Impeller, fan apparatus using the same, and method of manufacturing impeller

A technology of impellers and blades, which is applied to components of pumping devices for elastic fluids, pump devices, non-variable pumps, etc., and can solve problems such as increased noise levels and degradation of static pressure characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] 1. The first preferred embodiment

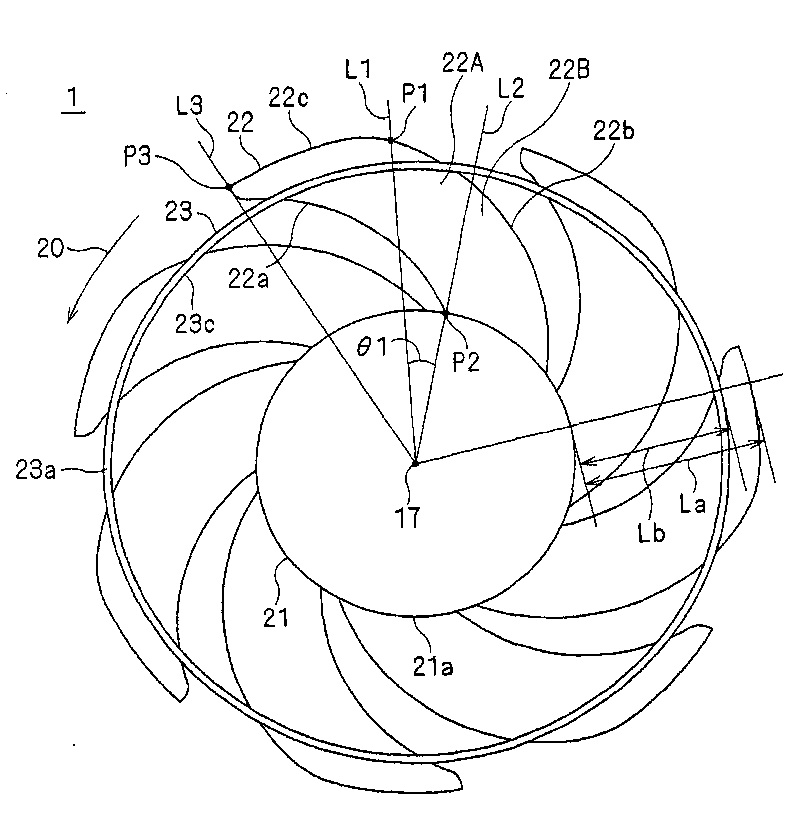

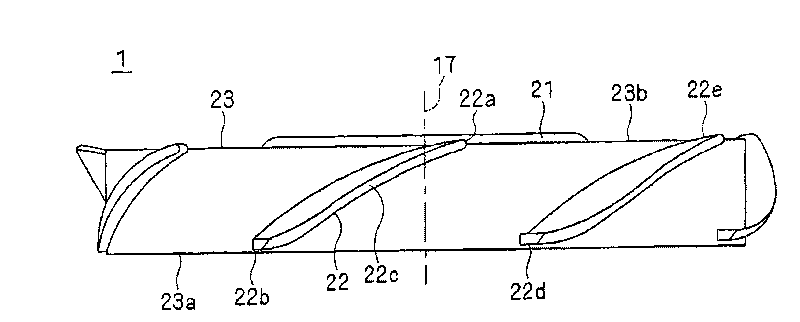

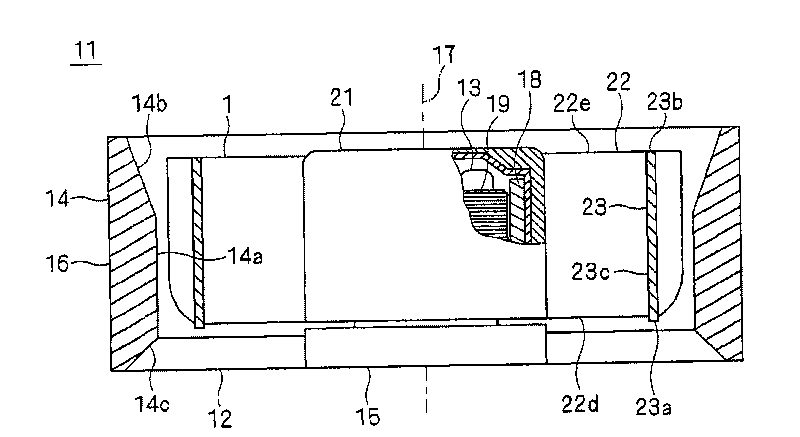

[0032] figure 1 It is a plan view of the impeller 1 according to the first preferred embodiment of the present invention viewed from the inlet side along the central axis 17. figure 2 Is like figure 1 A side view of the impeller 1 shown in. image 3 Is used as figure 1 A cross-sectional view of the fan assembly 11 of the impeller 1 shown in FIG.

[0033] Reference image 3 , The fan device 11 using the impeller 1 according to the preferred embodiment of the present invention includes an impeller 1, a plurality of stationary blades 12, a motor 13, an outer frame member 14 and a support member 15. The stator blades 12, the outer frame member 14 and the support member 15 define the housing 16 of the fan device 11. It is noted in this preferred embodiment that the stationary blade 12 and the supporting member 15 are provided on the outlet side (ie, along the central axis 17 of the impeller 1, for example, image 3 The lower side in the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com