Numerical-control replenishing processing method for composite multi-profile tools

A composite material and supplementary processing technology, which is applied in the field of numerical control processing of composite material tooling, can solve the problems of loose workpiece, small size, difficult processing, and difficult clamping, etc., to achieve the goal of solving loosening, reducing cutting amount, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The numerical control supplementary processing method of multi-surface tooling of composite materials, the steps are as follows:

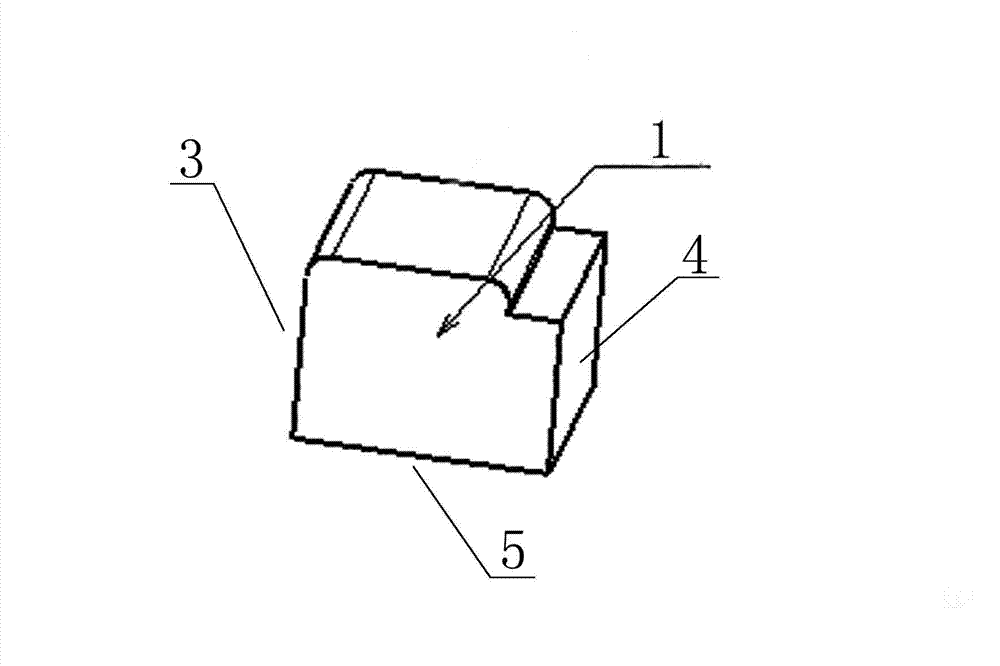

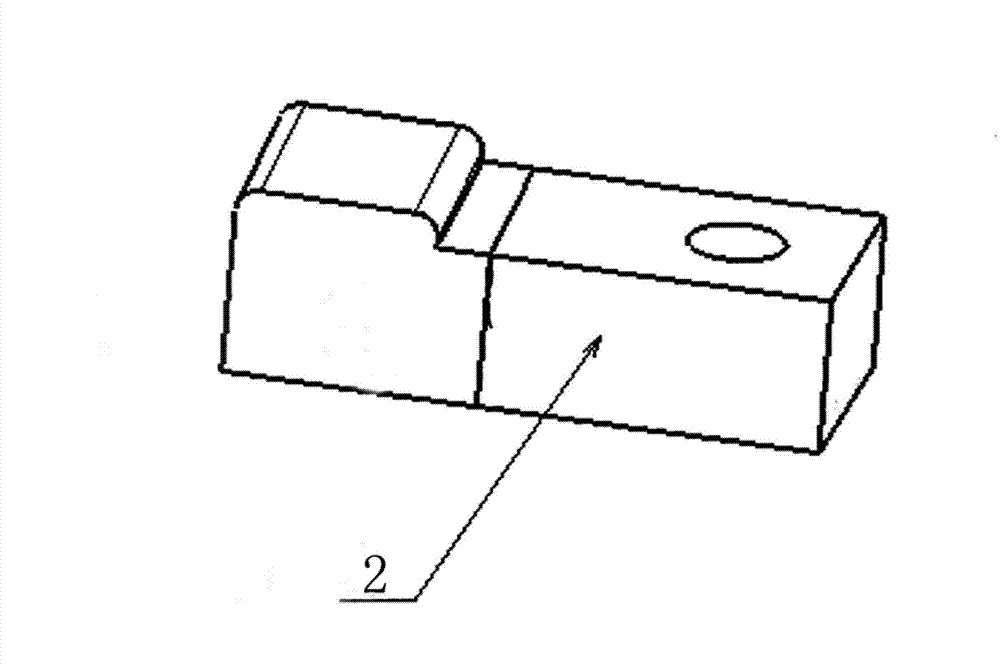

[0015] 1) if figure 1 As shown, the size of the parts to be processed: length*width*height is 21mm*16mm*15mm, first determine the relatively complex CNC machining surface, for complex profiles (complex profiles refer figure 1 The surface 3 in the middle has an open angle and a closed angle), leaving a 2-3mm machining allowance, and leaving a 1-2mm allowance for other surfaces; determine the clamping state required for workpiece processing: figure 1 The surface opposite to the middle surface 1 and the surface 1 is a parallel surface and is perpendicular to the bottom surface 5, and the adjacent surface 4 on the right is also perpendicular to the bottom surface 5. figure 1 Parts with similar characteristics, such as figure 2 As shown, the supplementary block 2 is supplemented along the parallel planes; for components without parallel planes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com