Method for constructing cross-over chambers with full-coal outsize cross section under host lane ceaseless transportation condition

A technology with extra-large cross-section and construction method, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc., can solve the problems such as the suspension of production of the belt lane in the working face and the impact on mine production, and achieve the effect of reducing the impact and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

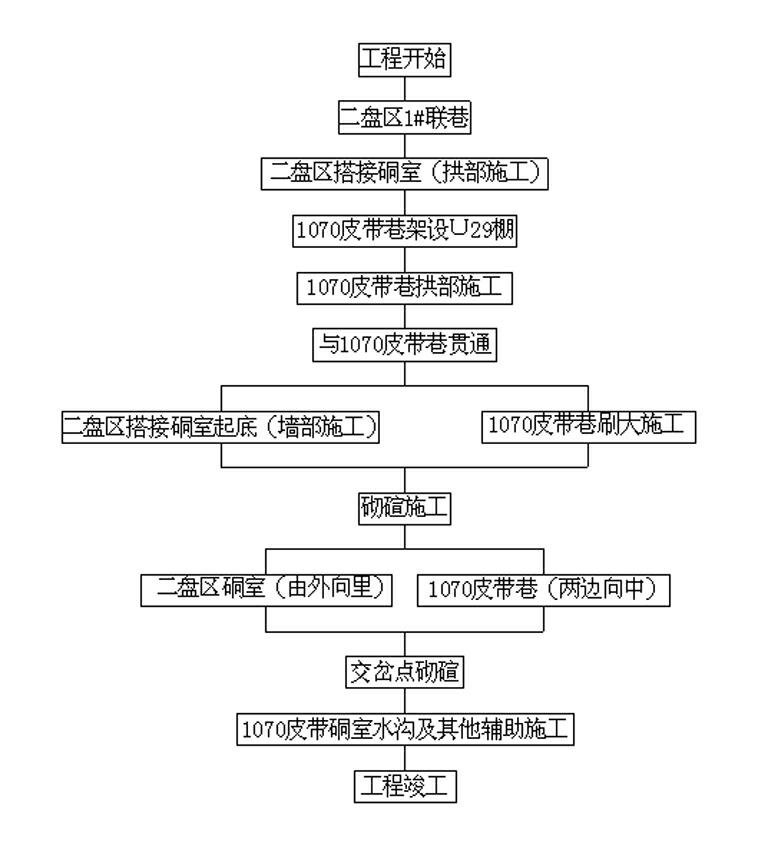

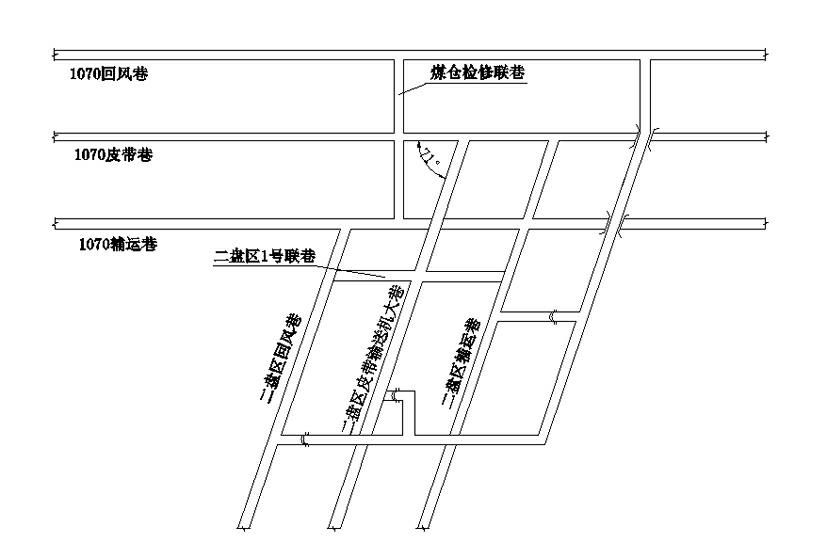

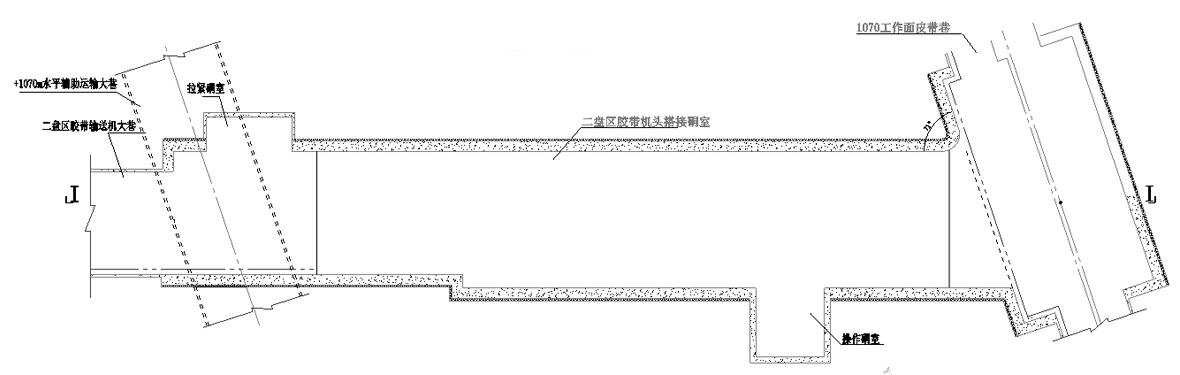

[0029] The construction method of an all-coal extra-large cross-section crossing chamber under the condition of uninterrupted transportation of the main roadway according to the present invention includes the construction of the lap joint chamber construction of the panel tape machine head, the construction of the lap joint chamber construction of the working face belt lane, and the construction of the working face belt Lane maintenance, the specific construction steps are (such as figure 1 shown):

[0030] (1) The head of the panel tape is lapped to the arch of the chamber,

[0031] (2) Maintenance of the working face belt lane, auxiliary facilities and cable protection,

[0032] (3) The construction of the arch portion of the chamber where the belt lane is lapped at the working face,

[0033] (4) Lap-joint chambers of belt machine heads in the penetrating panel and lap-joint chambers of belt lanes on the working face,

[0034] (5) The construction of the overlapping of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com