Control method for eliminating upwarp phenomenon of short-process ultra-thin strip steel

A control method and ultra-thin strip technology, which is applied in the field of hot-rolled strip manufacturing, can solve problems such as process instability of ultra-thin strip steel, achieve large-scale production with high stability, easy operation, and solve the effects of process instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: producing SPHC-B with a thickness of 0.8 mm.

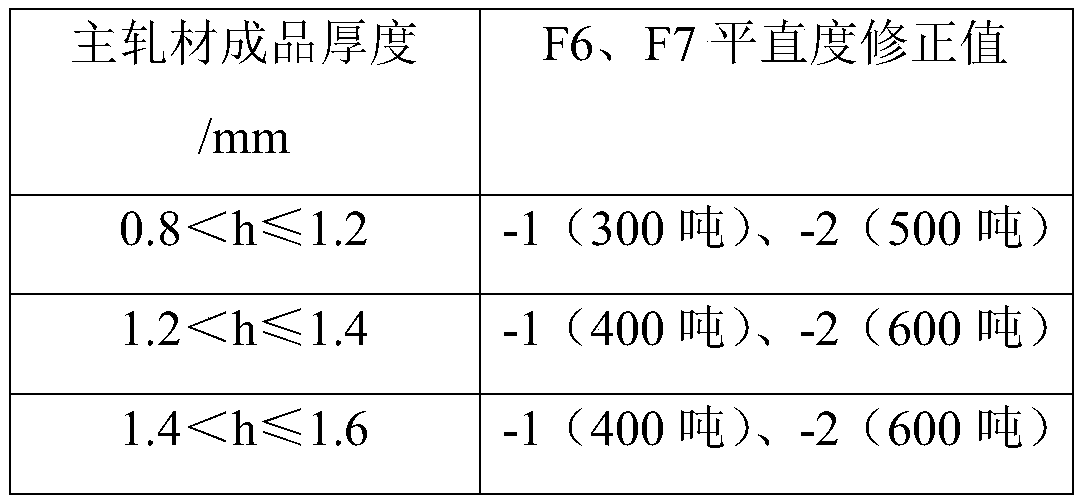

[0051] ①Rolling mill work roll pressure:

[0052]

[0053] ② Strip threading speed:

[0054] Finished product thickness / mm Strip head threading speed m / s 0.8 9.41

[0055] ③Sequence of dedusting water:

[0056]

[0057] ④Slight bilateral wave rolling:

[0058]

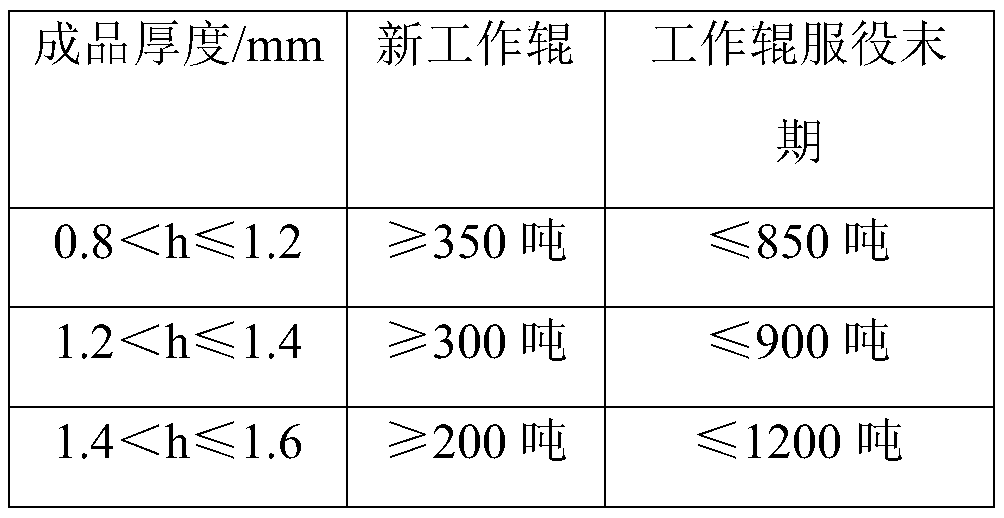

[0059] ⑤ Uneven wear of work rolls:

[0060]

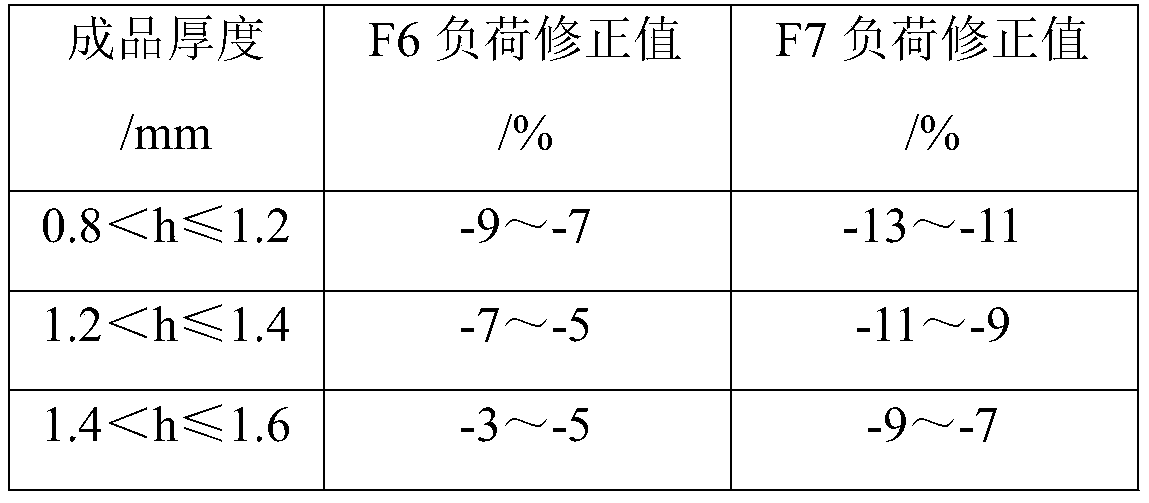

[0061] ⑥F6, F7 reduction rate:

[0062]

[0063] Effect: The problem of strip steel lifting did not occur throughout the year.

Embodiment 2

[0064] Embodiment 2: producing SPHC-B with a thickness of 1.0 mm.

[0065] ①Rolling mill work roll pressure:

[0066]

[0067] ② Strip threading speed:

[0068] Finished product thickness / mm Strip head threading speed m / s 1.0 9.52

[0069] ③Sequence of dedusting water:

[0070]

[0071] ④Slight bilateral wave rolling:

[0072]

[0073] ⑤ Uneven wear of work rolls:

[0074]

[0075] ⑥F6, F7 reduction rate:

[0076]

[0077] Effect: The problem of strip steel lifting did not occur throughout the year.

Embodiment 3

[0078] Embodiment three: producing SPHC-B with a thickness of 1.2 mm.

[0079] ①Rolling mill work roll pressure:

[0080]

[0081] ② Strip threading speed:

[0082] Finished product thickness / mm Strip head threading speed m / s 1.2 9.6

[0083] ③Sequence of dedusting water:

[0084]

[0085] ④Slight bilateral wave rolling:

[0086]

[0087] ⑤ Uneven wear of work rolls:

[0088]

[0089] ⑥F6, F7 reduction rate:

[0090]

[0091] Effect: The problem of strip steel lifting did not occur throughout the year.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com