Patents

Literature

46results about How to "Stable blowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

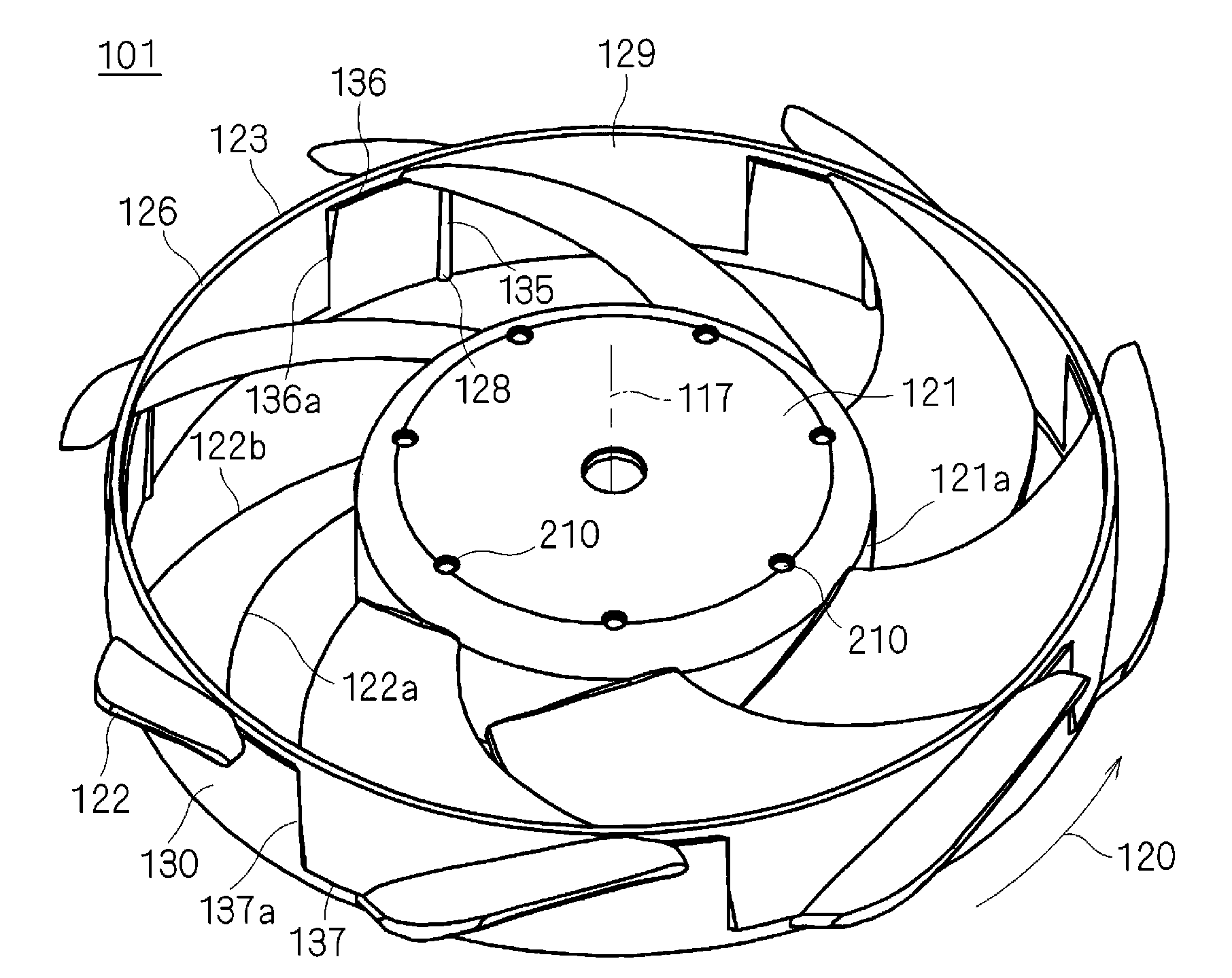

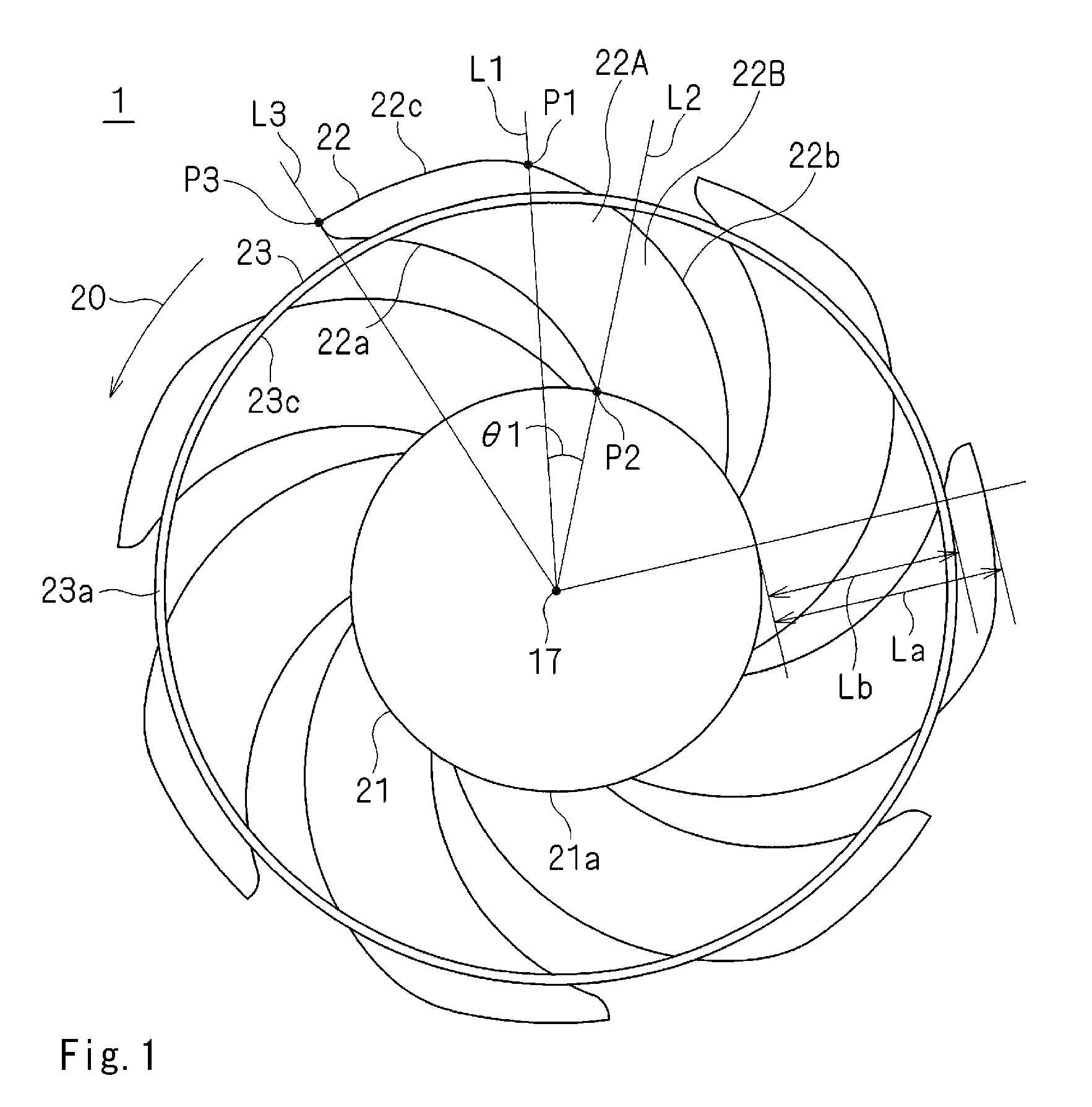

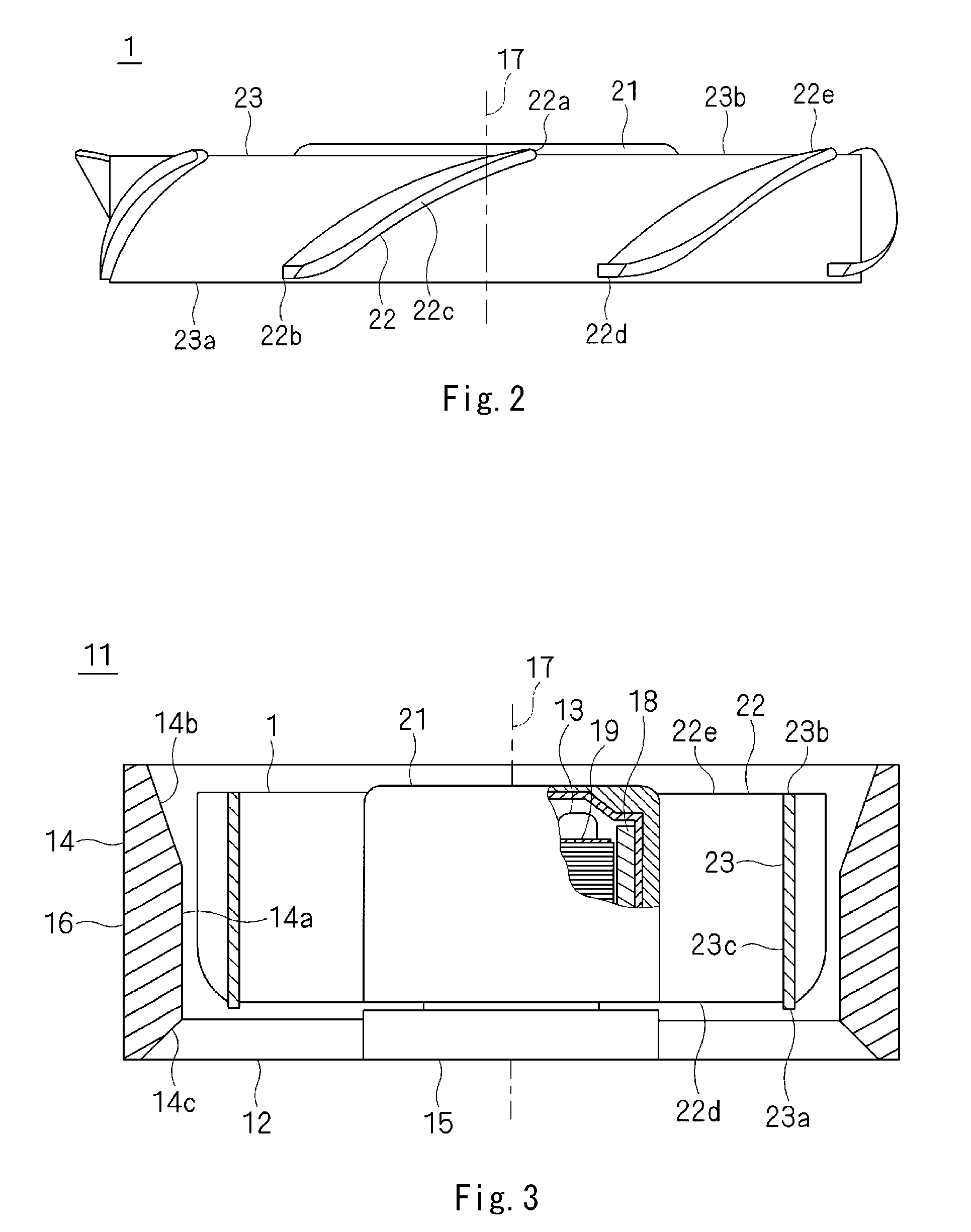

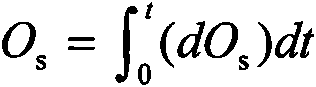

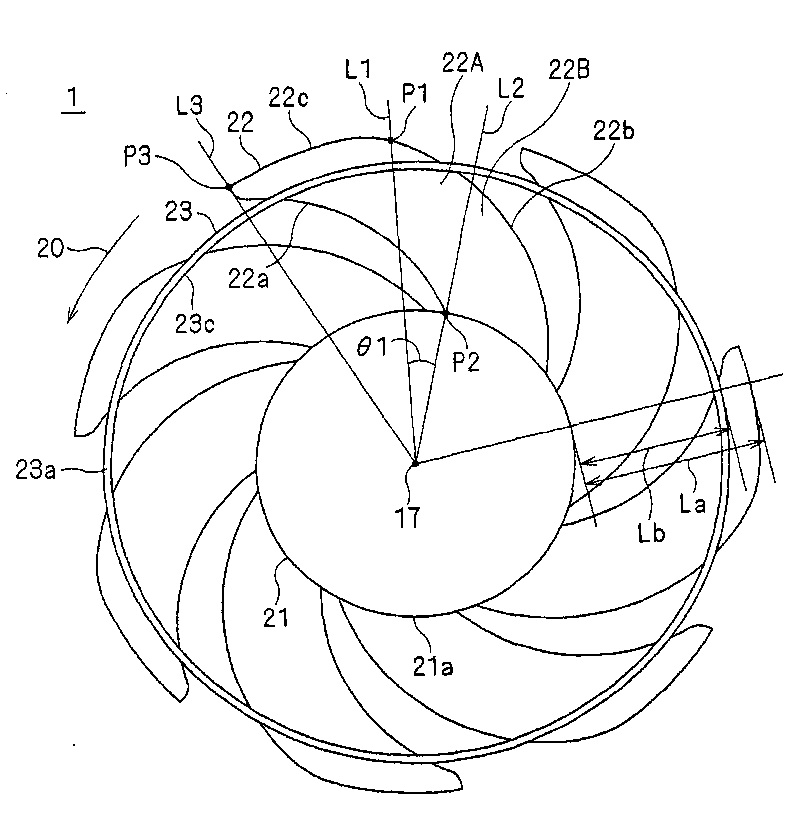

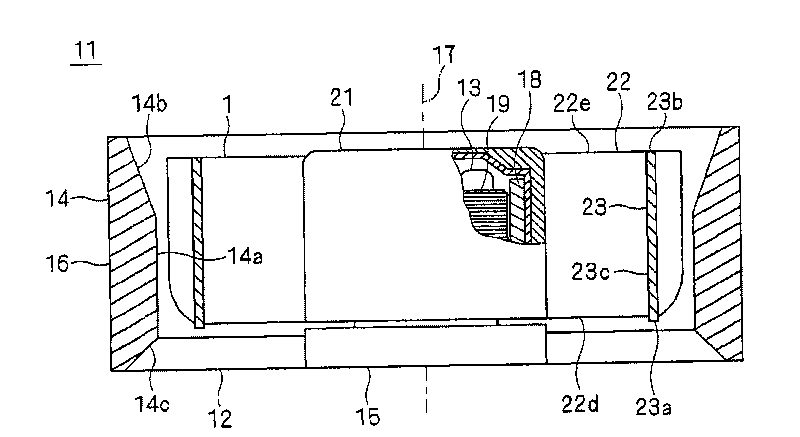

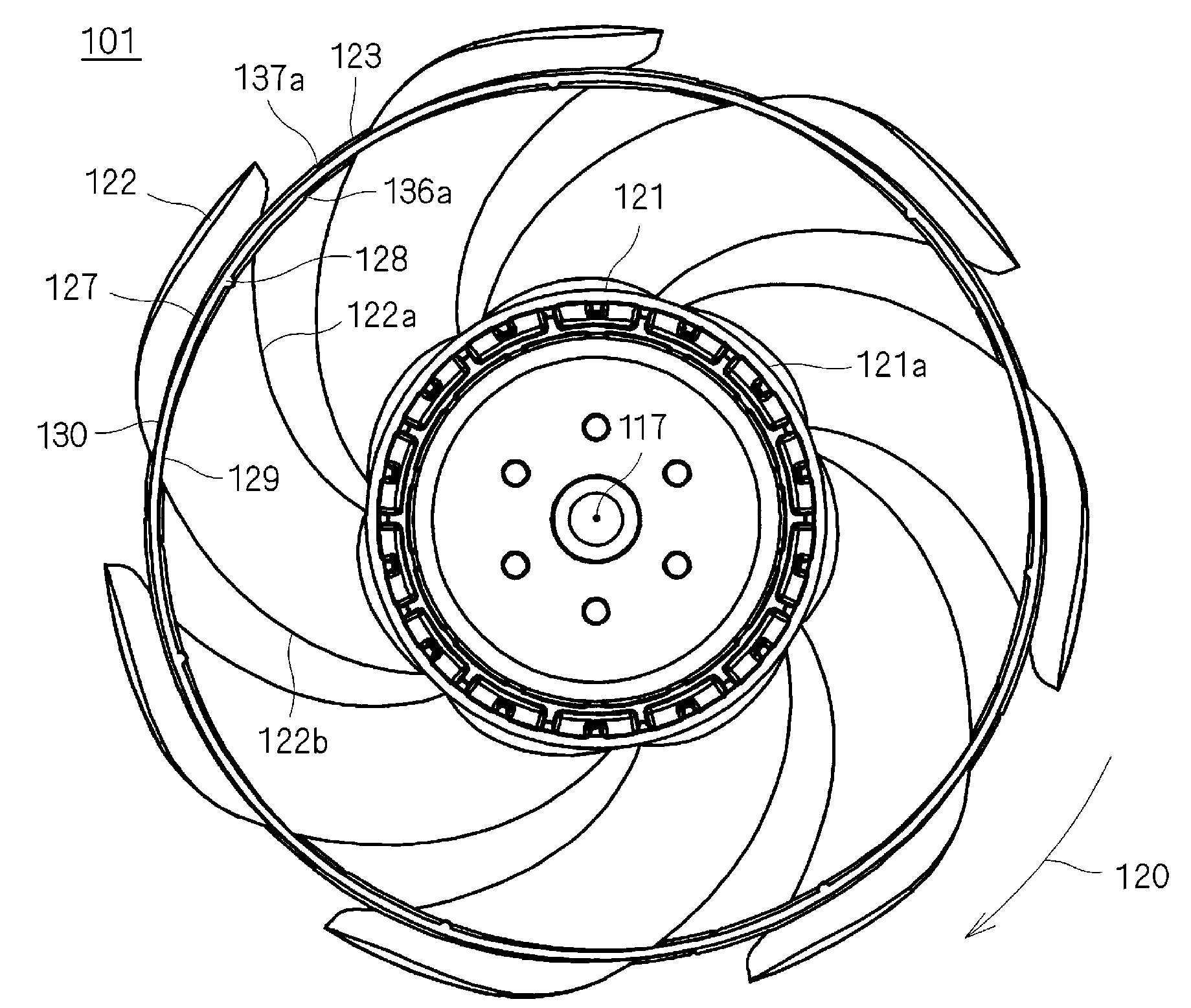

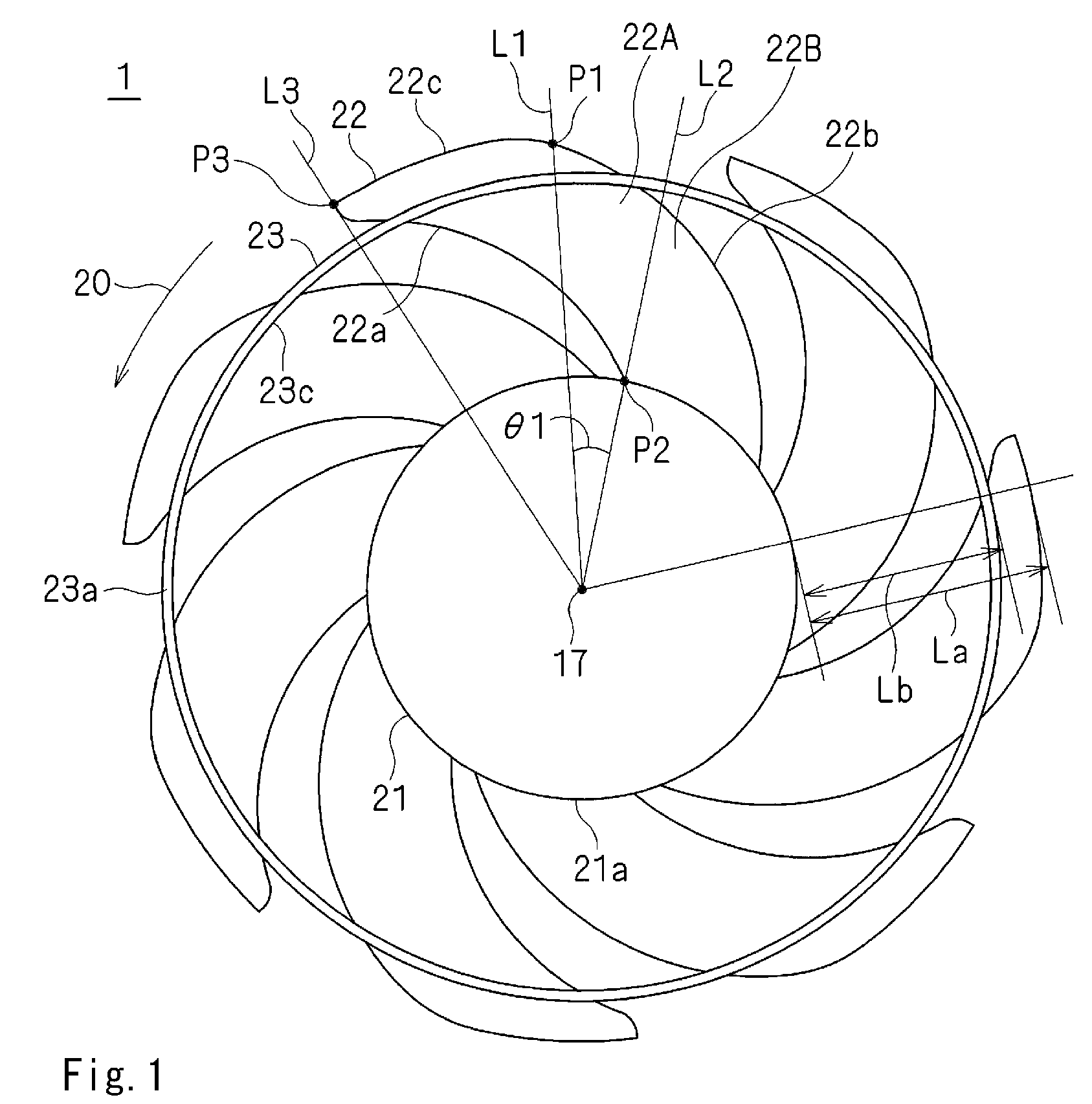

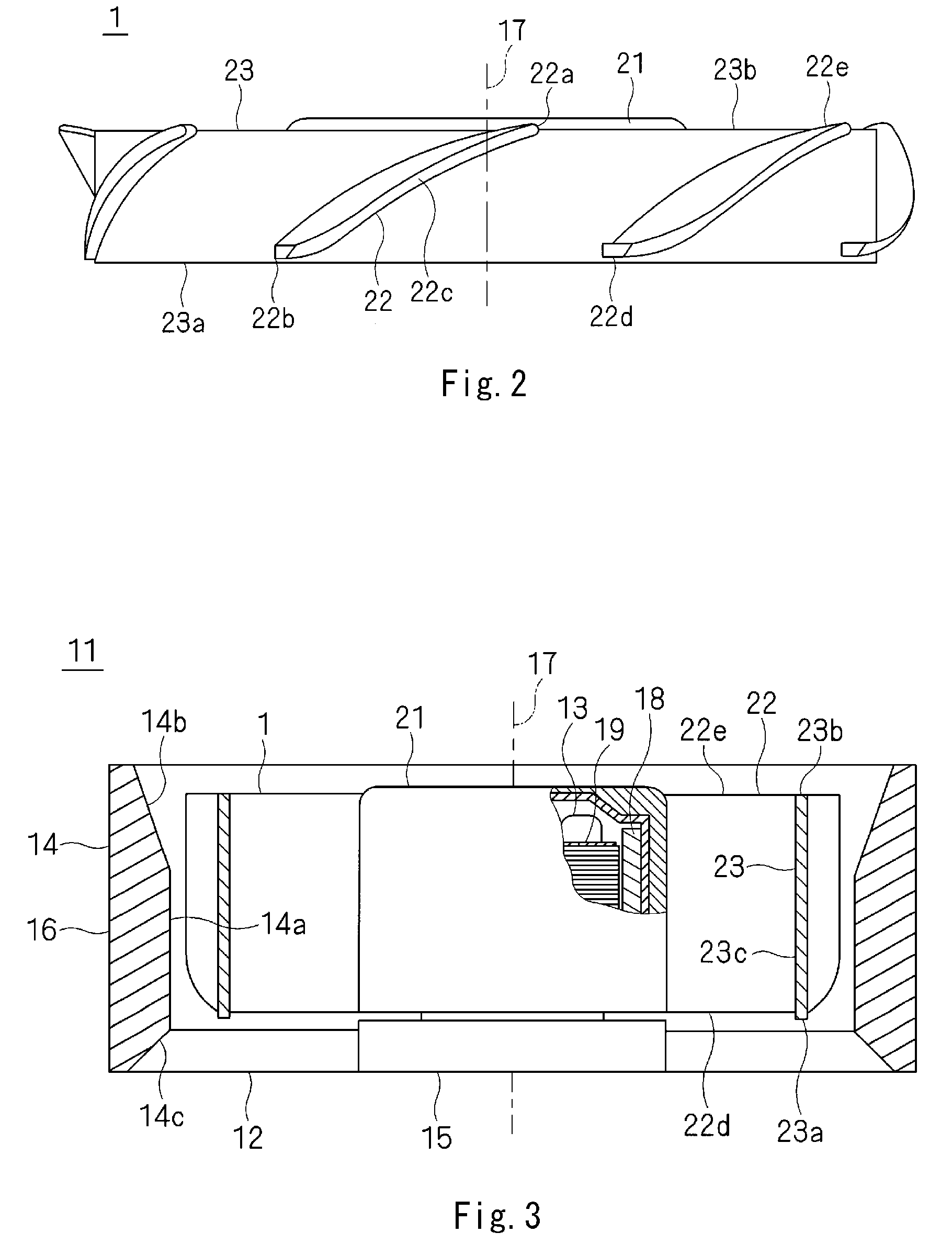

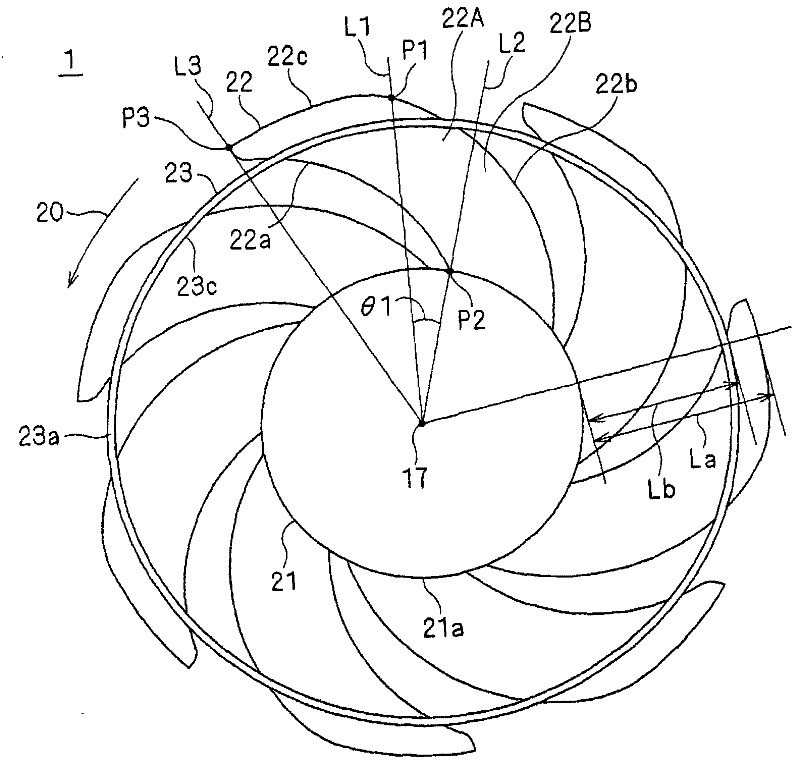

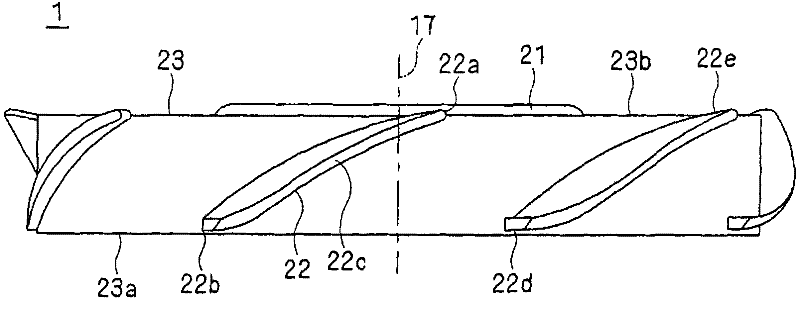

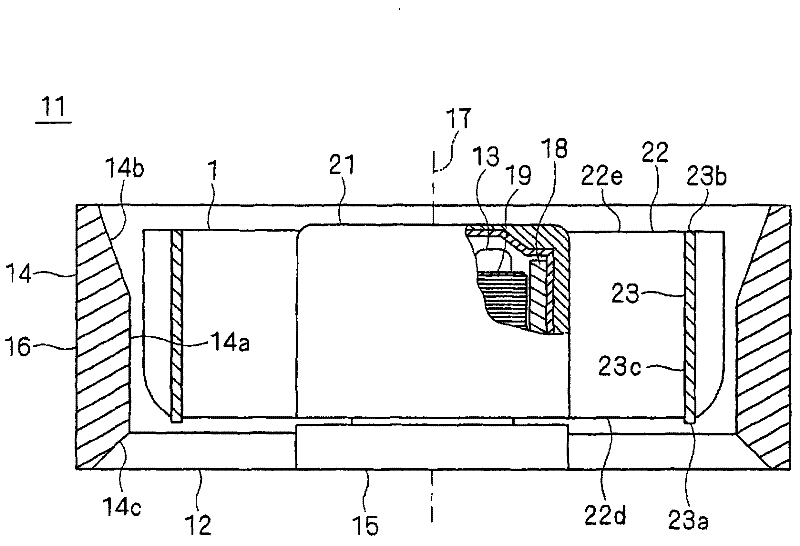

Impeller, fan apparatus using the same, and method of manufacturing impeller

ActiveUS20100086405A1Improve featuresReduce the impactPropellersRotary propellersImpellerLeading edge

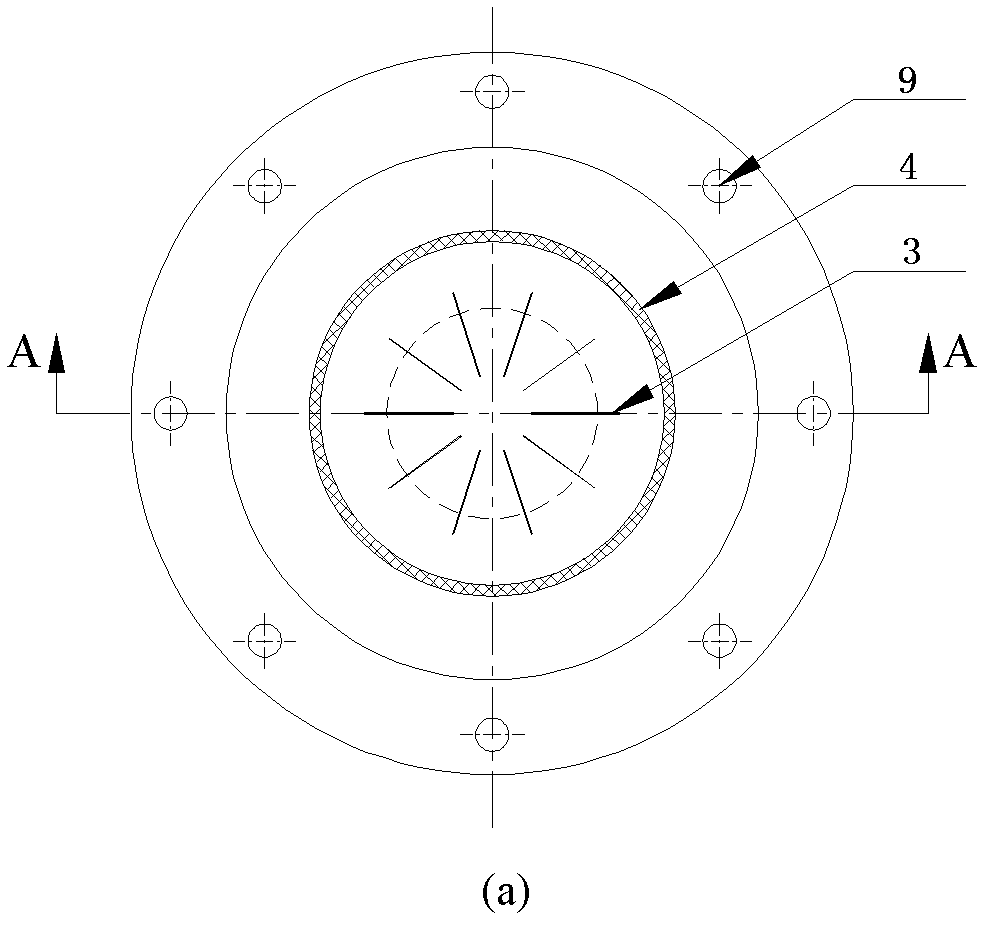

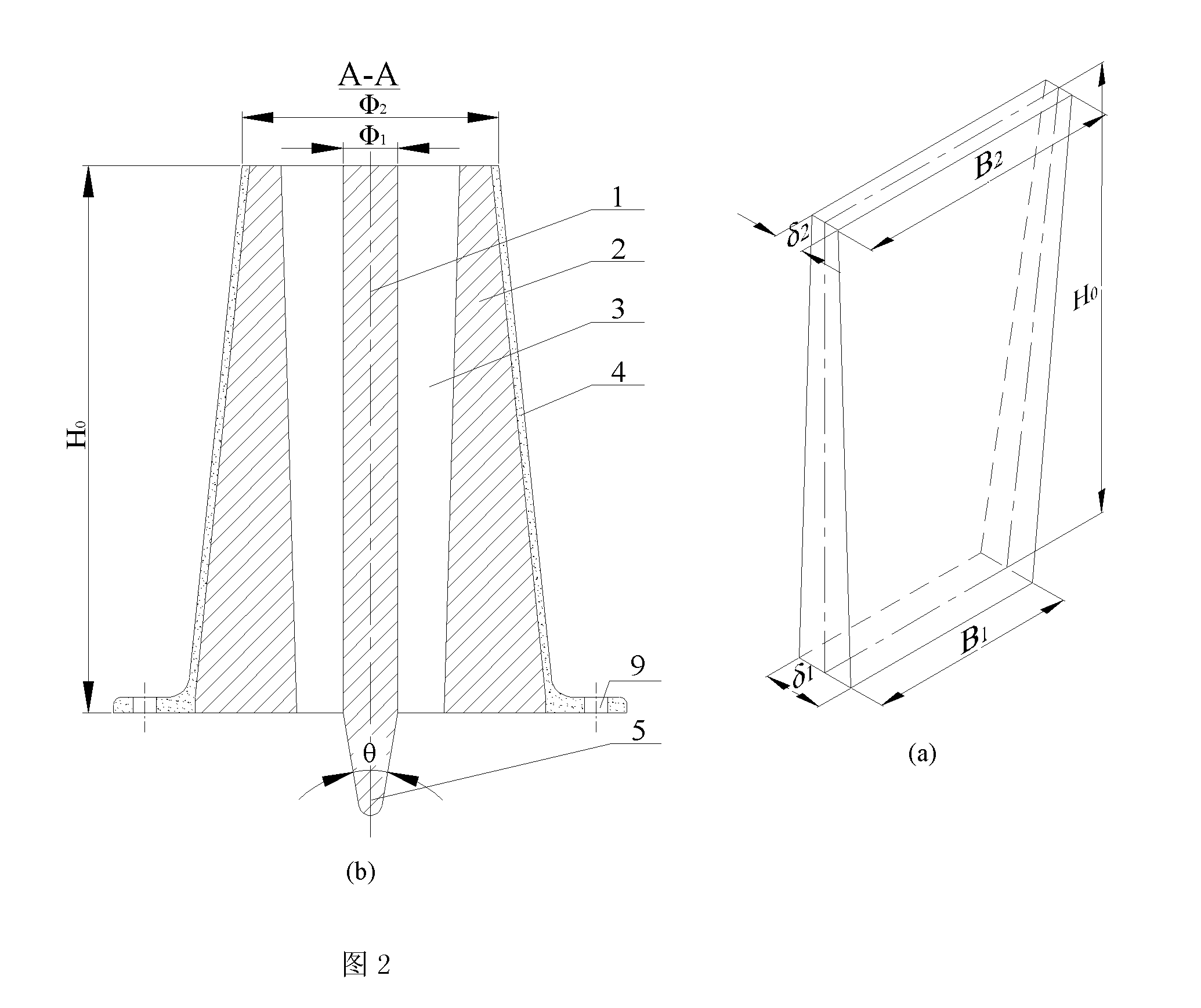

An impeller, a fan apparatus, and a method of manufacturing the impeller are provided. The impeller includes a support portion, a plurality of rotor blades, and a joining member. The joining member is a substantially annular member provided to strengthen the rotor blades against influence of a centrifugal force, and extends in a circumferential direction along a circle centered on a central axis so as to join the rotor blades to one another. In each of the rotor blades, a point of intersection of a leading edge of the rotor blade with a radially outer end of the rotor blade is positioned forward, with respect to a rotation direction, relative to a point of intersection of the leading edge with an outside surface of the support portion. The joining member is positioned radially inwards of the radially outer end of each of the rotor blades.

Owner:NIDEC SERVO CORP

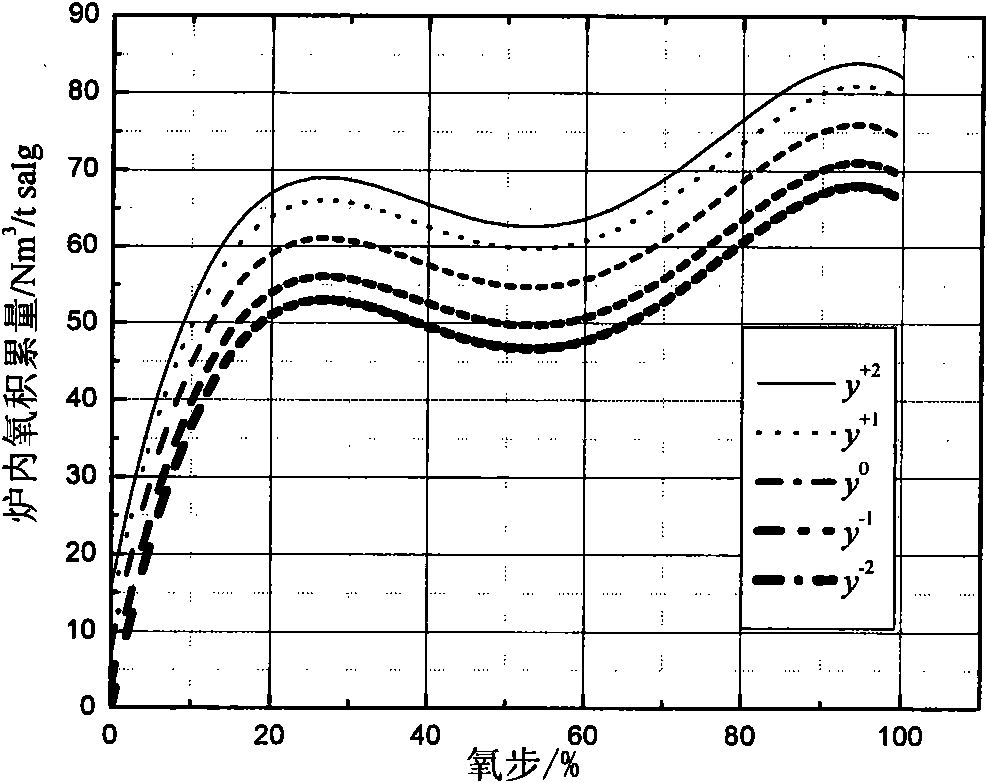

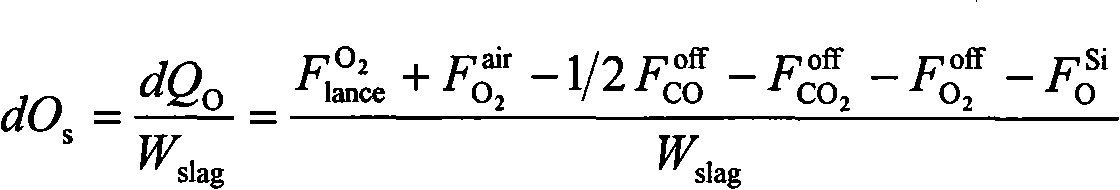

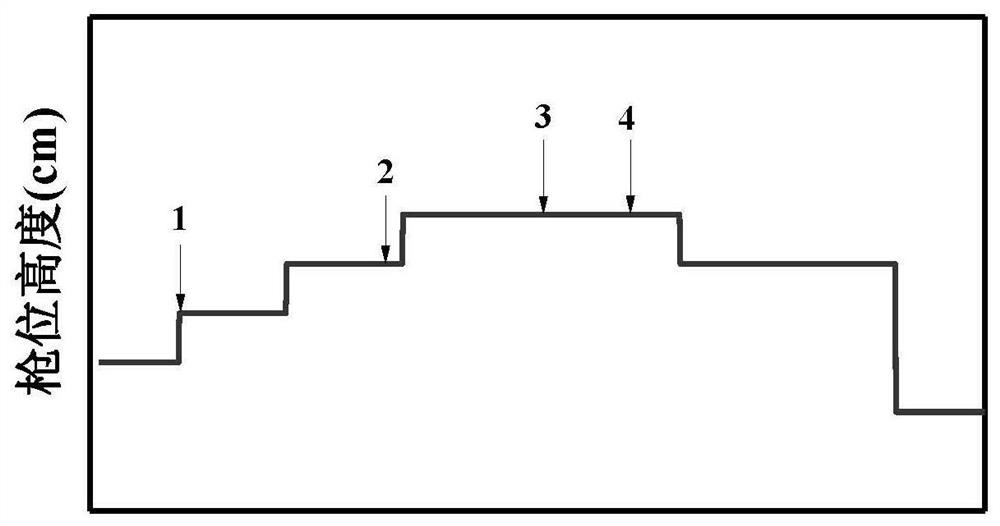

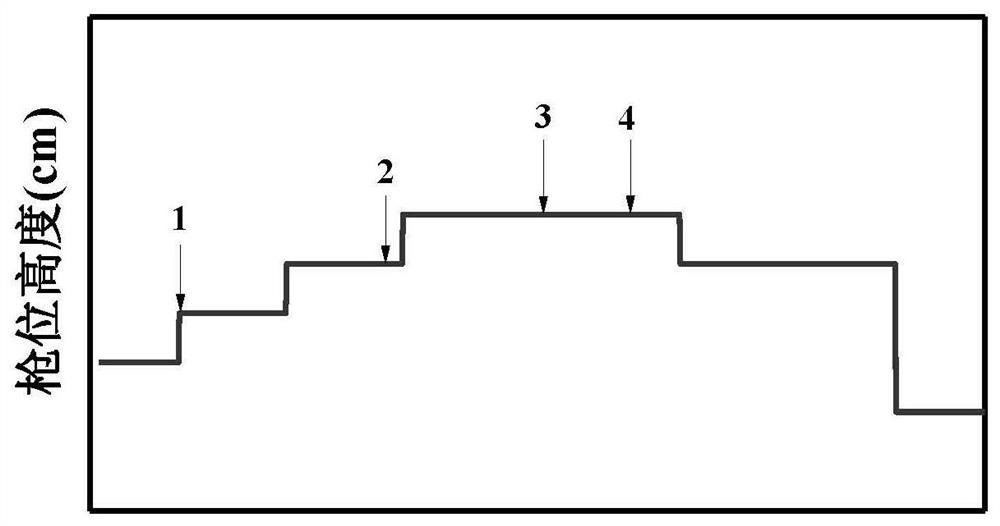

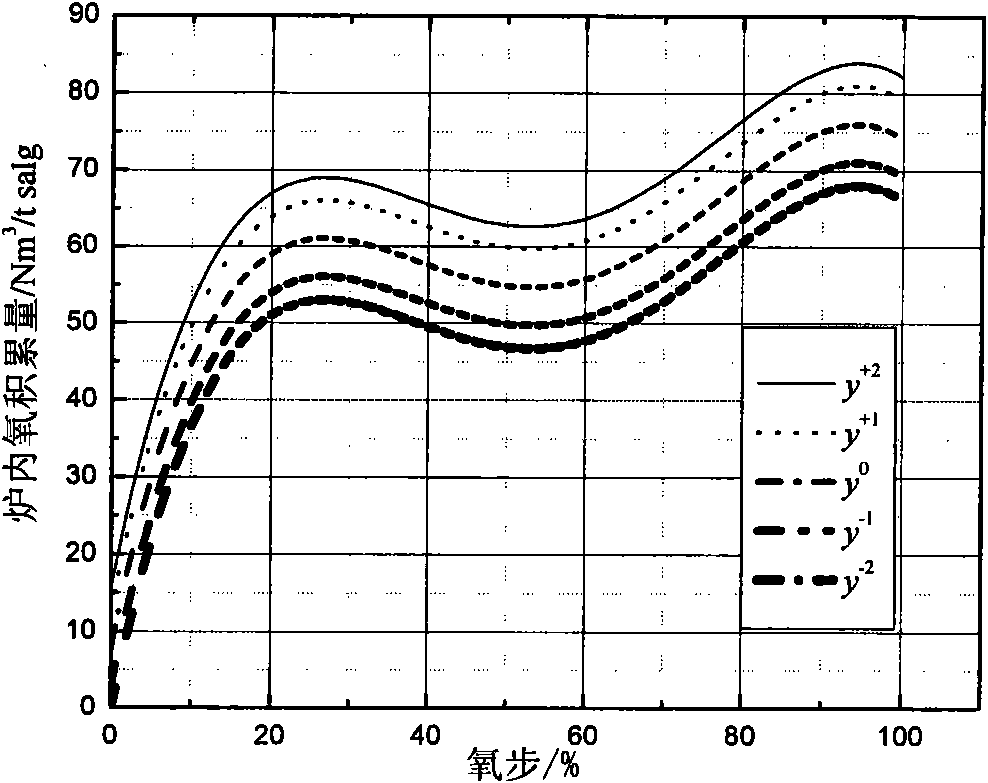

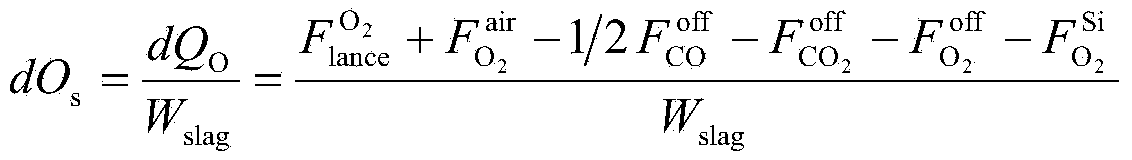

Automatic controlling method for converter oxygen lance used for converting low-carbon steel

ActiveCN102399933AEliminate splatterReduce dependenceManufacturing convertersAutomatic controlEngineering

The invention provides an automatic controlling method for a converter oxygen lance used for converting low-carbon steel. The method comprises a data collecting and analyzing step, a raw material controlling step, and an oxygen lance position controlling step. The method is characterized in that: during an entire low-carbon steel converting procedure in a converter, an oxygen lance position is controlled according to the variation of the accumulated amount of oxygen in the converter; the oxygen lance position is fixed as a slagging position since the converting is started to 20% of a total converting time is reached; the oxygen lance is automatically adjusted according to a determined scheme since 20% of the total converting time is reached to 90% of the total converting time is reached; the oxygen lance position is fixed as a carbon catching position since 90% of the total converting time is reached to 100% of the total converting time is completed, and a converting end point is determined according to the decarbonization speed; when a tapping requirement is satisfied, the oxygen lance is stopped, and the converting is stopped. With the method provided by the invention, the entire converting procedure can be continuously and dynamically corrected, such that oxygen lance position automatic controlling can be realized.

Owner:ANGANG STEEL CO LTD

Impeller, fan apparatus using the same, and method of manufacturing impeller

ActiveCN101713417AImprove featuresPrevent reverse airflowPump componentsPump installationsLeading edgeImpeller

An impeller, a fan apparatus, and a method of manufacturing the impeller are provided. The impeller includes a support portion, a plurality of rotor blades, and a joining member. The joining member is a substantially annular member provided to strengthen the rotor blades against influence of a centrifugal force, and extends in a circumferential direction along a circle centered on a central axis so as to join the rotor blades to one another. In each of the rotor blades, a point of intersection of a leading edge of the rotor blade with a radially outer end of the rotor blade is positioned forward, with respect to a rotation direction, relative to a point of intersection of the leading edge with an outside surface of the support portion. The joining member is positioned radially inwards of the radially outer end of each of the rotor blades.

Owner:JAPAN SERVO CO LTD

Alloy structure steel 42CrMo slab and production method thereof

The invention relates to an alloy structure steel 42CrMo slab and a production method thereof. The method comprises the following steps: (1) charging molten iron containing less than or equal to 0.030% of S, less than or equal to 0.120% of P and less than or equal to 0.85% of Si into a furnace; (2) smelting steel rods containing more than or equal to 0.10% of C and less than or equal to 0.008% of P in the converter at the temperature of 1650-1680 DEG C; (3) performing LF (low frequency) refining and adjusting the target values of the components, so that C is 0.41-0.43% of C, Si is 0.23-0.27%, Mn is 0.58-0.62%, S is less than or equal to 0.010%, P is less than or equal to 0.015%, Cr is 0.92-0.98%, Mo is 0.17-0.19%, Cu is less than or equal to 0.20% of Cu and Ni is less than or equal to 0.30%, wherein the discharge temperature of molten steel is 1560+45 DEG C in a first furnace and 1550+45 DEG C in a continuous casting furnace; (4) performing VD (vacuum degassing) refining under the vacuum of less than or equal to 67Pa for 15 minutes, meanwhile, performing weak argon blowing stirring of 0.15-0.20MPa, feeding 140-150m of CaSi wire with the diameter of phi13mm after breaking, and then performing weak argon blowing for more than or equal to 10 minutes, wherein the discharge temperature is 1560+ / -5 DEG C in the first furnace and 1550+ / -5 DEG C in the continuous casting furnace; and (5) performing continuous casting: controlling the water distribution of each secondary cooling zone of a slab caster by adopting a primary water meter, wherein the light pressing interval fs is 0.45-0.95, the distribution coefficients are shown in table 2, and the pressing quantity is 3.8mm. The method meets the production requirements of large-section 42CrMo slabs.

Owner:TIANJIN IRON & STEEL GRP

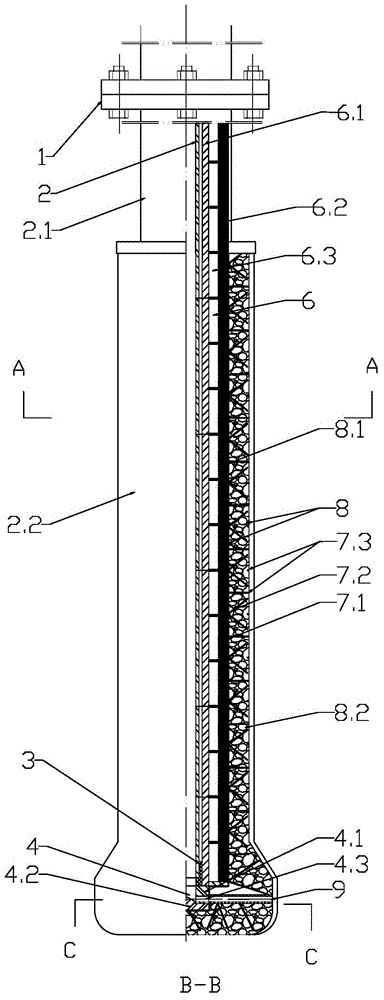

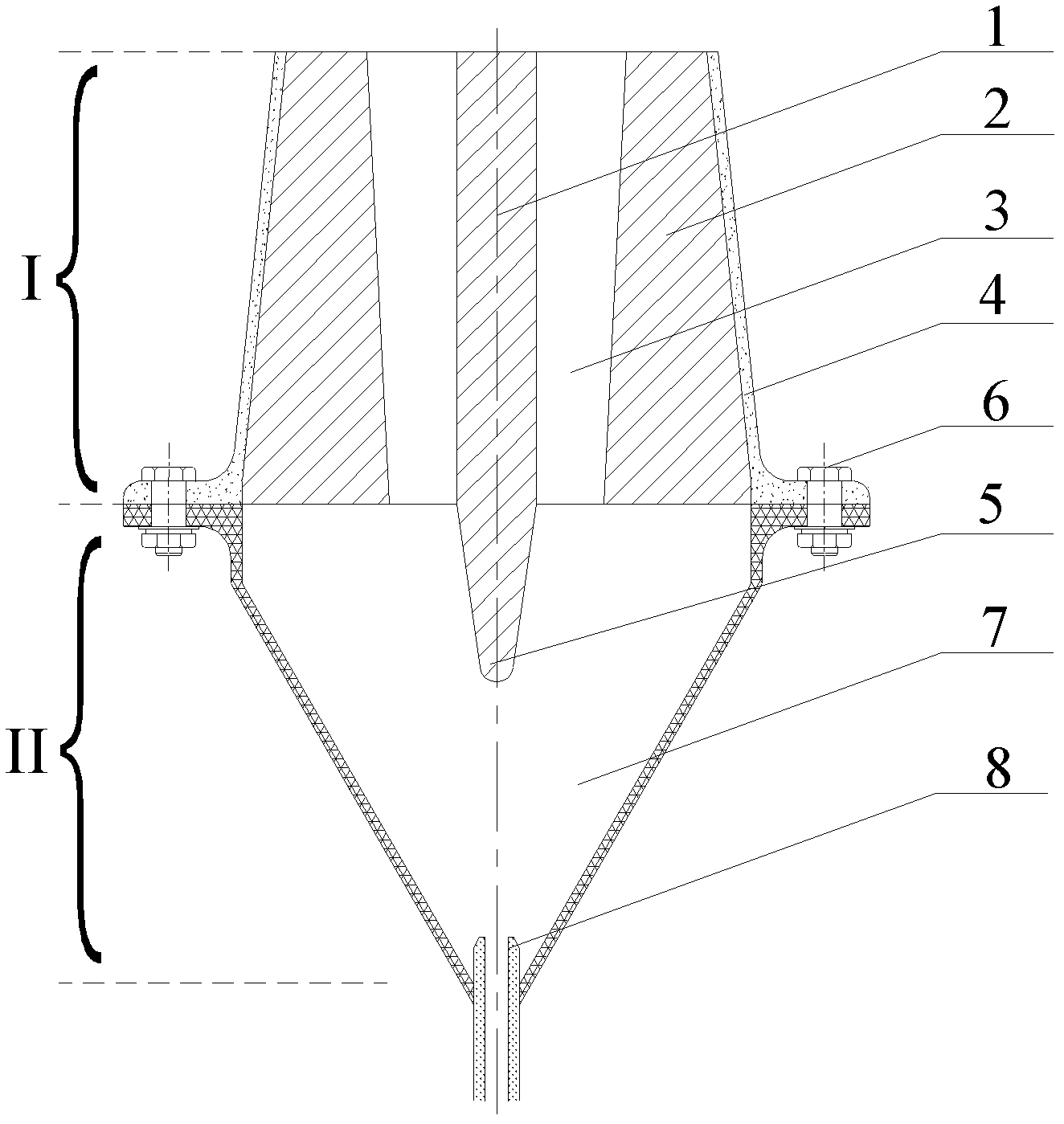

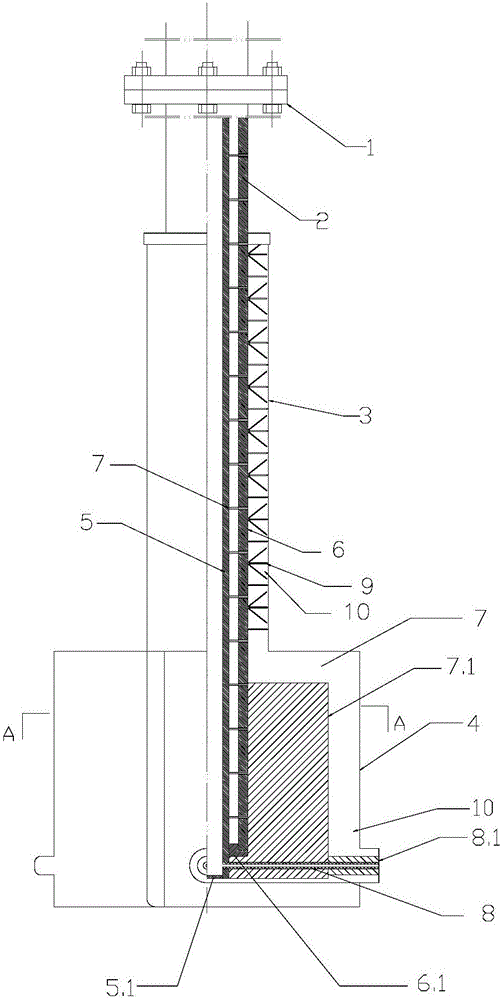

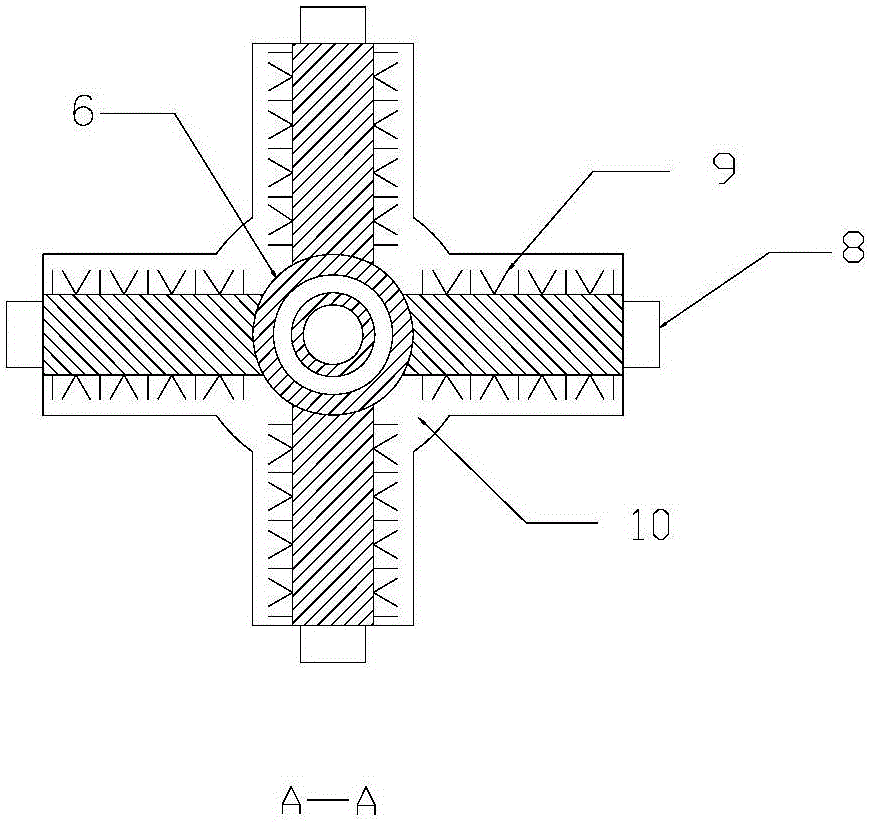

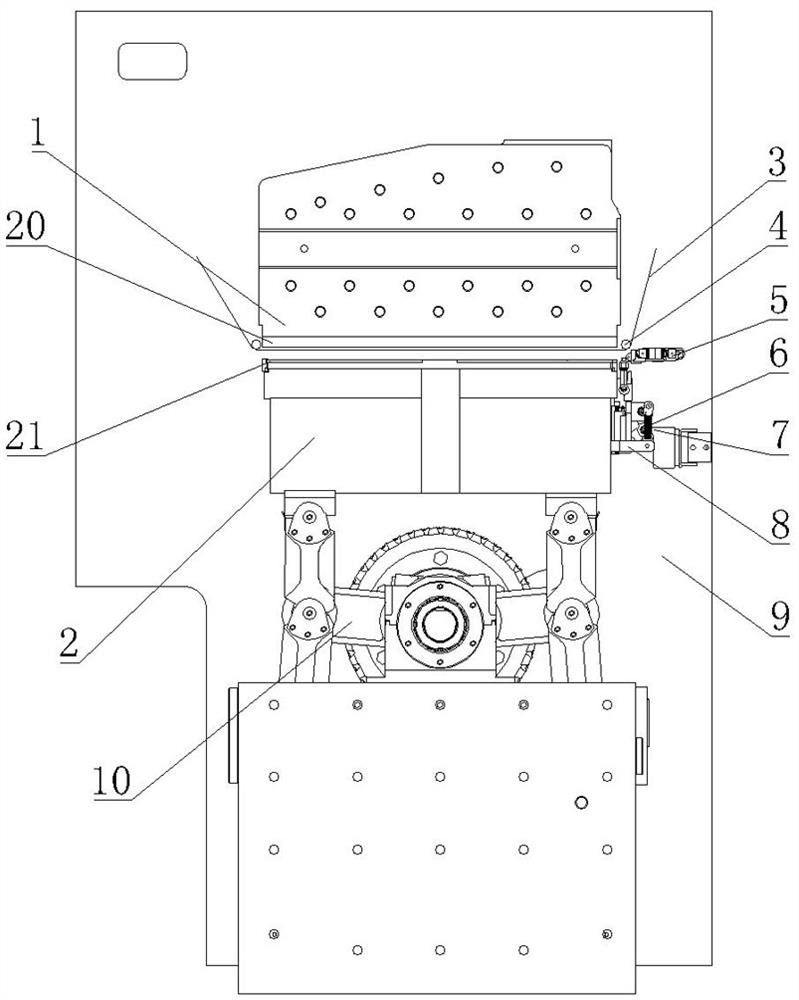

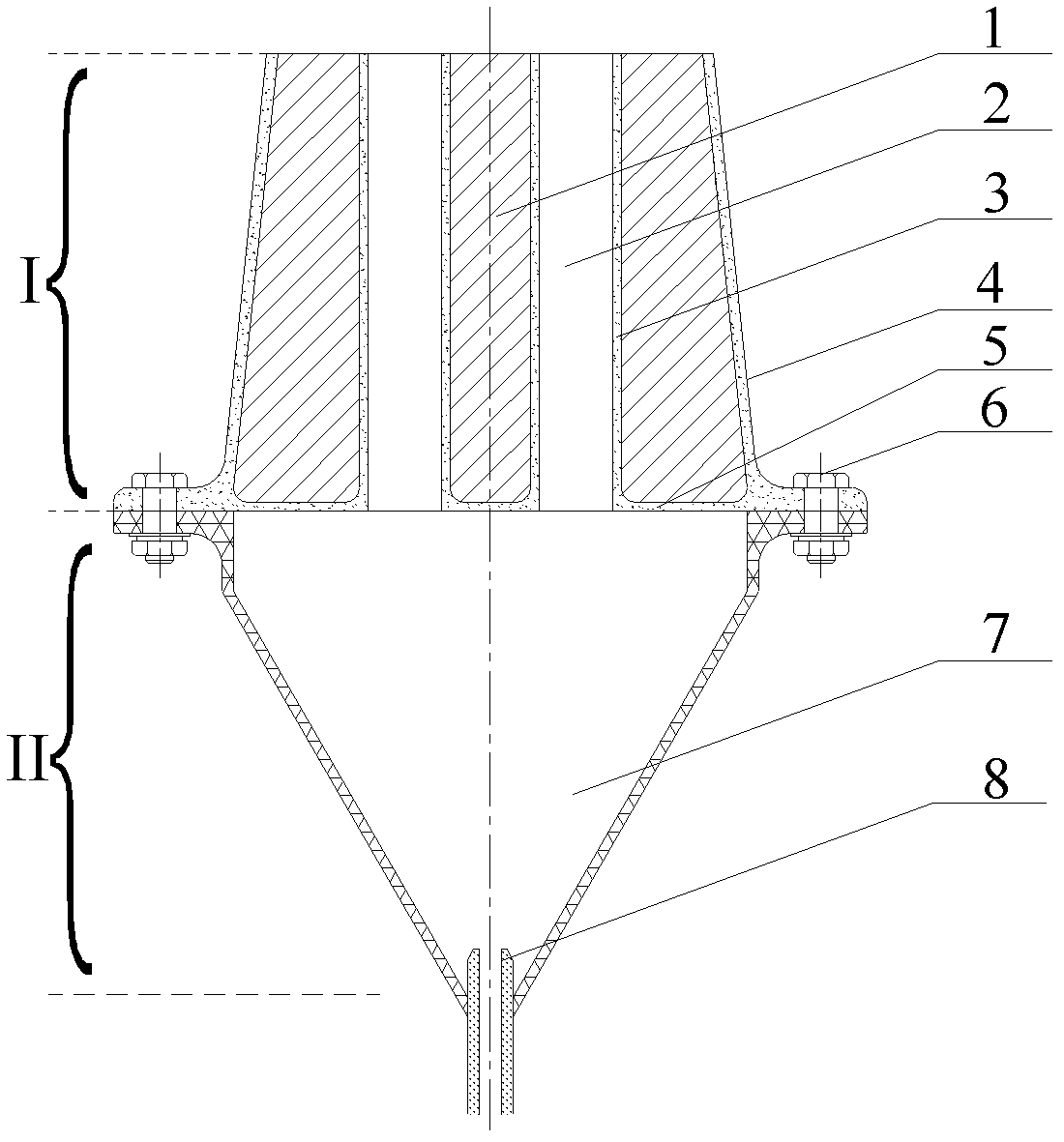

Direct injection molten iron desulphurization spray gun

The invention discloses a direct injection molten iron desulphurization spray gun for a metal particle magnesium or magnesium-based or calcium-based desulphurization agent. The direct injection molten iron desulphurization spray gun comprises a connecting flange and a gun barrel which are sequentially connected and communicated, wherein the gun barrel comprises a connecting section gun barrel and a gun body section gun barrel; the connecting section gun barrel comprises a gun core; a distributor is connected with the lower end of the gun core of the gun body section gun barrel; the distributor comprises an upper end short connecting pipe, a lower end plug platform and a plurality of through holes formed in the wall of the short connecting pipe; and each through hole is communicated with a jetting pipe, and the jetting pipes are distributed in a fire-proof pouring material liner positioned outside the side wall of the distributor. The direct injection molten iron desulphurization spray gun disclosed by the invention can be used for enhancing the jetting strength, extending the desulphurization reaction area and intensifying the gasification and dissolution of metal particle magnesium through structural design, and can be used for enhancing the adaptability on low-quality metal particle magnesium and jetting desulphurization of molten iron tanks with different sizes, extending the adaptive capacity of a process and reducing the consumption cost of the molten iron desulphurization metal particle magnesium through the improvement of desulphurization process steps.

Owner:武汉钢铁有限公司

Low-phosphorous steel smelting method of mixed blowing of oxygen and nitrogen of top blowing oxygen lance of converter

InactiveCN103160637AGas supply intensity does not decreaseLow oxygen supplyManufacturing convertersProcess efficiency improvementMelting tankSteelmaking

The invention relates to a low-phosphorous steel smelting method of mixed blowing of oxygen and nitrogen of a top blowing oxygen lance of a converter, and belongs to the technical field of converter steelmaking. The low-phosphorous steel smelting method of mixed blowing of the oxygen and the nitrogen of the top blowing oxygen lance of the converter includes the following steps that firstly, blowing of a dephosphorizing phase is conducted in the converter, blowing time is controlled in 6-9min, and normal blowing is conducted after deslagging; top-blowing air is mixed gas of the nitrogen and the oxygen in the dephosphorizing phase of the converter; and raw materials which are used by steelmaking are melted iron scrap steel, and scrap ratio is 5%-15%. The low-phosphorous steel smelting method of mixed blowing of the oxygen and the nitrogen of the top blowing oxygen lance of the converter has the advantages that a part of nitrogen is mixed into the top-blowing gas in the dephosphorizing phase, so that low oxygen supply is reached, and simultaneously top-blowing gas supply strength is not reduced (top-blowing mixing intensity is not reduced). Control of molten bath temperature1300DEG C-1380DEG C in the dephosphorizing phase is reduced, and dephosphorizing rate of the dephosphorizing phase is improved, low-phosphorou and extremely low-phosphorous steel with fished phosphorous content lower than 60ppm is achieved. High-phorphorous molten iron can be adopted to smelt, blowing is stable, and dephosphorizing efficiency is high.

Owner:SHOUGANG CORPORATION

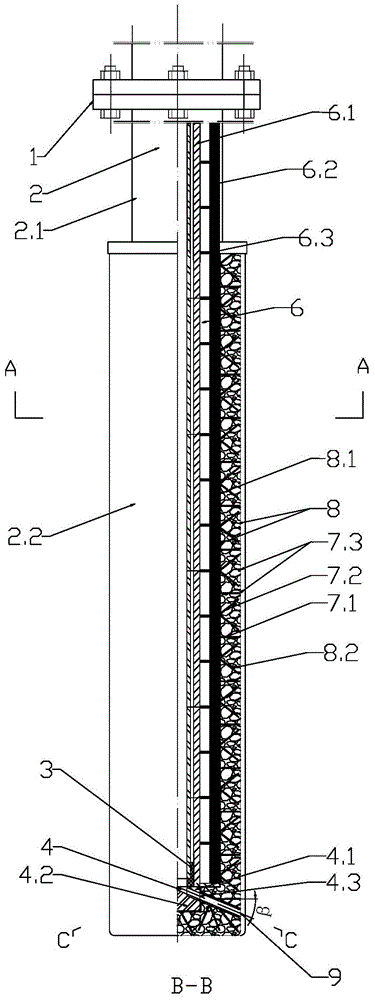

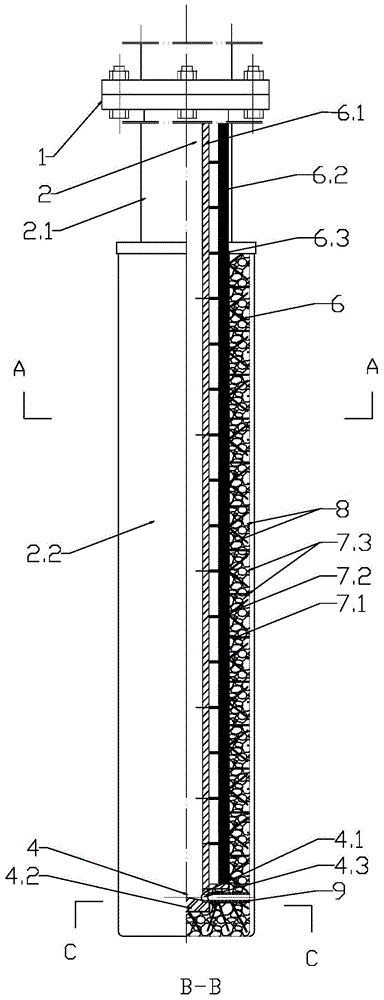

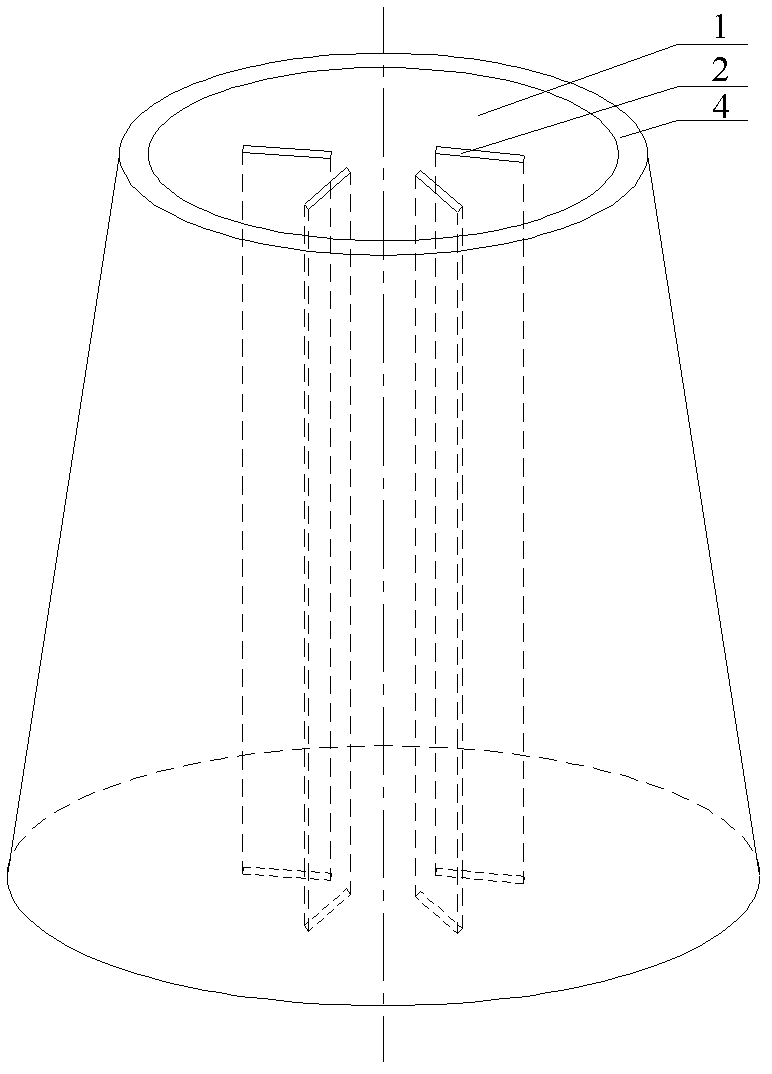

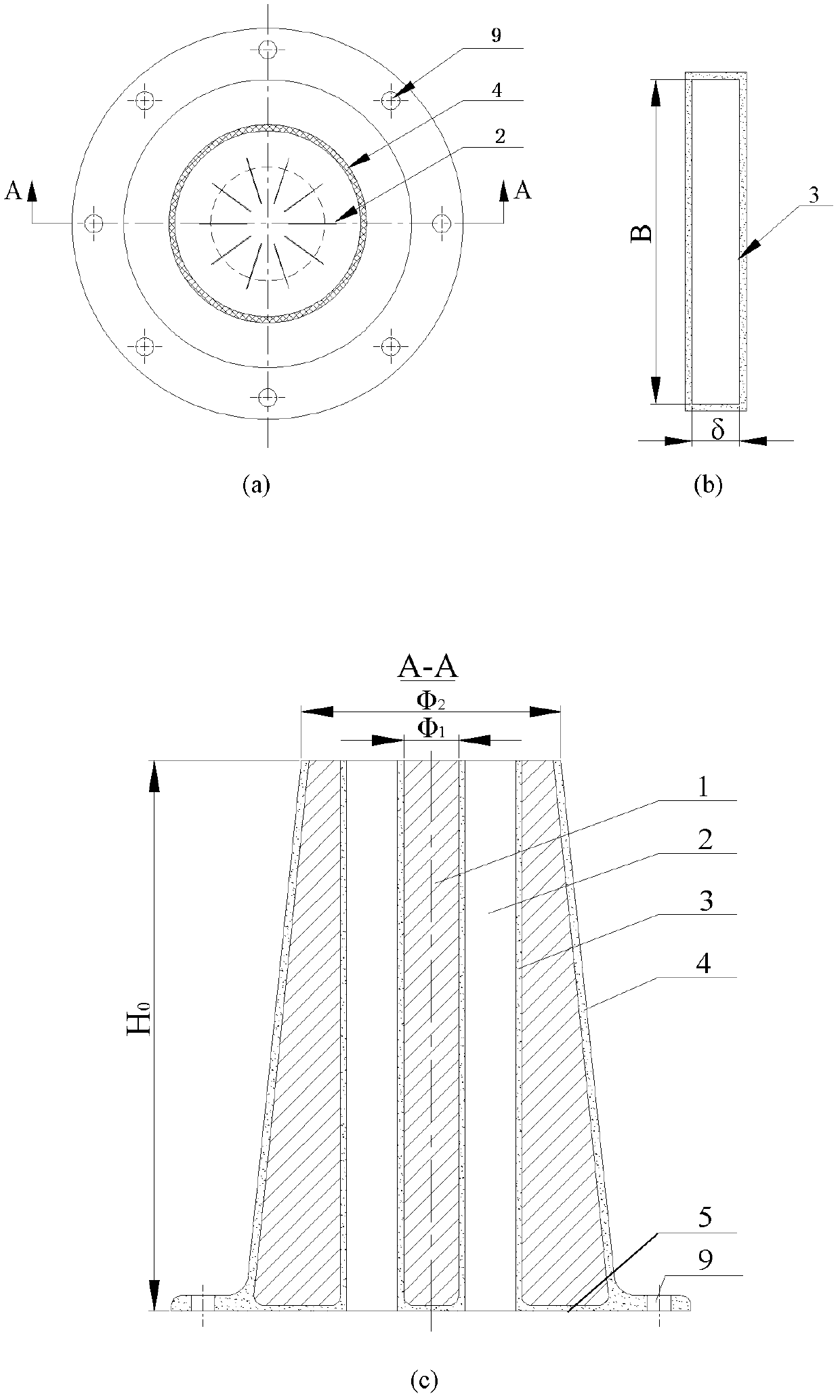

Pillar slot type anti-blocking ladle bottom blowing powder spraying device

InactiveCN102274958AAvoid Dusting RequirementsReduce kinetic energy lossMelt-holding vesselsBrickRefractory

The invention relates to a frustum slit type anti-blocking ladle bottom-blown powder injection device, and belongs to the technical field of steel refining. A frustum slit type powder injection component is filled with refractory material, and four frustum-shaped slits are symmetrically distributed in the refractory material. The frustum slit type anti-blocking ladle bottom-blown powder injectiondevice realizes high-efficiency, continuous and stable injection, has high injection rate and low pulsing probability, can obviously improve uniform powder air flow delivery rate in slits, and is stable in injection, low in abrasion of air bricks, safe and reliable.

Owner:NORTHEASTERN UNIV

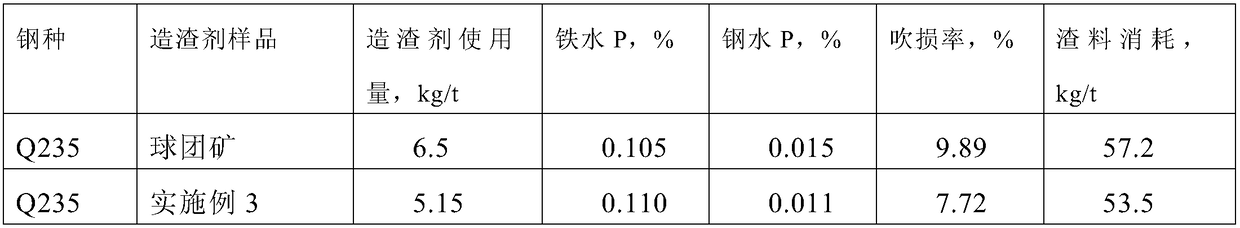

Freon-free slagging agent for rotating furnace

The invention discloses a freon-free slagging agent for a rotating furnace, mainly comprising the following materials in parts by weight: 5-30 parts of manganese (Mn), 0-20 parts of silicon dioxide (SiO2) and 10-50 parts of total iron (TFe). The freon-free slagging agent is prepared into 5-50mm particles and the adding amount thereof is determined according to the silicon content in molten iron and is controlled to be within 5-7kg / t steel. The freon-free slagging agent has the advantages of prolonging the service life of a rotating furnace body, reducing the wastage rate of fettling material, accelerating the joint concentration of steelmaking of the rotating furnace, and reducing the time of daily maintenance and overhauling. Under the condition that the materials and the status of equipment are not changed, after the rotating furnace is added with the freon-free slagging agent, the technical indexes are all improved with different degrees, also the blowing is stable, the slagging is good, the phenomenon that the slag is re-dried is avoided, the operating conditions of steelmaking of the rotating furnace are improved, certain main consumption indexes of the rotating furnace take on downward trend, and the effects of dephosphorization and desulfurization are superior to that of other slagging agents.

Owner:郑州市鑫磊冶金材料有限公司

Rotary blowing desulphurization spray gun applicable to molten iron jars of various dimensions or various desulfurizing agents

The invention discloses a rotary blowing desulphurization spray gun applicable to molten iron jars of various dimensions or various desulfurizing agents. The rotary blowing desulphurization spray gun comprises a connecting flange, a connecting section spray gun body, a gun body section spray gun body and a spray gun section; a plurality of rotating blades are arranged on a main pipe of the spray gun section and the outer wall of a reinforced pipe; each rotating blade comprises a blade metal core; a plurality of inner insertion type spraying pipes are arranged on the side wall of the bottom of the main pipe symmetrically; each inner insertion type spray pipe penetrates through the corresponding blade metal core; a graphite sleeve is arranged on the outer wall of each inner insertion type spray pipe of the corresponding blade metal core. By means of the spray gun, in the blowing desulfurization process, the ascent time of the desulfurizing agents is prolonged, and the ratio of bubbles which are penetrated through is increased substantially, the mixing time of a molten pool is shortened remarkably, the desulphurization dynamics conditions of a desulphurization reaction are improved remarkably, the undulation of the liquid level of molten iron is reduced, and therefore the spray gun can be used for blowing desulphurization of the various desulfurizing agents and the molten iron jars of various dimensions.

Owner:武汉钢铁有限公司

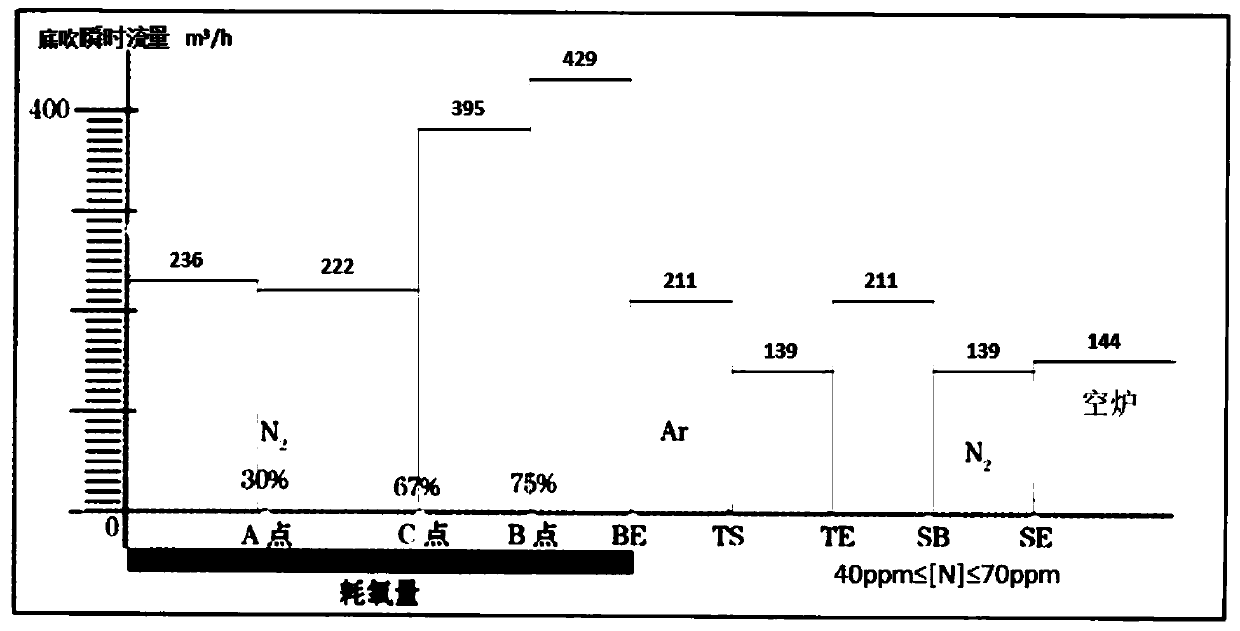

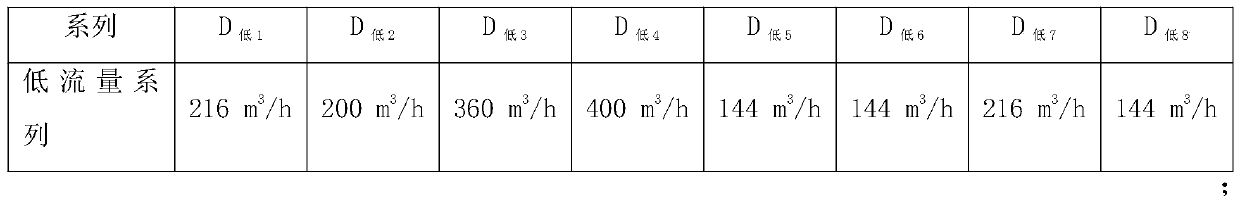

Bottom-blowing flow dynamic control method of top-bottom combined blowing converter

InactiveCN110157848ARealize dynamic controlSolve fixed problemsSteel manufacturing process aspectsIncreasing energy efficiencyEngineeringOxygen content

The invention provides a bottom-blowing flow dynamic control method of a top-bottom combined blowing converter. Firstly, three flow series composed of a high-flow series, a medium-flow series and a low-flow series are added based on three bottom-blowing air supply modes, three bottom blowing air supply modes and three flow series are permuted and combined into nine basic bottom-blowing curves, wherein the time coordinate axes of the basic bottom-blowing curves are provided with eight time intervals; in addition, the measured carbon content [C], the oxygen content [O], a molten pool liquid level a, and an end point temperature T of the converter blowing end point of the previous furnace as well as the furnace age of a next furnace to be blown are taken as variable parameters to be substituted into a formula, then the nine basic bottom blowing curves are dynamically corrected through formula calculation, thus the bottom blowing instantaneous flow after dynamic correction is the bottom blowing instantaneous flow of the actual blowing of the next furnace. According to the bottom-blowing flow dynamic control method of the top-bottom combined blowing converter, the problem that the bottom blowing flow is fixed is solved, the dynamic control of the bottom blowing flow is realized, thus reducing the carbon oxygen product at the blowing end point and improving the metallurgical effect of the bottom blowing as well as the quality of the molten steel.

Owner:山东钢铁集团有限公司

Method for producing nickel-based steel from high-phosphorus molten iron

ActiveCN111411300AOptimizing the Converter ProcessMeet the needs of industrial productionManufacturing convertersProcess efficiency improvementTemperingSlag

The invention discloses a method for producing nickel-based steel from high-phosphorus molten iron, and relates to the technical field of steel smelting. By adopting converter smelting, the P contentof used molten iron is 0.130% to 0.150%, by adopting a method of slag retention at the early stage and double slag at the later stage, the final smelting temperature is 1580-1620 DEG C, in the middleand later periods of smelting, the bottom stirring flow is 350-400 NL / min, the final slag alkalinity is 4.0, the final slag control amount is 10-12 tons, the converter decarburization rate is larger than or equal to 99%, and the dephosphorization rate is larger than or equal to 96%; and through LF refining, RH vacuum treatment, arc continuous casting machine pouring, by adopting TMCP rolling and ACC water cooling to 300 + / -20 DEG C, air cooling is performed to room temperature, a steel plate is heated to 550 + / -10 DEG C, tempering is performed for 3*h min, and air cooling is performed to roomtemperature. The converter process is optimized, a product is conveyed to a heating furnace to be heated after vacuum treatment and casting of an arc-shaped continuous casting machine, TMCP rolling and ACC water cooling are adopted, and after tempering treatment, performance detection is qualified.

Owner:NANJING IRON & STEEL CO LTD

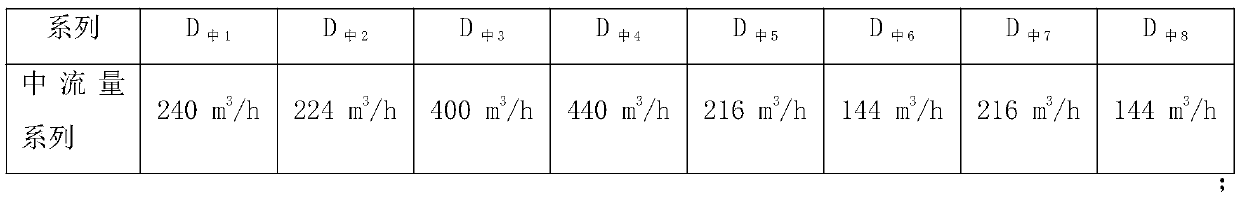

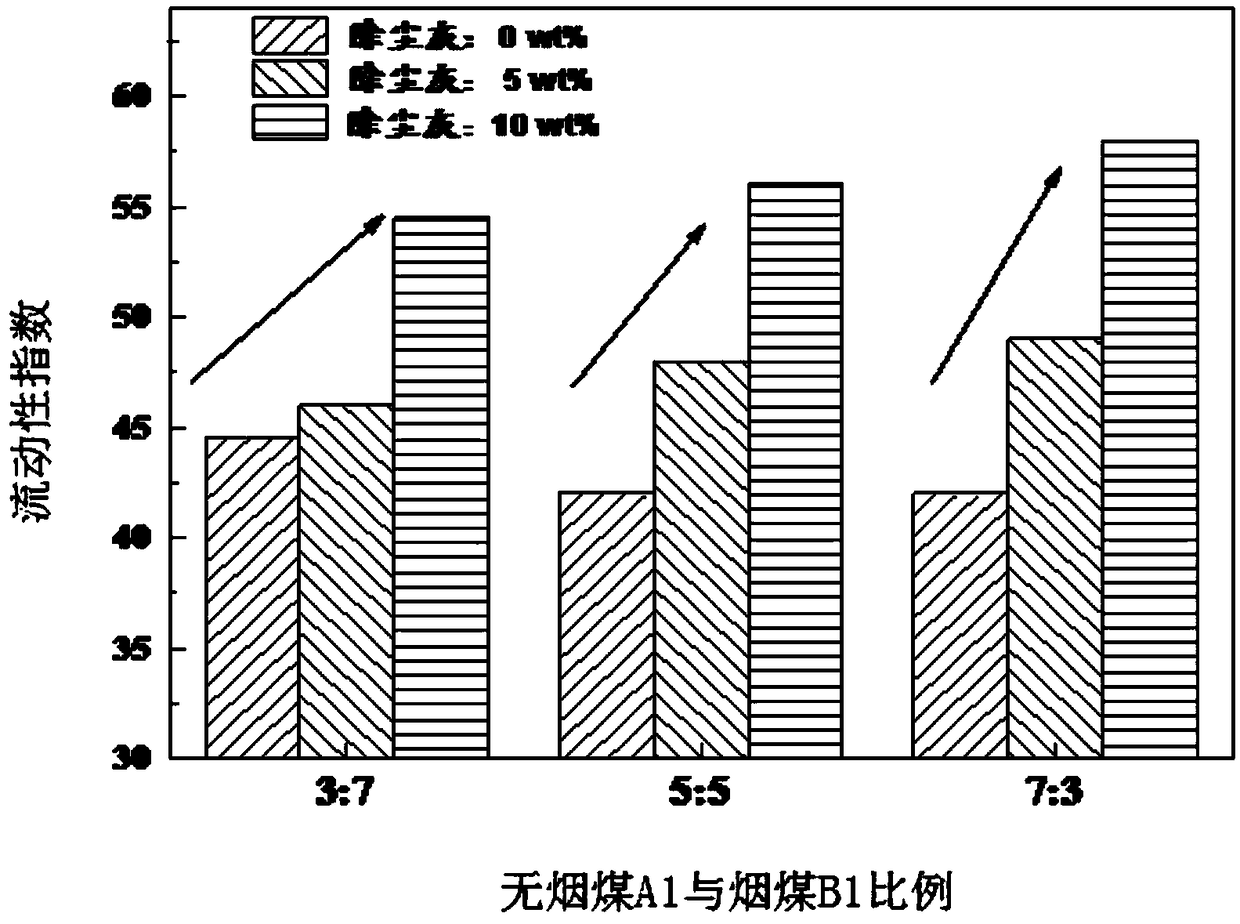

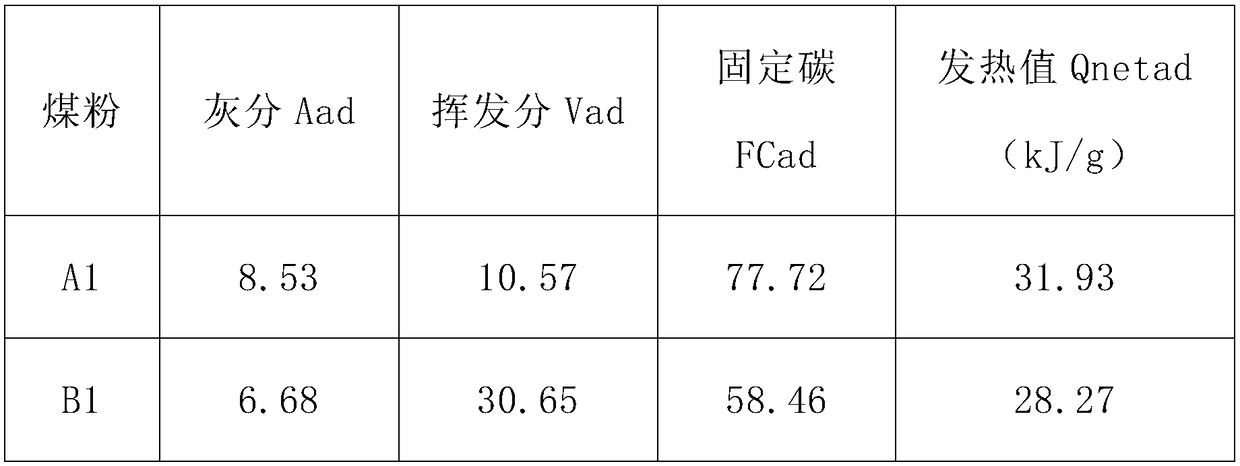

Additive for improving fluidity of pulverized coal for blast furnace injection and using method thereof

The invention belongs to the technical field of blast furnace ironmaking, and particularly relates to an additive for improving the fluidity of pulverized coal for blast furnace injection and a usingmethod thereof. The using method comprises the steps that dried metallurgical dedusting ash and the pulverized coal are mixed evenly and injected into a blast furnace from a blast furnace coal gun. The using method can not only improve the flowing performance of the pulverized coal for injection, but also increase the source of iron-bearing minerals in blast furnace ironmaking, so as to achieve stable injection of the pulverized coal and reduce production cost.

Owner:NORTHEASTERN UNIV

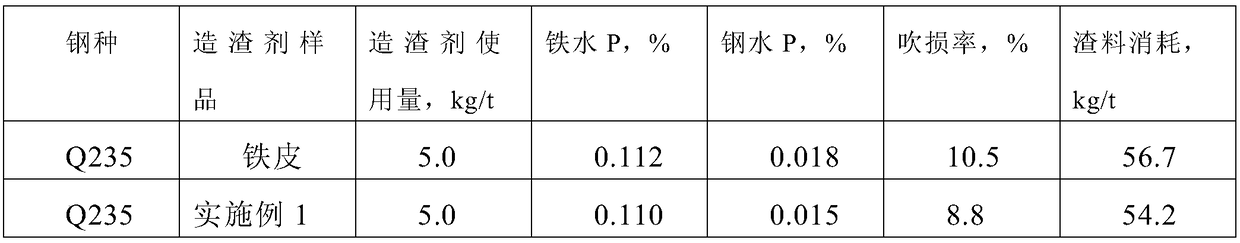

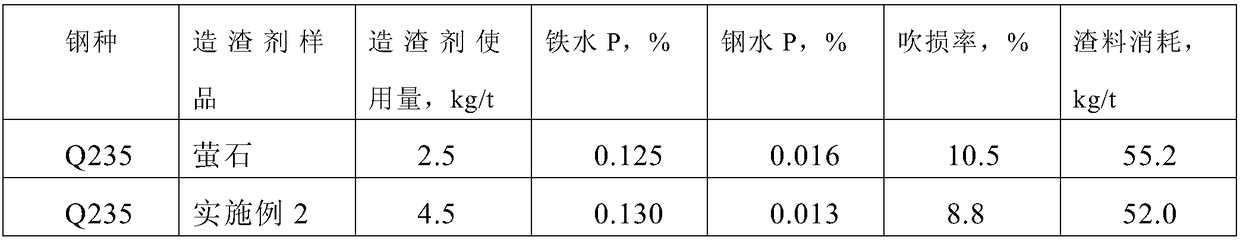

Premelting composite slugging agent for converter and preparation method thereof

InactiveCN109338027AConducive to smeltingResist drynessManufacturing convertersProcess efficiency improvementEnvironmental resistanceSlag

The invention relates to a premelting composite slugging agent for a converter and a preparation method thereof. The slugging agent comprises raw materials of lime, ferric oxide powder, activated aluminum oxide powder, low-sulfur cement, silica powder and an activating agent, wherein the raw materials comprise the following components in percentage by mass: 15-35% of CaO, 15-35% of Fe2O3, 5-15% ofAl2O3, 5-15% of MgO, and not greater than 15% of SiO; and the slugging agent contains not greater than 0.25% of impurity element S. According to the slugging agent, the raw materials are environmentally friendly; the melting point is low; the slagging speed is high; the breathability of slags can be obviously improved; the splashing in the converting process is reduced; and meanwhile, the slugging effect in the converting process can be effectively improved through the slugging agent, and the converting process is stable; the slugging agent avoids re-drying and gun adhering; in addition, theend point oxygen of a converter can be decreased after the converting slugging effect is improved, so that the oxidization of the slags can be reduced; the steel iron consumption is decreased; and theproduction cost is reduced.

Owner:武汉钢铁有限公司

Impeller, fan apparatus using the same, and method of manufacturing impeller

An impeller, a fan apparatus, and a method of manufacturing the impeller are provided. The impeller includes a support portion, a plurality of rotor blades, and a joining member. The joining member is a substantially annular member provided to strengthen the rotor blades against influence of a centrifugal force, and extends in a circumferential direction along a circle centered on a central axis so as to join the rotor blades to one another. In each of the rotor blades, a point of intersection of a leading edge of the rotor blade with a radially outer end of the rotor blade is positioned forward, with respect to a rotation direction, relative to a point of intersection of the leading edge with an outside surface of the support portion. The joining member is positioned radially inwards of the radially outer end of each of the rotor blades.

Owner:NIDEC SERVO CORP

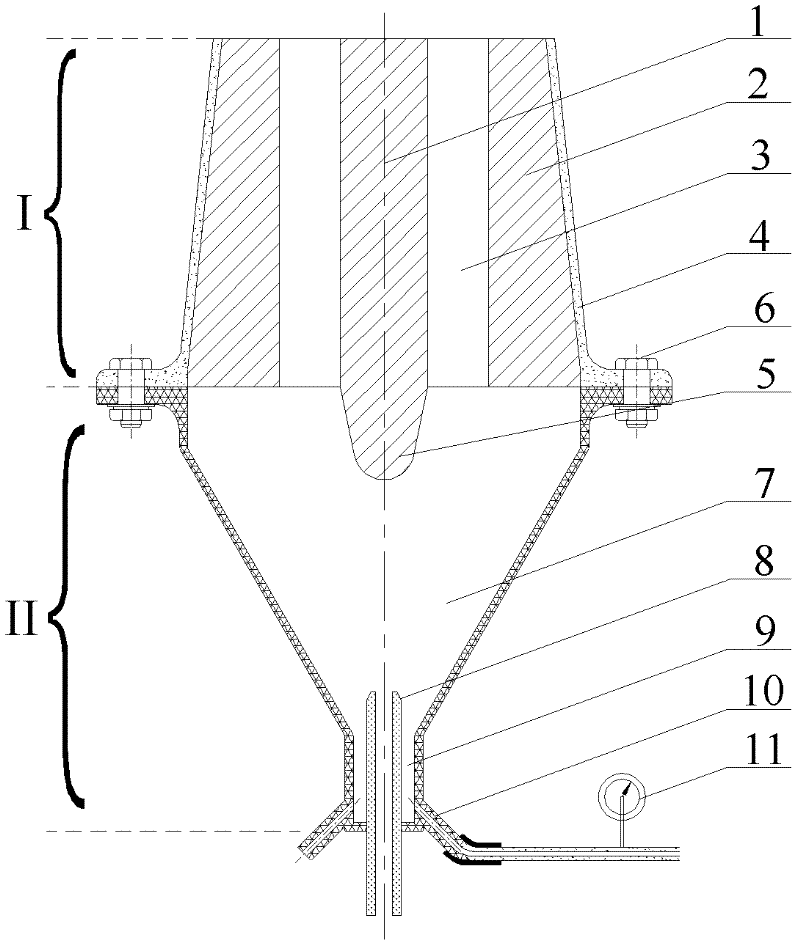

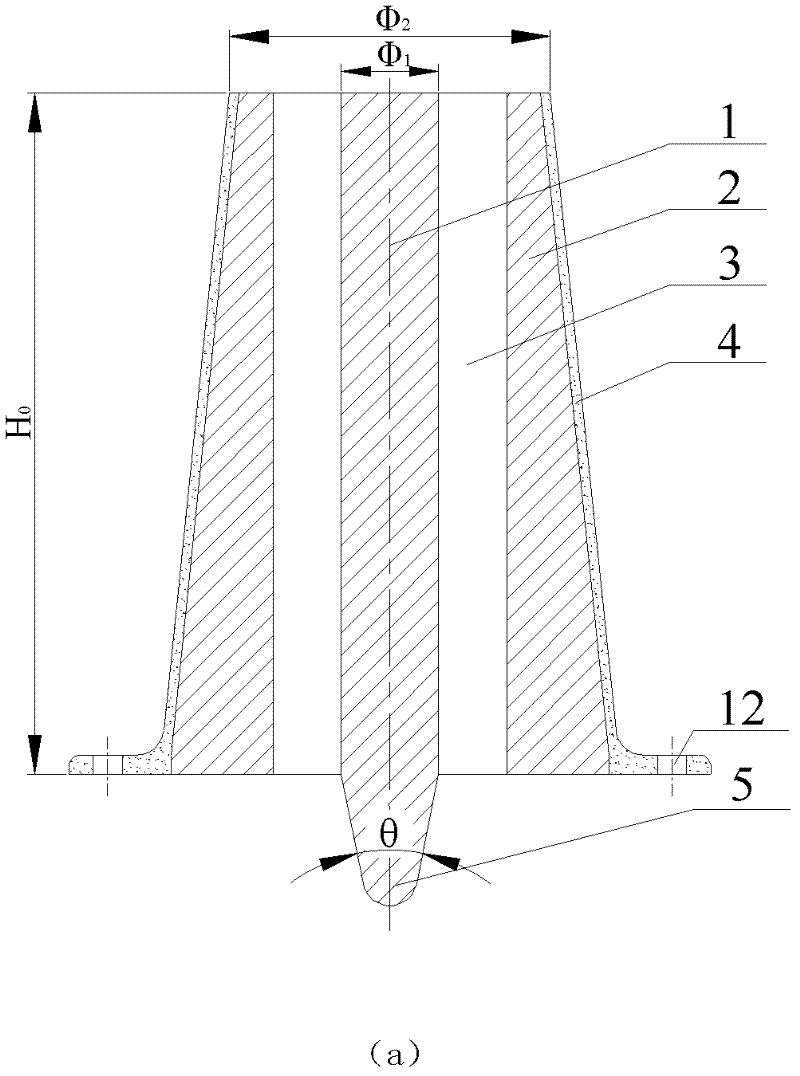

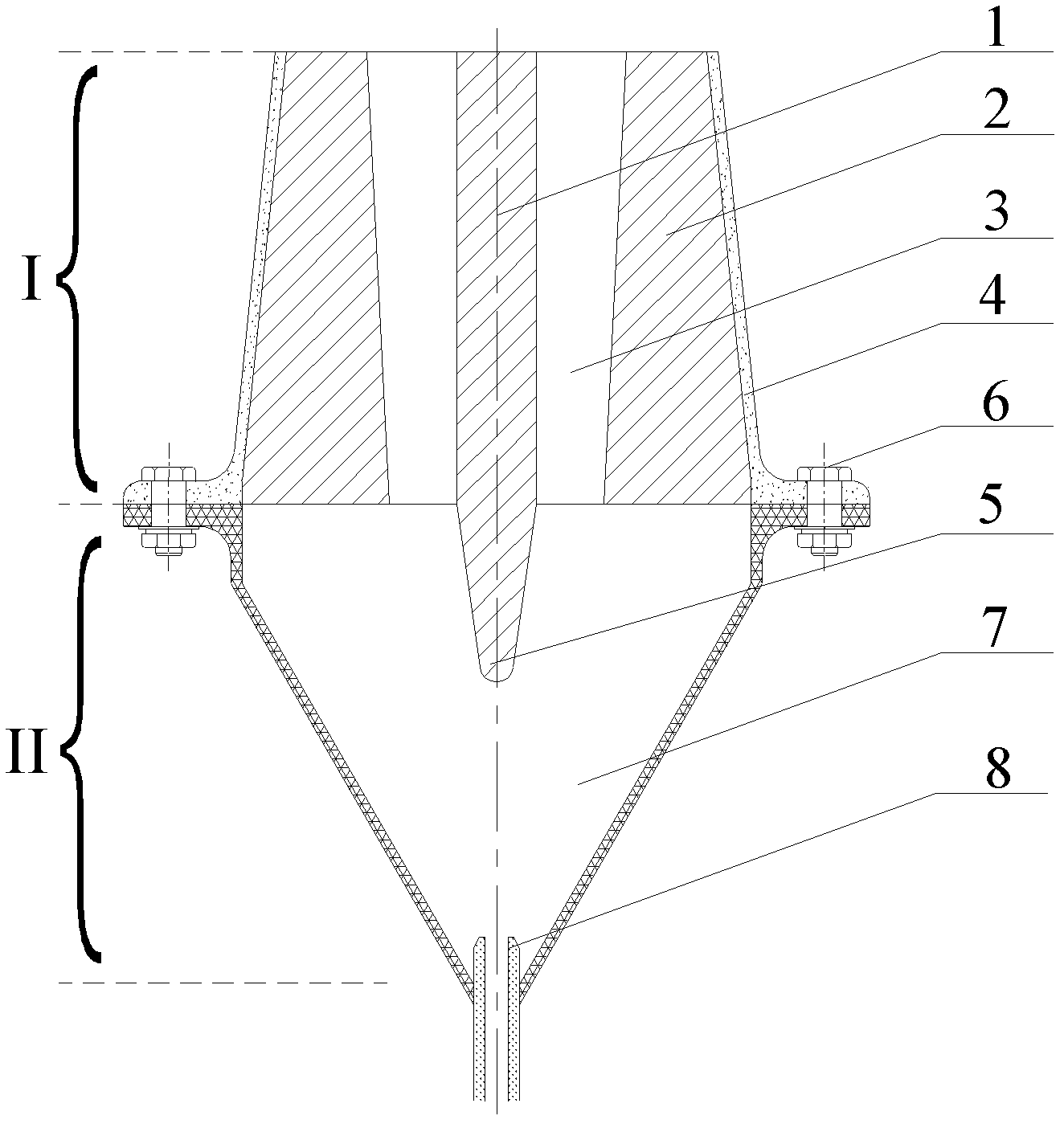

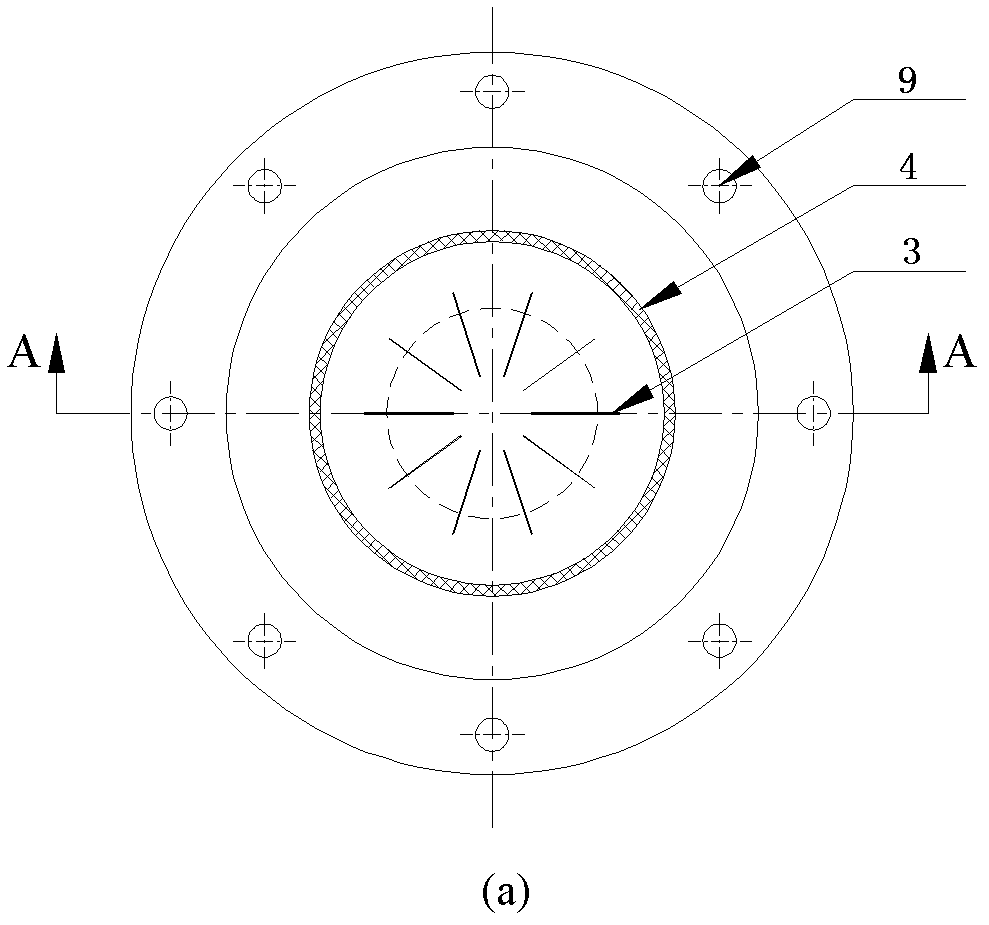

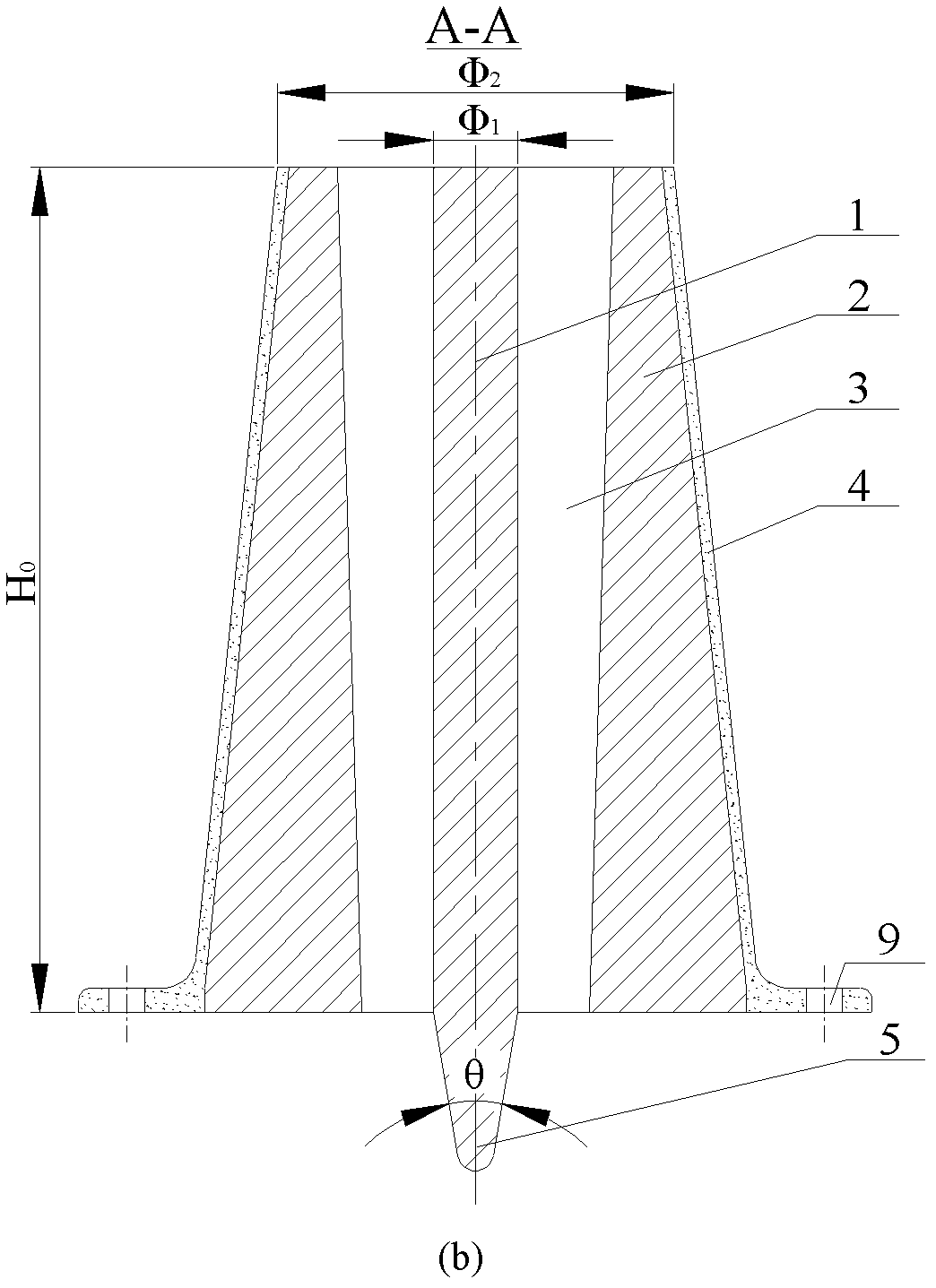

A device for blowing and spraying powder at the bottom of a ladle in a cyclone-protected gas storage chamber

The invention discloses a ladle bottom blowing power injection device with a whirlwind-type flow-smoothing gas storage chamber, and belongs to the technical field of steel smelting. The ladle bottom blowing power injection device with a whirlwind-type flow-smoothing gas storage chamber comprises a slit-type powder injection component I and the whirlwind-type flow-smoothing gas storage chamber II.A fire-resistant material is filled into the slit-type powder injection component. Multiple slits are distributed uniformly in the fire-resistant material. A middle axle plane which passes through ends which belong to the slits and are close to an axle center, and a vertical plane where the slits are arranged form an included angle gamma. The bottom of the whirlwind-type flow-smoothing gas storage chamber is connected with a whirlwind-type accelerating chamber. A low end of the whirlwind-type accelerating chamber is provided with a whirlwind-type gas flow conveying pipes. The whirlwind-type gas flow conveying pipes are arranged at both sides of a power-gas flow conveying pipe and form respectively beta angles with the power-gas flow conveying pipe. The ladle bottom blowing power injectiondevice with the whirlwind-type flow-smoothing gas storage chamber can reduce obviously a degree of powder-gas flow pulsation, accumulation of falling powder, and resistance to a powder-gas flow when the powder-gas flow is fed into the slits, can improve obviously a uniform flow conveying rate of the powder-gas flow in the slits. The ladle bottom blowing power injection device with the whirlwind-type flow-smoothing gas storage chamber has the advantages of stable blowing, small pulsation, low corrosion on fire-resistant materials, safe and reliable characteristics, feasibility for continuous and stable blowing and long service life of fire-resistant materials.

Owner:NORTHEASTERN UNIV LIAONING

Molten steel deoxidizing and microalloying method

PendingCN109680115AUniform composition and temperature of molten ironStable blowingManufacturing convertersElectric furnaceChemical compositionSmelting

The invention provides a molten steel deoxidizing and microalloying method. The molten steel deoxidizing and microalloying method comprises the following steps of blowing oxygen to the top of a top-bottom combined blowing converter, blowing inert gas to the bottom of the top-bottom combined blowing converter for smelting, or blowing inert gas to the bottom of molten steel in an electric furnace for smelting; after main chemical components are qualified, blowing a deoxidizing agent to the bottom with inert gas as a carrier for refining; and when the oxygen content in the molten steel is less than or equal to 200 ppm, blowing alloyed powder into the molten steel with inert gas as a carrier for microalloying treatment, wherein the blowing amount of the alloyed powder is less than or equal to10 kg / t of the molten steel.According to the molten steel deoxidizing and microalloying method, the inert gas is blown to the bottom, and after the deoxidizing agent is blown into the molten steel todeoxidize the molten steel, the alloyed powder is blown for direct microalloying, so that components of the molten steel can be more uniform; a brand new concept is provided for directly microalloyingmicroalloy elements in the steel material production process; the microalloy elements existing in the form of solid solution can be effectively obtained out of a steel material, and thus, the steel performance is improved.

Owner:WUHAN UNIV OF SCI & TECH

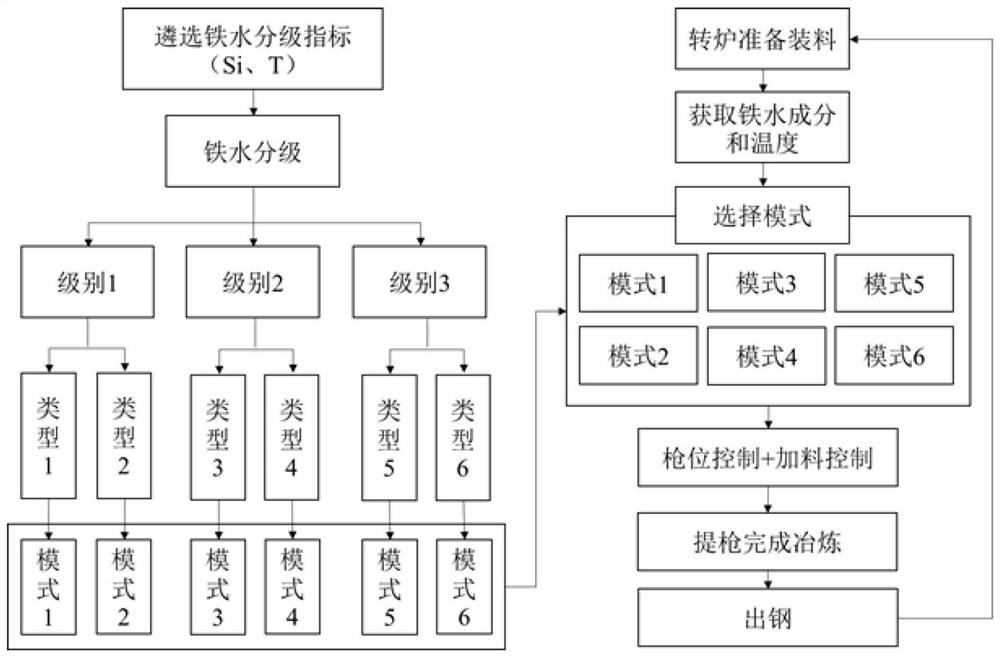

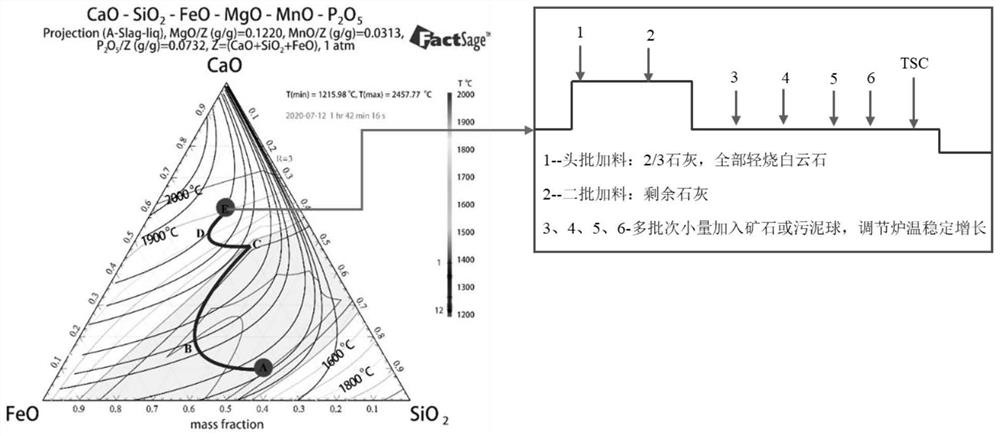

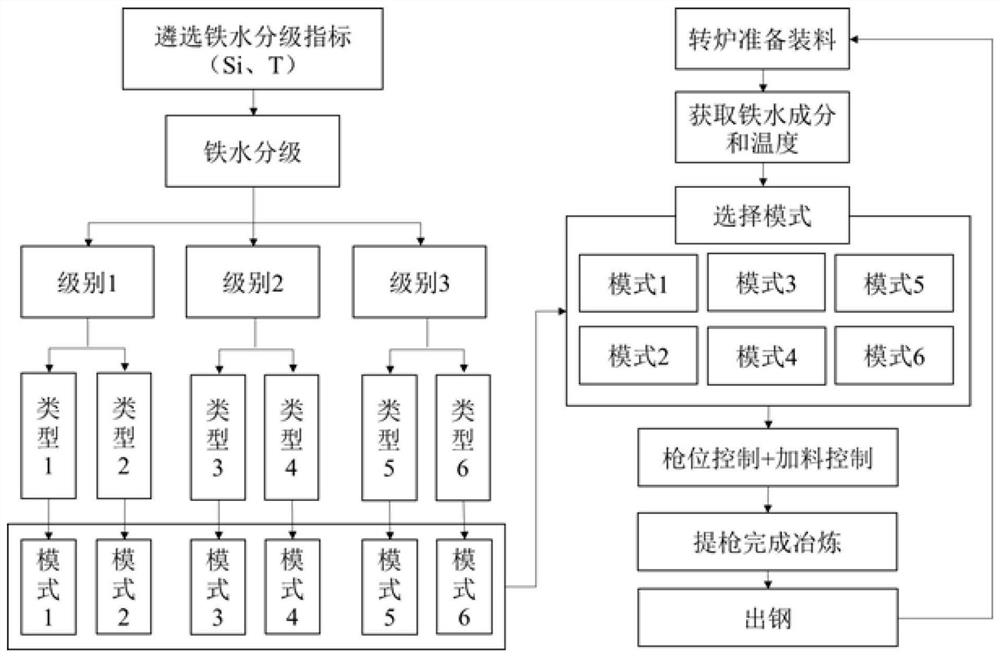

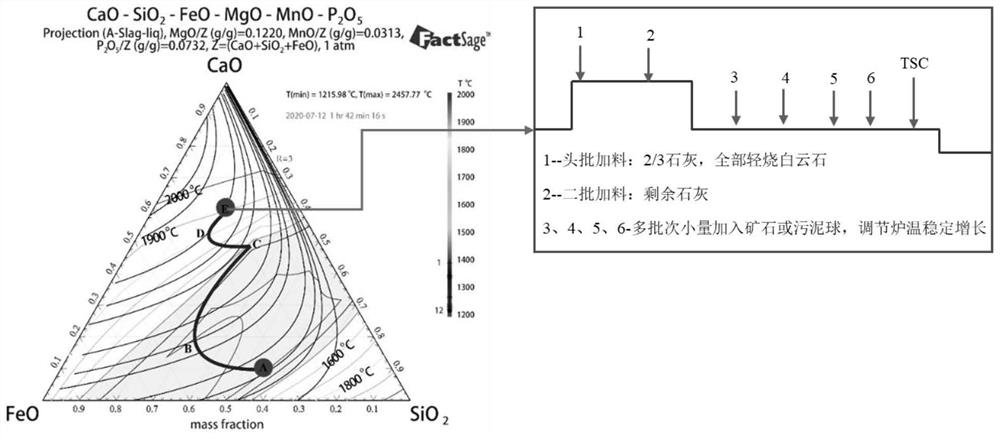

Converter multi-mode smelting method based on molten iron grading system

ActiveCN113981167AStable blowingReduce consumptionSteel manufacturing process aspectsIncreasing energy efficiencySlagMaterial consumption

The invention provides a converter multi-mode smelting method based on a molten iron grading system. The converter multi-mode smelting method comprises the following steps: firstly, selecting grading indexes of molten iron, formulating the molten iron grading system, designing blowing modes matched with different grades of molten iron according to the different grades of molten iron, firstly obtaining components and temperature of the molten iron before charging, and selecting the corresponding blowing mode to assist in completing smelting. According to the method, the molten iron with large component fluctuation is classified based on the 'differential' thought in mathematics, the molten iron falling into the same category can be regarded as stable, the same blowing mode is adopted, stable blowing of the converter can be achieved, blowing accidents caused by large fluctuation of the molten iron are avoided, the dephosphorization effect can be improved to a certain degree, and material consumption can be reduced, the slag production amount is reduced, the smelting period is shortened, and the good metallurgical effect is achieved.

Owner:UNIV OF SCI & TECH BEIJING

Impeller, fan apparatus using the same, and method of manufacturing impeller

ActiveCN101713417BImprove featuresPrevent reverse airflowPump componentsPump installationsLeading edgeImpeller

An impeller, a fan apparatus, and a method of manufacturing the impeller are provided. The impeller includes a support portion, a plurality of rotor blades, and a joining member. The joining member is a substantially annular member provided to strengthen the rotor blades against influence of a centrifugal force, and extends in a circumferential direction along a circle centered on a central axis so as to join the rotor blades to one another. In each of the rotor blades, a point of intersection of a leading edge of the rotor blade with a radially outer end of the rotor blade is positioned forward, with respect to a rotation direction, relative to a point of intersection of the leading edge with an outside surface of the support portion. The joining member is positioned radially inwards of the radially outer end of each of the rotor blades.

Owner:JAPAN SERVO CO LTD

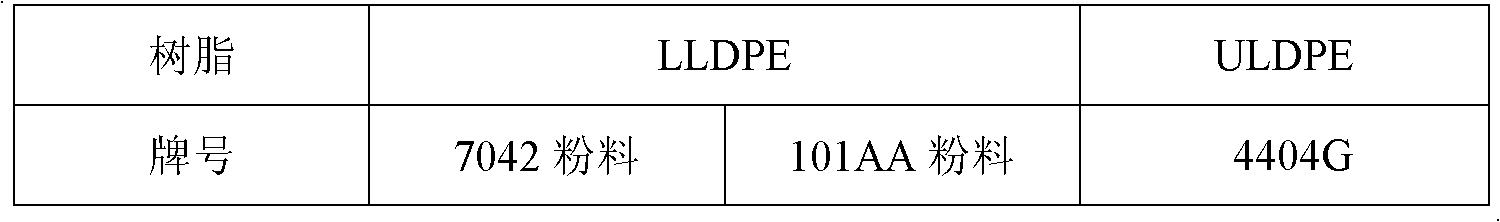

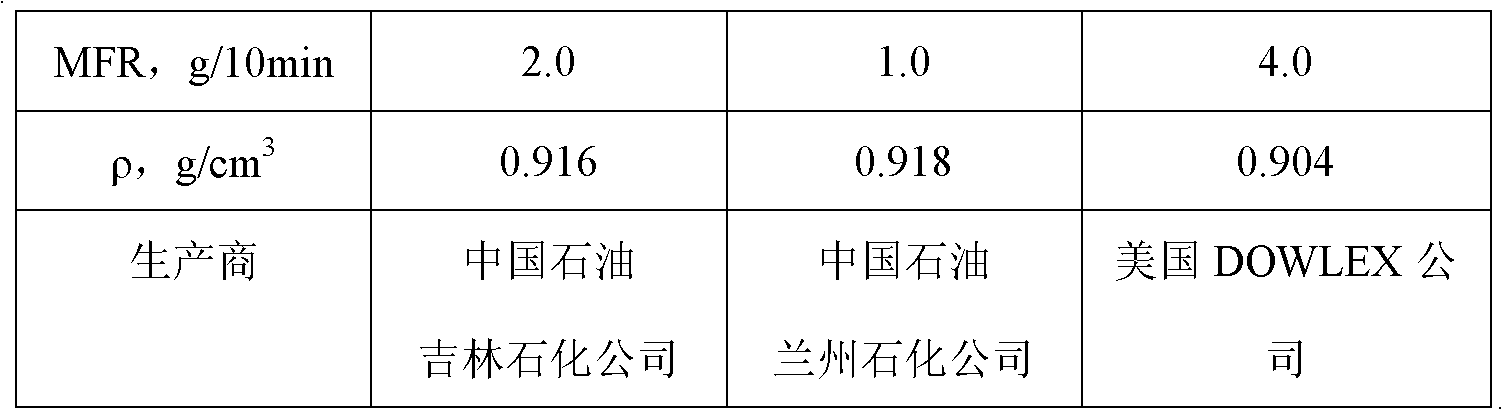

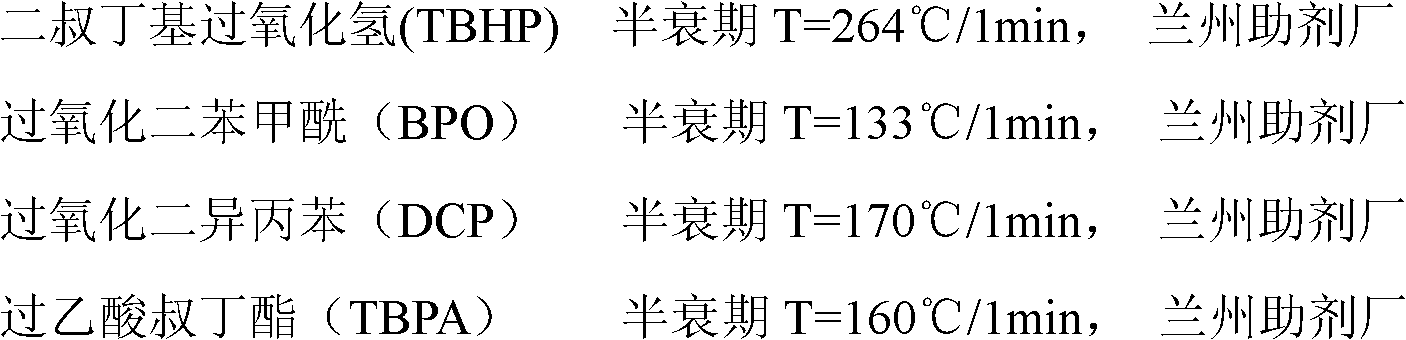

Polyethylene resin composition for weathering resistance agriculture film, and preparation method thereof

ActiveCN102924800AReduce refractionReduce rangeLow-density polyethyleneLinear low-density polyethylene

The present invention provides a linear low density polyethylene (LLDPE) resin composition for a weathering resistance agriculture film and a preparation method thereof. The resin composition comprises, by weight of LLDPE, (1) 100% of LLDPE, (2) 0.05-0.3% of a compound cross-linking aid, and (3) 10-30% of ultra-low density polyethylene (ULDPE) weathering resistance master batch. With the composition, a broad width shed plastic film (a width of more than or equal to 8 m and a thickness of more than or equal to 80 mum) can be blown out without any blending, fisheyes on the surface of the shed plastic film are less, weathering resistance is excellent, and natural damage can not occur after the shed plastic film continuously covers a greenhouse for more than 40 months. The present invention further provides a preparation method for the resin composition, wherein the preparation method has advantages of short procedure, simple process, low development cost, stable product quality and the like.

Owner:PETROCHINA CO LTD

Frustum slit type anti-blocking ladle bottom-blown powder injection device

InactiveCN102274958BAvoid Dusting RequirementsReduce kinetic energy lossMelt-holding vesselsBrickRefractory

Owner:NORTHEASTERN UNIV LIAONING

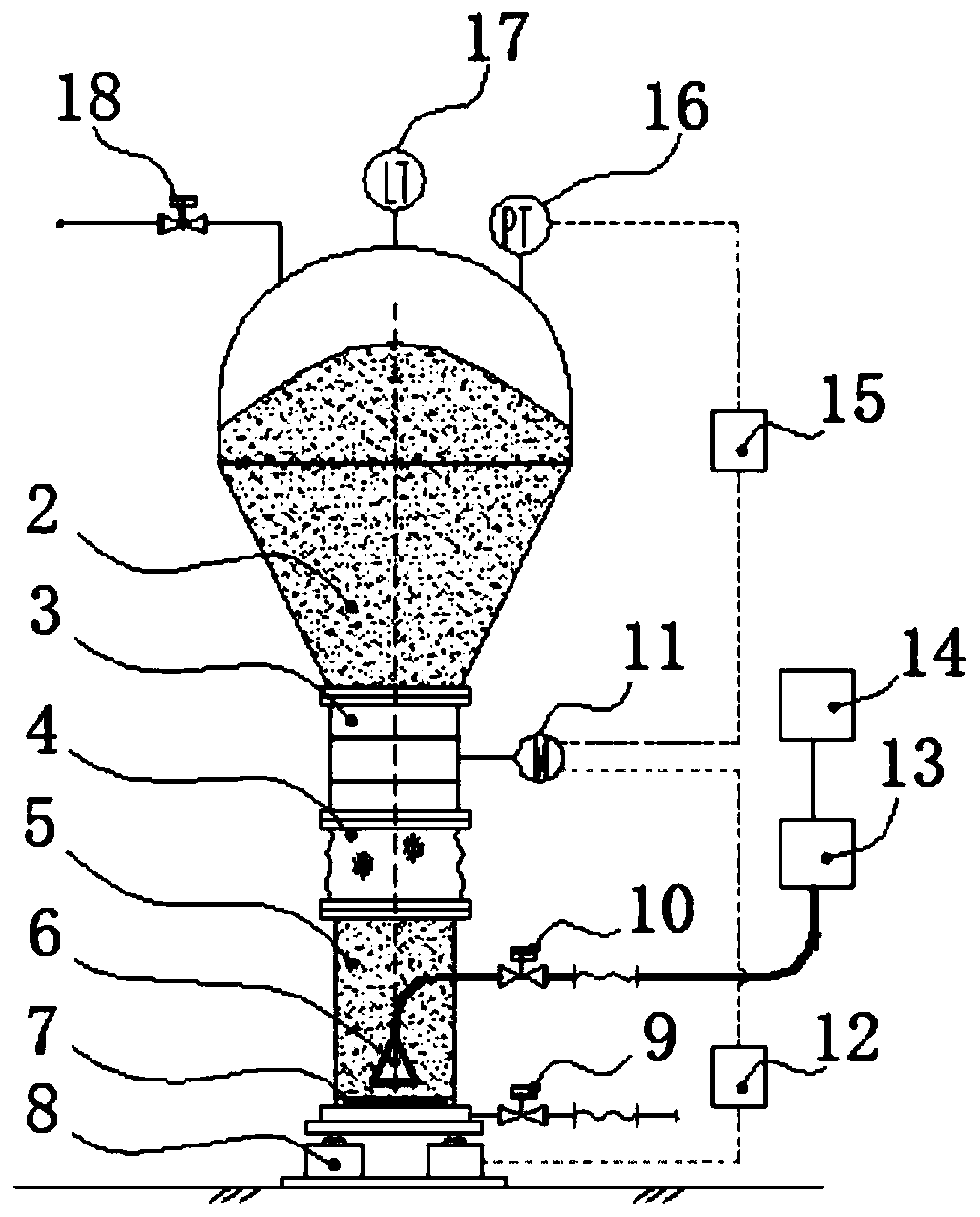

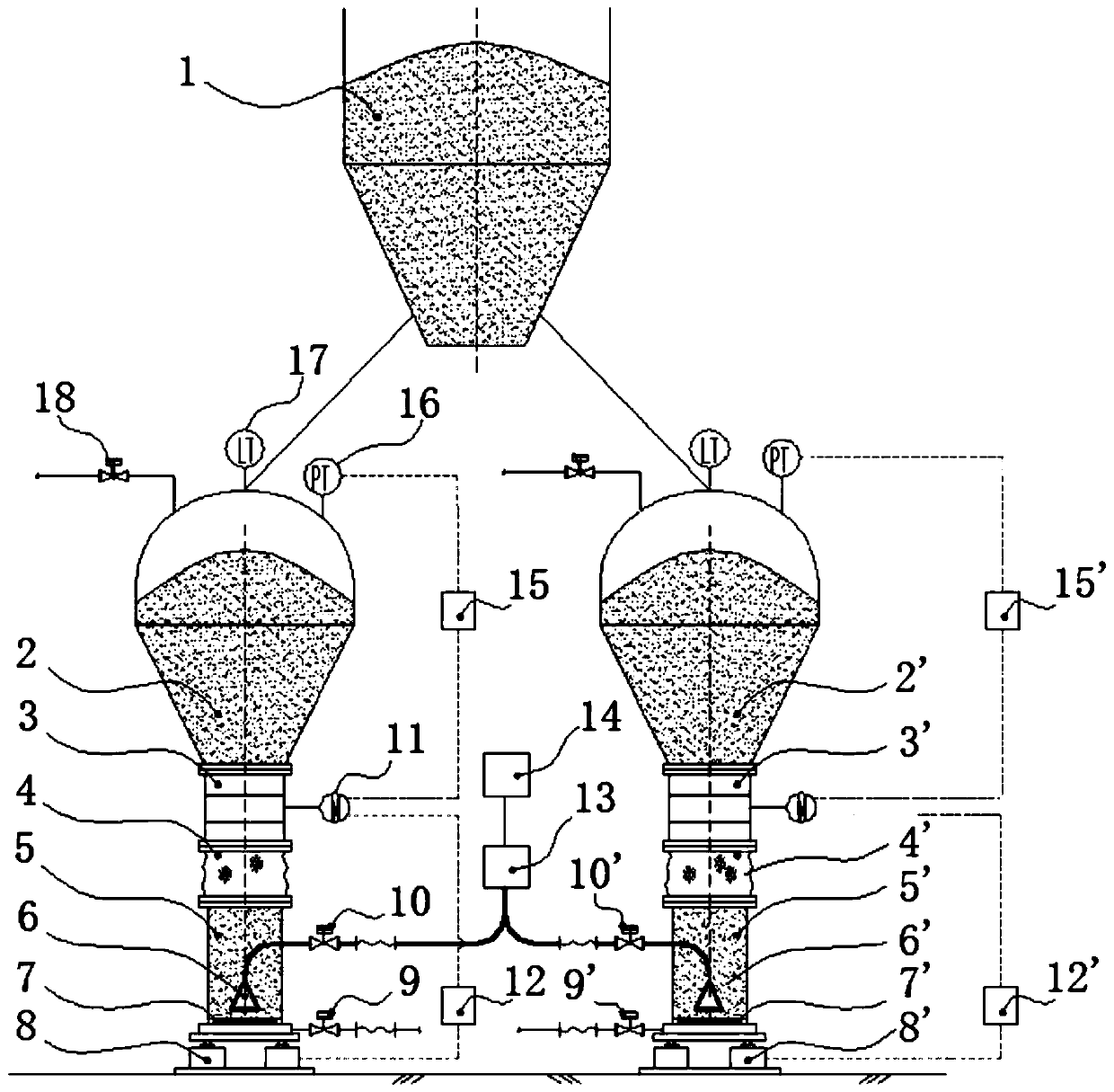

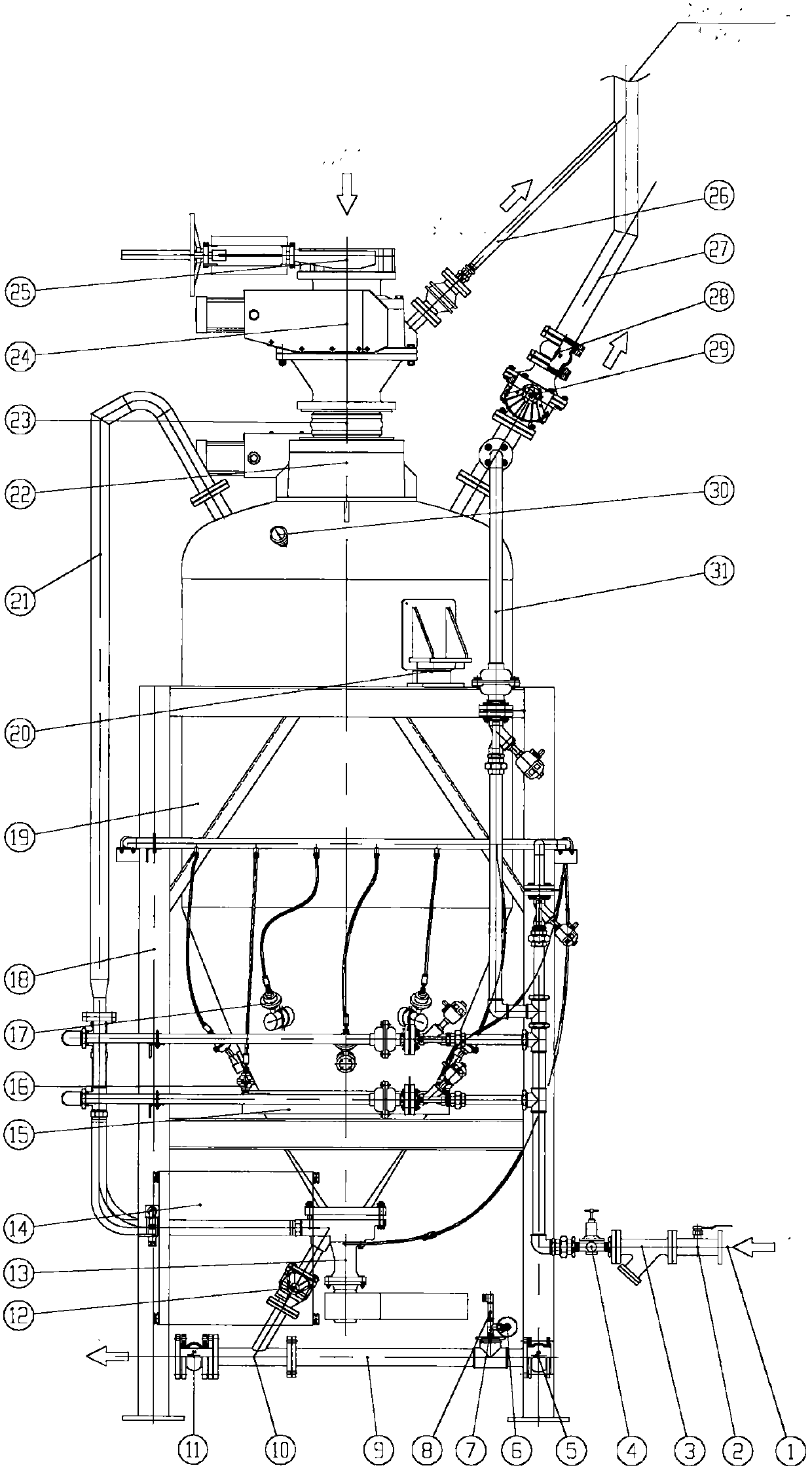

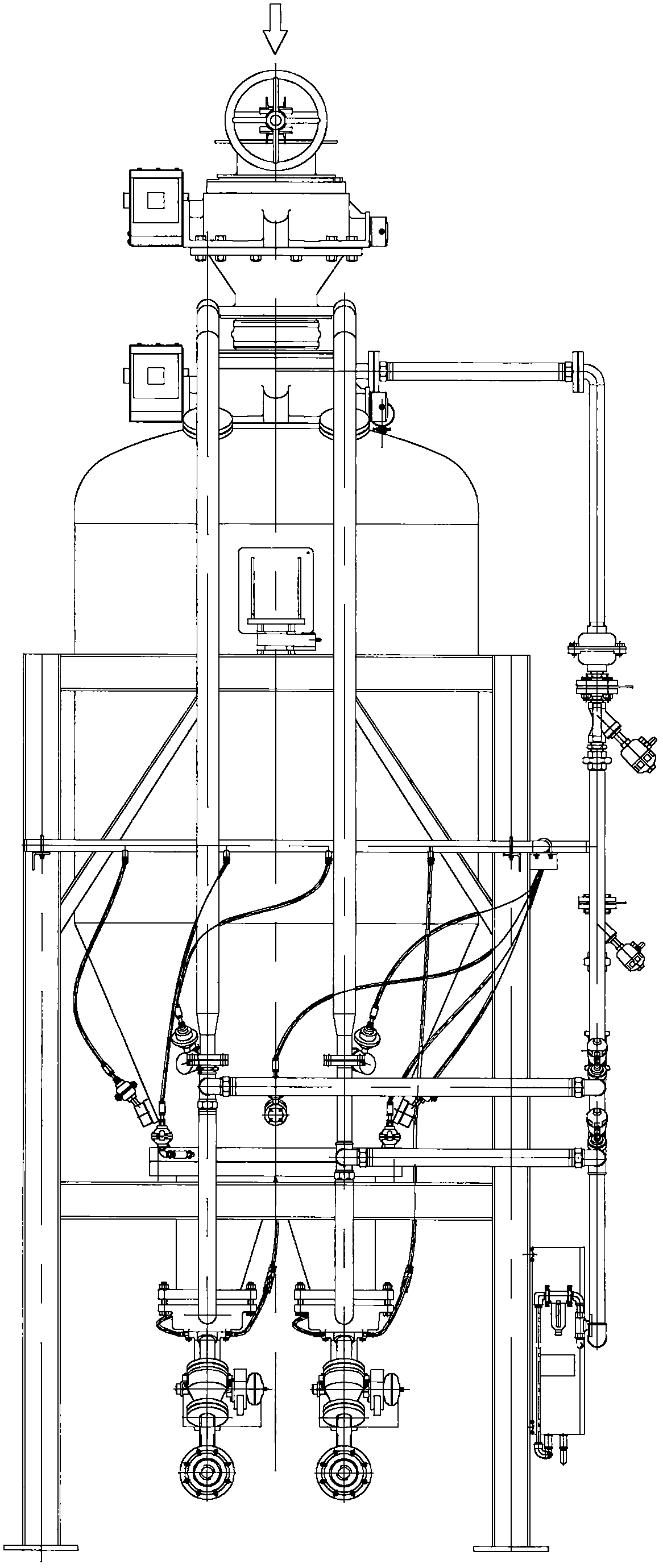

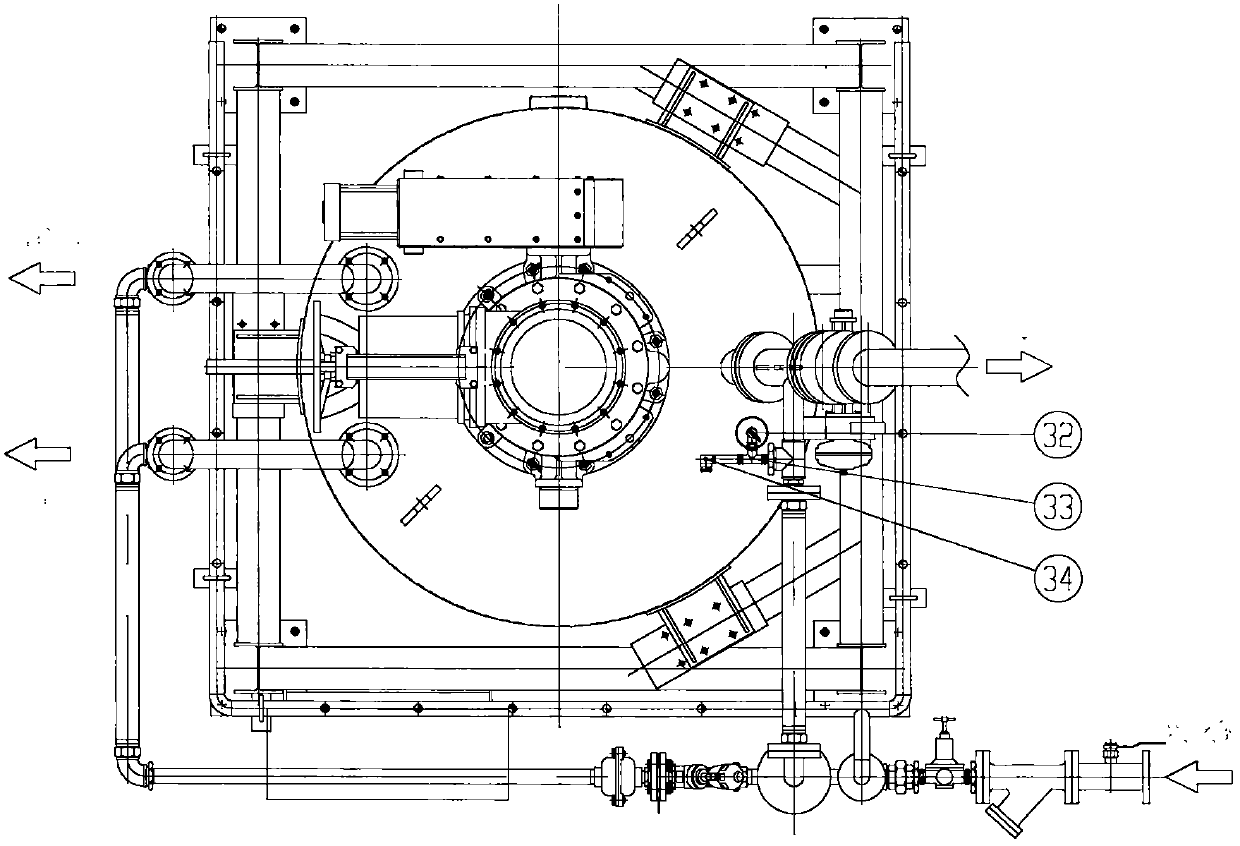

Fluidifying tank, blast furnace coal injecting device and system and a control method

PendingCN109897923AHigh measurement accuracyStable blowingBlast furnace componentsBlast furnace detailsEngineeringCoal

The invention discloses a blast furnace coal injecting device. The blast furnace coal injecting device comprises an injecting tank, a quantitative feeding device, and a quantitative feeding device driving mechanism. The blast furnace coal injecting device is characterized by further comprising a fluidifying tank and a weighing device; and the fluidifying tank is arranged on the weighing device, communicates with the quantitative feeding device, and is flexibly connected with the quantitative feeding device. The blast furnace coal injecting device is provided with the fluidifying tank and the weighing device in an outlet of the quantitative feeding device, and adopts a coal injecting quantity two-stage control method to achieve the purpose of further improving the injecting quantity metering precision.

Owner:CISDI RES & DEV CO LTD

A method for producing nickel-based steel from high-phosphorus molten iron

ActiveCN111411300BHigh phosphorus contentReduce phosphorus contentManufacturing convertersProcess efficiency improvementSlagHeating furnace

The invention discloses a method for producing nickel-based steel from high-phosphorus molten iron, which relates to the technical field of iron and steel smelting. It uses a converter for smelting, and the P content of the molten iron used is 0.130% to 0.150%. The end point temperature is 1580-1620°C, the bottom stirring flow rate in the middle and later stages of smelting is 350-400NL / min, the final slag basicity is 4.0, and the final slag control amount is 10-12 tons. The decarburization rate of the converter is ≥99%, and the dephosphorization rate is ≥96%. ; After LF refining, RH vacuum treatment, arc casting machine casting, TMCP rolling, ACC water cooling to 300±20°C and air cooling to room temperature, steel plate heating to 550±10°C, tempering for 3×h minutes, air cooling to room temperature. The converter process is optimized, the product is vacuum treated, cast by the arc continuous casting machine, and then sent to the heating furnace for heating, TMCP rolling and ACC water cooling are adopted, and the performance test is qualified after tempering treatment.

Owner:NANJING IRON & STEEL CO LTD

A multi-mode smelting method based on molten iron classification system

ActiveCN113981167BStable blowingReduce consumptionSteel manufacturing process aspectsManufacturing convertersSlagMaterial consumption

The invention provides a converter multi-mode smelting method based on the molten iron classification system. First, the classification index of the molten iron is selected, the molten iron classification system is formulated, and the matching blowing mode is designed for the molten iron of different grades, and the molten iron is first obtained before charging. composition and temperature, and select the corresponding blowing mode to assist in the completion of smelting. The invention is based on the idea of "differentiation" in mathematics, and classifies molten irons with relatively large fluctuations in composition. The molten irons falling in the same category can be regarded as stable, and the same blowing mode can be used to realize the stable blowing of the converter. It avoids blowing accidents caused by large fluctuations of molten iron, not only can improve the dephosphorization effect to a certain extent, but also can reduce material consumption, reduce slag production, shorten smelting cycle, and have good metallurgical effects.

Owner:UNIV OF SCI & TECH BEIJING

Low-oxygen pressure converter steelmaking method

The invention discloses a low-oxygen pressure converter steelmaking method. The low-oxygen pressure converter steelmaking method is characterized in that when the actual oxygen supply flow cannot achieve the oxygen flow of objective requirement, the oxygen pressure is smaller than 0.85 Mpa and greater than or equal to 0.75 Mpa, or the oxygen pressure is smaller than 0.75 Mpa and greater than or equal to 0.65 Mpa, or the oxygen pressure is smaller than 0.65 Mpa, the position of an oxygen lance, the adding amount of light burned dolomite and active lime and the carbon catching time are adjusted according to the oxygen pressure. Compared with the prior art, the low-oxygen pressure converter steelmaking method has the beneficial effects that stable blowing and safe production can be achieved at low oxygen pressure; production interruption or delay of progress of works caused by low oxygen pressure is avoided; corrosion of high-oxidability slag on a lining is reduced; the risk of a safety accident is also effectively reduced.

Owner:ANGANG STEEL CO LTD

Automatic controlling method for converter oxygen lance used for converting low-carbon steel

ActiveCN102399933BEliminate splatterReduce dependenceManufacturing convertersAutomatic controlData acquisition

The invention provides an automatic controlling method for a converter oxygen lance used for converting low-carbon steel. The method comprises a data collecting and analyzing step, a raw material controlling step, and an oxygen lance position controlling step. The method is characterized in that: during an entire low-carbon steel converting procedure in a converter, an oxygen lance position is controlled according to the variation of the accumulated amount of oxygen in the converter; the oxygen lance position is fixed as a slagging position since the converting is started to 20% of a total converting time is reached; the oxygen lance is automatically adjusted according to a determined scheme since 20% of the total converting time is reached to 90% of the total converting time is reached; the oxygen lance position is fixed as a carbon catching position since 90% of the total converting time is reached to 100% of the total converting time is completed, and a converting end point is determined according to the decarbonization speed; when a tapping requirement is satisfied, the oxygen lance is stopped, and the converting is stopped. With the method provided by the invention, the entire converting procedure can be continuously and dynamically corrected, such that oxygen lance position automatic controlling can be realized.

Owner:ANGANG STEEL CO LTD

A double chamber kiln injection system

ActiveCN107091483BStable blowingUniform and stable blowingFuel feeding arrangementsLump/pulverulent fuel feeder/distributionEngineeringDistributor

The invention relates to a novel double-chamber kiln jetting system mainly applicable to jetting of coal powder for a double-chamber kiln. The double-chamber kiln jetting system is mainly composed of a manual gate valve, dome valves, flexible joints, a jetting tank inlet dome valve, a jetting tank, vertical rotary feeding machines, a weighing device, a level gage, pressure transmitters, a fluidization device, conveying pipelines, a wear-resisting bend, distributors, a MCC control cabinet, a PLC control cabinet, an upper computer and the like. The bottom of each jetting device is provided with two vertical metering rotary feeding machines, the outlet of each feeding machine is connected with one main conveying pipeline, the conveying pipelines are provided with pipeline switching valves, each main pipeline on a kiln body platform is divided into two braches, each branch pipe corresponds to one distributor, and coal powder are jet by the distributors into 33 spry guns corresponding to kiln chambers. The system has the advantages that the jetting precision is high, and jetting is stable and will not be affected by changes of material characteristics and fluctuation of pressure in a kiln; due to the unique vertical rotary feeding structure design, it is ensured that the coal spraying system is smooth and free of fluctuation, it is ensured that coil powder is evenly and stably jet in the pipeline and free of blockage; and variable-frequency speed-control continuous quantitative feeding can be achieved, and the feeding amount can be automatically adjusted on line.

Owner:北京瑞德克气力输送技术股份有限公司

Gold stamping blowing device

The invention discloses a gilding blowing device which is provided with an upper die table and a lower die table, a gilding plate is arranged on the upper die table, a coining steel plate is arranged on the lower die table, the lower die table is connected with a first lifting driving assembly, the gilding blowing device further comprises a blowing pipe, blowing heads are arranged on the blowing pipe at intervals, the blowing pipe is arranged on a lifting seat, and the lifting seat is movably arranged on the lower die table. When the gripper row penetrates through the upper die table and the lower die table, the lower die table ascends to conduct gold stamping operation, the second lifting driving assembly drives the lifting base and the air blowing pipe to ascend, the air blowing head is made to be higher than the lower die table, when the lower die table descends, the air blowing head blows air, and before the gripper row moves, the air blowing head is driven by the second lifting driving assembly to blow air. The second lifting driving assembly drives the lifting base and the air blowing pipe to descend, so that the air blowing head is lower than the lower die table. After gold stamping is completed, paper and a gold foil base material can be stably blown to be separated, then the paper is driven by the gripper row to be conveyed backwards, and the gold stamping quality is guaranteed.

Owner:ZHEJIANG DAYUAN MACHINERY

A kind of alloy structural steel 42crmo slab and its production method

The invention relates to an alloy structure steel 42CrMo slab and a production method thereof. The method comprises the following steps: (1) charging molten iron containing less than or equal to 0.030% of S, less than or equal to 0.120% of P and less than or equal to 0.85% of Si into a furnace; (2) smelting steel rods containing more than or equal to 0.10% of C and less than or equal to 0.008% of P in the converter at the temperature of 1650-1680 DEG C; (3) performing LF (low frequency) refining and adjusting the target values of the components, so that C is 0.41-0.43% of C, Si is 0.23-0.27%, Mn is 0.58-0.62%, S is less than or equal to 0.010%, P is less than or equal to 0.015%, Cr is 0.92-0.98%, Mo is 0.17-0.19%, Cu is less than or equal to 0.20% of Cu and Ni is less than or equal to 0.30%, wherein the discharge temperature of molten steel is 1560+45 DEG C in a first furnace and 1550+45 DEG C in a continuous casting furnace; (4) performing VD (vacuum degassing) refining under the vacuum of less than or equal to 67Pa for 15 minutes, meanwhile, performing weak argon blowing stirring of 0.15-0.20MPa, feeding 140-150m of CaSi wire with the diameter of phi13mm after breaking, and then performing weak argon blowing for more than or equal to 10 minutes, wherein the discharge temperature is 1560+ / -5 DEG C in the first furnace and 1550+ / -5 DEG C in the continuous casting furnace; and (5) performing continuous casting: controlling the water distribution of each secondary cooling zone of a slab caster by adopting a primary water meter, wherein the light pressing interval fs is 0.45-0.95, the distribution coefficients are shown in table 2, and the pressing quantity is 3.8mm. The method meets the production requirements of large-section 42CrMo slabs.

Owner:TIANJIN IRON & STEEL GRP

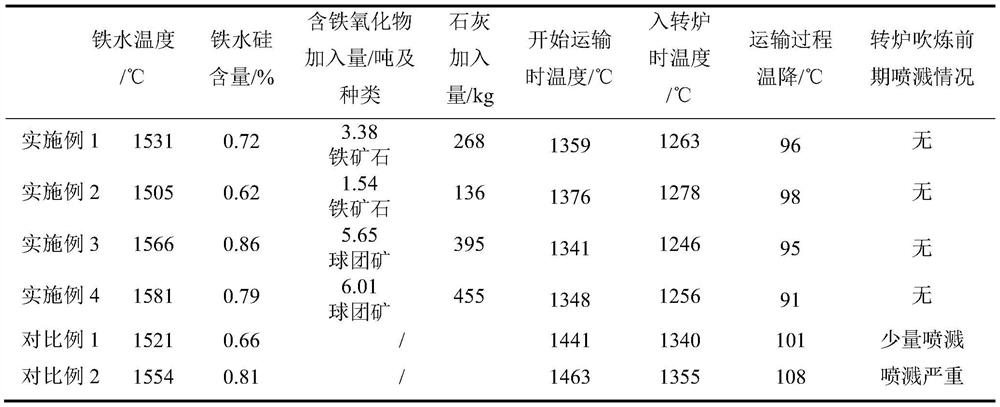

Treatment method of high-temperature high-silicon molten iron

The invention discloses a treatment method of high-temperature high-silicon molten iron, and relates to a ferrous metallurgy technology. The treatment method of the high-temperature high-silicon molten iron is characterized in that iron-containing oxide is added before a ladle or a torpedo ladle receives the high-temperature high-silicon molten iron, and the iron-containing oxide comprises sintered ore, pellet ore and oxide scale, so that the temperature of the molten iron is reduced, and the purpose of reducing the heat dissipation capacity of the molten iron in the conveying process is achieved; when the ladle or the torpedo ladle receives the molten iron, 100-500 kg of lime is added in order to restrain foam slag from overflowing, the particle size range of the lime is 10-20 cm, and therefore splashing caused by rapid rising of the temperature of a molten pool in the early stage of converter blowing is avoided. By reasonably reducing the temperature of the high-temperature high-silicon molten iron, blowing in the earlier stage of the converter blowing is stable, smooth operation of the converter working procedure is facilitated, and the problems that the high-temperature high-silicon molten iron is large in heat loss, and the converter blowing is difficult to stably carry out are solved.

Owner:MAANSHAN IRON & STEEL CO LTD

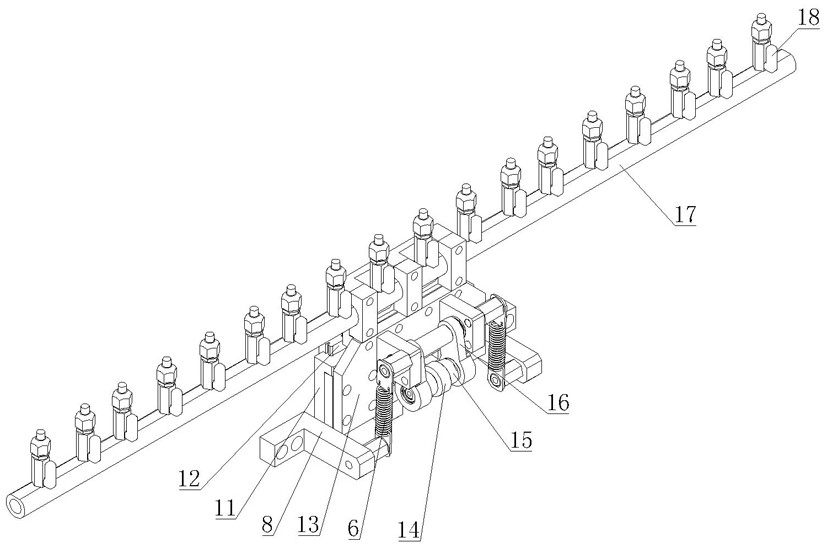

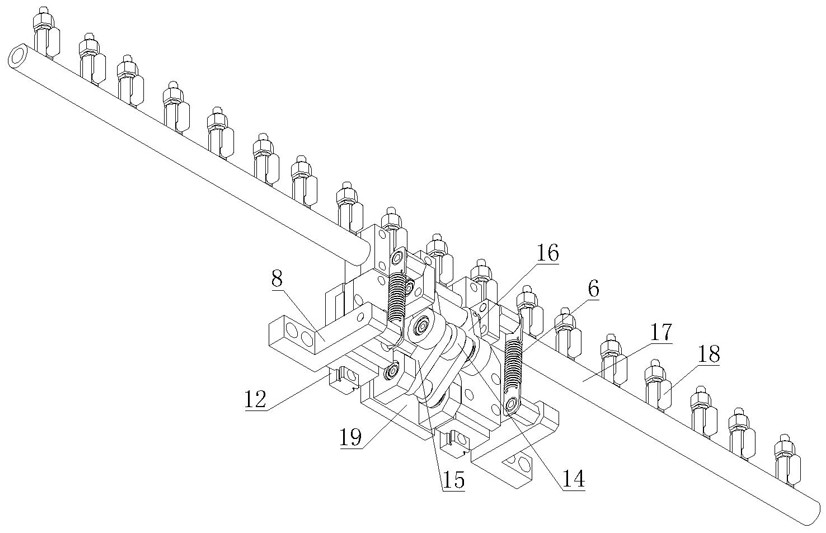

Metal slit-type ladle bottom blowing powder injection apparatus

The invention provides a metal slit-type ladle bottom blowing powder injection apparatus which belongs to the steel refining technical field. The apparatus comprises two parts of a metal slit-type powder injection element and an air accumulating chamber, the metal slit-type powder injection element is connected with the air accumulating chamber through flange bolts; wherein the metal slit-type powder injection element comprises an external metal shell and an refractory material which has slits inside, a metal plate is provided on an inner wall of the slit, a metal base plate is provided on the bottom of the refractory material, a through hole provided on the metal base plate is communicated with the slits, the circumference of the metal base plate is connected with the metal shell, the bottom of the metal plate is connected with the metal base plate, the top of the metal plate is positioned at the top of the slit. The invention has the advantages that the strength for powder injectionsmelting is enhanced, the strength is high at the high temperature, the metal slits are welded for difficult deformation, the apparatus of the invention has the advantages of good airtight, stable blowing, low manufacture cost, large adjustable scope of power and air amount, long usage life, safety and reliability.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com