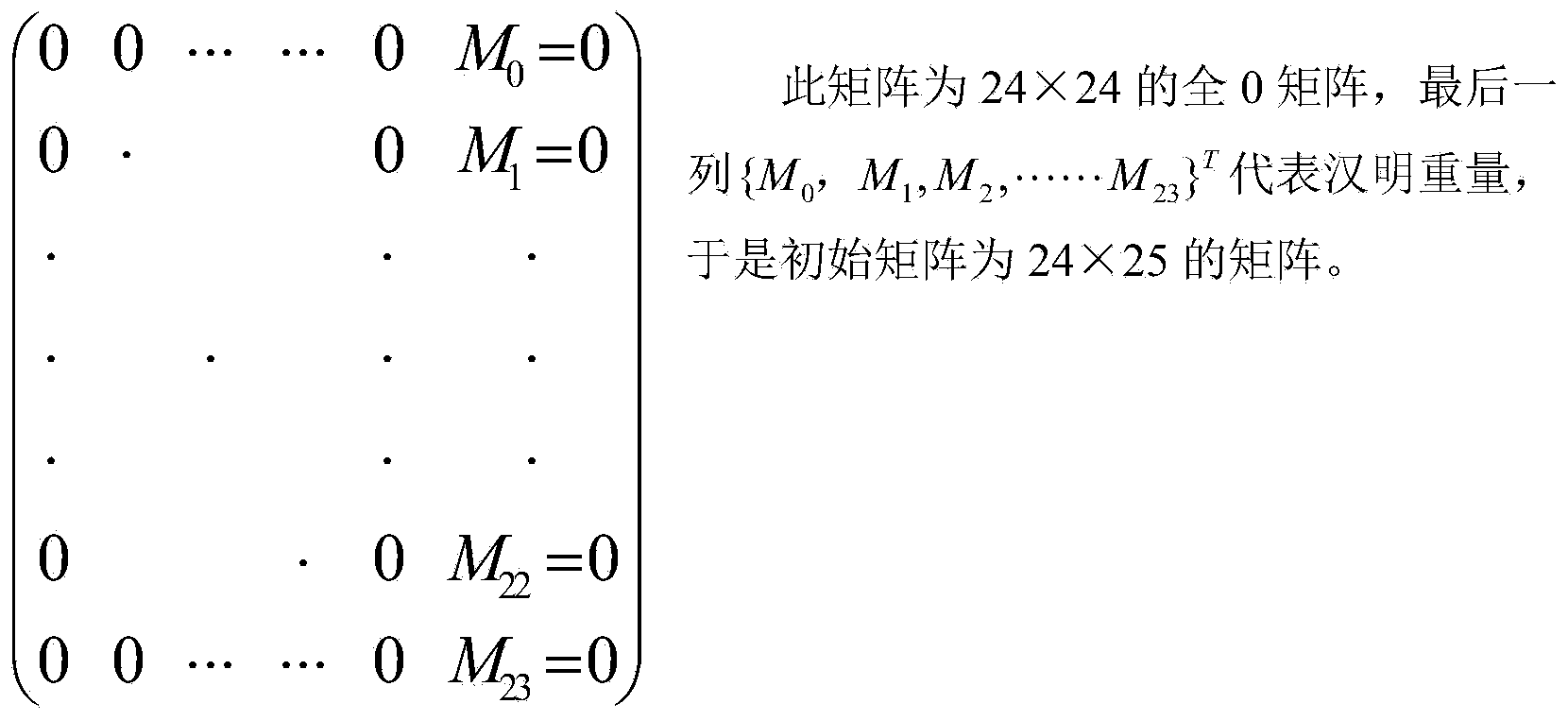

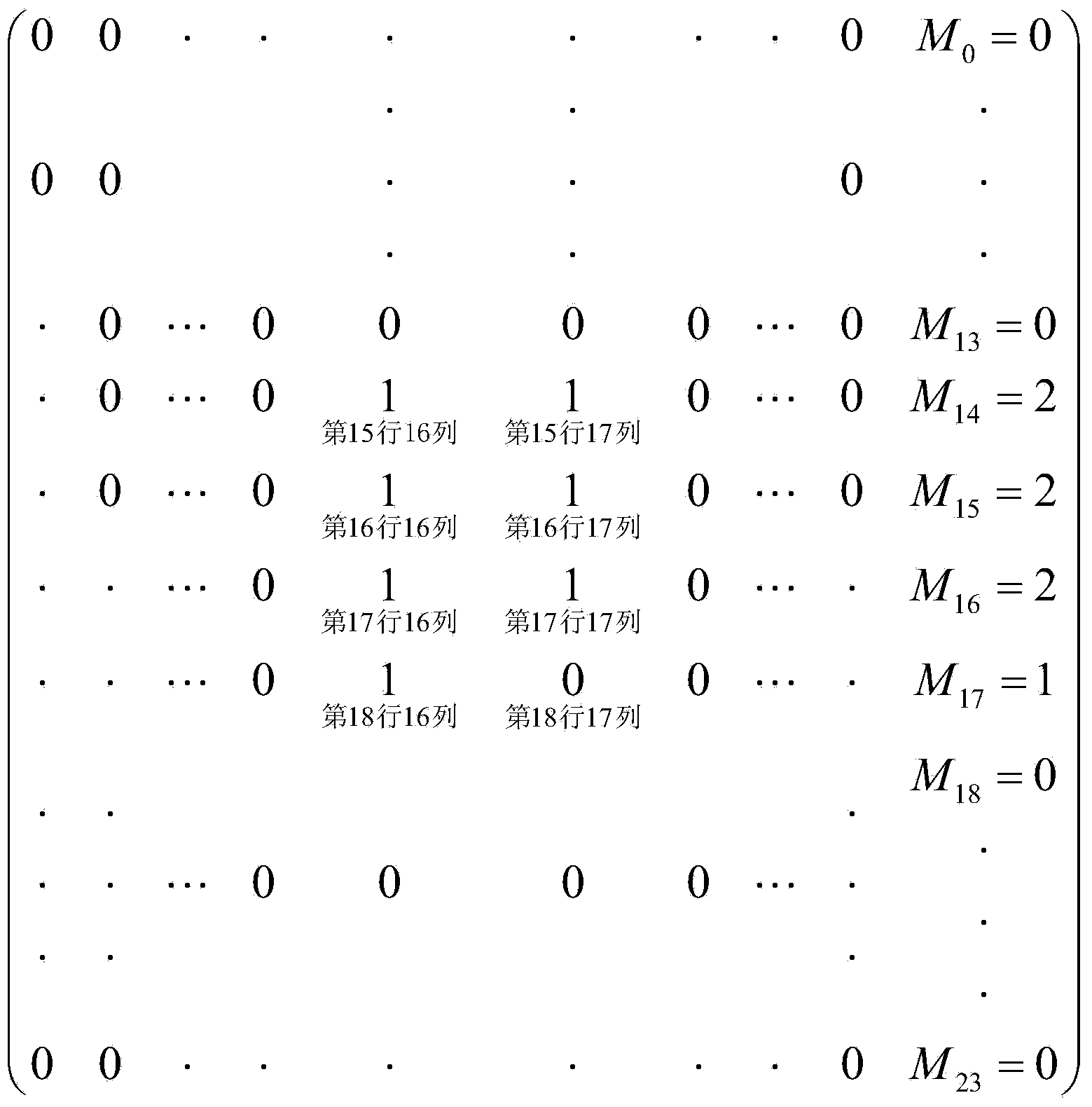

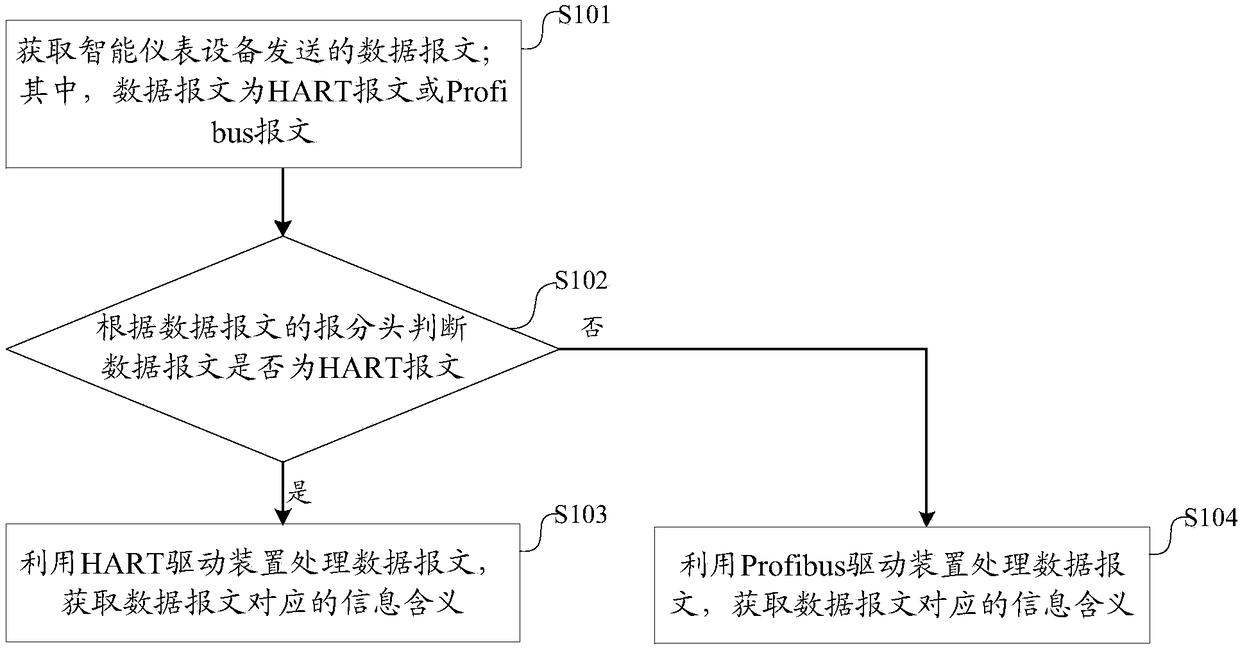

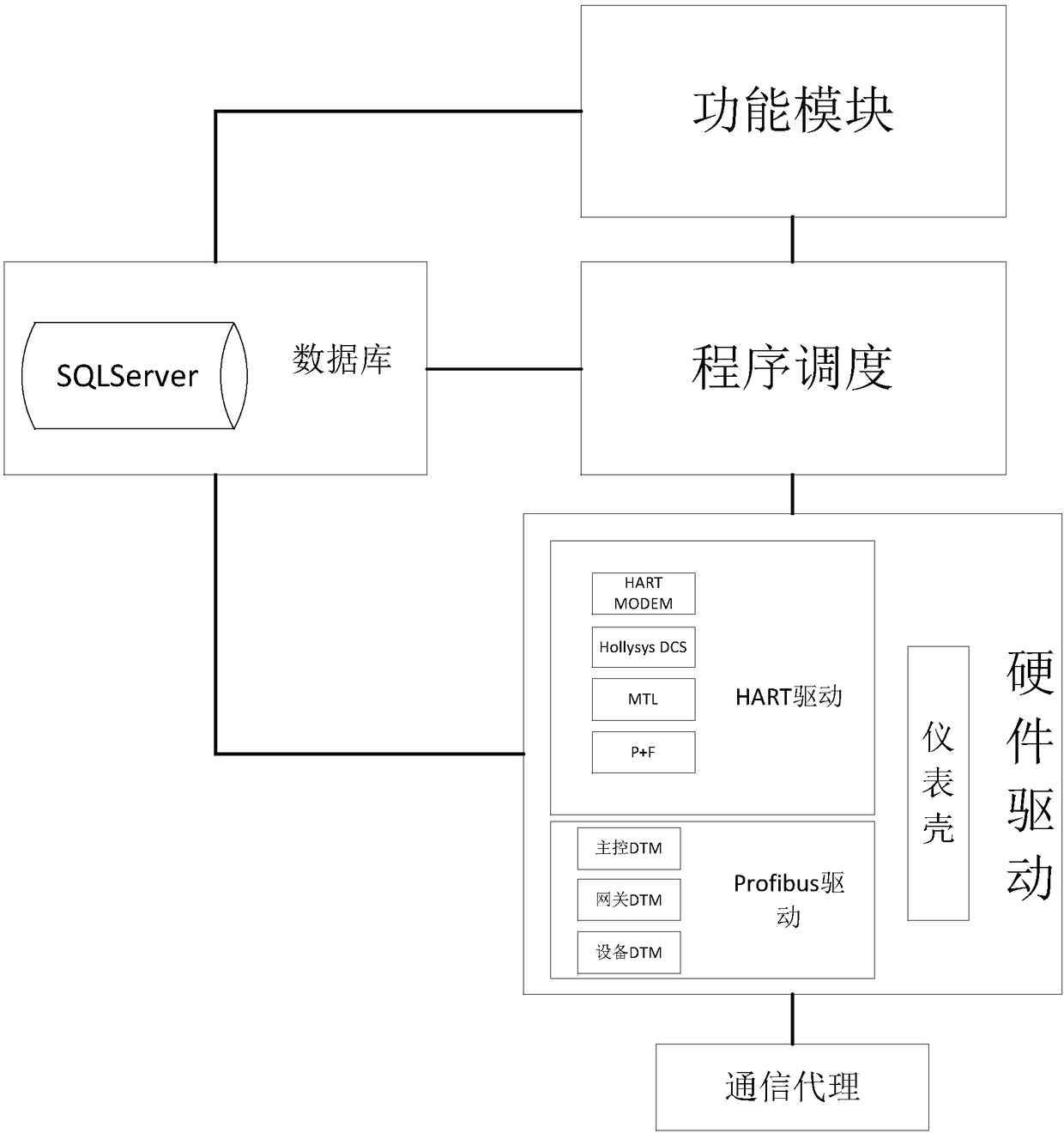

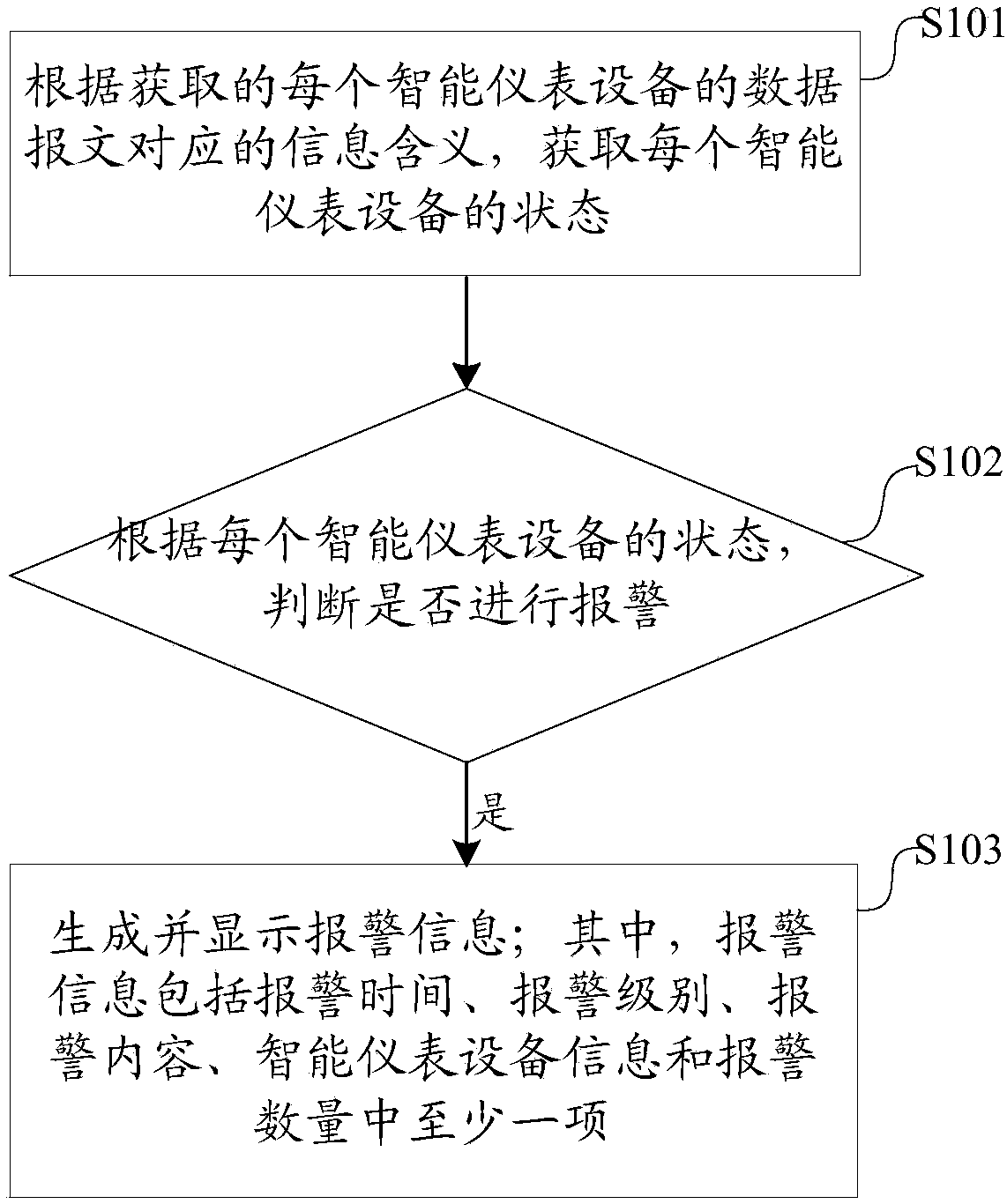

Data management method and system of intelligent instrument device

The invention discloses a data management method and system of an intelligent instrument device. The method comprises the following steps: obtaining a data message sent by the intelligent instrument device; judging whether the data message is a HART message according to a message header of the data message; if so, processing the data message by using a HART driving device, and obtaining information meaning corresponding to the data message; and if not, processing the data message by using a Profibus driving device, and obtaining the information meaning corresponding to the data message. According to the data management method and system disclosed by the invention, split processing is performed on the message header of the data message, the data messages of different protocols are processedby the corresponding driving devices, the data message of the intelligent instrument device supporting the HART and Profibus protocols can be parsed, and various interfaces are provided for collecting the data functions of the intelligent instrument device, so that the availability of existing intelligent instrument device can be improved, the device maintenance cost is reduced, the plant operation is optimized, and the profitability is increased.

Owner:HANGZHOU HOLLYSYS AUTOMATION

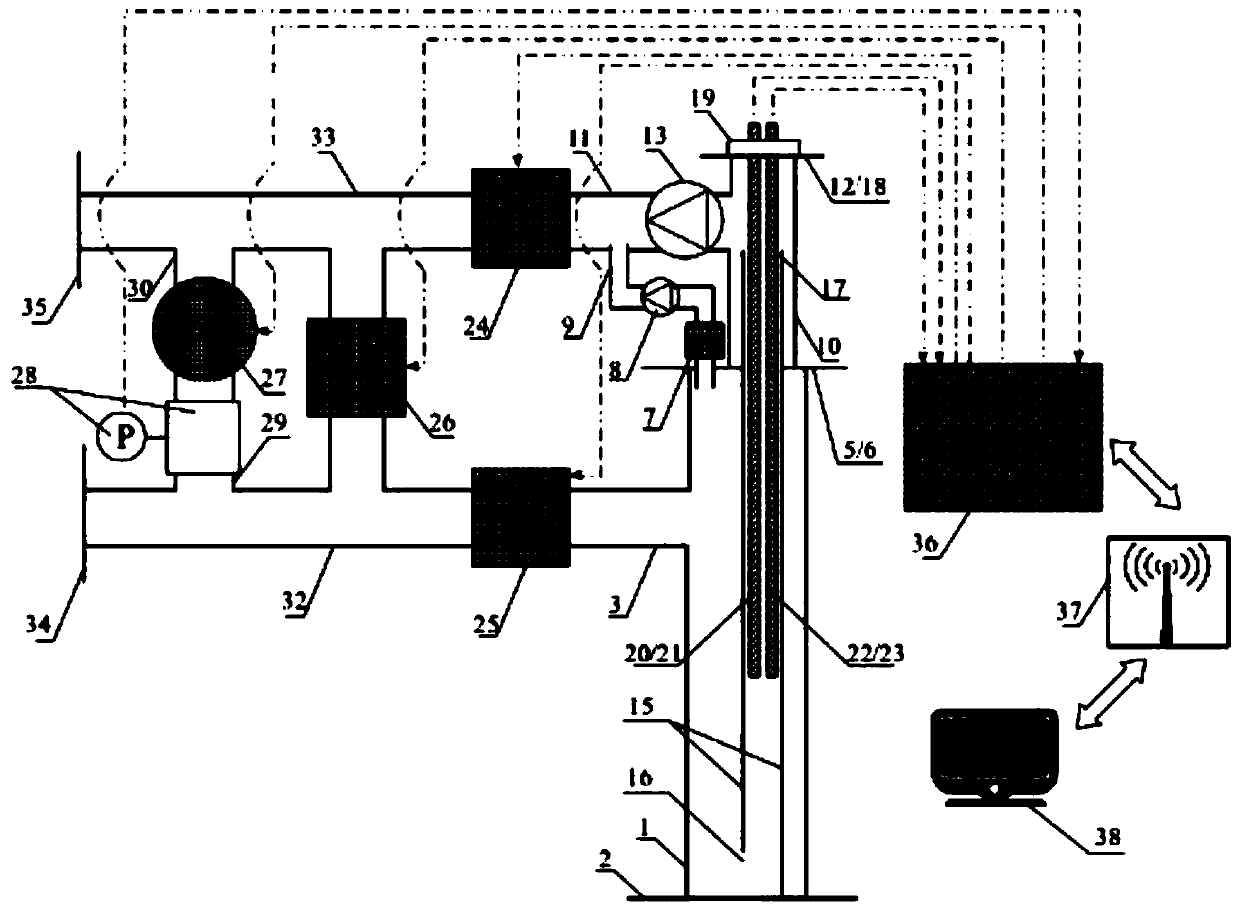

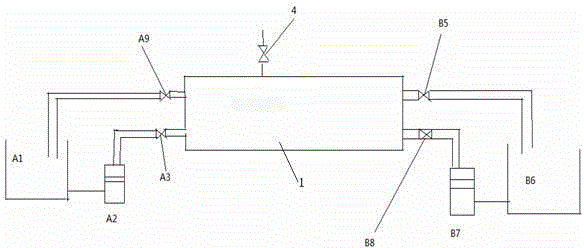

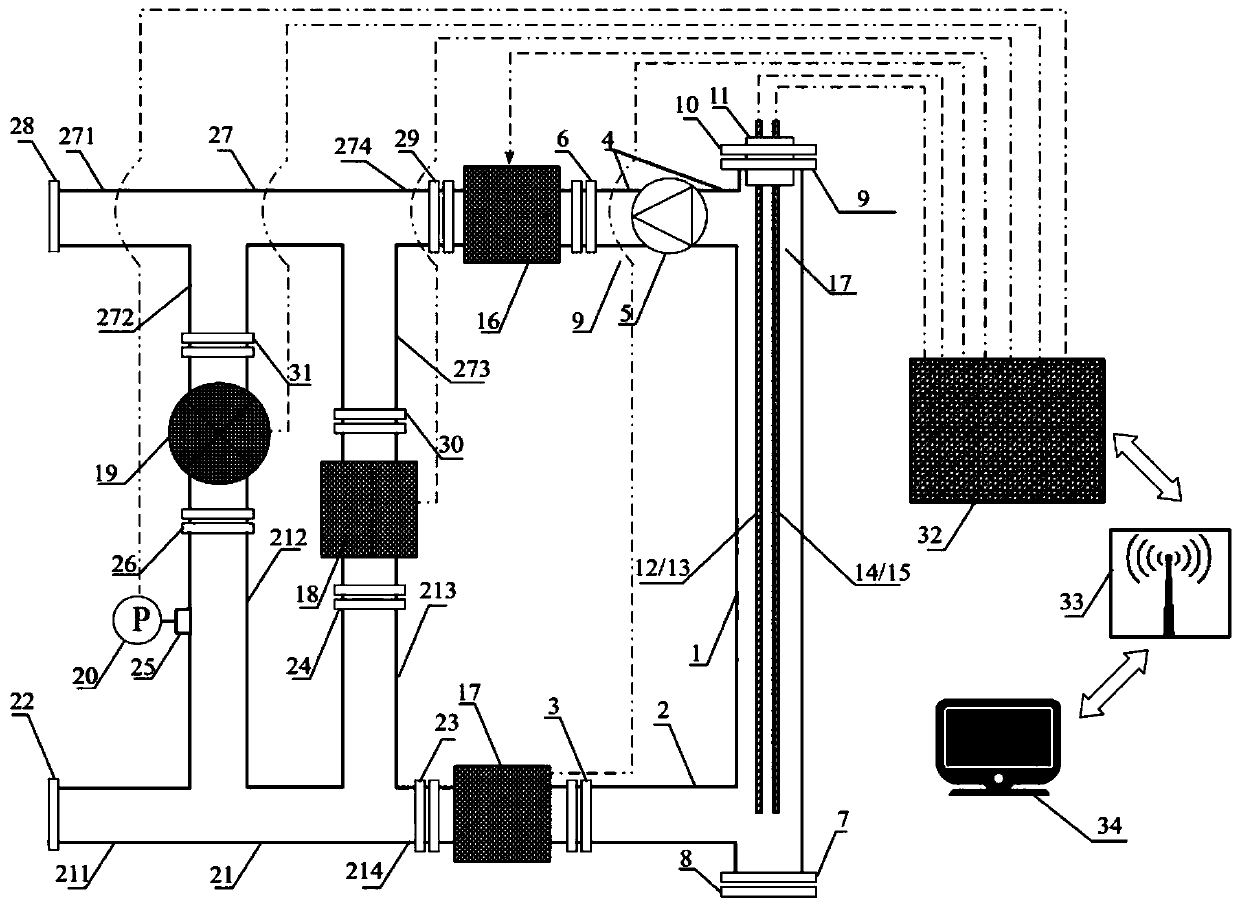

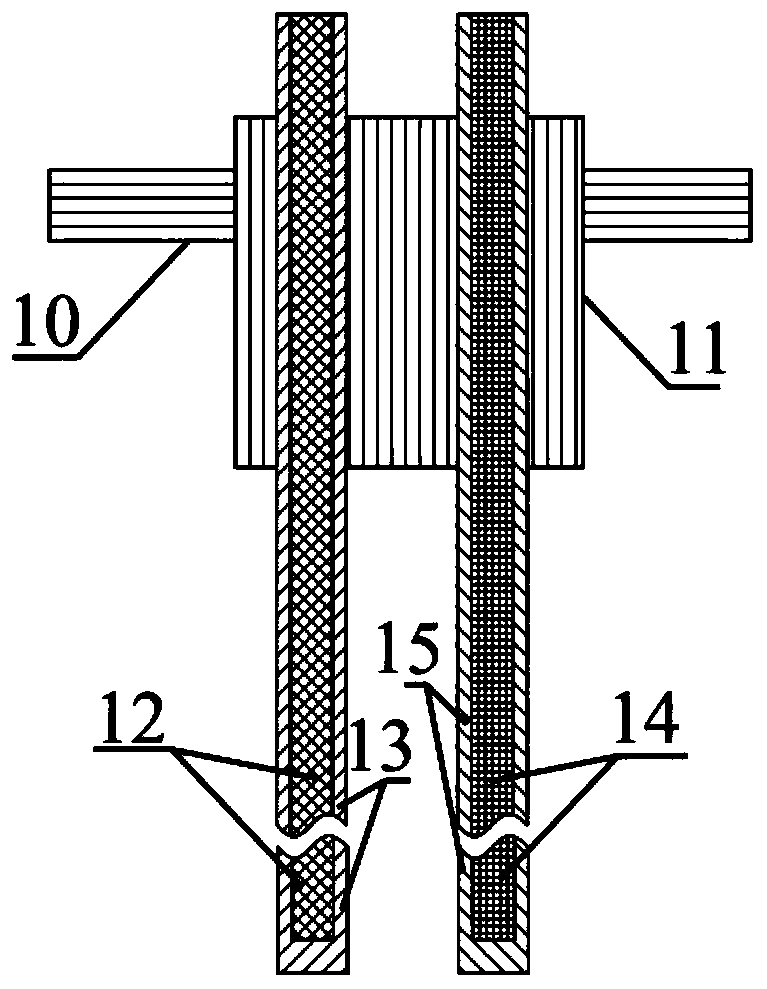

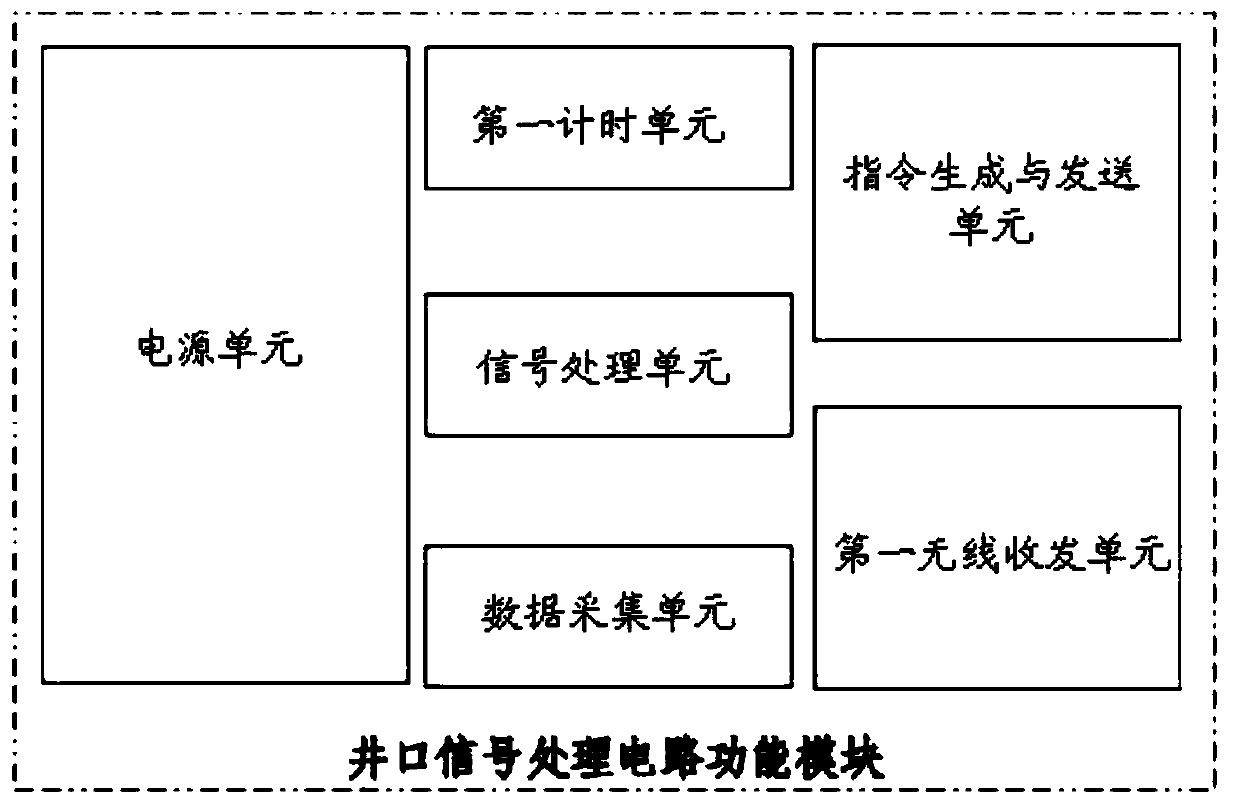

Wellhead oil-gas-water three-phase flow static moisture content measuring system and control method thereof

InactiveCN109975526ALittle impact on productionReduce manufacturing costConstructionsAnalysing gaseous mixturesCapacitanceSignal processing circuits

The invention discloses a wellhead oil-gas-water three-phase flow static moisture content measuring system and a control method thereof, and relates to the technical field of oil production logging. The measuring system mainly comprises a wellhead oil-gas-water three-phase flow static moisture content measuring device and a signal processing sub-system; fluid in the wellhead oil-gas-water three-phase flow static moisture content measuring device flows or keeps motionless by a on-off control valve group; gas-liquid separation is carried out through a gas-liquid separation tank; moisture contentof the fluid is calculated through a capacitance level gauge; pressure monitoring and early warning for decompression are carried out through an electronic valve and a pressure gauge; and the signalprocessing sub-system comprises a wellhead signal processing circuit, a base station and a computer and is used for collecting, transmitting and analyzing moisture content signals and remote control.The system has advantage of simple structure, high measuring precision, low manufacturing and maintaining costs, being installed in a large scale and the like.

Owner:YANSHAN UNIV

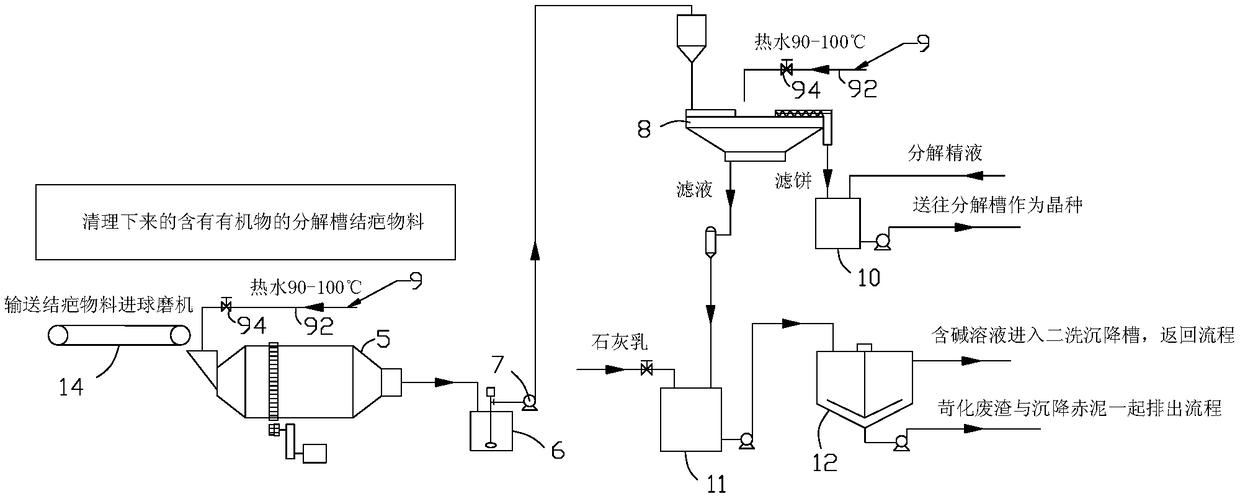

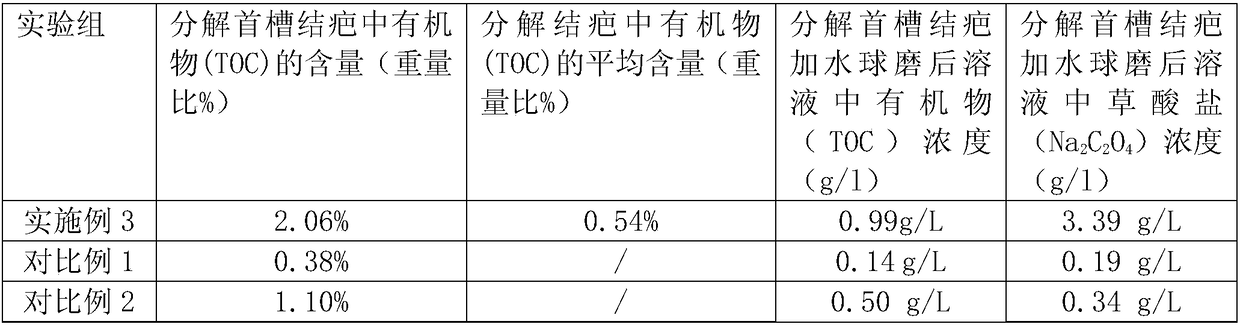

Method and system for eliminating organic matters in aluminium oxide production process

ActiveCN109052441ANo wasteAvoid accumulationAluminates/aluminium-oxide/aluminium-hydroxide purificationAluminium hydroxideDecomposition

The invention provides a method for eliminating organic matters in an aluminium oxide production process. The method comprises the following steps that a crystallization auxiliary is added into undecomposed aluminium hydroxide refined liquor; the undecomposed aluminium hydroxide refined liquor containing the crystallization auxiliary and decomposed mother liquor are subjected to heat exchange; theundecomposed aluminium hydroxide refined liquor subjected to heat exchange and aluminum hydroxide crystal seeds subjected to decomposed seed filtering are mixed and stirred in a mixing tank to obtainmixed liquid, wherein the stirring speed is 70-90 r / min; the stirred mixed liquid enters a decomposition tank for decomposition; washing and causticizing treatment is conducted on scabs attached to the decomposition tank. According to the method, an organic matter crystal precipitation process is adjusted to be conducted in a seed decomposition working section, a better reaction environment is provided for organic matter precipitation, then the mixing tank is added between a heat exchanger and the decomposition tank, through the crystallization auxiliary and action of stirring, crystal seed particles which are evener and uniform in size are generated, increase of the particle size of aluminium hydroxide particles is promoted, organic matter form and critical concentration change is caused, large organic matter druses are induced, and the purpose of improving the organic matter precipitation amount is achieved.

Owner:广西田东锦鑫化工有限公司

Quick leak stop method for water seal tank of dry quenching furnace

ActiveCN103788965ALittle impact on productionSimple processCoke quenchingCoke ovenUltimate tensile strength

The invention discloses a quick leak stop method for a water seal tank of a dry quenching furnace, relates to the field of dry quenching furnace overhauling and provides a quick leak stop method for a water seal tank of a dry quenching furnace, which has a good leak stop effect. The quick leak stop method for a water seal tank of a dry quenching furnace comprises the following steps: after preparing for the leak repairing work, slowly pouring the castable to the leak point, slowly stirring the castable and tamping the castable to the leak point of the water seal tank; and after the castable is combined with water in the water seal tank, sintering so that the castable is firmly combined with the water seal tank to block the leak point, wherein the addition of the castable can be stopped when the water seal tank stops leaking or the leak is slight. The castable comprises the following components: 42-45wt% of SiO2, 52-55wt% of Al2O3 and 1-2.5wt% of Fe2O3; and the particle size of the castable is 0-1mm. The method disclosed by the invention is simple in process; the combination effect between the castable and the water seal tank is good even at a high temperature, the combination strength is good and wear, vibration and stripping resistance, firmness and durability are achieved; and in leak repairing, the dry quenching furnace does not need to be cooled to a cold state, and the influence on the production of the dry quenching furnace is little.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

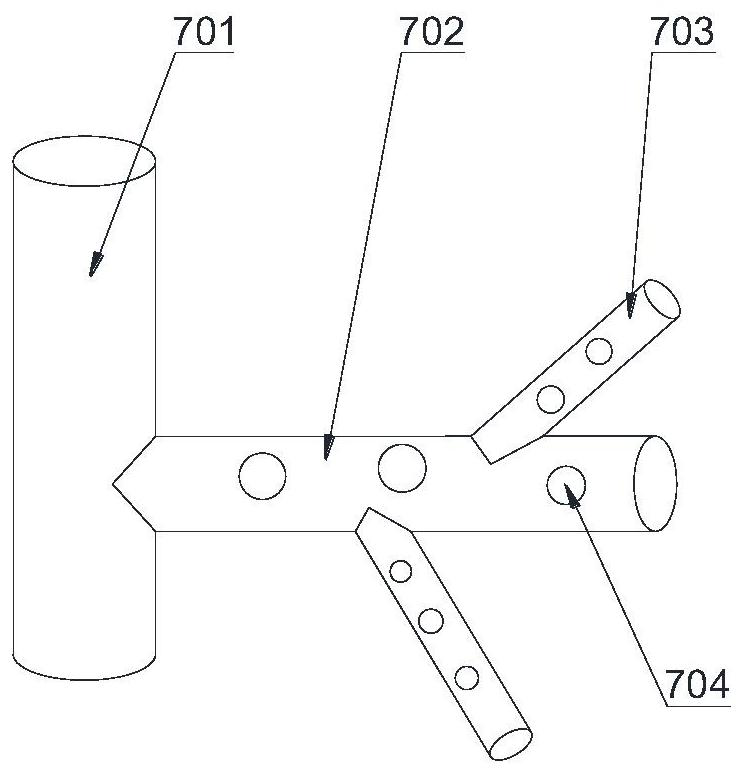

Method for constructing internal dam body of internally-discharged strip mine dump

ActiveCN113106988ABlock as soon as possibleReduce leakageBarrages/weirsProtective foundationStructural engineeringAquifer

The invention discloses a method for constructing an internal dam body of an internally-discharged strip mine dump. The method comprises the following steps that an upper surface connecting line of an original water-resisting layer is taken as an artificial water-resisting layer to fill a reference datum upper boundary; a dam body foundation pit is arranged, and a trapezoidal base platform is arranged on the center line of the dam body foundation pit; a halfpace-shaped water retaining dam core wall is built on the artificial water-resisting layer, and a reinforcing mesh and a grouting pipeline are arranged in the water retaining dam core wall; a foundation anti-seepage layer, waterproof geotechnical cloth and a clay anti-seepage layer are sequentially laid on the side, close to an original aquifer, of the water retaining dam core wall; advancing of a dumping working face is enhanced on the side, away from the original aquifer, of the water retaining dam core wall, and strip mine stripping objects are discharged to form a supporting body; a space between the clay anti-seepage layer and the original aquifer is filled to form a plugging body; and the construction is carried out according to the steps, the dump continues dumping, the facility formed in the steps is buried inside the dump, and a continuous water retaining dam is formed. The dam body is coordinated with strip mine stripping, mining and discharging operation, the water blocking effect is good, the dam body reliability is high, the influence on production is small, and the cost is low.

Owner:CHINA UNIV OF MINING & TECH

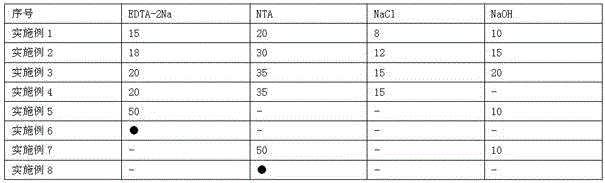

Descaling agent for brine transportation pipeline, as well as usage method thereof

InactiveCN104450293AAvoid harmLittle impact on productionHollow article cleaningInorganic non-surface-active detergent compositionsEthylenediamineAcetic acid

The invention discloses a descaling agent for a brine transportation pipeline. The descaling agent comprises the following raw materials in parts by weight: 15-20 parts of ethylenediamine tetraacetic acid disodium, 20-35 parts of nitrilotriacetic acid, 10-20 parts of sodium hydroxide and 8-15 parts of sodium chloride. A usage method of the descaling agent comprises the following steps: mixing the descaling agent with a defoaming agent and water according to a weight ratio of (1-1.2):(0.1-0.15):1000 to obtain a mixed liquid, and enabling the mixed liquid to be always in a flowing state in a to-be-cleaned brine transportation pipeline by adopting a single-pipe circulating technology or a two-pipe circulating technology, so that the scale dissolving effect of the mixed liquid can be improved. Based on the complexing principle, gypsum scale layers can be removed by the descaling agent, the descaling agent is convenient and safe to use, the descaling efficiency is high, the descaling quality is good, especially the gypsum scale layer in a mirabilite brine transportation pipeline can be entirely eliminated, the damage of the traditional acid pickling to the pipeline can be solved, the construction period is short, and the production of enterprises is hardly affected.

Owner:SICHUAN XINAN JIANAN CORROSION ENG

Method for glue amount on-line detecting of glue

ActiveCN107377304AAccurate dosageAvoid wastingLiquid surface applicatorsCoatingsEngineeringSolid content

The invention discloses a method for glue amount on-line detecting of glue. The method comprises the following steps that a glue drum of a compound machine is placed on an electronic scale, and the glue is injected into the glue drum of the compound machine, and according to the manufacturer information of the glue, the effective solid content of the glue is recorded; the breadth of film materials to be glued and compounded is measured, and the breadth Wm is recorded, the compound machine is started, the vehicle speed of the compound machine is adjusted, the vehicle speed Vm / min of the compound machine during normal working is recorded, and the current weighing numerical value M1g of the electronic scale is recorded; and timekeeping is conducted by using a second chronograph, timekeeping time t minute is recorded, the current weighing numerical value M2g of the electronic scale is recorded, the above obtained data are correspondingly put into equations of M2-M1, L=V*t, S=L*W and (the glue using amount M / the gluing total area S)*the effective solid content of the glue, and the glue amount of the film materials at a unit area is calculated and obtained. By means of the method of glue amount on-line detecting of the glue, the glue amount can be more precisely detected, the glue using amount can be reduced, and the problem that the glue is too much or too less is prevented.

Owner:FUJIAN DALI FOOD TECH CO LTD

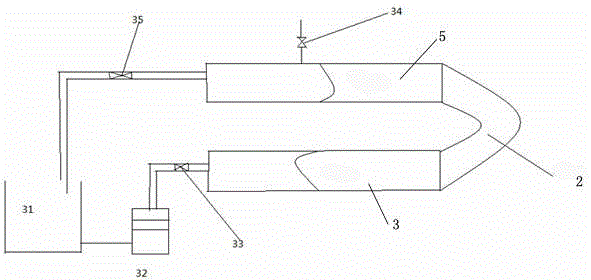

Reverse osmosis system with compressed air blowing function

ActiveCN102070258AImprovement of online cleaning effectLittle impact on productionWater/sewage treatment bu osmosis/dialysisReverse osmosisWater treatment systemInlet valve

The invention relates to a reverse osmosis system with a compressed air blowing function, belonging to the technical field of reverse osmosis water treatment systems. The reverse osmosis system with the compressed air blowing function comprises a reverse osmosis membrane pressure container, a water inlet pipe and a concentrated water discharging pipe, wherein the water inlet pipe is connected with the water inlet end of the reverse osmosis membrane pressure container; the concentrated water discharging pipe is connected with the water outlet end of the reverse osmosis membrane pressure container; and the reverse osmosis system is also provided with a gas inlet valve which is matched with the water inlet end of the reverse osmosis membrane pressure container. The reverse osmosis system has the advantages that the structural design is reasonable, effective and fast online cleaning can be realized, the cleaning effect is good, and normal use is not influenced.

Owner:杭州英普环境技术股份有限公司

Wellhead oil-water phase flow static moisture content measurement system and control method thereof

ActiveCN109975525ALittle impact on productionReduce manual workloadConstructionsMaterial testing goodsCapacitanceSignal processing circuits

The invention discloses a wellhead oil-water phase flow static moisture content measurement system and a control method thereof, and relates to the technical field of petroleum production logging. Thesystem mainly includes a wellhead oil-water phase flow static moisture content measurement device and a signal processing subsystem; the wellhead oil-water phase flow static moisture content measurement device realizes the flowing and stationary of fluid in a medium bin through a control valve set, the gas-liquid separation of oil and water can be performed in the medium bin under the action of gravity, and the moisture content of the fluid can be calculated through a capacitance level gauge; the device performs pressure monitoring and early warning pressure relief simultaneously through a pressure gauge and an electric valve; and the signal processing subsystem includes a wellhead signal processing circuit, a base station and a computer, and is used for controlling, collecting, transmitting and analyzing the moisture content signals and remote control of the wellhead oil-water phase flow static moisture content measurement device. The system has advantages of being simple in structure, high in measuring accuracy and low in manufacturing and maintenance cost, and can be equipped in large scale.

Owner:YANSHAN UNIV

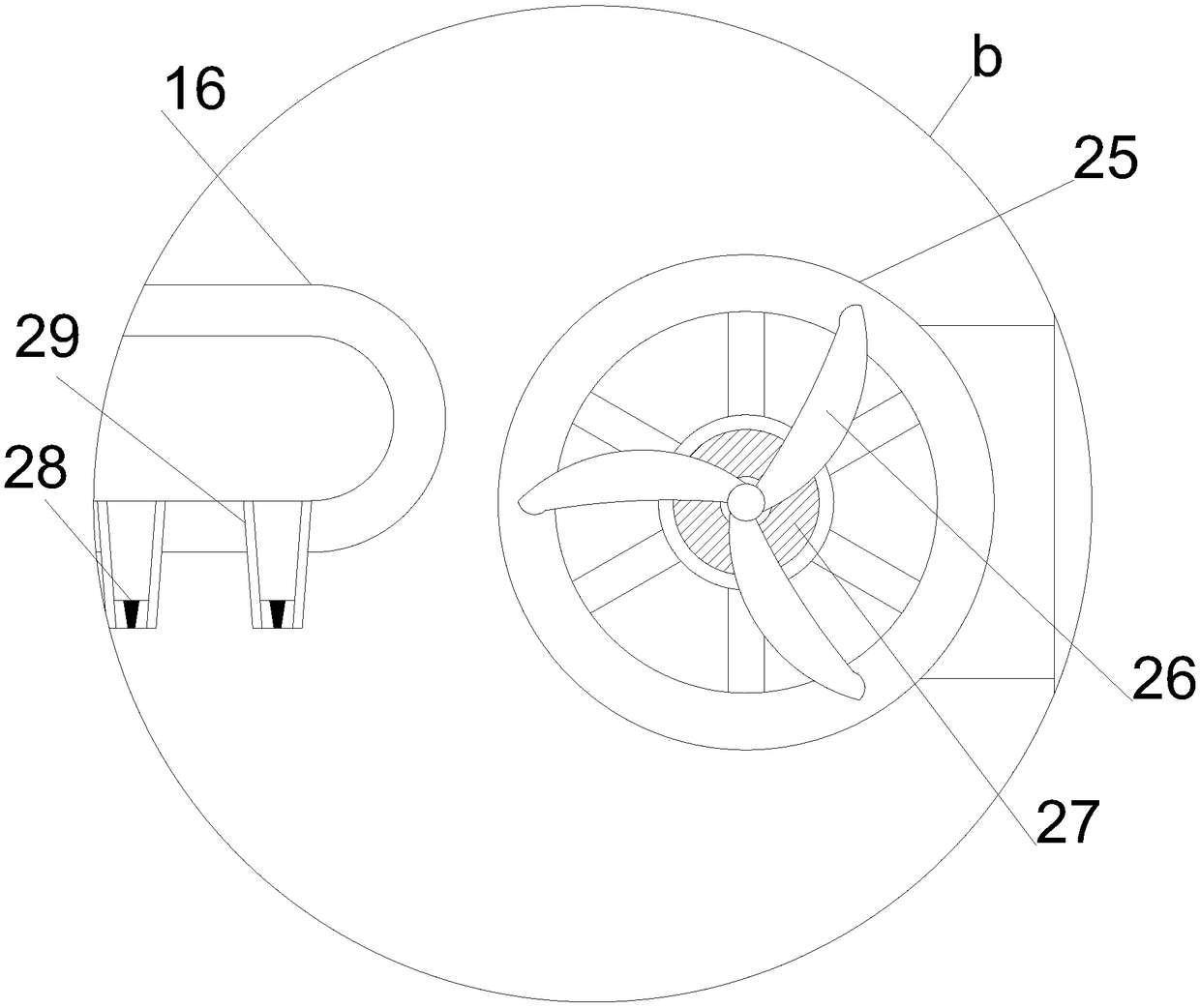

Internet of Things fish pond oxygenation robot

ActiveCN109042475AWorking surface is stableFloating smoothlyPisciculture and aquariaRemote controlEngineering

The invention discloses an Internet of Things fish pond oxygenation robot. The robot comprises a horizontally arranged annular buoyancy mounting plate, the inner side of the annular buoyancy mountingplate is vertically upward provided with a spherical mounting cover, a guide lifting mounting cylinder vertically penetrates through the middle of the upper end of the spherical mounting cover, an annular buoyancy cylinder is horizontally arranged on the outer side of the annular buoyancy mounting plate through a fixing mounting column arranged at the equal angle, the inside of the guide lifting mounting cylinder is vertically provided with a guide lifting mounting column through a guide lifting structure, a deflector hole is inserted vertically inside the guide lifting mounting column, the upper end of the guide lifting mounting column protrudes from the lifting mounting cylinder, a collecting installation cover is horizontally arranged, and a uniform aeration oxygenation structure is arranged at the lower end of the guide lifting mounting column. The robot has the advantages of compact structure design, stable floating, long aeration time, good oxygenation effect, stable working surface, small influence on fishery production, convenient remote control and the like.

Owner:江门南职导游服务有限公司 +1

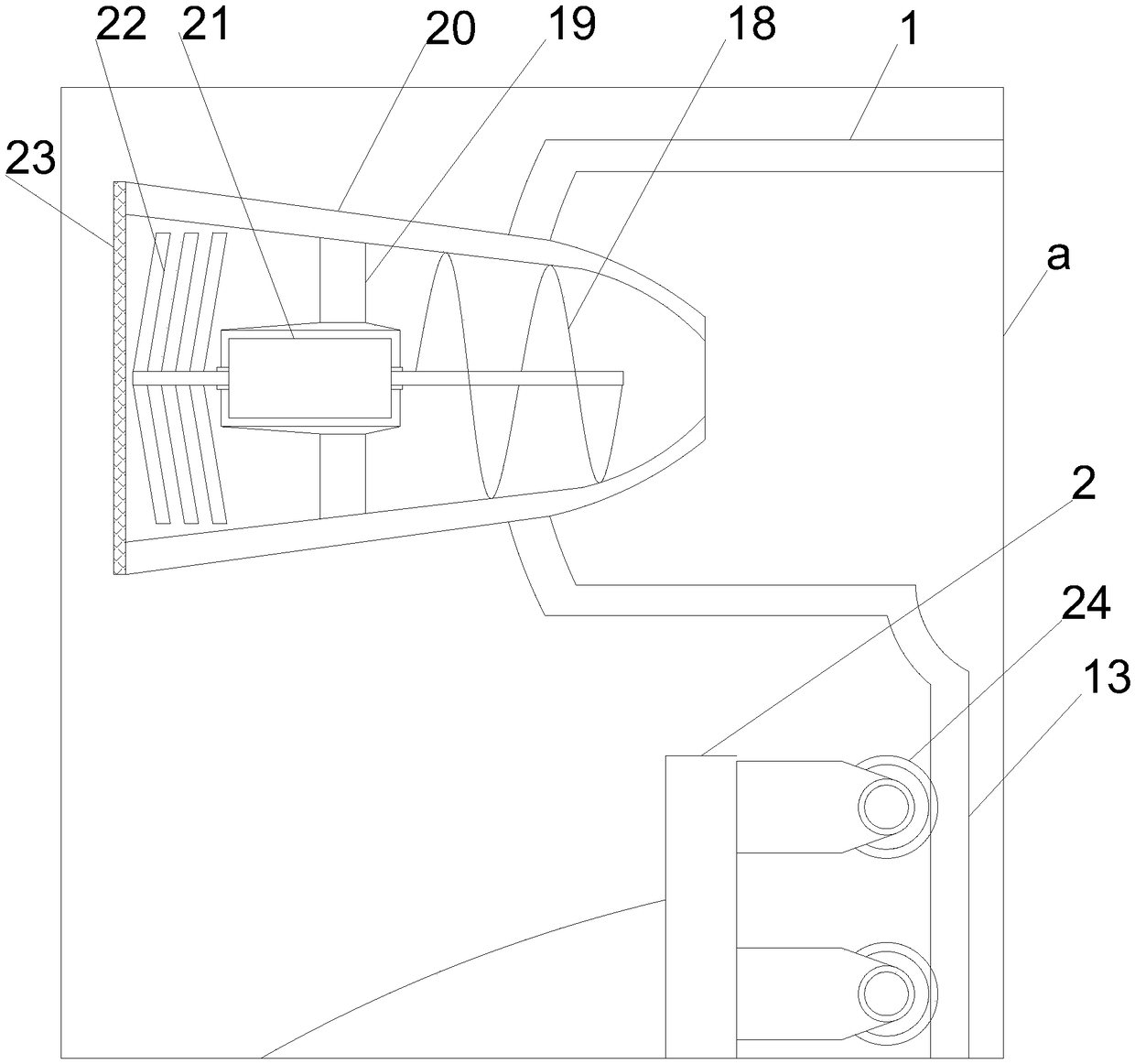

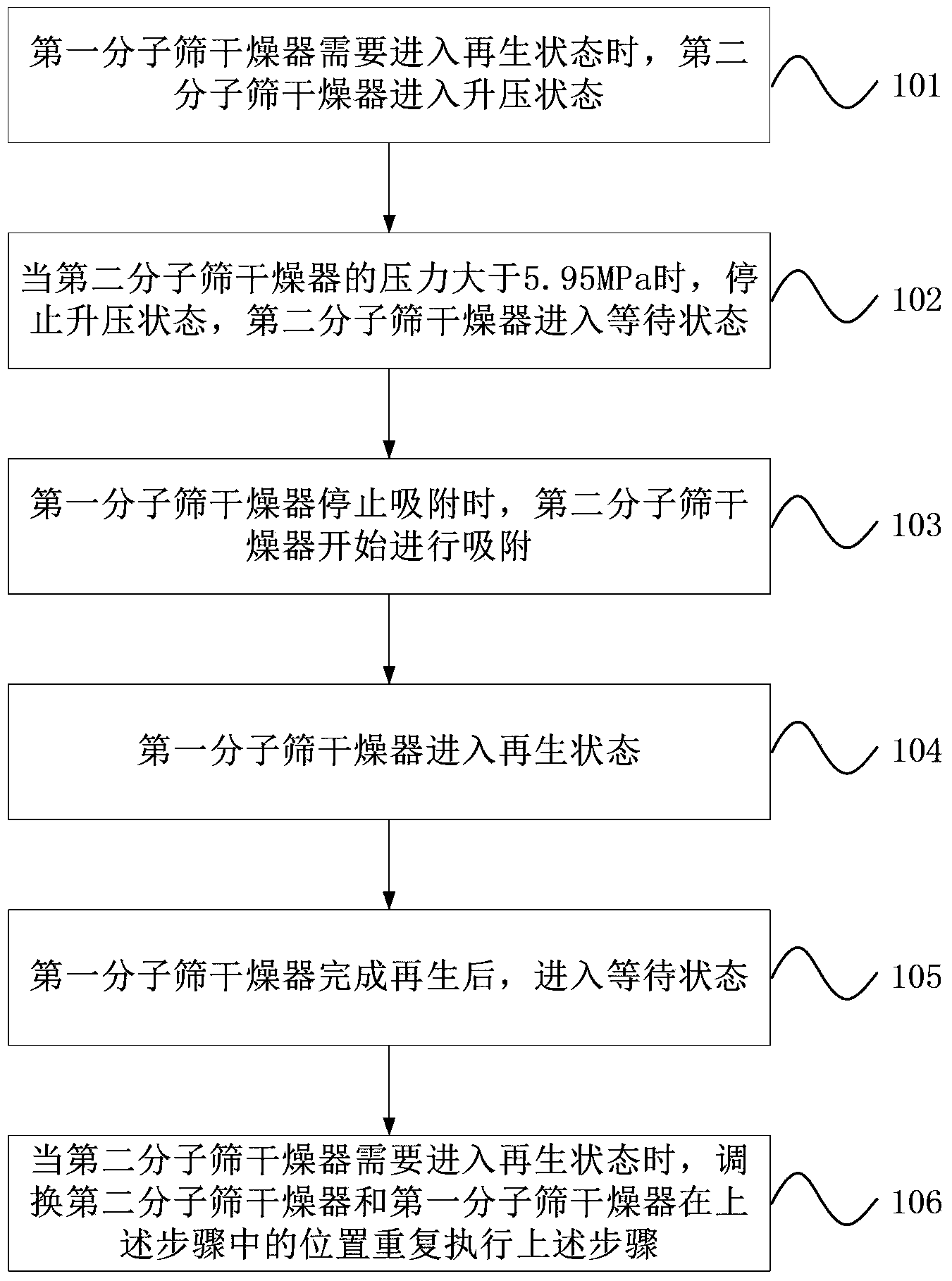

Molecular sieve drying and dehydration method by using synthetic ammonia process

InactiveCN103406004AEfficient removalAchieve removalDispersed particle separationAmmonia preparation/separationMolecular sievePressure rise

The invention provides a molecular sieve drying and dehydration method by using a synthetic ammonia process. According to the molecular sieve drying and dehydration method, when a first molecular sieve dryer is required to enter a regeneration state, a second molecular sieve dryer enters a pressure-rising state; when the pressure of the second molecular sieve dryer is greater than 5.95 MPa, the second molecular sieve dryer enters a wait state; when the first molecular sieve dryer stops adsorption, the second molecular sieve dryer starts to adsorb; the first molecular sieve dryer enters the regeneration state and enters a wait state after the regeneration is finished; when the second molecular sieve dryer is required to enter the regeneration state, the second molecular sieve dryer and the first molecular sieve dryer are exchanged to repeat the steps at the position in the step. According to the molecular sieve drying and dehydration method, vapor and residual carbon oxide capable of causing poisoning of a synthesis catalyst can be effectively removed. The energy conservation and environmental protection requirements are met, and the production efficiency of enterprises can be effectively improved.

Owner:内蒙古鄂尔多斯联合化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com