Control method for eliminating horizontal-vibration linear offset of tail of short-process thin strip steel

A control method and technology for thin strip, applied in the field of hot-rolled strip manufacturing, can solve the problem of unstable process of ultra-thin strip, achieve high-stability large-scale production, easy operation, and reduce the occurrence of defective products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Embodiment 1: SPHC-B with a specification of 1.2mm*1219mm is produced.

[0096] ① Centering of mill guide plate:

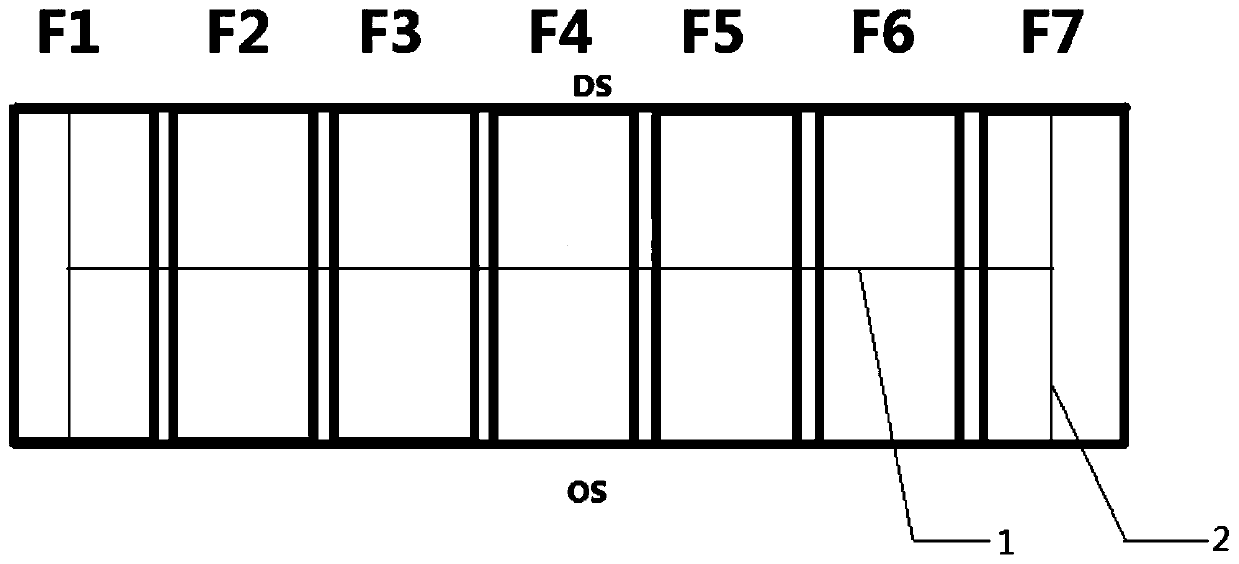

[0097] frame F2 F3 F4 F5 F6 F7 Alignment correction -2 -2 3 0 2 -2

[0098] ②Looper angle:

[0099] rack number Turning small amount difference (°) F1 4 F2 4 F3 4 F4 3 F5 3 F6 3

[0100] ③Rolling force and roll bending force at the end of rolling:

[0101] rack number Rolling force (KN) Bending force (KN) F5 16500 786 F6 12000 570 F7 9500 675

[0102] ④Water system shutdown sequence:

[0103]

[0104] ⑤Work roll rolling tonnage:

[0105] Finished product thickness / mm End of service of work rolls 1.2 848.303 tons

[0106] ⑥ Baking temperature:

[0107] Finished product thickness / mm Baking temperature (°C) Temperature difference between head and tail (℃) 1.2 1165 5

[0108] Effect: There was ...

Embodiment 2

[0109] Embodiment 2: Production of Q235B with a specification of 1.4mm*1250mm.

[0110] ① Centering of mill guide plate:

[0111] frame F2 F3 F4 F5 F6 F7 Alignment correction -2 -3 3 0 2 -2

[0112] ②Looper angle:

[0113] rack number Turning small amount difference (°) F1 4 F2 4 F3 4 F4 3 F5 3 F6 3

[0114] ③Rolling force and roll bending force at the end of rolling:

[0115] rack number Rolling force (KN) Bending force (KN) F5 17800 689 F6 12600 587 F7 9500 692

[0116] ④Water system shutdown sequence:

[0117]

[0118] ⑤Work roll rolling tonnage:

[0119] Finished product thickness / mm End of service of work rolls 1.4 887.43 tons

[0120] ⑥ Baking temperature:

[0121] Finished product thickness / mm Baking temperature (°C) Temperature difference between head and tail (℃) 1.4 1178 7

[0122] Effect: There was ...

Embodiment 3

[0123] Embodiment 3: Production of Q235B with a specification of 1.8mm*1500mm.

[0124] ① Centering of mill guide plate:

[0125] frame F2 F3 F4 F5 F6 F7 Alignment correction -2 -2 3 0 2 -2

[0126] ②Looper angle:

[0127] rack number Turning small amount difference (°) F1 4 F2 4 F3 4 F4 3 F5 3 F6 3

[0128] ③Rolling force and roll bending force at the end of rolling:

[0129] rack number Rolling force (KN) Bending force (KN) F5 16800 309 F6 14100 402 F7 9900 543

[0130] ④Water system shutdown sequence:

[0131]

[0132] ⑤Work roll rolling tonnage:

[0133] Finished product thickness / mm End of service of work rolls 1.8 1142.63 tons

[0134] ⑥ Baking temperature:

[0135] Finished product thickness / mm Baking temperature (°C) Temperature difference between head and tail (℃) 1.8 1178 8

[0136] Effect: There was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com