Method and system for eliminating organic matters in aluminium oxide production process

A production process and organic matter technology, applied in the field of organic matter removal methods and systems, can solve problems affecting the precipitation of organic matter, difficulty in filtration, loss of activity, etc., and achieve the effects of reduced production costs, good dissolution effects, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

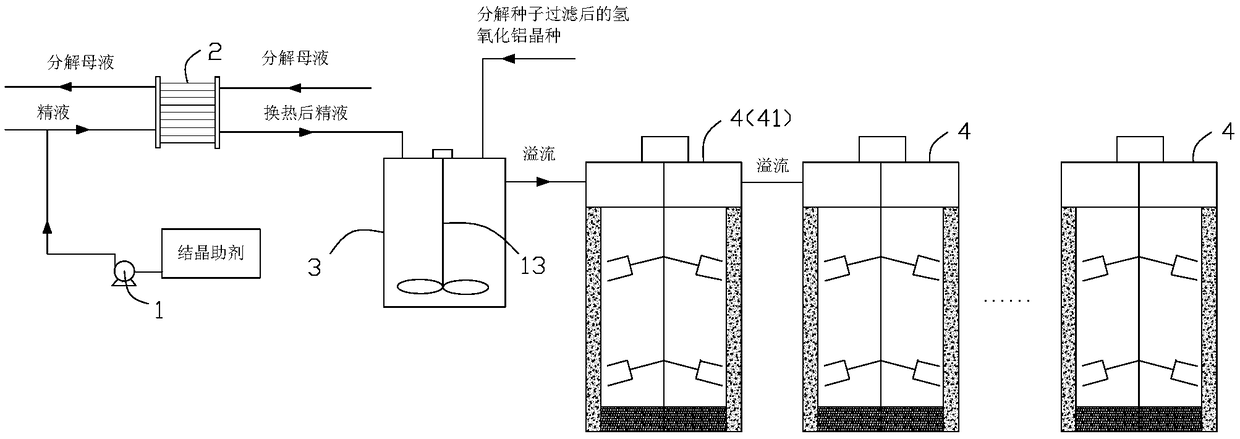

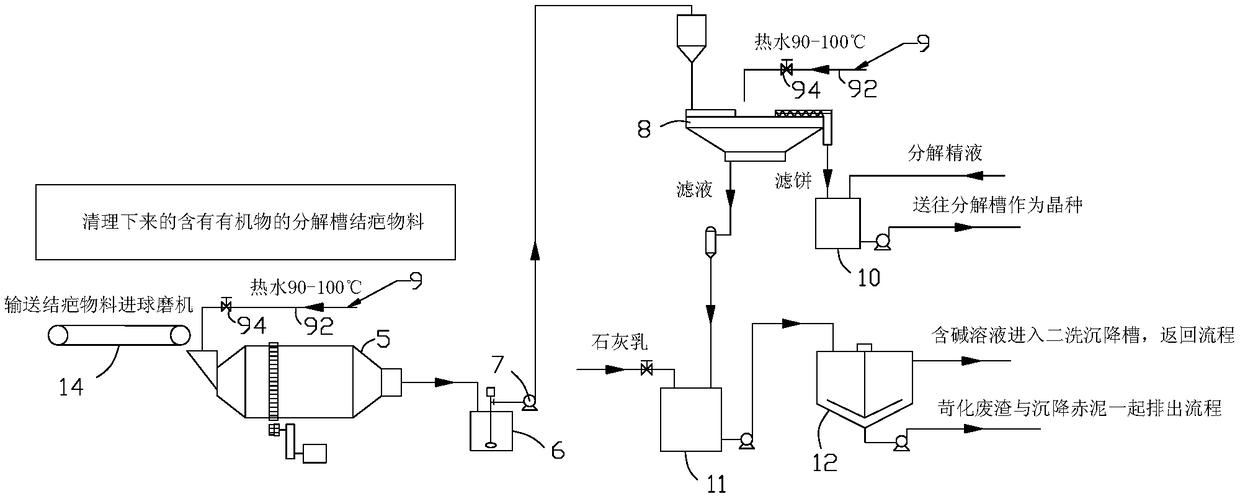

[0035] See also figure 1 and figure 2 , Embodiment 1 of the present invention provides a system for removing organic matter in the alumina production process, including a feeding pump 1, a heat exchanger 2, a mixing tank 3, a decomposition tank 4, a ball mill 5, a slurry tank 6, and a slurry pump 7 , Flat plate filter 8, water supply device 9, filter cake tank 10, causticizing tank 11 and settling tank 12.

[0036] The feeding pump 1 is connected to the inlet of the heat exchanger 2, so that the semen before the decomposition of aluminum hydroxide added with a crystallization aid is passed into the heat exchanger 2 to exchange heat with the decomposed mother liquor, and the outlet of the heat exchanger 2 is connected to the mixing tank 3 . In this embodiment, the heat exchanger 2 is a plate heat exchanger. It can be understood that in other embodiments, the heat exchanger 2 can also use other types of heat exchangers. A stirrer 13 is installed on the mixing tank 3 to stir ...

Embodiment 2

[0047] The elimination system and method of organic matter in the alumina production process of Example 2 are roughly the same as those of Example 1, except that in this embodiment, the amount of crystallization aid added is 10 parts per million of the volume flow rate of semen Five (15 volume PPM); the stirring speed in the mixing tank 3 is 87r / min, and the stirring time is 3min; the temperature of the hot water passing into the ball mill 5 and the flat disc filter 8 is 100°C; the decomposition is controlled by the heat exchange process The temperature of the first tank 41 was 62°C.

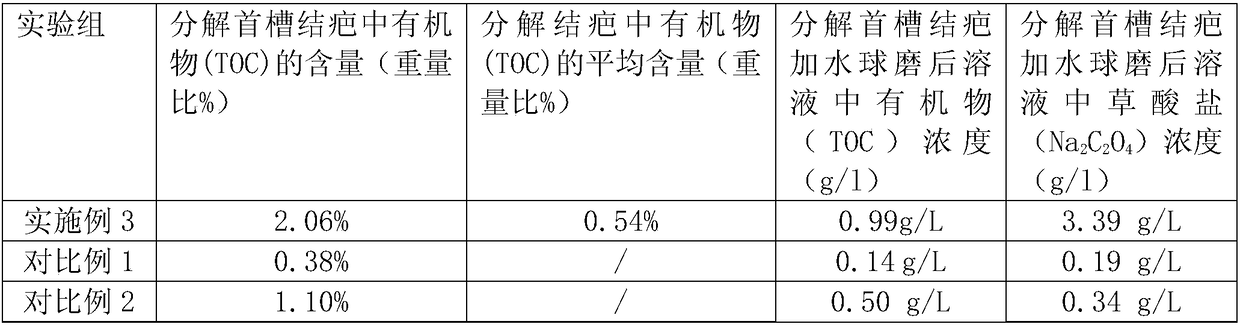

Embodiment 3

[0049] The elimination system and method of organic matter in the alumina production process of Example 3 are roughly the same as those of Example 1, except that in this embodiment, the amount of crystallization aid added is 2 parts per million of the volume flow rate of semen Ten (20 volume PPM); The stirring speed in the mixing tank 3 is 90r / min, and the stirring time is 2min; The temperature of the first tank 41 was 63°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com