A beneficiation process for processing refractory mixed iron ore containing various iron minerals

A technology for iron ore and iron minerals is applied in the field of beneficiation technology for processing refractory mixed iron ore containing various iron minerals, which can solve the problem of uneven distribution of iron minerals in particle size and unsatisfactory quality of iron concentrate. , iron minerals cannot be effectively recovered, etc., to achieve the effect of benefiting the grinding efficiency and ability, improving the effect, and benefiting the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with drawings and embodiments.

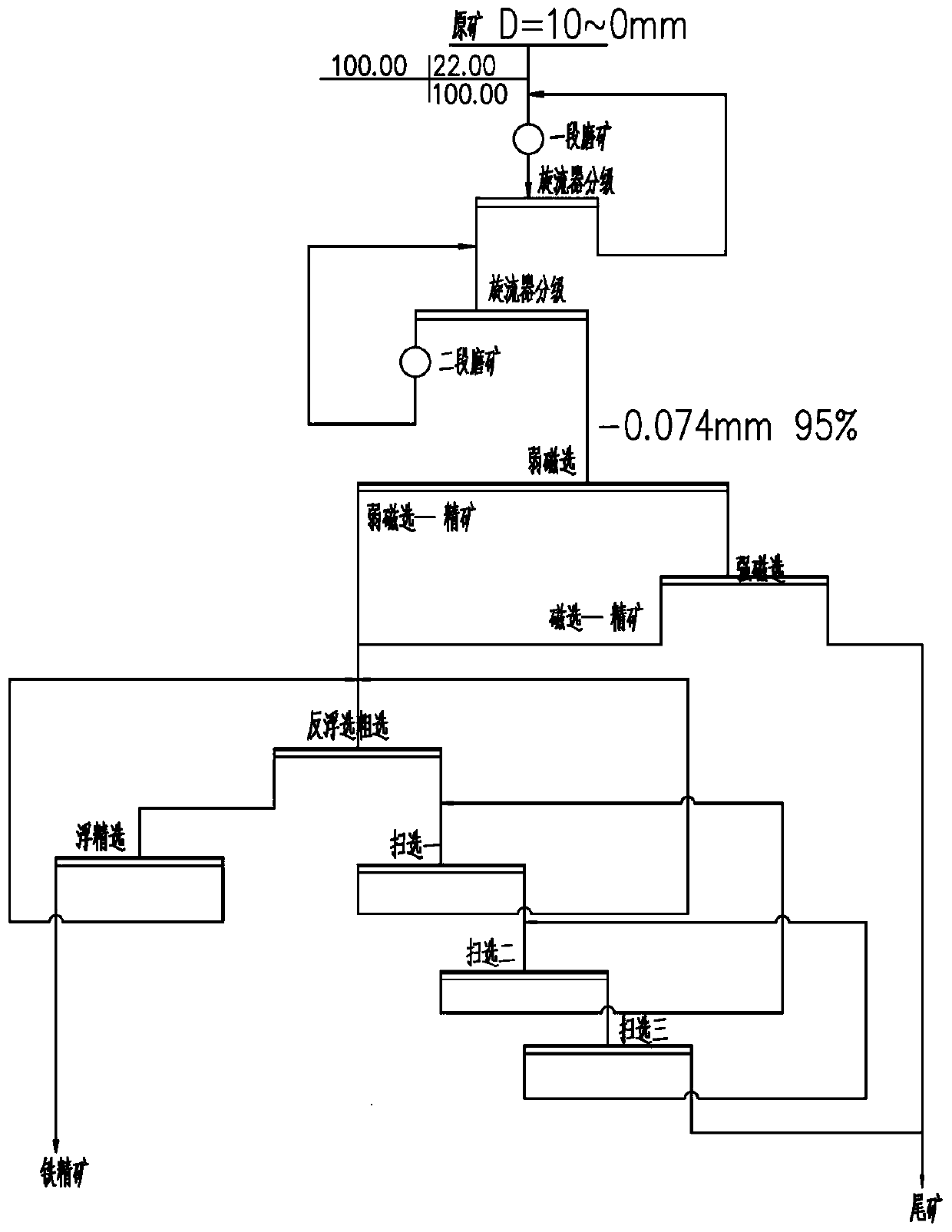

[0032]A concentrator in Gansu adopts the original process to process a typical mixed iron ore whose main useful minerals are specularite, hematite, siderite and a small amount of magnetite. Due to the high content of specularite and siderite in production , resulting in the final concentrate grade produced by the original technological process being only 60%.

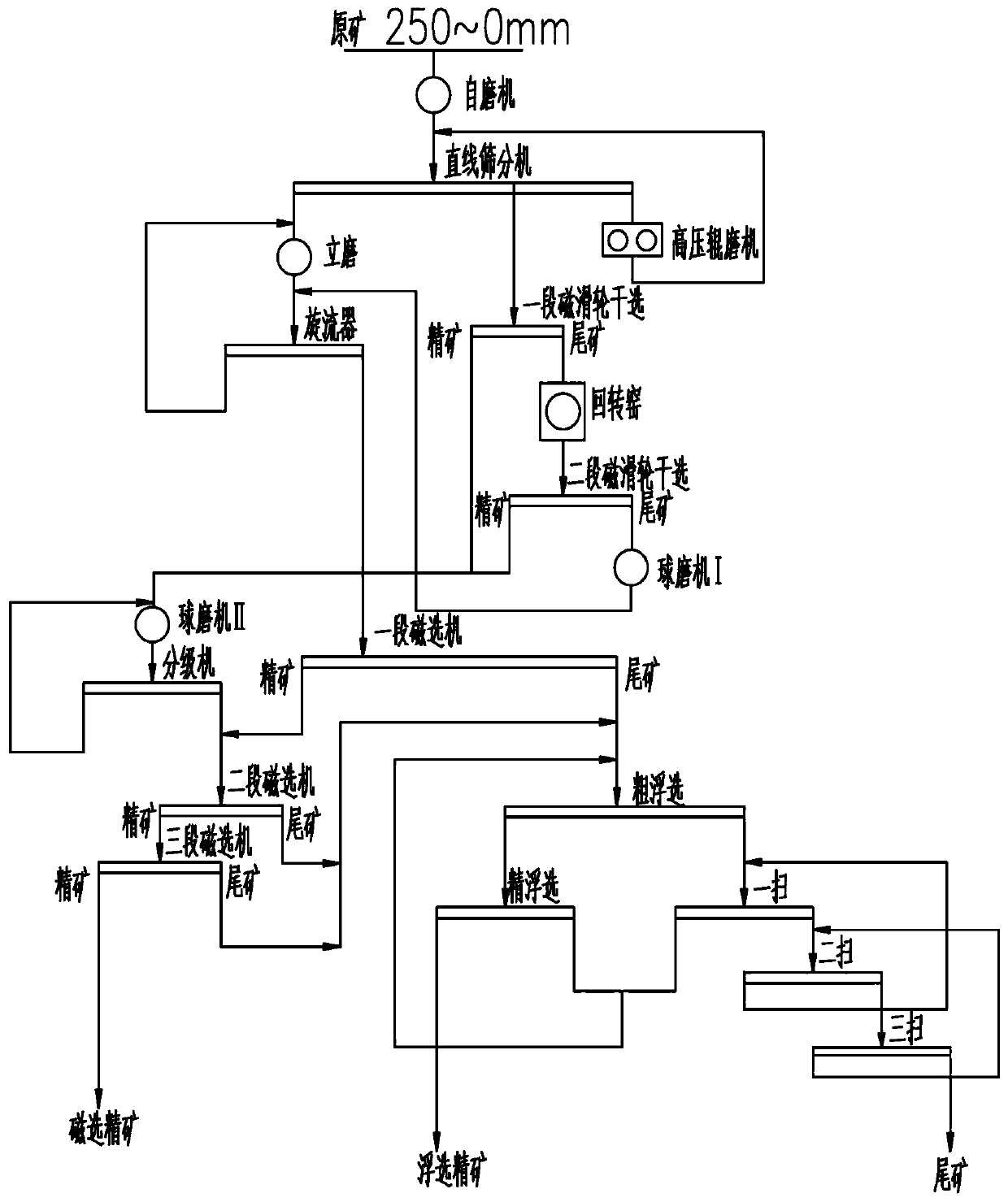

[0033] Such as figure 2 As shown, a kind of beneficiation process for processing refractory mixed iron ore containing various iron minerals of the present invention is characterized in that: the raw ore with iron grade of 22% and particle size of 250mm-0 mm is fed into a section of autogenous mill , to obtain self-grinding products with a particle size of 30mm-0 mm, which are fed into a double-layer linear vibrating screen to obtain three screening products with a particle size of +10mm, 10mm-1mm and 1mm-0mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com