Reversing lifting conveyor and conveying system

A conveyor and horizontal conveying technology, which is applied to conveyor objects, transportation and packaging, roller tracks, etc., can solve the problem of not having material frame or material tray reversing transportation and buffering functions, and achieves compact structure and low energy consumption. , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

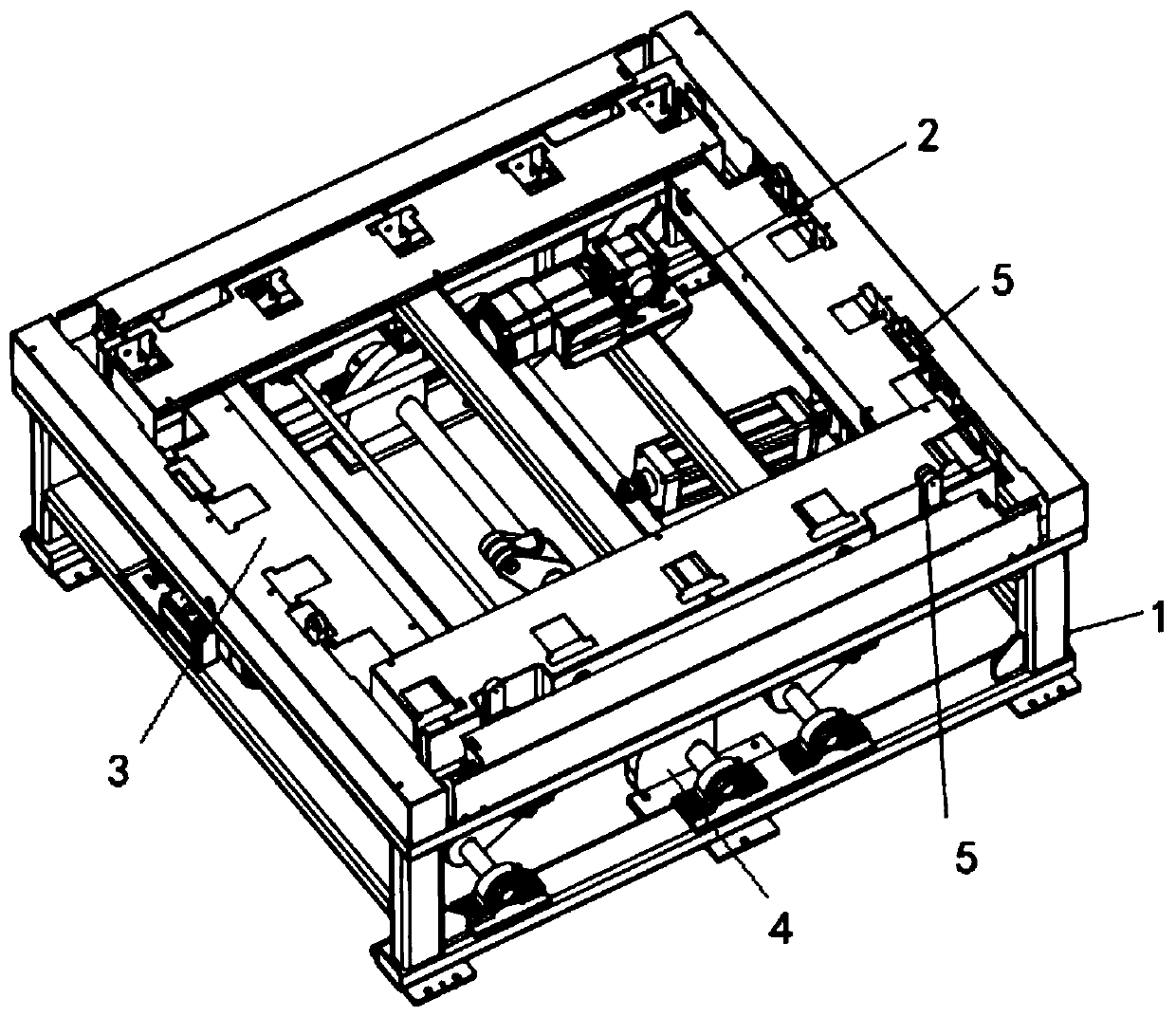

[0055] Please refer to Figure 1 to Figure 3 , a reversing lift conveyor, comprising:

[0056] Rack 1;

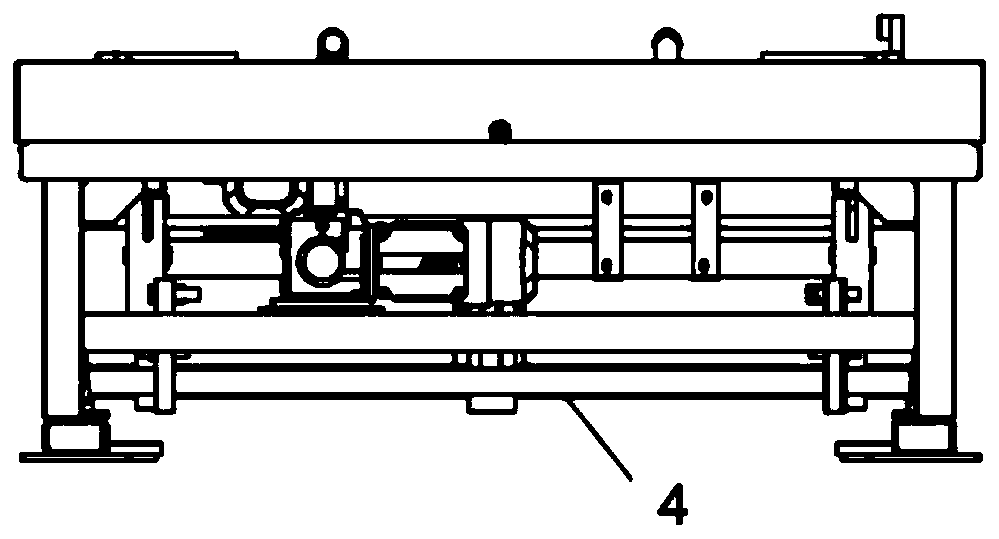

[0057] The lifting mechanism 4 is arranged on the frame 1;

[0058] The horizontal conveying mechanism 2 can carry out horizontal conveying; the horizontal conveying mechanism 2 is arranged on the lifting mechanism 4, and is driven by the lifting mechanism 4 to carry out lifting movement;

[0059] The longitudinal conveying mechanism 3 is arranged on the frame 1 and can carry out longitudinal conveying;

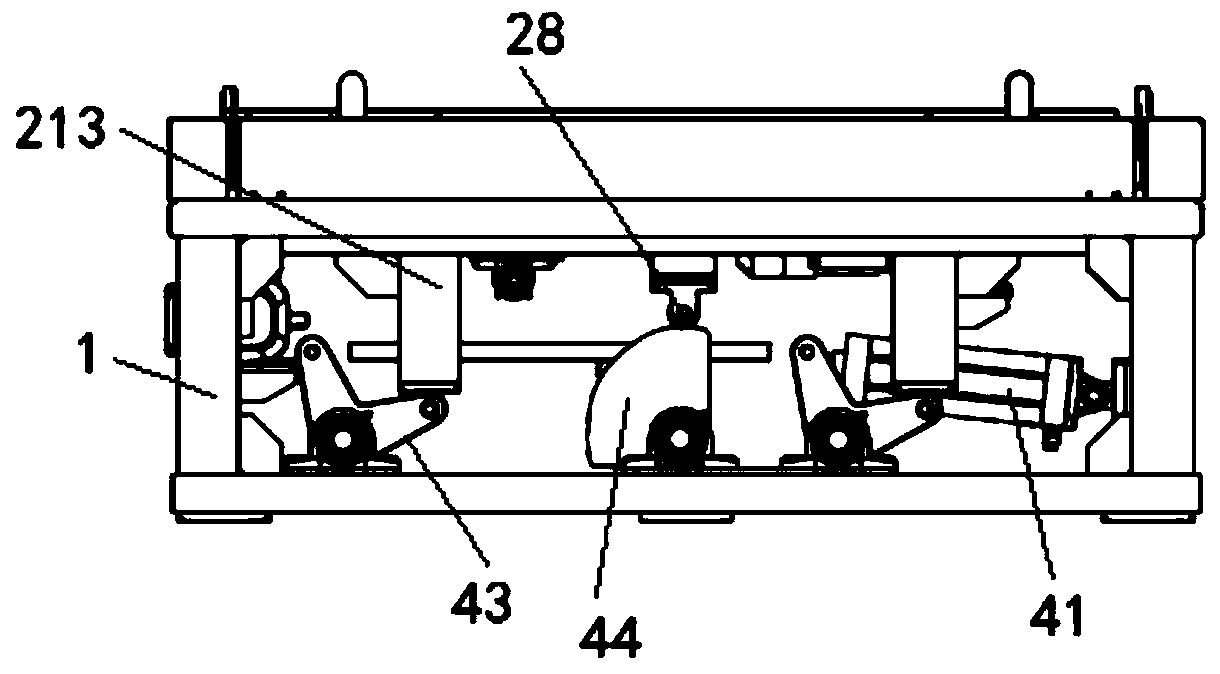

[0060]The blocking mechanism 5 is respectively arranged on the lateral side and the longitudinal side of the frame 1 correspondingly, and can be used to block the horizontal transmission and the vertical transmission of the material frame or the material pallet.

[0061] In this example, please refer to Figure 4 The longitudinal conveying mechanism 3 includes several longitudinal rollers 33 and longitudinal motors 31 for longitudinal transmission, and several longitud...

Embodiment 2

[0083] This embodiment provides a reversing elevating conveying system, which includes several reversing elevating conveyors described in Embodiment 1. The two adjacent conveyors in the longitudinal direction are transported by the longitudinal conveying mechanism 3, and The two adjacent conveyors are transported by the transverse conveying mechanism 2 .

[0084] The conveying system has no specific limit on the number of conveyors, which can be determined according to the actual production line requirements. Please refer to Figure 12 , the workpiece arrives at the grabbing point of the robot from the incoming material direction, and the robot grabs the workpiece to the four framing stations of A / B / C / D. Conveying and circular conveying system with buffer function. The empty material frame is placed on the conveyor ① by the loading station, and then started by the conveyor ①, and transported to the frame loading station A / B / C / D respectively through the entire transportation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com