System for synergistically treating domestic garbage through cement kiln and method thereof

A technology for co-processing and domestic waste, applied in combustion methods, lighting and heating equipment, furnace types, etc., can solve problems such as less processing capacity, and achieve the effects of small environmental impact, easy operation and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

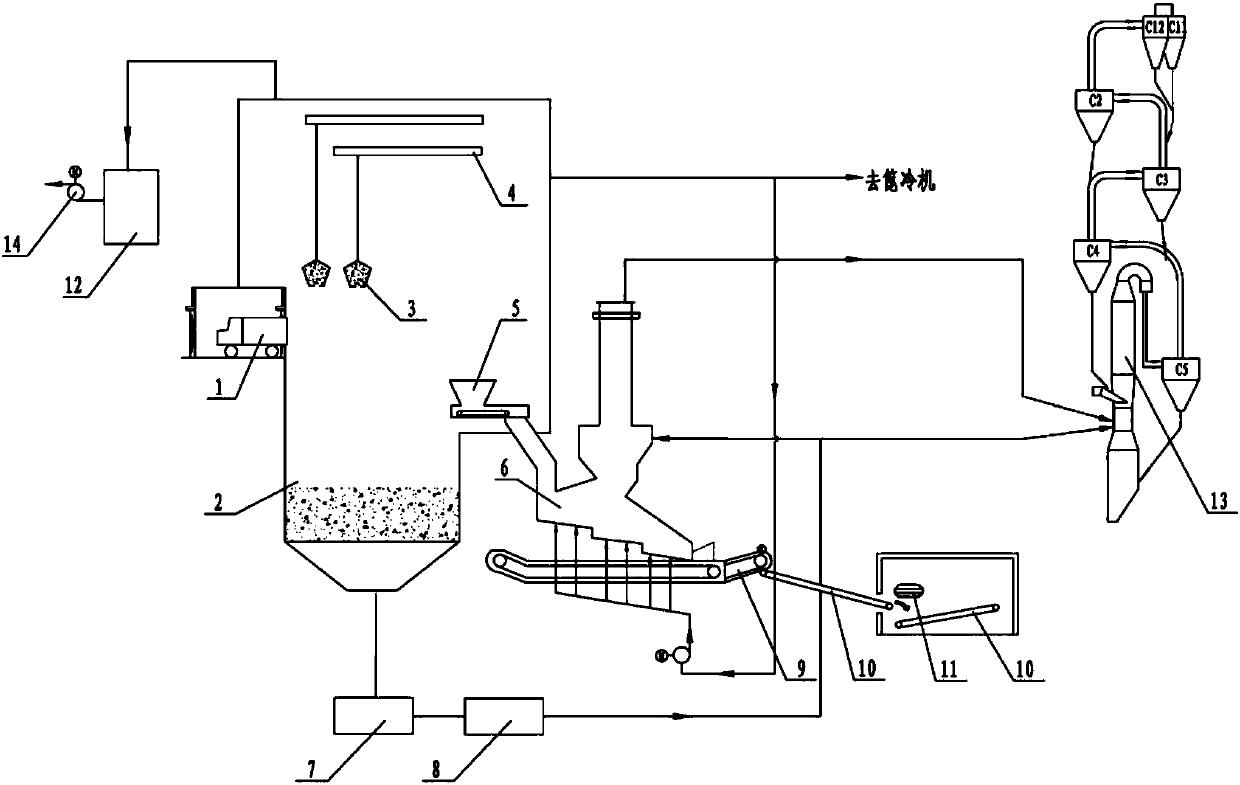

[0027] Further description will be made below in conjunction with drawings and embodiments.

[0028] A cement kiln co-processing domestic waste system in this embodiment includes a feed system, a gasification incineration system, a slag discharge system, an odor treatment system, and a leachate treatment system. The feeding system includes a garbage storage pit 2 and a feeding device 5; a crane 4 and a driving grab 3 are arranged above the garbage storage pit 2; the feeding device 5 is connected with the grate furnace 6 of the gasification incineration system, and the garbage Drying, gasification, and incineration in 6, the grate furnace 6 is connected to the cement kiln calciner 13, the flue gas after the grate furnace 6 is burned is sent to the calciner 13; the burnt slag is collected by the slag discharge system and sent to the raw material batching The station participates in batching and grinding into raw material powder. The slag discharge system includes a scraper slag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com