Treatment method of high-temperature high-silicon molten iron

A processing method and technology for molten iron, applied in the field of iron and steel metallurgy, can solve the problems of reducing the heat dissipation capacity of molten iron, reducing the temperature of molten iron, and high consumption of iron and steel materials, and achieving the effects of reducing heat dissipation capacity, increasing the amount of molten iron, and stable blowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

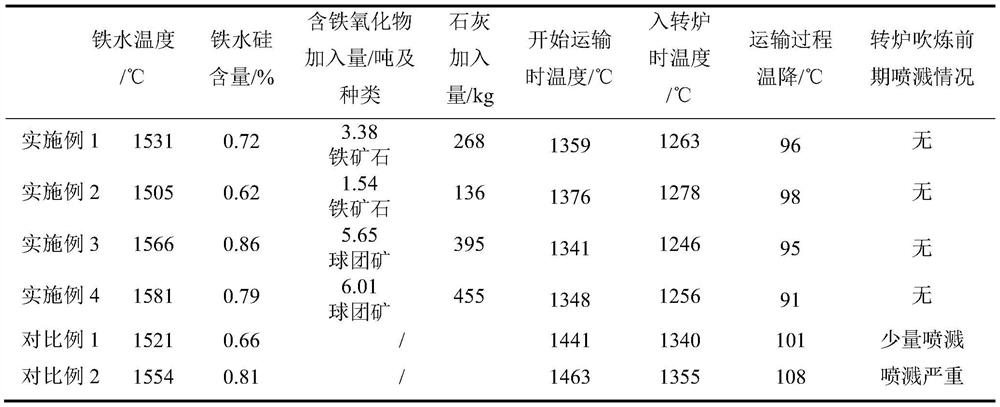

[0022] A treatment method for high-temperature high-silicon molten iron in this embodiment uses 300-ton torpedo tanks for the transportation of molten iron. Iron-containing oxides are added before molten iron. The high-temperature high-silicon molten iron is: molten iron temperature ≥ 1500 ° C, molten iron Si element mass fraction ≥ 0.6%; 100-500kg of lime, the lime particle size range is: 10-20cm, which is used to inhibit the reaction of C element and iron oxide in the molten iron to form foamy slag. The specific test conditions are shown in the table below.

[0023] Table 1 High-temperature high-silicon hot water treatment test table

[0024]

[0025] It can be seen from the experimental results that the high-temperature high-silicon molten iron treated by this technical scheme uses excess heat for heating and reducing iron-containing oxides when the torpedo tank receives the molten iron, increasing the amount of molten iron and keeping the temperature of the molten iron ...

Embodiment 2

[0027] A treatment method for high-temperature high-silicon molten iron in this embodiment has the same basic structure as in Embodiment 1. The difference and improvement are that the iron-containing oxides include sintered ore, pelletized ore, iron oxide scale, wherein sintered ore, pelletized ore The mass ratio of iron oxides in the pellets and iron oxides is ≥90%, and the added amount of the iron-containing oxides is:

[0028] M=1.43×10 -4 ×(T 1- a×△T-T 2 )×M 铁水 ;

[0029] Among them, M is the amount of iron oxide added / ton, M 铁水 is the mass of molten iron / ton, T 1 is the tapping temperature / °C, the value range of a is: 1.84~1.95, △T is the annual average temperature drop / °C during the process of transporting molten iron from the ironworks to the steelworks, where T 2 It is the target temperature / °C before entering the converter.

[0030] Wherein, the target temperature T before the converter 2 for:

[0031] T 2 =1280-((b×Si content of molten iron)-0.60%)×10 4 ×c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com