Pre-excavation guide tunnel filling method for roadside support for secondary reuse of roadway with artificial side

A technology of roadside support and secondary reuse, which is applied in fillings, underground chambers, and earthwork drilling, etc., can solve the problems of large section shrinkage, difficult roadway maintenance, and slow coal mining speed, and achieve section shrinkage. Small, eliminates roadway instability, and has the effect of fast road formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below with reference to the accompanying drawings.

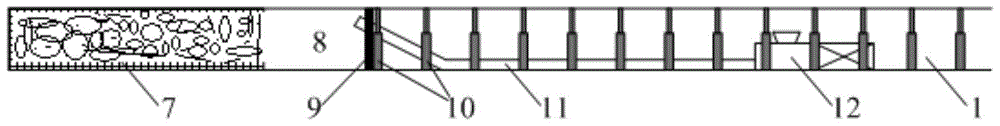

[0045] Such as Figure 1-9 As shown, the pre-excavation guide tunnel of the present invention is filled with artificial side and the secondary reuse roadside support roadway forming method is:

[0046] The first step: excavation of the first working face and the lower mining roadway 5a, 5b

[0047] Step 1.1: Pre-excavation of mining roadway guide tunnel 1 under the first working face

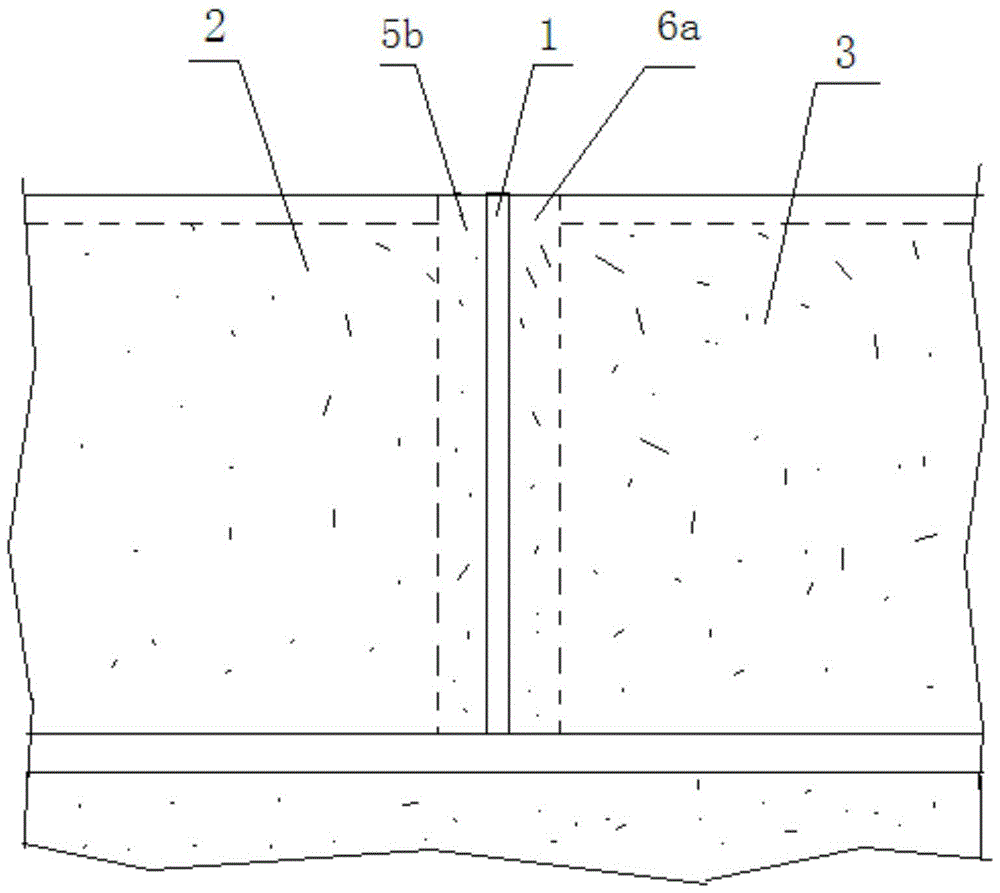

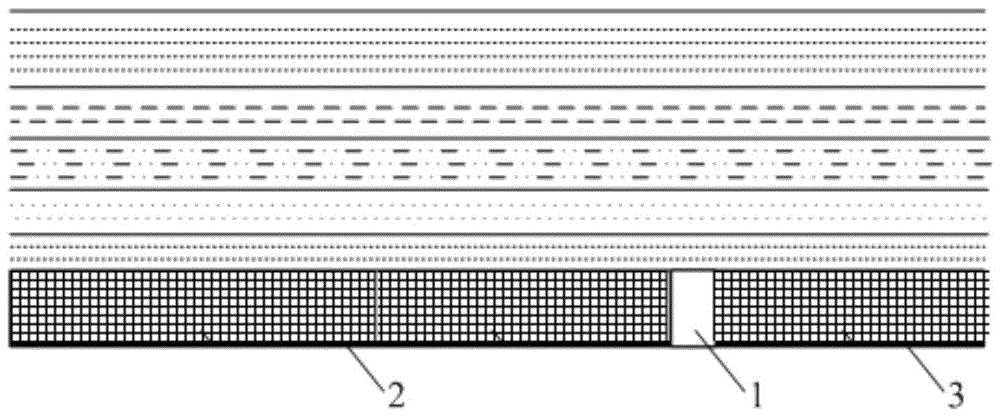

[0048] Such as figure 1 and figure 2 As shown, before the excavation of the mining roadway 5b under the first working face, firstly, at the lower side of the mining roadway 5b under the first working face, excavate a 2m-wide mining roadway guide tunnel 1 under the first working face. The leading tunnel 1 of the mining roadway is equal to the height and length of the mining roadway 5b under the first working face, and temporary support is used; the temporary support is determ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com