Wellhead oil-water phase flow static moisture content measurement system and control method thereof

A technology for measuring system and water content, which is applied in the direction of measuring devices, earthwork drilling, wellbore/well components, etc. It can solve the problems of reduced life, narrow measuring range, and short measuring range, and achieve low manufacturing and maintenance costs. and the effect of simple structure and reduced manual workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

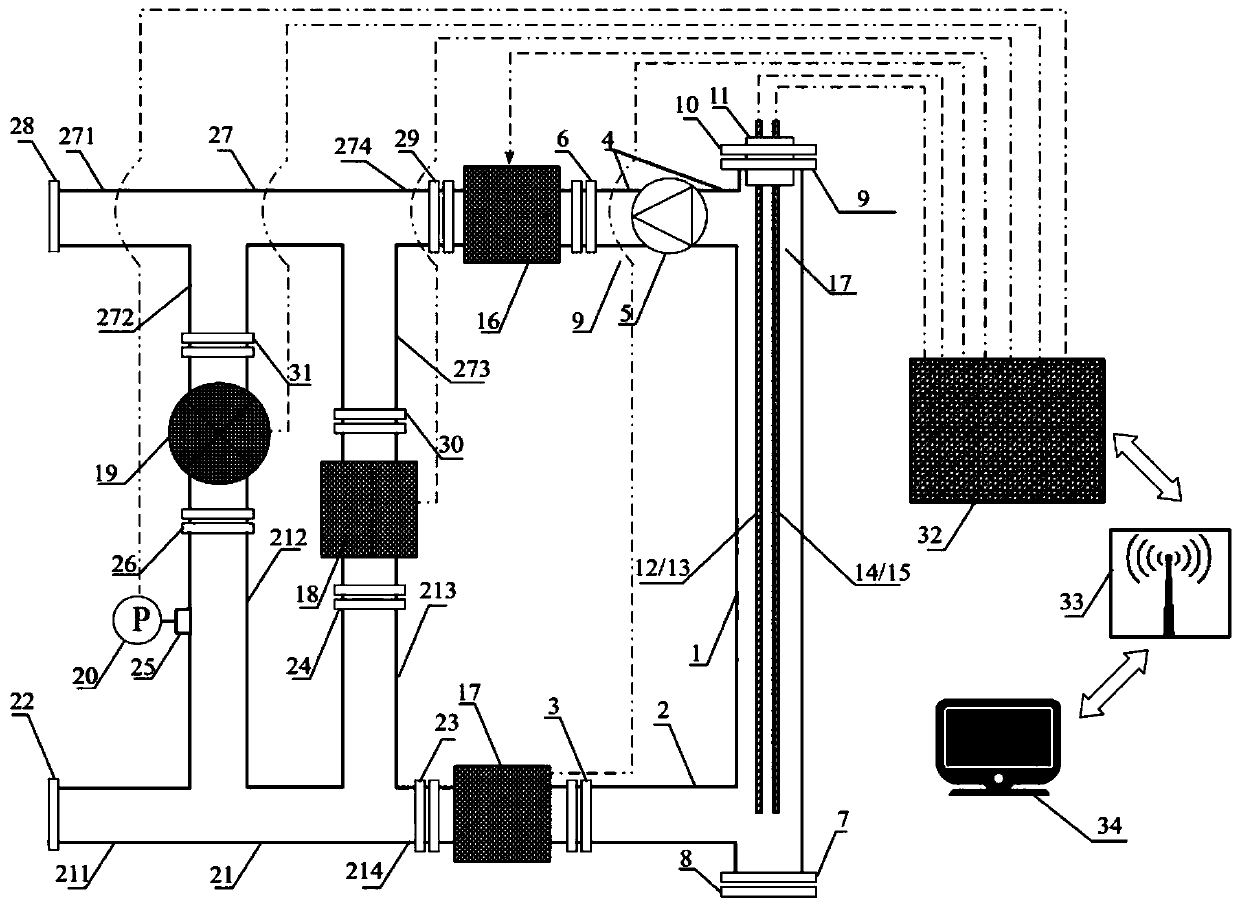

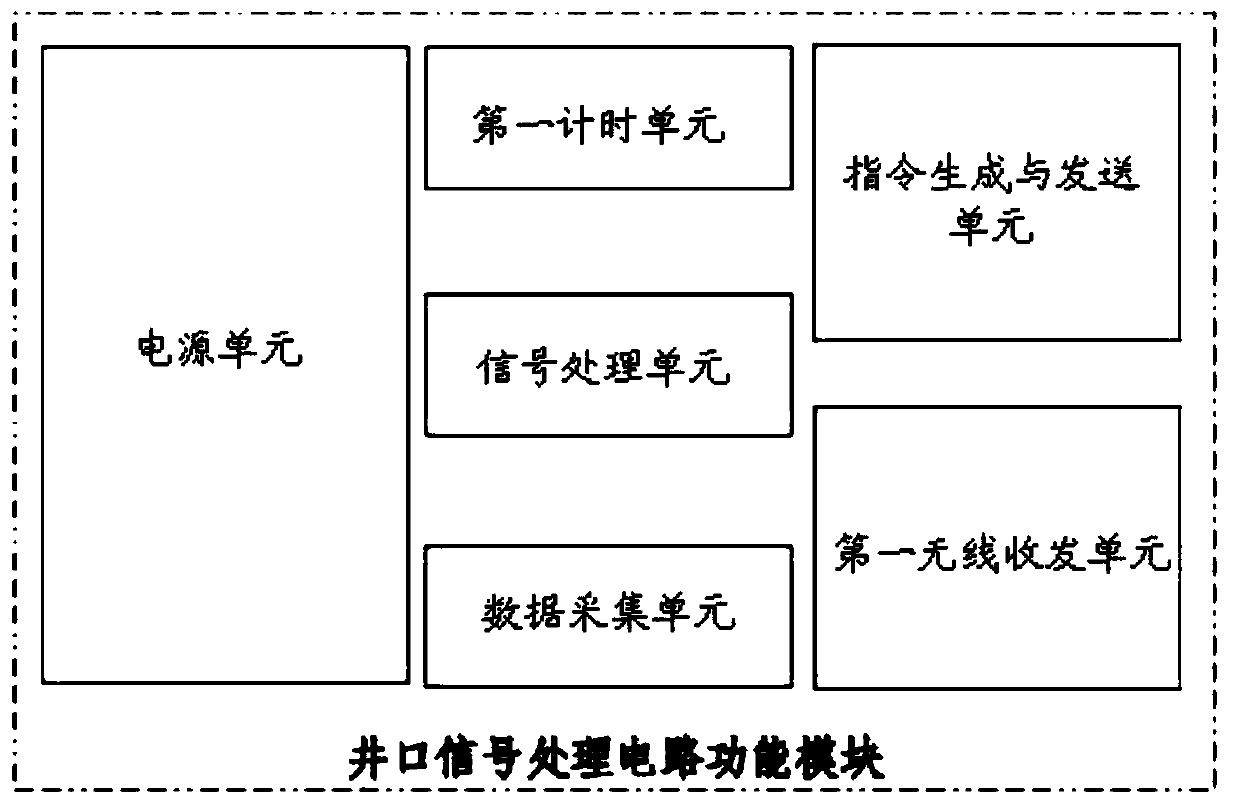

[0047] An embodiment of the present invention provides a wellhead oil-water two-phase flow static water cut measurement system, the system includes a wellhead oil-water two-phase flow static water cut measurement device and a signal processing subsystem; the wellhead oil-water two-phase flow static water cut measurement device is used for Static water cut measurement and pipeline pressure detection; the signal processing subsystem is used to acquire, transmit, and process the measurement data collected by the wellhead oil-water two-phase flow static water cut measurement device, and output cycle measurement control instructions and manual control instructions to control the wellhead oil-water The working state of the two-phase flow static moisture content measurement device.

[0048] The wellhead oil-water two-phase flow static water content measurement device includes a medium bin assembly, an on-off control valve group, an early warning processing module, a liquid inlet pipe ...

Embodiment 2

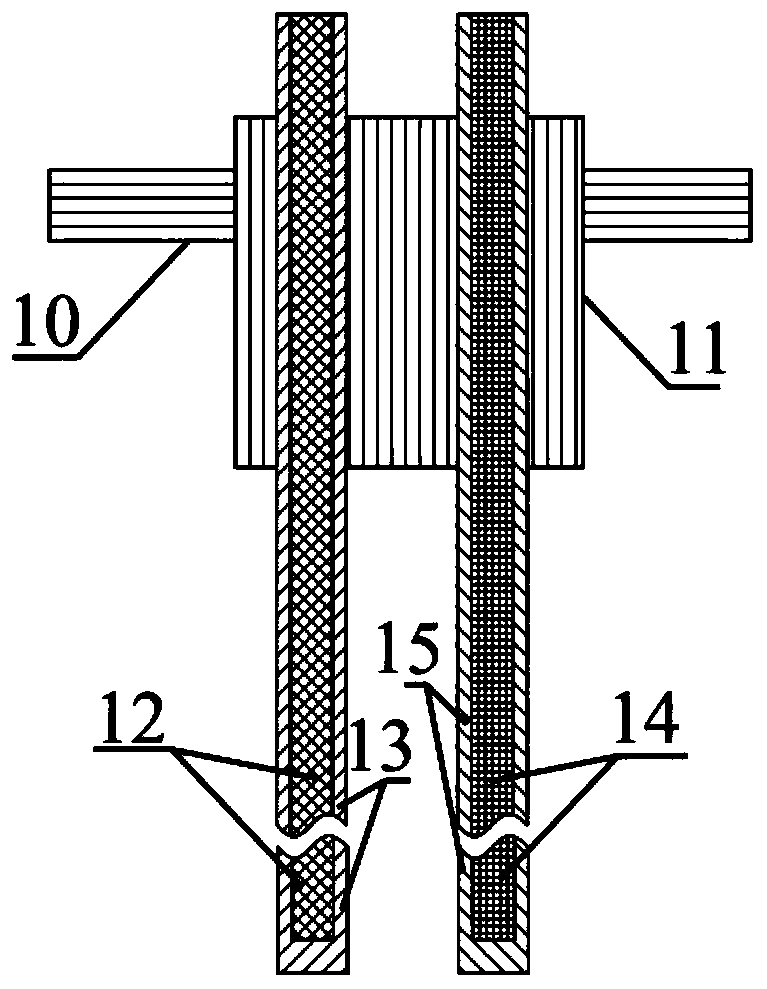

[0052] Such as Figure 1-2 As shown, a wellhead oil-water two-phase flow static water cut measurement system provided by an embodiment of the present invention includes a wellhead oil-water two-phase flow static water cut measurement device and a signal processing subsystem. The wellhead oil-water two-phase flow static water cut measurement device performs automatic measurement of static water cut and pipeline pressure monitoring through the on-off control valve group; the signal processing subsystem collects the signal data of the wellhead oil-water two-phase flow static water cut measurement device, Transmission, processing and cyclic measurement control, command transmission.

[0053] The wellhead oil-water two-phase flow static water cut measurement device provided by the embodiment of the present invention includes a medium assembly, an on-off control valve group, an early warning processing module, a liquid inlet pipeline assembly, a liquid outlet pipeline assembly, and ...

Embodiment 3

[0075] Such as figure 1 with Image 6 As shown, the wellhead oil-water two-phase flow static water cut measurement device has three states when it is working, namely the initial state, measurement state and early warning state, among which:

[0076] In the initial state, the No. 3 solenoid valve 18 is opened, No. 1 solenoid valve 16 and No. 2 solenoid valve 17 are closed, the electric valve 19 is closed, and the pressure gauge 20 detects the fluid pressure in the pipeline in real time, and the fluid passes through the liquid inlet in sequence on the flow route. Lan 22, liquid inlet four-way pipe 21, No. 3 solenoid valve liquid inlet installation flange 24, No. 3 solenoid valve 18, No. 3 solenoid valve liquid outlet installation flange 30, liquid outlet four-way pipe 27, outlet The liquid port flange 28 flows out of the device and the fluid is not measured.

[0077] When the wellhead oil-water two-phase flow static water cut measurement device is in the initial state and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com