Frustum slit type anti-blocking ladle bottom-blown powder injection device

A slot-type, powder-spraying technology, used in casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems of short service life of powder-spraying components, serious impact of powder-spraying components, and narrow gaps of powder-spraying components. Small pulsation probability, stable blowing, continuous and stable powder flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

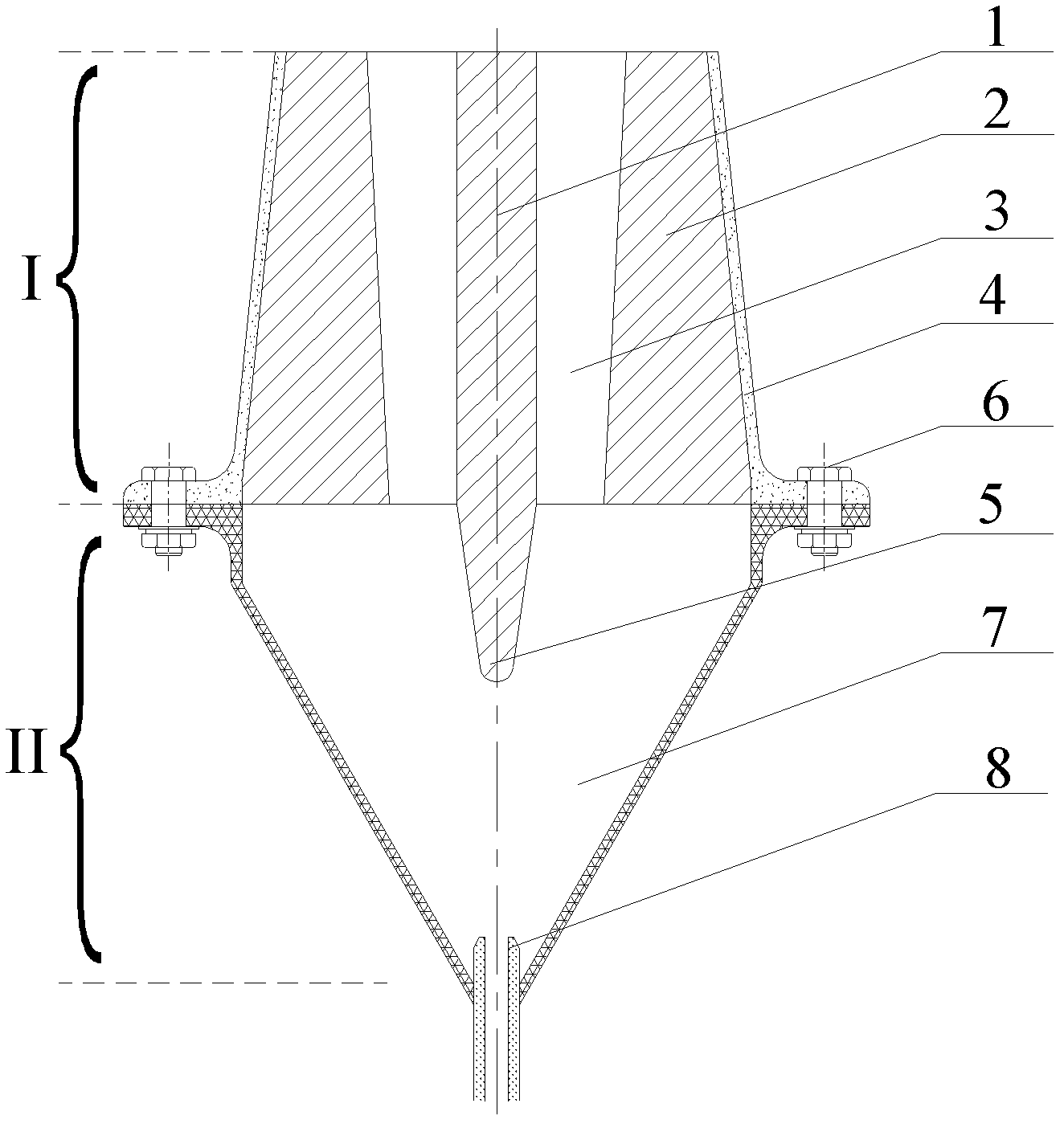

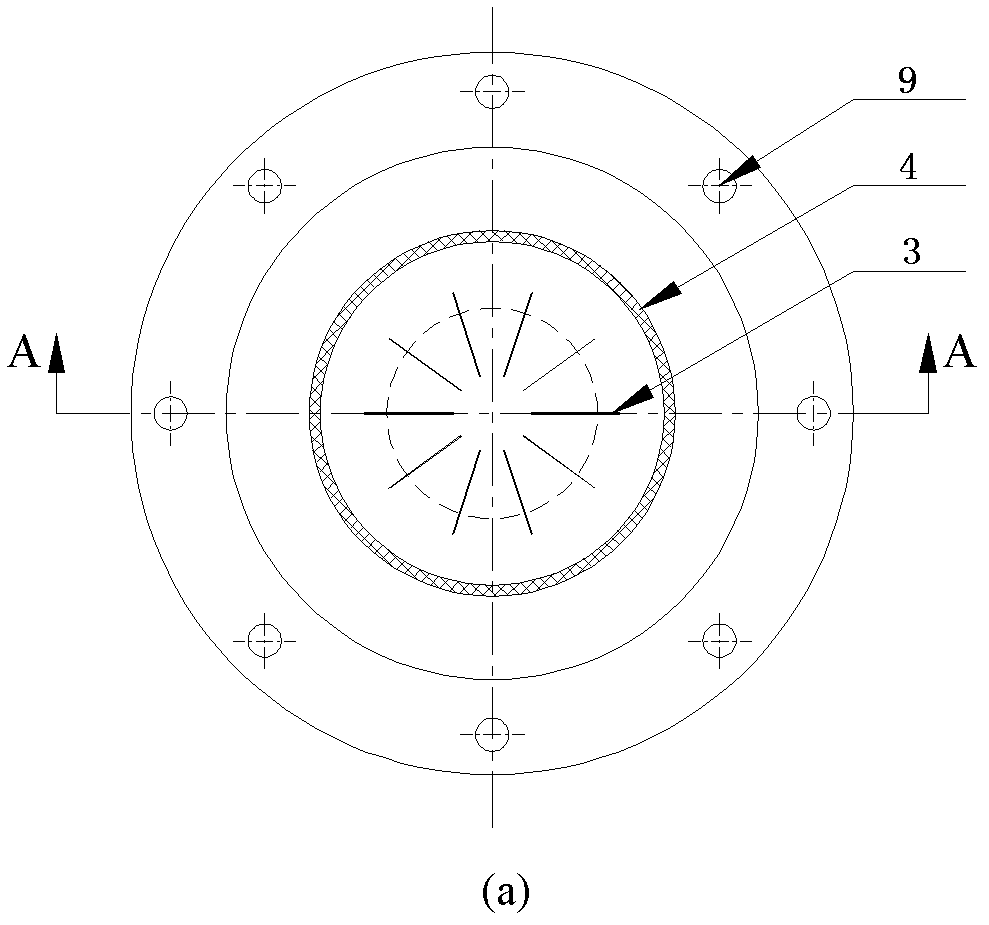

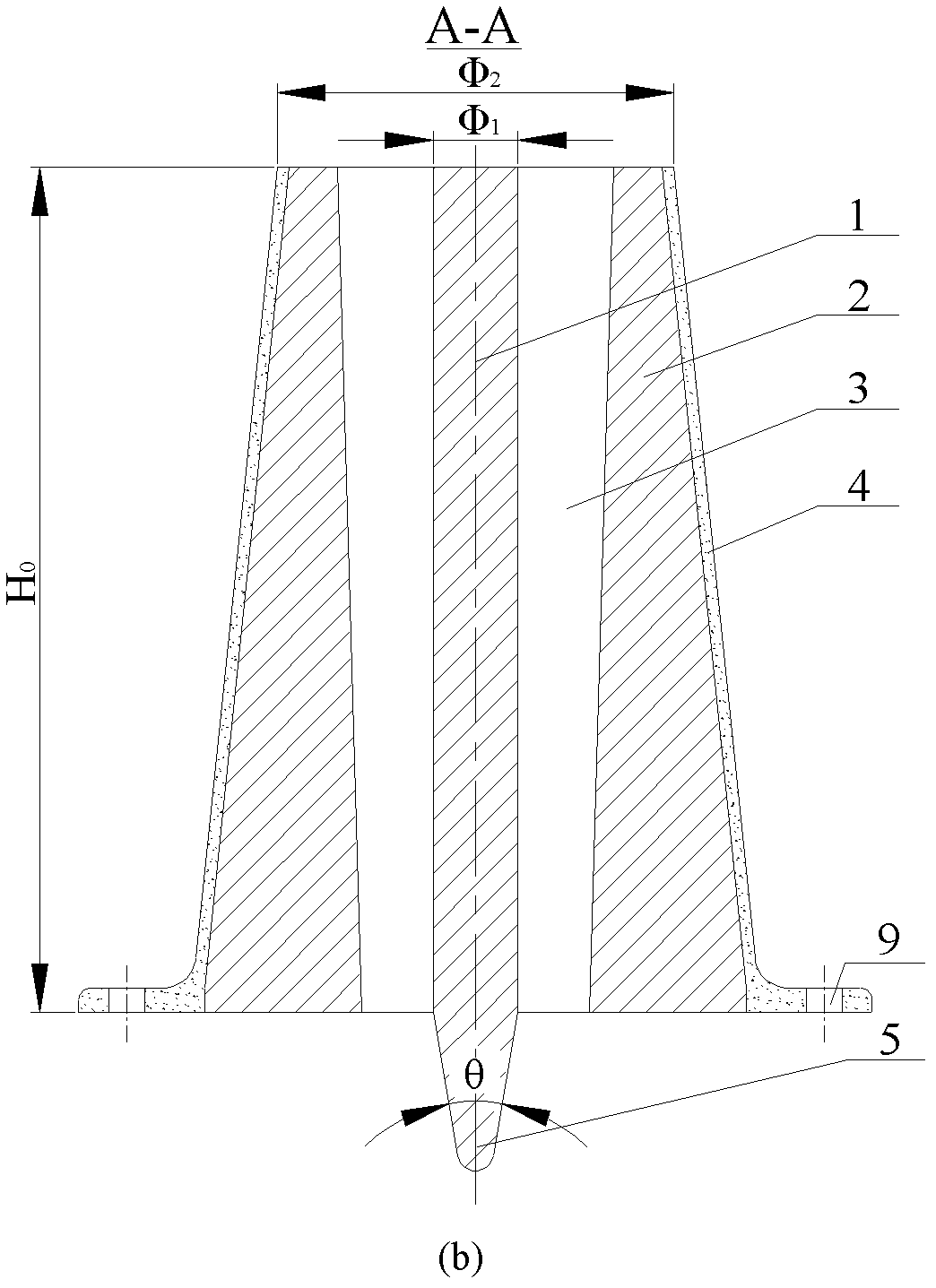

[0027] In this embodiment, a ridged slot type anti-blocking ladle bottom blowing powder injection device, such as figure 2 (a) and figure 2 As shown in (b), the main parameters of the embodiment are as follows:

[0028] (1) Breathable bricks are used as refractories, and the inner diameter of the brick core is Φ 1 :The design principle is: not only to avoid too small inner diameter of the brick core, which will cause the powder airflow to polymerize in the ladle melting pool to form a large bubble cloth bag, but also to avoid too large inner diameter of the brick core to reduce jet penetration; the inner diameter of the ventilating brick core Φ 1 The value range of is: Φ 1 =6~300mm, take Φ in this embodiment 1 =15mm;

[0029] (2) Outer diameter of breathable brick Φ 2 : The design principle is: under the premise of ensuring the strength of the breathable brick, according to the inner diameter of the breathable brick core and the arrangement of the gaps, the value range is: Φ 2 =30~...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com