Side-supporting roadway forming method by pre-digging guide cavern and filling with artificial side wall for secondary use

A technology of roadside support and secondary reuse, which is applied in fillings, underground chambers, earthwork drilling, etc. The effect of stable, small section shrinkage and fast lane formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below with reference to the accompanying drawings.

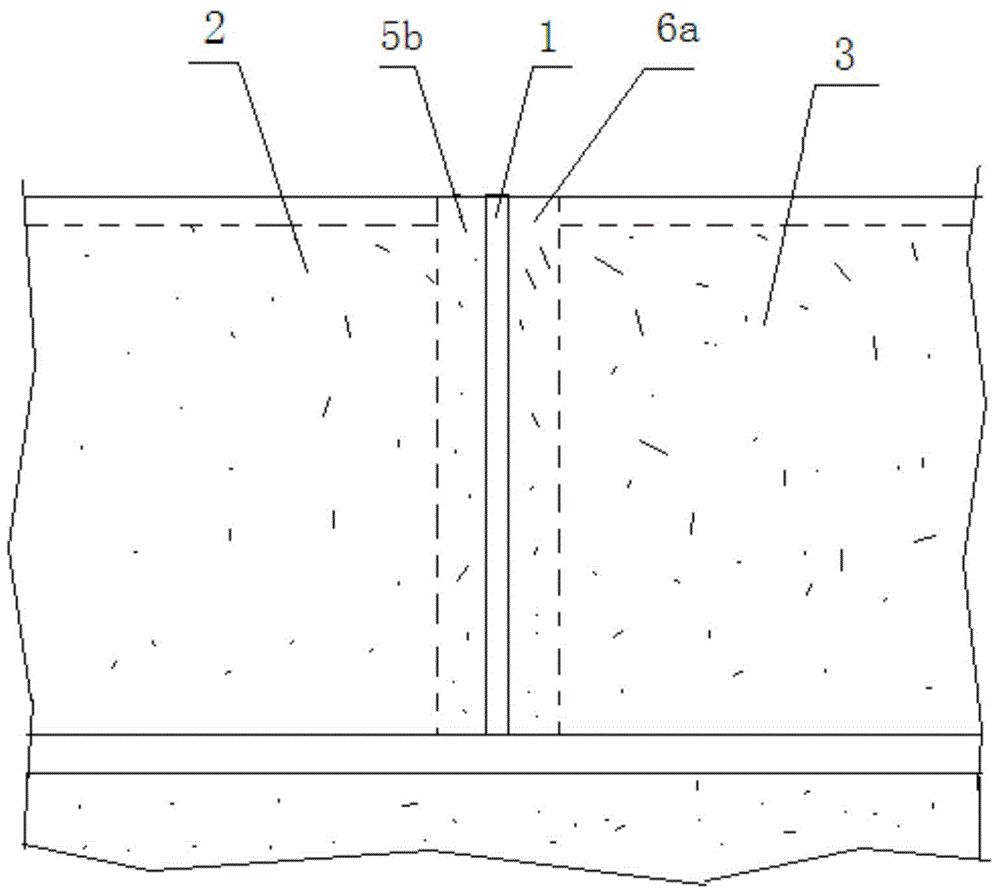

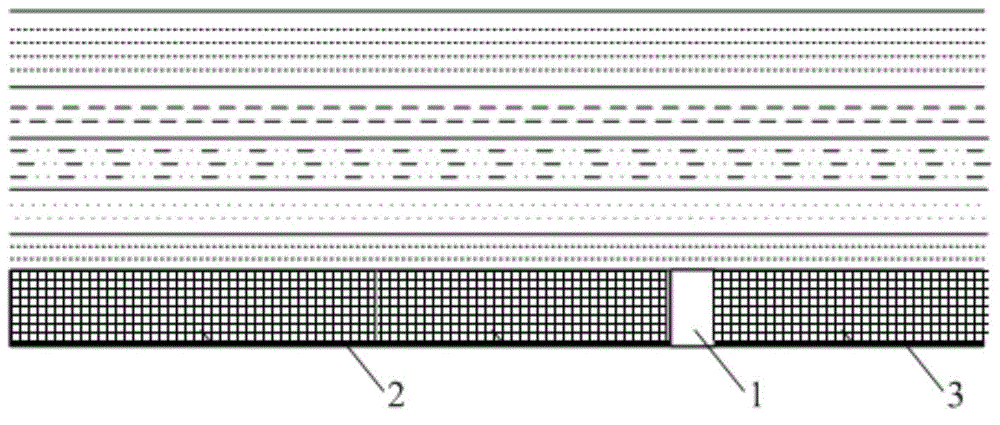

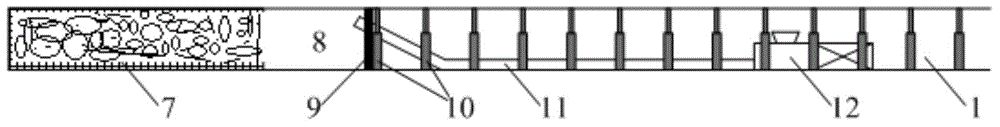

[0045] Such as Figure 1-9 As shown, the pre-excavation guide tunnel of the present invention is filled with artificial side and the secondary reuse roadside support roadway forming method is:

[0046] The first step: excavation of the first working face and the lower mining roadway 5a, 5b

[0047] Step 1.1: Pre-excavation of mining roadway guide tunnel 1 under the first working face

[0048] Such as figure 1 and figure 2 As shown, before the excavation of the mining roadway 5b under the first working face, firstly, at the lower side of the mining roadway 5b under the first working face, excavate a 2m-wide mining roadway guide tunnel 1 under the first working face. The leading tunnel 1 of the mining roadway is equal to the height and length of the mining roadway 5b under the first working face, and temporary support is used; the temporary support is determ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com