Gold stamping blowing device

An air blowing device and air blowing tube technology, which is applied in printing, printing machines, rotary printing machines, etc., can solve the problems of limited blowing separation effect and poor hot stamping effect, and achieve the effect of avoiding collision and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

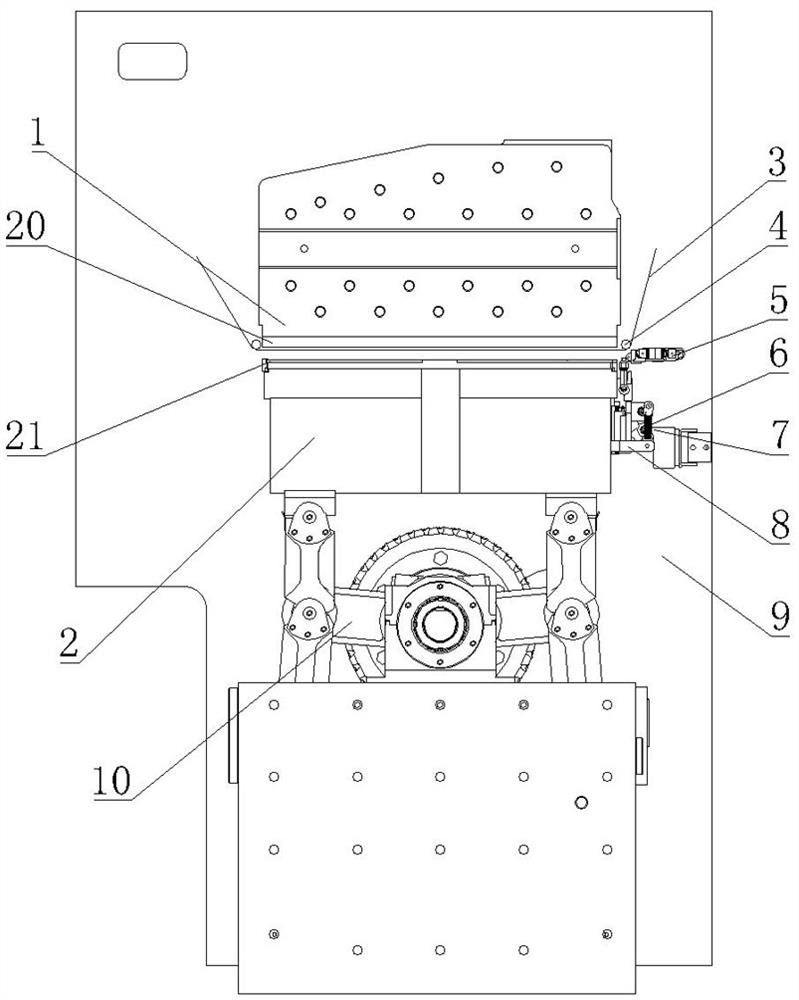

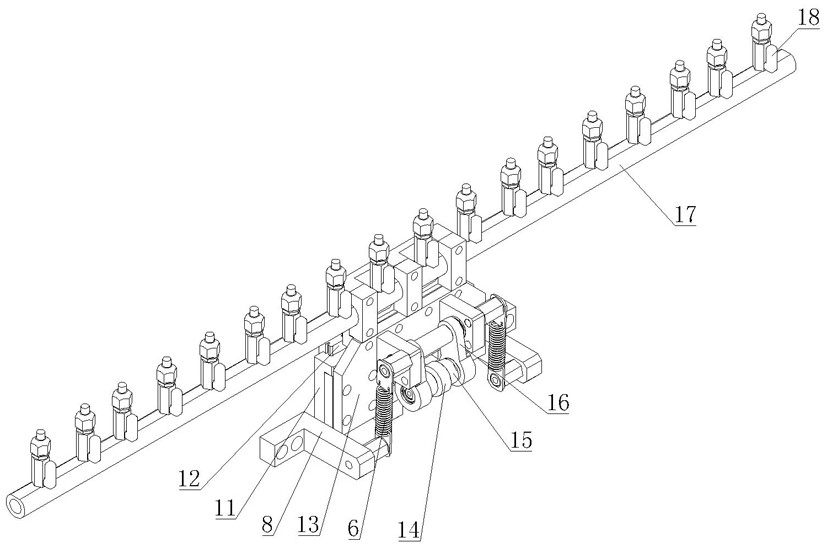

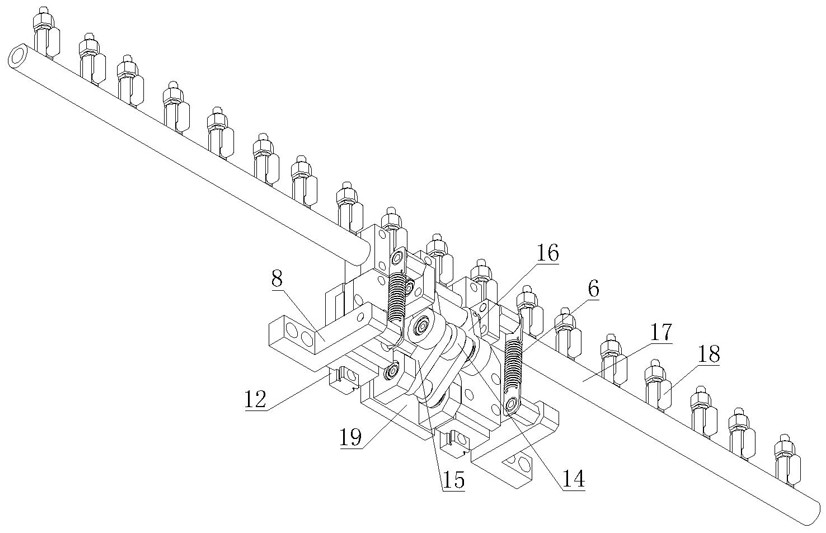

[0015] As shown in the figure, a bronzing air blowing device disclosed by the present invention has a fixed upper mold table 1, on which a bronzing plate 20 is arranged, and a lower mold table 2 is arranged cooperatively below the upper mold table 1 , the lower mold table 2 is provided with an embossed steel plate 21, the lower mold table 2 is connected with the first lift drive assembly, the first lift drive assembly includes a crank, the crank is connected with the lower mold table 2 through the connecting rod assembly 10, and then drives the lower mold table 2 The mold table 2 is lifted and lowered, which belongs to the prior art, so it will not be described in detail. It also includes an air blowing pipe 17, which is connected to an air compressor. On the air blowing pipe 17, blowing heads 18 are arranged at intervals, and the air blowing pipe 17 is set to lift On the seat 13, the lifting seat 13 is movably arranged on the lower mold table 2, and is connected with the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com