Blast furnace cinder water quenching processing unit

A blast furnace slag and treatment device technology, which is applied in the field of iron-making blast furnace slag treatment devices, can solve the problems of large amount of supplementary water for slag flushing, high labor intensity for slag cleaning, complicated equipment and facilities, etc. The effect of forward running of blast furnace and prolongation of equipment life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

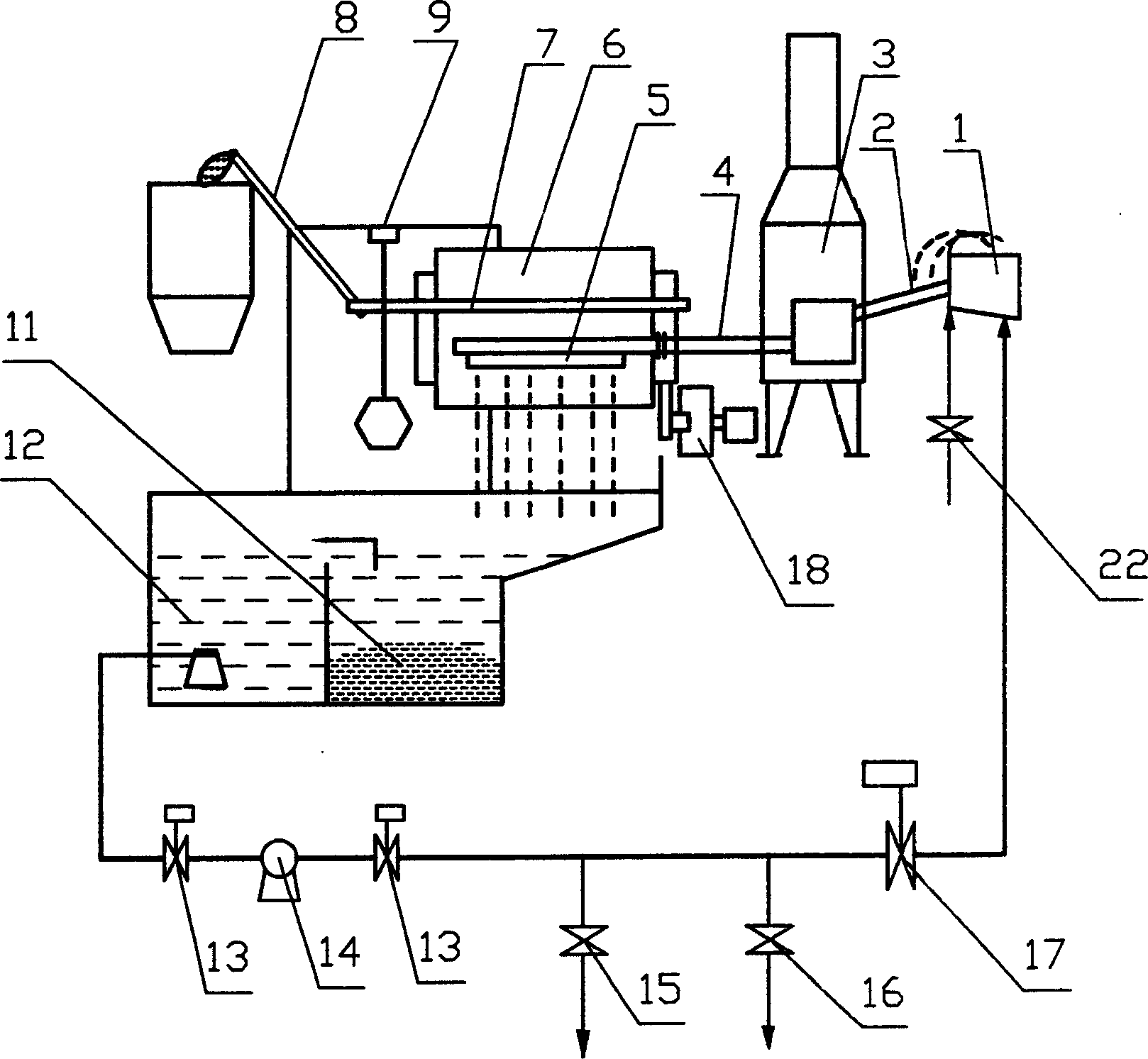

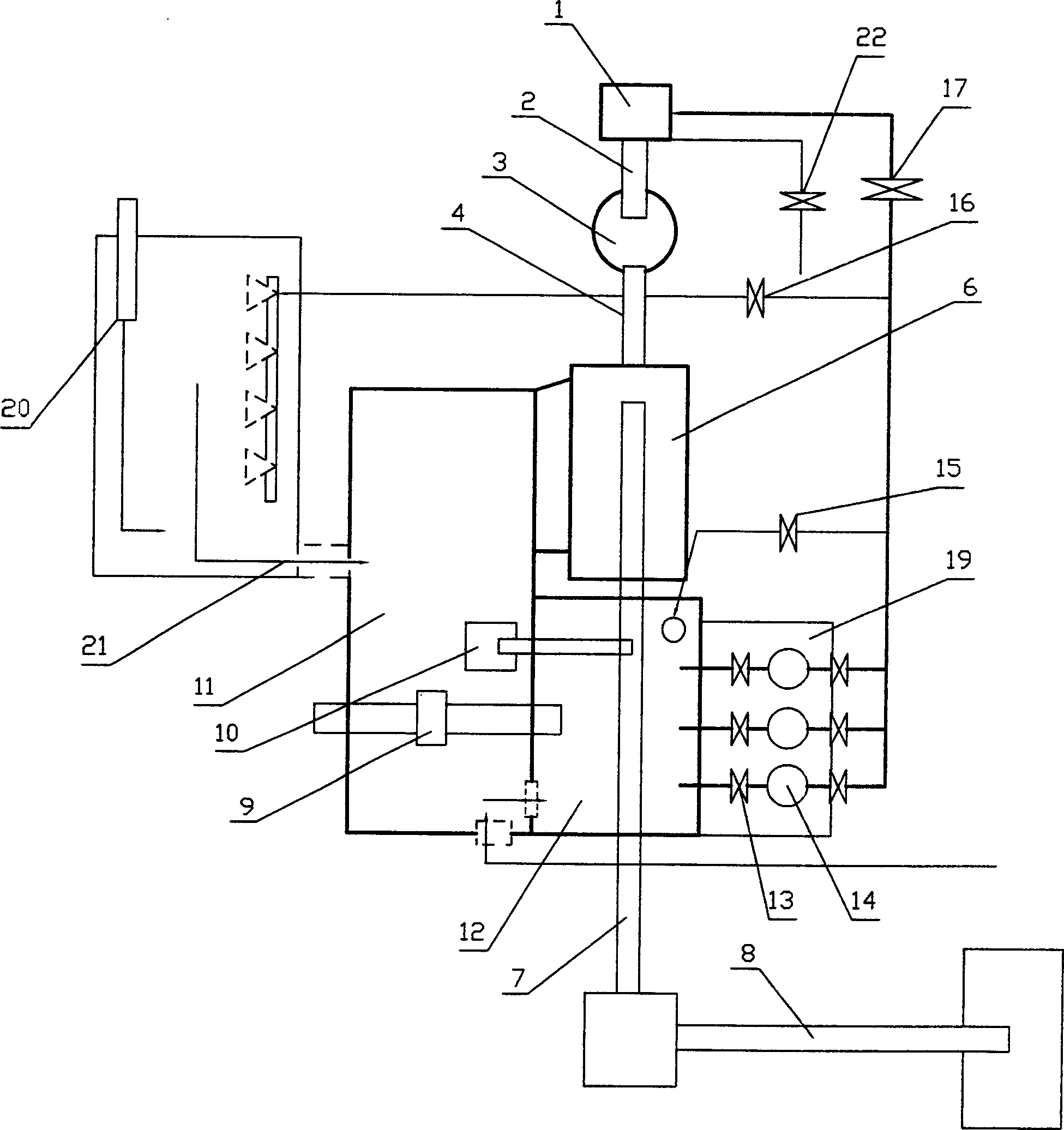

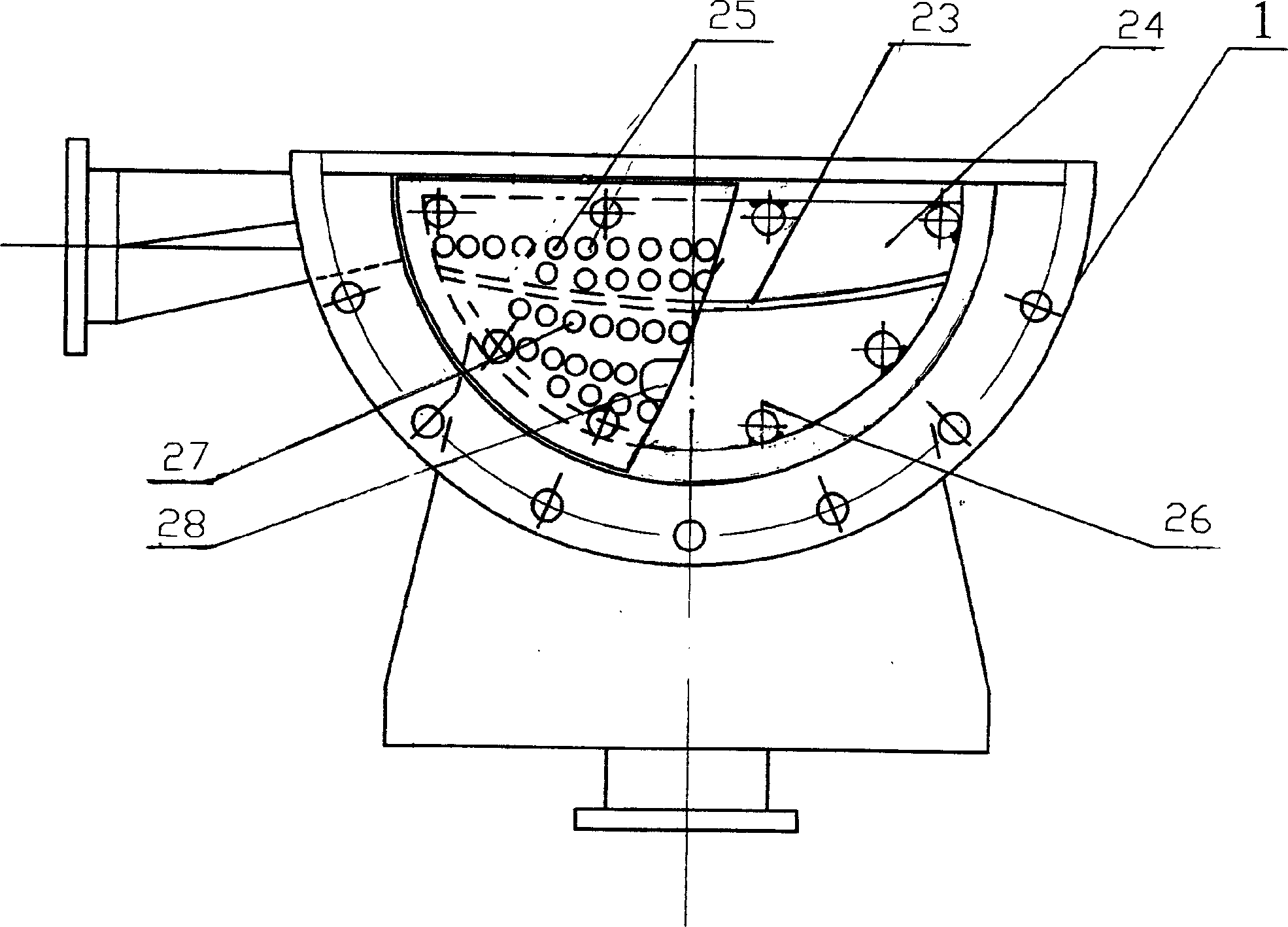

[0018] From Figure 1 to Figure 2 It can be seen that the embodiment of the present invention is composed of a granulator 1, a water slag ditch 2, a water slag tank 3, a connecting pipe 4, a distributor buffer tank 5, a drum filter 6, a belt conveyor 7 in a cylinder, and a transfer belt conveyor 8 , grab crane 9, chute funnel 10, sedimentation tank 11, reservoir 12, electro-hydraulic gate valve 13, slag flushing pump 14, pressure relief valve 15, dry slag pit sprinkler valve 16, slag flushing gate valve 17, drum drive 18. Composed of pump pit 19, furnace top washing water return pipe 20, dry slag pit return ditch 21, and industrial water purification valve 22. A water slag ditch 2 is set under the granulator 1, connecting the granulator 1 and the water slag tank 3, the upper part of the water slag tank is provided with an exhaust hood, the lower part is connected with the connecting pipe 4, and the distributor buffer tank 5 connected with the connecting pipe 4 extends into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com