A kind of method adopting lignin as reducing agent to produce direct reduced iron

A technology for lignin and reduced iron, applied in fluidized bed furnaces, furnaces, furnace types, etc., can solve the problems of unutilized lignin, complicated production process, increase production cost, etc., and achieve the effect of increasing fixed carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Take lignin as a reducing agent, mix it with iron ore powder according to C / O=1 (molar ratio), then take 5g sample and put it into a cylindrical mold for cold pressing, the pressure is 12KPa, and the time is 3min. The diameter of the sample taken is 10mm and the height is 10mm. Wherein the lignin particle size exceeds 40 mesh sieve, and the content of iron ore powder particle size exceeds 200 mesh sieve is 92%.

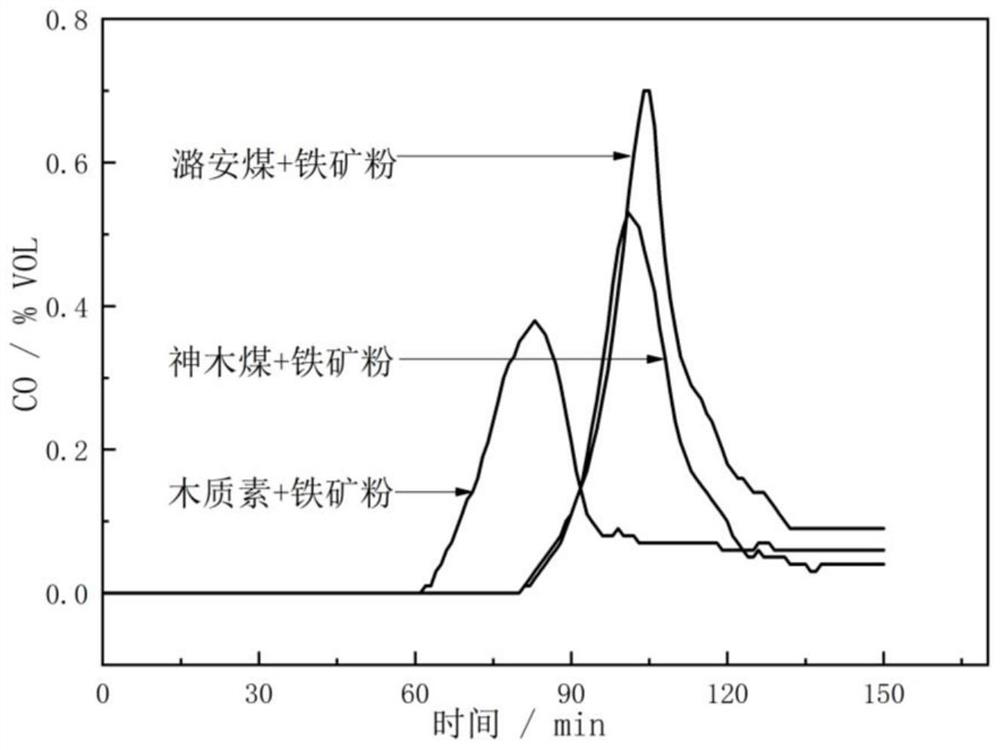

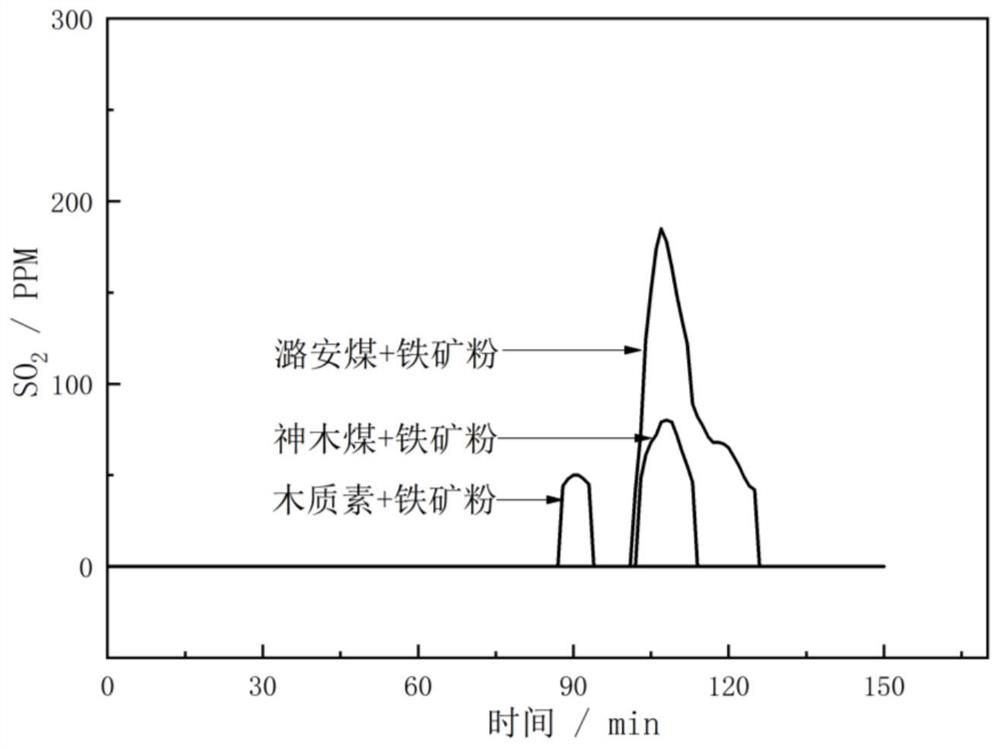

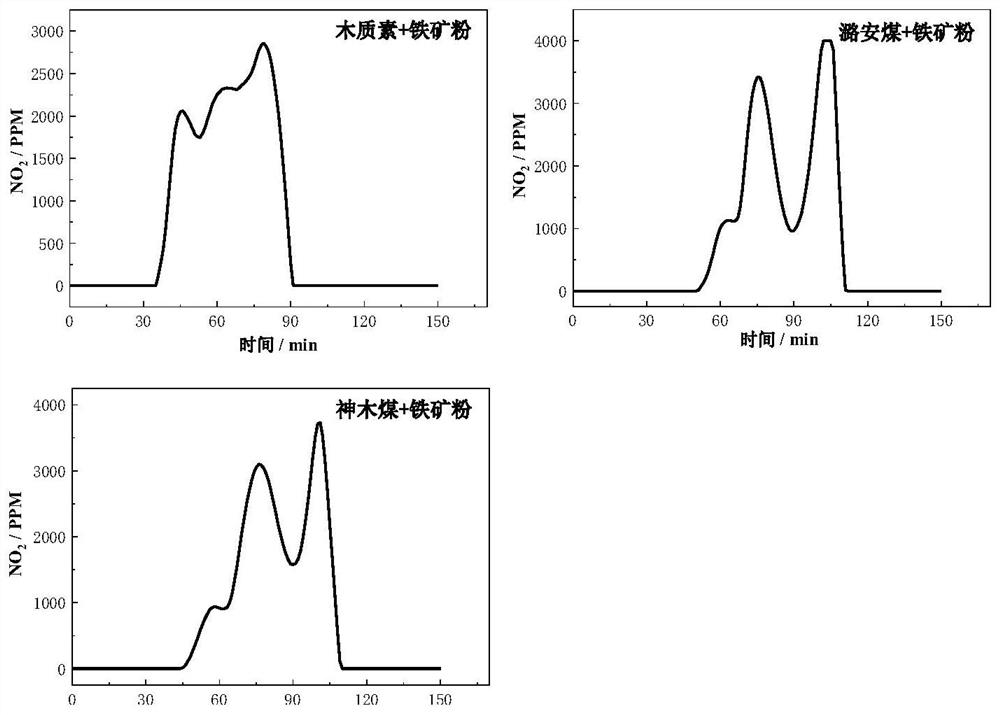

[0048] Then put the pressed cylindrical sample into the reduction furnace and heat it up to 600°C for 30 minutes with the furnace temperature rising at a rate of 10°C / min, then raise the temperature to 1100°C for 30 minutes, and finally cool down to room temperature with the furnace, and flow through the whole process 3L / h nitrogen. Detection of changes in gas composition during the reaction, including NO 2 , NO, SO 2 and CO 2 , and detect the content of total iron and metallic iron of direct reduced iron after the reaction, and observe its microscopic morp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com