Method for computer simulation of installation construction of oven protection equipment of coke oven

A technology of computer simulation and furnace protection equipment, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problems of representativeness, poor guidance, large errors, long time consumption, etc., to achieve short time consumption, reliable data, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

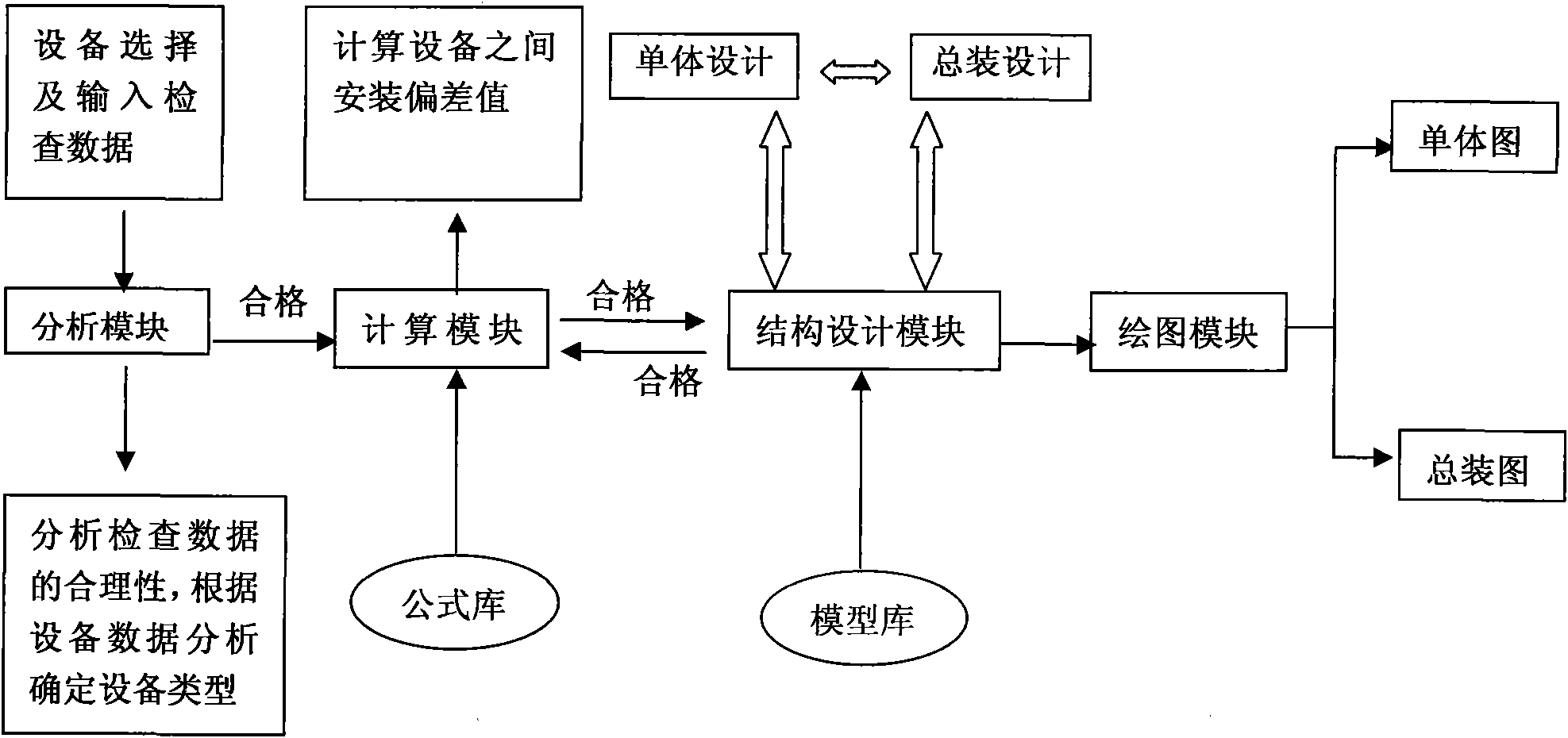

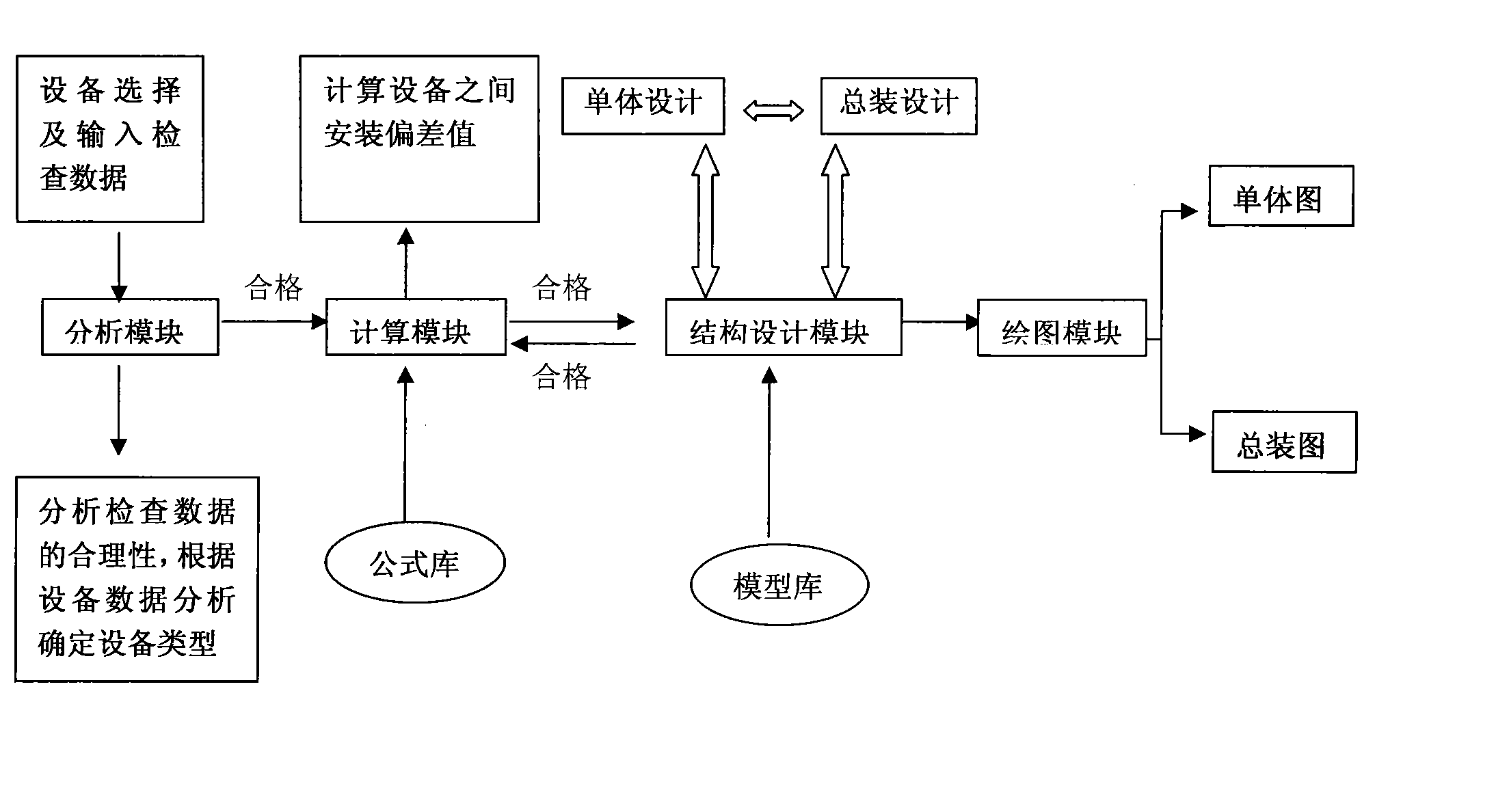

[0023] Such as figure 1 As shown, the computer simulation coke oven protection equipment installation and construction method is a secondary development based on SOLIDWORKS software. The CAD system uses Visual Basic 6.0 as a development tool, Access as a design parameter database management tool, and SolidWorks2006 as a platform Secondary development carried out.

[0024] The system is divided into analysis module, calculation module, structure design module and drawing module. The modules are programmed independently, and the modules are connected through parameter data, and the corresponding data verification interface is compiled to ensure the consistency and correctness of the data. The single arrow in the figure indicates the data flow direction and data call, and the double-headed arrow indicates the associated design.

[0025] Specific steps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com