Converter multi-mode smelting method based on molten iron grading system

A smelting method and multi-mode technology, applied in the field of metallurgy, can solve the problems of unstable blowing, large fluctuations and instability of molten iron composition, etc., and achieve the effect of avoiding blowing accidents, good metallurgical effect, and stable blowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the accompanying drawings and specific implementation.

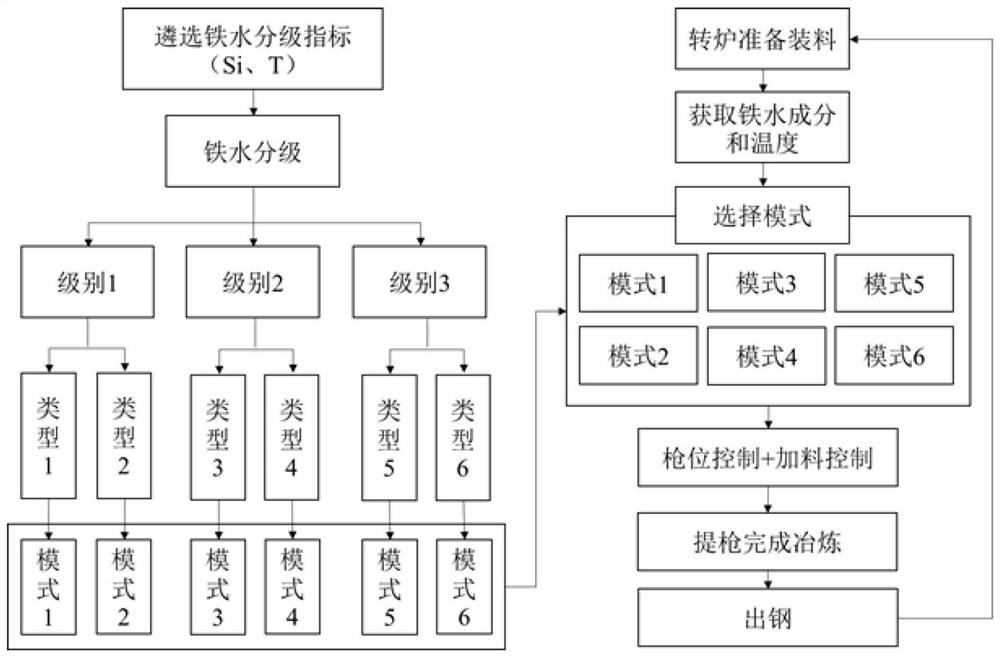

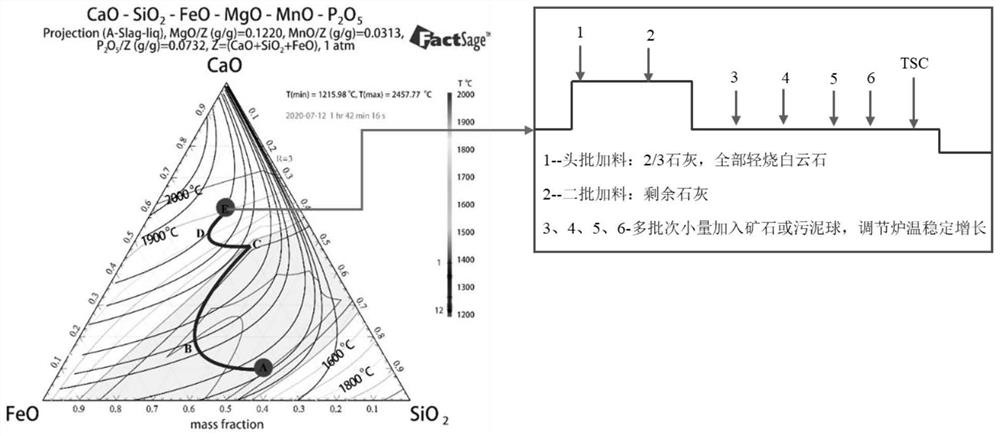

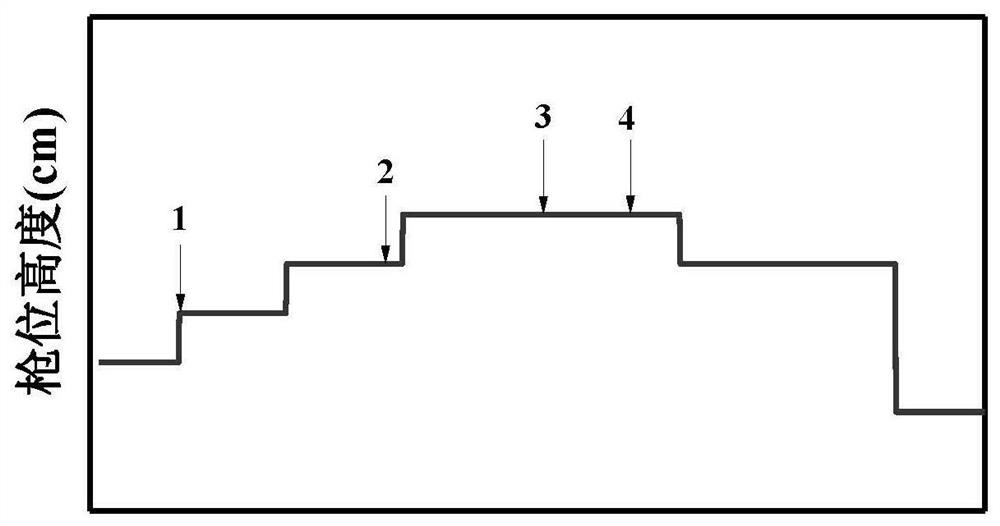

[0072] In the specific embodiment of the present invention, the multi-mode smelting method based on molten iron classification is as follows: figure 1 As shown, for the 120t converter, its molten iron classification and mode division include the following parts:

[0073] (1) Selection of grading indicators

[0074] In order to determine the hot metal classification index, the hot metal information of a steel mill was investigated, and it was found that the hot metal composition of the iron factory does not measure carbon, so the carbon content of the hot metal at the station is unknown to the steel factory, so the carbon content of the hot metal is not used as the hot metal classification index for the time being. In this implementation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com