Grade-adjustable cylindrical magnetic separator

A cylindrical magnetic separator and adjustable technology, applied in the fields of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of increasing enterprise investment and operating costs, expensive mixing facilities, and complicated raw material procurement, etc. Reduce investment and operating costs, increase silica content, and improve economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

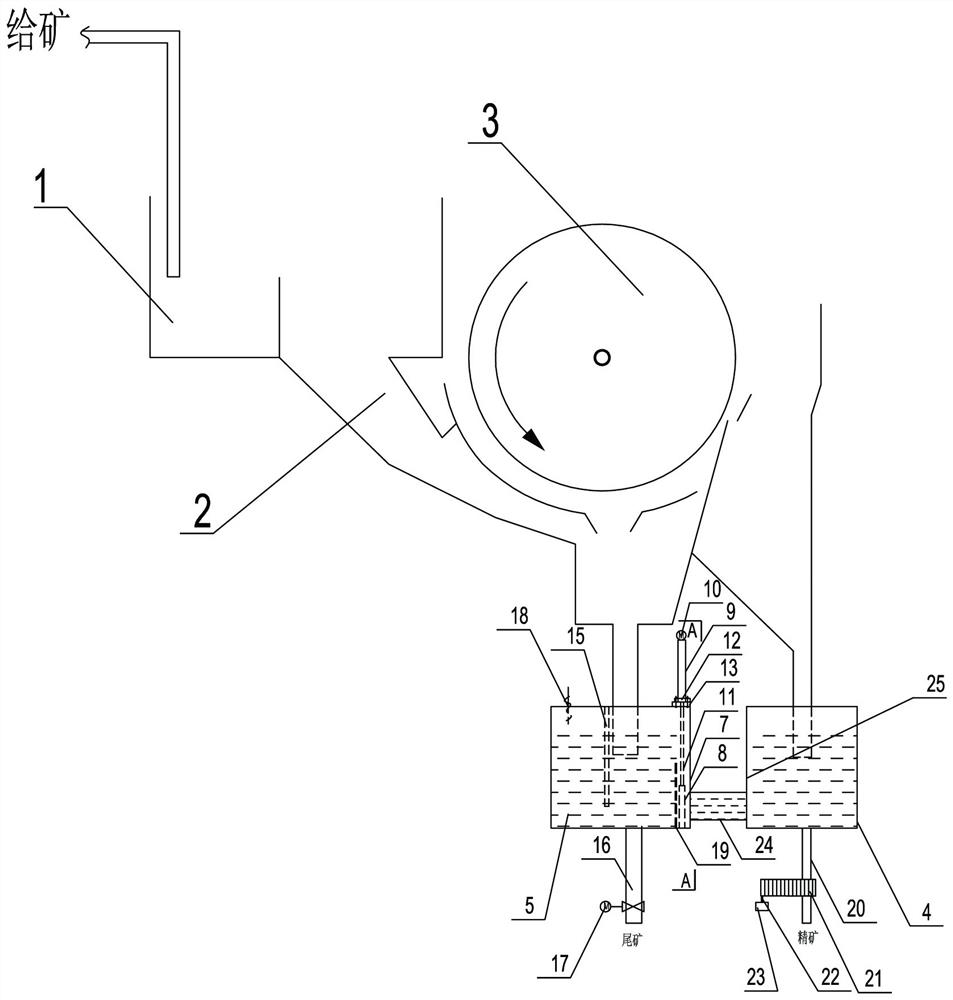

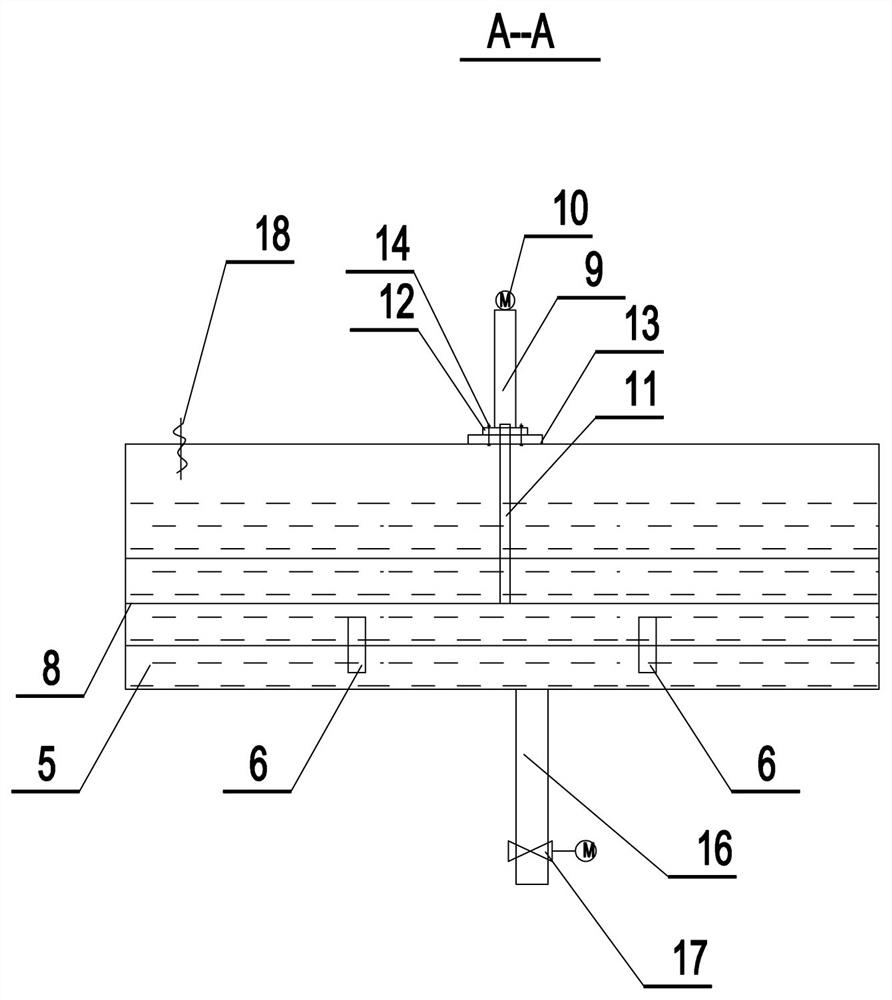

[0022] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 , 2 As shown, a kind of adjustable grade drum type magnetic separator of the present invention comprises the ore feeding box 1 of the drum type magnetic separator, the sorting tank 2, the sorting drum 3, the concentrate box 4, and the concentrate box discharge ore Pipe 20, tailings box 5, tailings box ore discharge pipe 16 and control box, described concentrate box 4 is connected with the concentrate port of sorting tank 2, and described tailings box 5 is connected with the bottom of the sorting tank The tailings discharge outlet is connected, and it is characterized in that a long partition plate 15 is arranged along the length direction of the tailings box 5, and the partition plate 15 divides the tailings box into a left box body and a right side box body. Two parts of the box body, the upper edge of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com