Method for treating iron-containing dusts in steel plant by using melting gasification furnace

A technology for melting gasifiers and iron and steel plants, which is applied in the field of iron-containing dust in iron and steel plants, which can solve pollution and other problems, achieve the effects of reducing costs, low investment, and improving the strength of agglomerates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

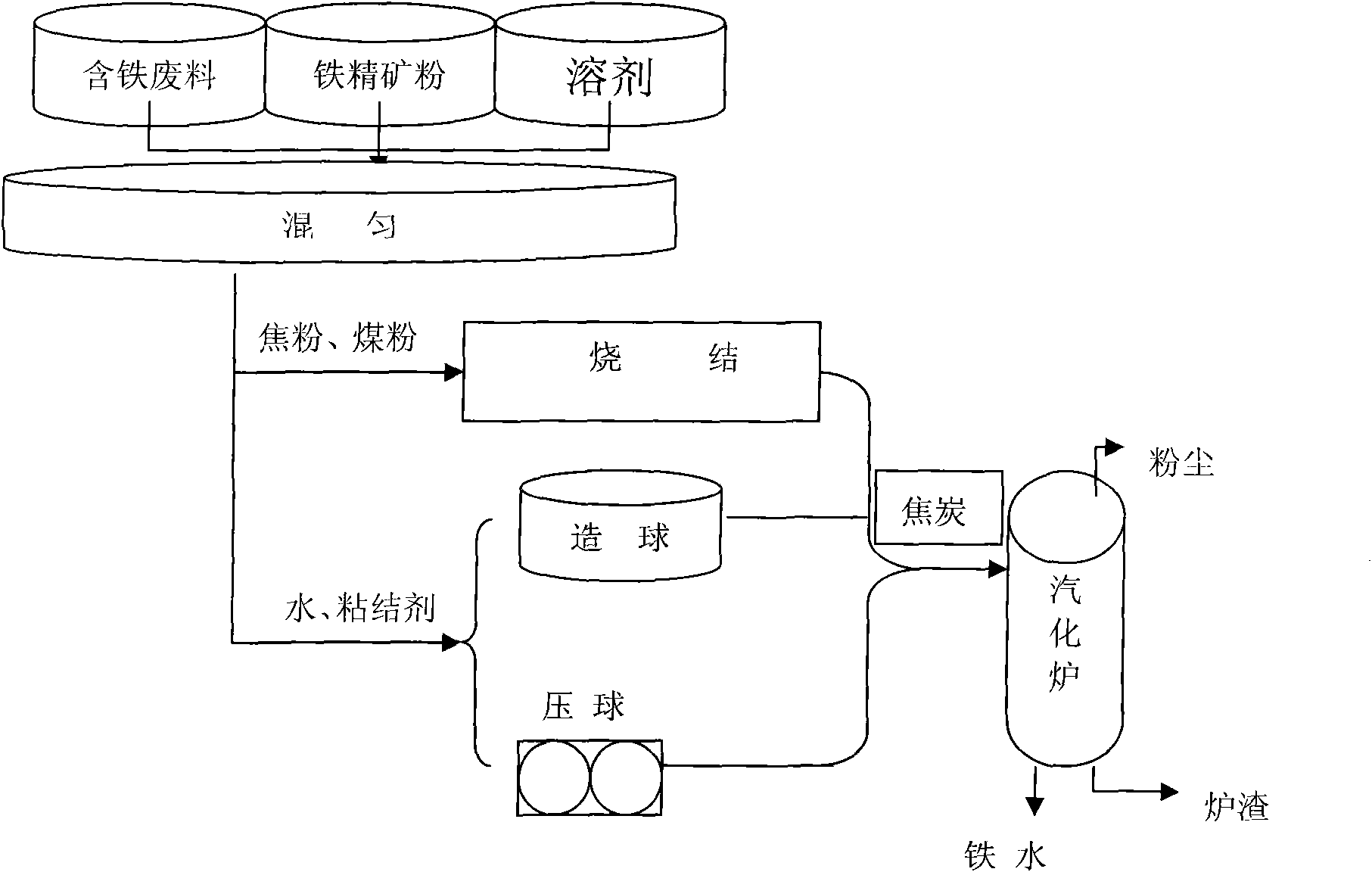

Method used

Image

Examples

Embodiment 1

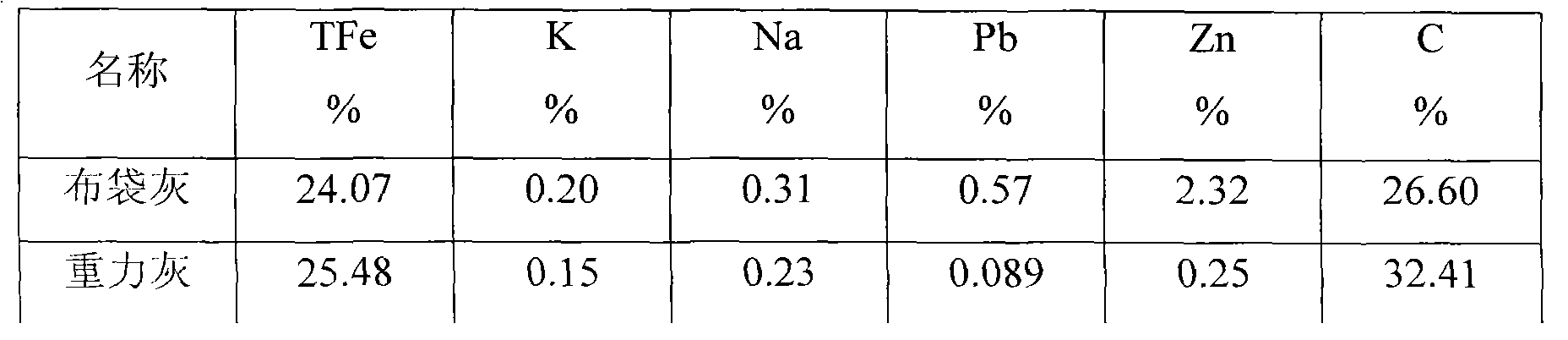

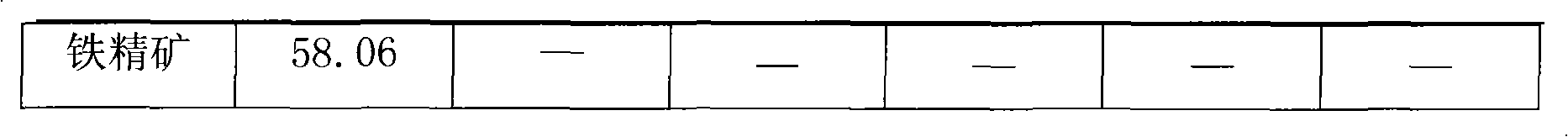

[0028] What this embodiment adopts is (see Table 1 for composition) blast furnace bag ash, blast furnace gravity ash, and add a certain amount of iron ore concentrate powder, reducing agent and binding agent, adjust carbon content at 15%~20%, binding Add 1% to 3% additives, mix well, add water, press into lumps, and after drying, spread the lumps into a high-wind-temperature melting-gasifier through a distribution system to smelt molten iron. The content of harmful elements such as potassium, sodium, lead and zinc in molten iron is very low and can be ignored, and the content of zinc in blast furnace dust has increased.

[0029] Table 1 embodiment uses raw material composition (mass fraction)

[0030]

[0031]

Embodiment 2

[0033] The raw materials used in this example are the same as those in Example 1. The mixed raw materials are mixed with coke powder so that the total carbon content is about 10%. The speed is 1.55m / min, the ignition temperature is 1110°C, and the air pressure is 2.5KPa. After the sintered ore is cooled, it is distributed into the high-temperature melting and gasifier through the distribution system to smelt molten iron. The content of potassium, sodium, lead and zinc in molten iron is very small and can be ignored, and the content of zinc in blast furnace dust has increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com