Preparation method of vanadium titanomagnetite hot briquette

A technology of vanadium-titanium magnetite and hot briquetting, applied in furnaces, shaft furnaces, furnace types, etc., can solve problems that are not conducive to energy saving and coke reduction of blast furnaces, increase sintering costs, increase production costs, etc., and achieve good market application prospects , strong adaptability of raw materials, and the effect of improving the level of smelting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

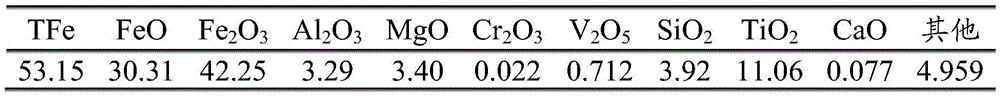

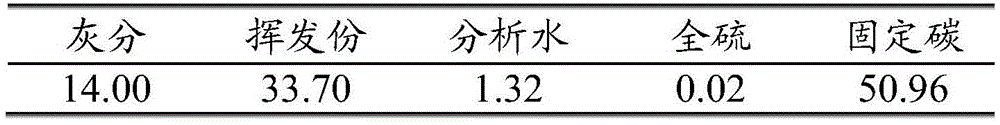

[0017] First, the vanadium-titanium magnetite, bituminous coal, and metallurgical lime are crushed and screened, and then the carbon ratio is (FC / O) of 0.8, that is, the vanadium-titanium magnetite is 80.24wt%, the bituminous coal is 18.06wt%, and the metallurgical The proportion of lime is 1.70wt% after mixing. The composition of the vanadium-titanium magnetite of this embodiment is shown in Table 1. The vanadium-titanium magnetite has a particle size of less than 0.15mm, and the vanadium-titanium magnetite with a particle size of less than 0.074mm accounts for the total vanadium-titanium magnetite by volume percentage. 40.86% of iron ore. The composition of the bituminous coal in this embodiment is shown in Table 2, wherein the colloidal layer index of the bituminous coal is 11, the particle size of the bituminous coal is less than 0.15mm, and the bituminous coal with the particle size less than 0.074mm accounts for 70.34% of the total bituminous coal by volume percentage. M...

Embodiment 2

[0022] First, the vanadium-titanium magnetite, bituminous coal, and metallurgical lime are crushed and screened, and then the carbon ratio (FC / O) is 1.2, that is, the vanadium-titanium magnetite is 72.24wt%, and the coal powder is 23.63wt%. The proportion of metallurgical lime is 4.13wt% after mixing, so as to obtain a uniformly mixed material. Wherein, the component content and particle size composition of each component in the uniformly mixed material are the same as those in Example 1.

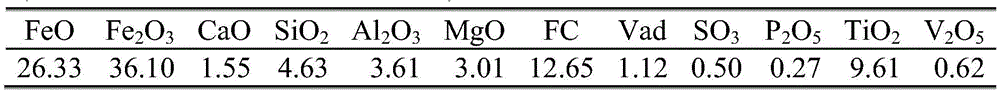

[0023] Second, heat the uniformly mixed materials so that the temperature of the uniformly mixed materials after heating is 200°C. After that, the heated material is hot pressed to form an ellipsoidal vanadium-titanium magnetite hot-pressed block with a size of 21mm×19mm×13mm. Among them, the linear pressure of the roller ball press is 6.0t / cm. The main chemical composition of the hot-pressed vanadium-titanium magnetite obtained after pressing is shown in Table 4, where the basicity of the h...

Embodiment 3

[0027] First, the vanadium-titanium magnetite, bituminous coal, and metallurgical lime are crushed and screened, and then the carbon ratio is (FC / O) of 1.4, that is, the vanadium-titanium magnetite is 70.22wt%, and the coal powder is 28.15wt%. The metallurgical lime is mixed with a proportion of 1.63wt% to obtain a uniformly mixed material. Wherein, the component content and particle size composition of each component in the uniformly mixed material are the same as those in Example 1.

[0028] Second, heat the uniformly mixed materials so that the temperature of the uniformly mixed materials after heating is 280°C. After that, the heated material is hot pressed to form an ellipsoidal vanadium-titanium magnetite hot-pressed block with a size of 38mm×30mm×173mm. Among them, the linear pressure of the roller ball press is 6.0t / cm. The main chemical components of the hot-pressed vanadium-titanium magnetite obtained after pressing are shown in Table 5, wherein the alkalinity of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com