Quick replacement method of counterbalance of four-high mill

A four-high rolling mill and replacement method technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of long construction period, high construction cost, and reduced production efficiency, and achieve small production impact, short construction period, and The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

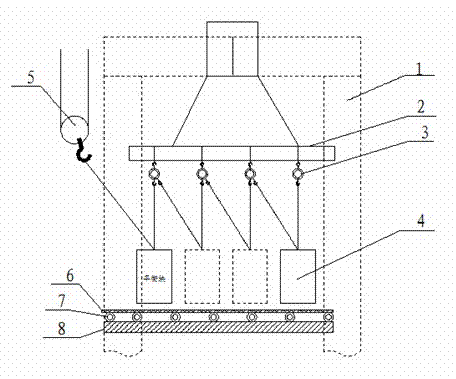

[0027] Referring to the accompanying drawings, a method for quickly and quickly replacing the balance weight of a large four-roll rolling mill. When overhauling the balance weight of a large four-high rolling mill, the replacement of the balance weight fixed in the rolling mill archway is carried out in sequence as follows:

[0028] Step 1: Three-party security confirmation, stop the media;

[0029] The second step: Lay the backing plate on the work roll change track;

[0030] Step 3: Remove the connecting bolts of the balance weight;

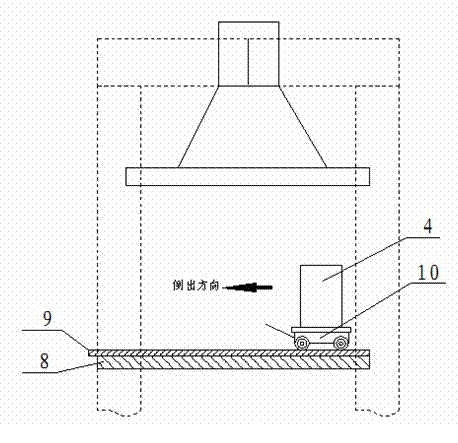

[0031] Step 4: Use the manufactured traversing trolley to reverse the balance weight from the inside of the rolling mill;

[0032] Step 5: Lift the removed balance weight away by driving.

[0033] The backing plate described in the second step in the above steps is a steel plate of δ20mm.

[0034] The moving direction of the trolley described in the fourth step in the above steps is from right to left.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com