Quality control detection method and application of hot-rolled high-carbon wire rod for high-strength stranded wire

A technology for controlling detection and wire rod, applied in the field of iron and steel metallurgy, it can solve the problems of poor cross-section representation of wire rod and complaints of broken wires from downstream wire drawing users, and achieve the effect of improving user satisfaction, strong representativeness and avoiding limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for quality control and detection of hot-rolled high-carbon wire rods for high-strength strands, the specific steps are as follows:

[0041] (1) Standard sampling: The hot-rolled wire rod needs to be cooled to below 50°C on the C-shaped hook. The length of the uncooled section of the wire rod head on the rolling line must be cut off, and then the spline is cut. The length of the spline is not more than 500mm, preferably 350mm. ±50mm.

[0042] (2) Sample preparation: Use a straightener to straighten the wire rod sample, and then put it into a heating furnace for artificial aging. The aging temperature is 150±10°C, and the aging time is 3±0.5h. After the aging is over, the sample is taken out. and cooled to room temperature in still air.

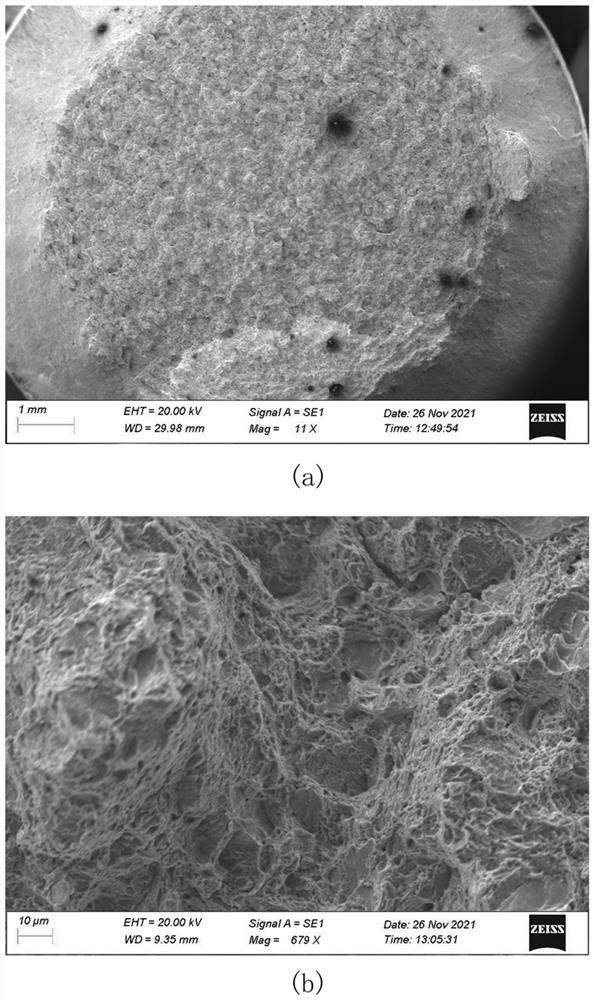

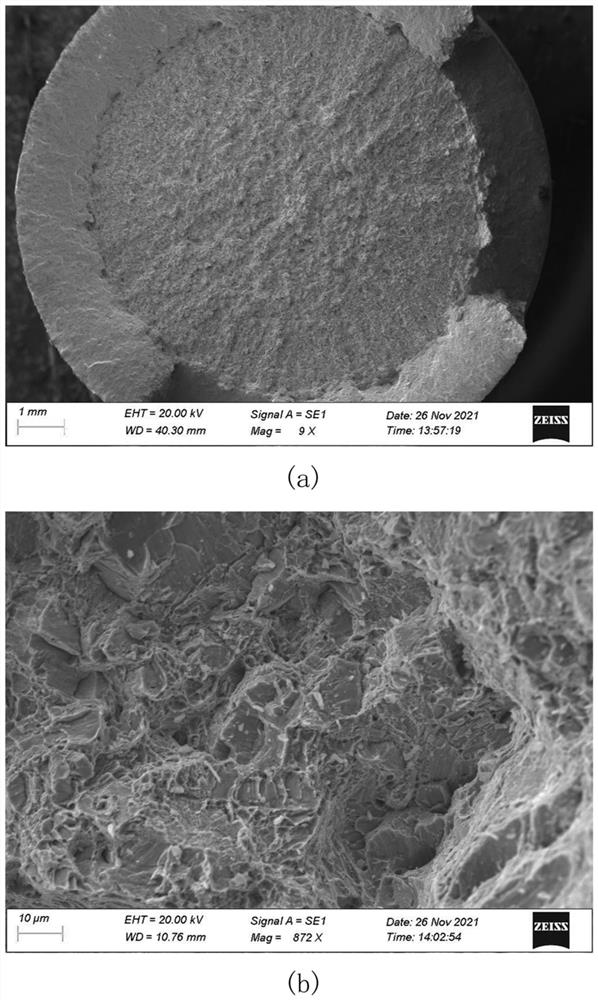

[0043] (3) Sample inspection: The prepared sample is subjected to a tensile test on a mechanical tensile testing machine, and the tensile strength and the reduction of area ψ are detected after breaking. The tensile strength i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com