Governance method of floor heave of mine roadway during mining

A mining roadway and roadway technology, which is applied in the direction of mining equipment, earthwork drilling, pillars/brackets, etc., can solve the problems of immature floor construction equipment, affecting the normal use of the roadway, wasting man-hours, etc., and achieves short installation time, easy operation, The effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

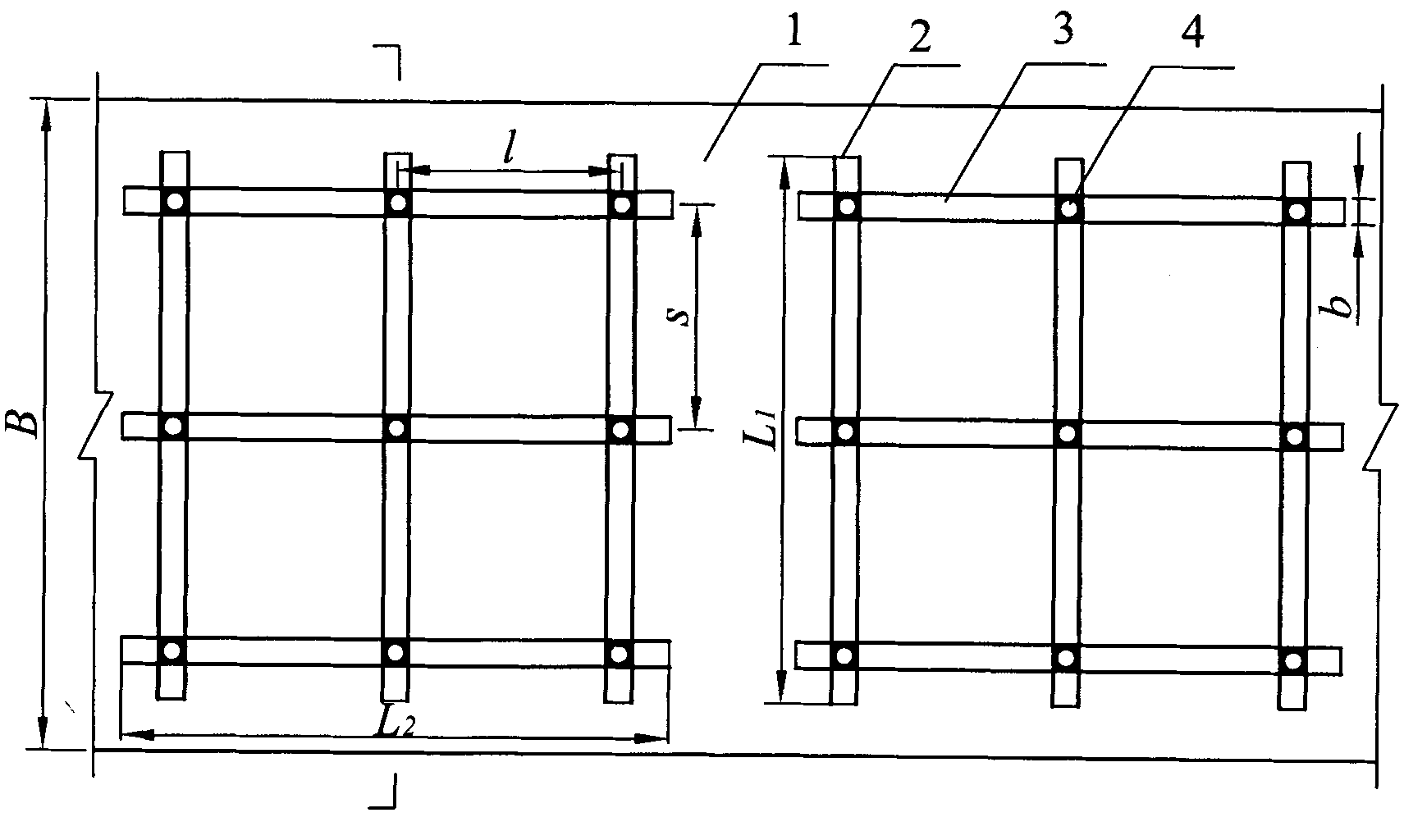

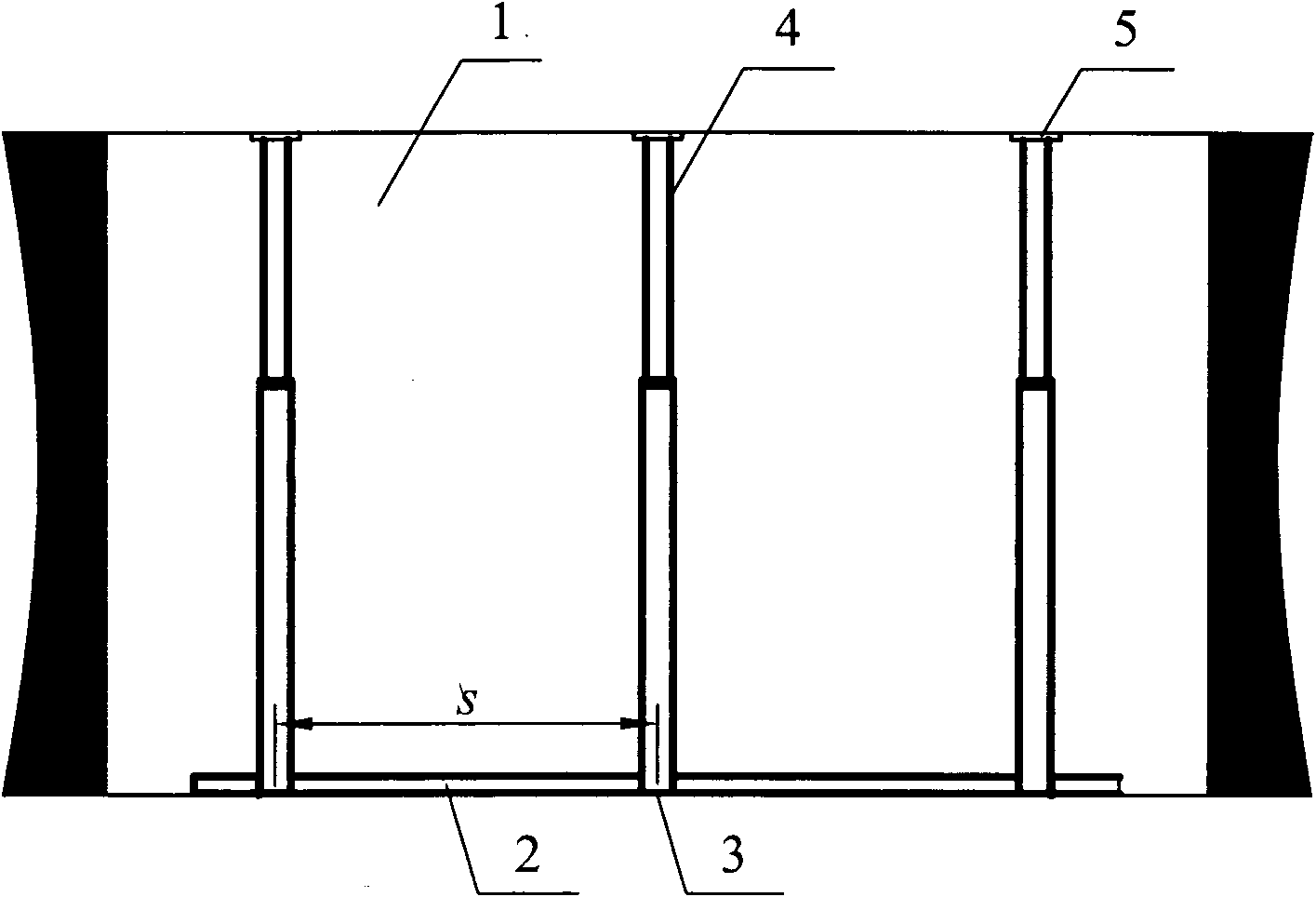

[0015] In the figure, within the length range affected by mining in front of the coal mining face, a pillar bottom beam structure composed of longitudinal channel steel beam 3 and transverse channel steel beam 2 is placed on the floor of mining roadway 1. A single hydraulic strut 4 is installed between the top plates, and the pressure of the top plate is transmitted to the bottom plate through the single hydraulic strut 4, and at the same time, the high support resistance of the single hydraulic strut 4 itself is used to achieve the purpose of controlling the bottom drum.

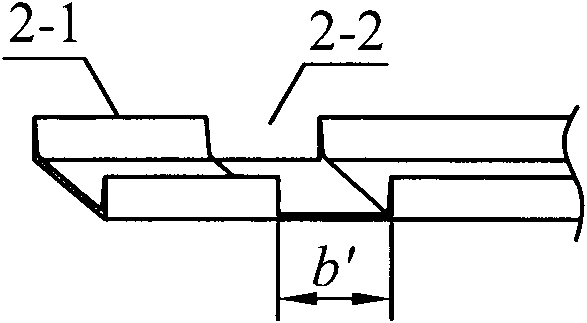

[0016] The roadway bottom drum control method during the mining period of the present invention first processes a plurality of channel steels 2-1 with notches 2-2 on the side of the channel steels on the ground, the channel steels are divided into transverse channel steel beams 2 and longitudinal channel steel beams 3, and Transport to the construction site; then stack the channel steel vertically and horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com