Method for matching mixed coal with relatively high heating value

A technology with high calorific value and high calorific value, which is applied in the field of ironmaking and can solve problems such as the lack of research on mixing and matching of pulverized coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

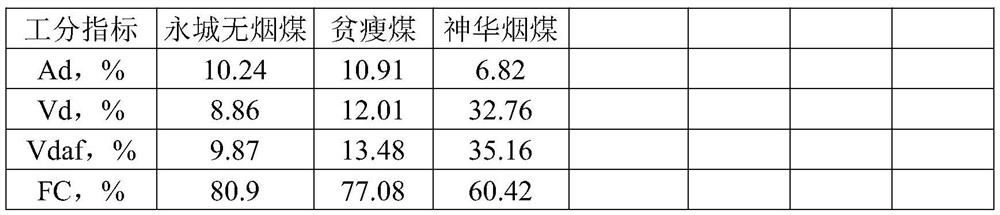

[0022] Embodiment 1: the determination of mixed coal components and proportioning

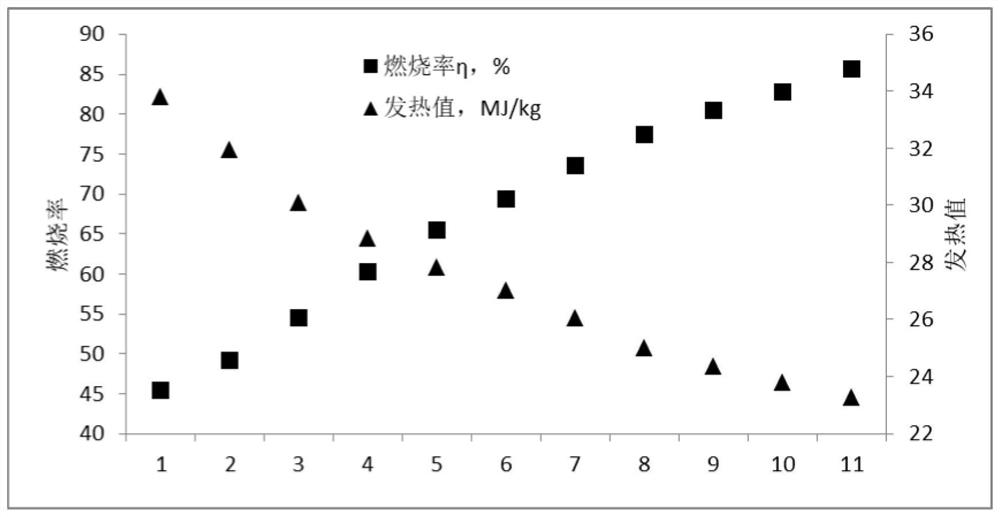

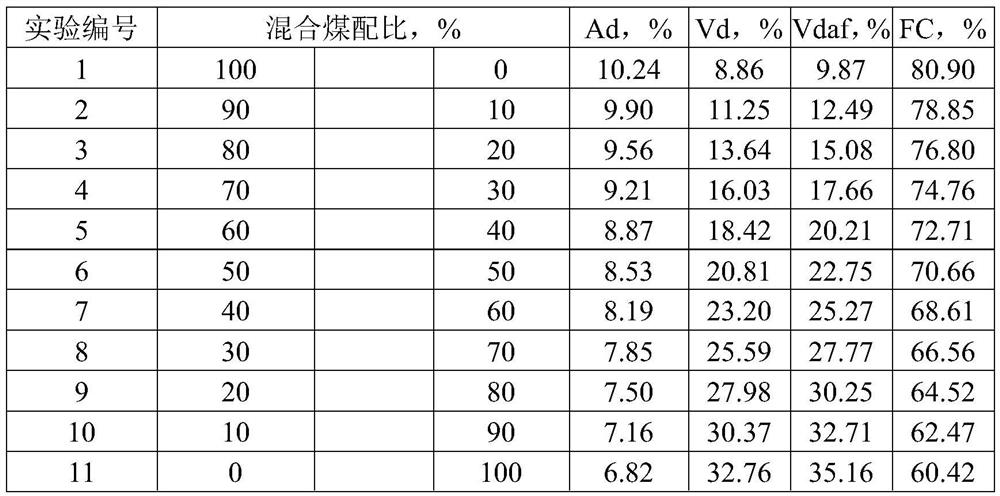

[0023] Several groups of mixed coal experimental schemes were designed using the orthogonal method, and the details of each scheme are shown in Table 1:

[0024] Table 1 Experimental scheme of combustion performance of mixed coal

[0025]

[0026]

[0027] It can be seen from Table 1 that the dry basis volatile content is 8.86% under the condition of full anthracite injection, and 32.76% under the condition of full bituminous coal injection. The fixed carbon is gradually reduced, and the ash content is also gradually reduced. In experiment number 6, when the mixed coal is 50% anthracite + 50% bituminous coal, the fixed carbon is 70.66%, and the volatile matter on a dry basis is 20.81%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com