Energy-saving premixing internal combustion type blast-furnace gas steel ladle baking device

A blast furnace gas and baking device technology, which is applied to casting melt containers, metal processing equipment, casting equipment, etc., can solve the problem that the temperature measuring device cannot accurately feedback the temperature of the bottom of the ladle, and the blast furnace gas cannot meet the baking temperature. , blast furnace gas is not easy to ignite, etc., to achieve the effect of saving energy consumption, optimizing design, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] specific implementation

[0046] Below in conjunction with accompanying drawing, the present invention is further described.

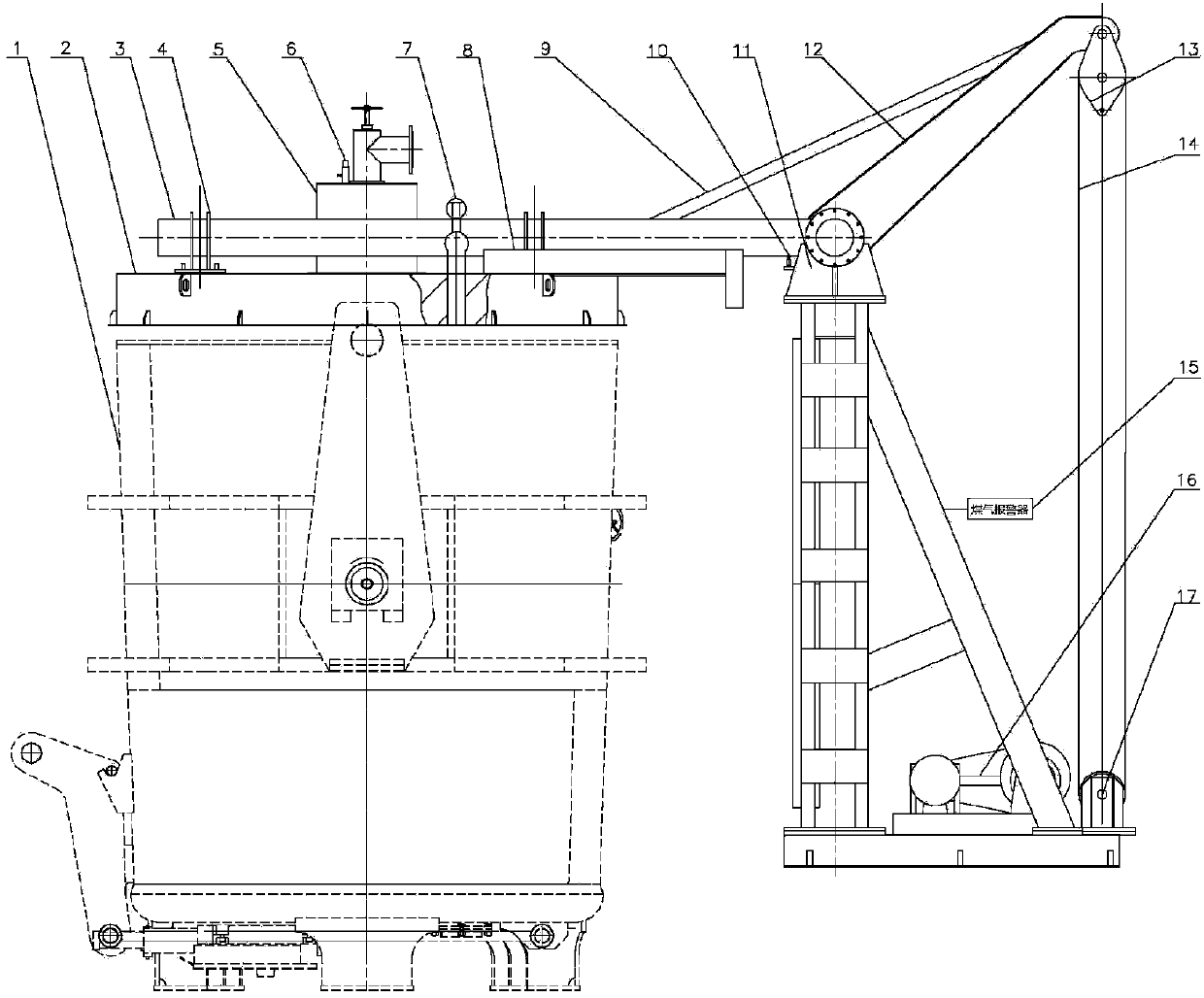

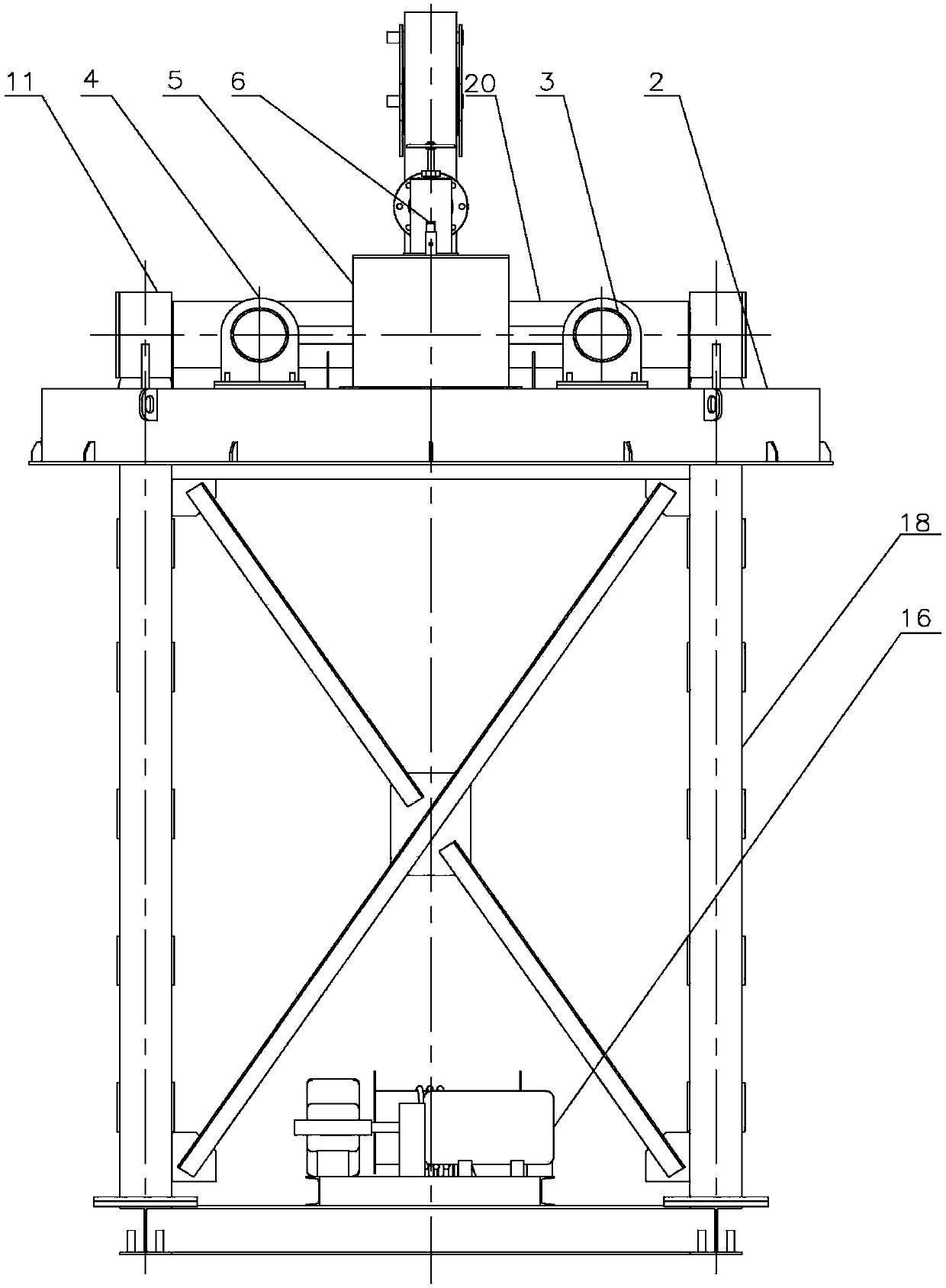

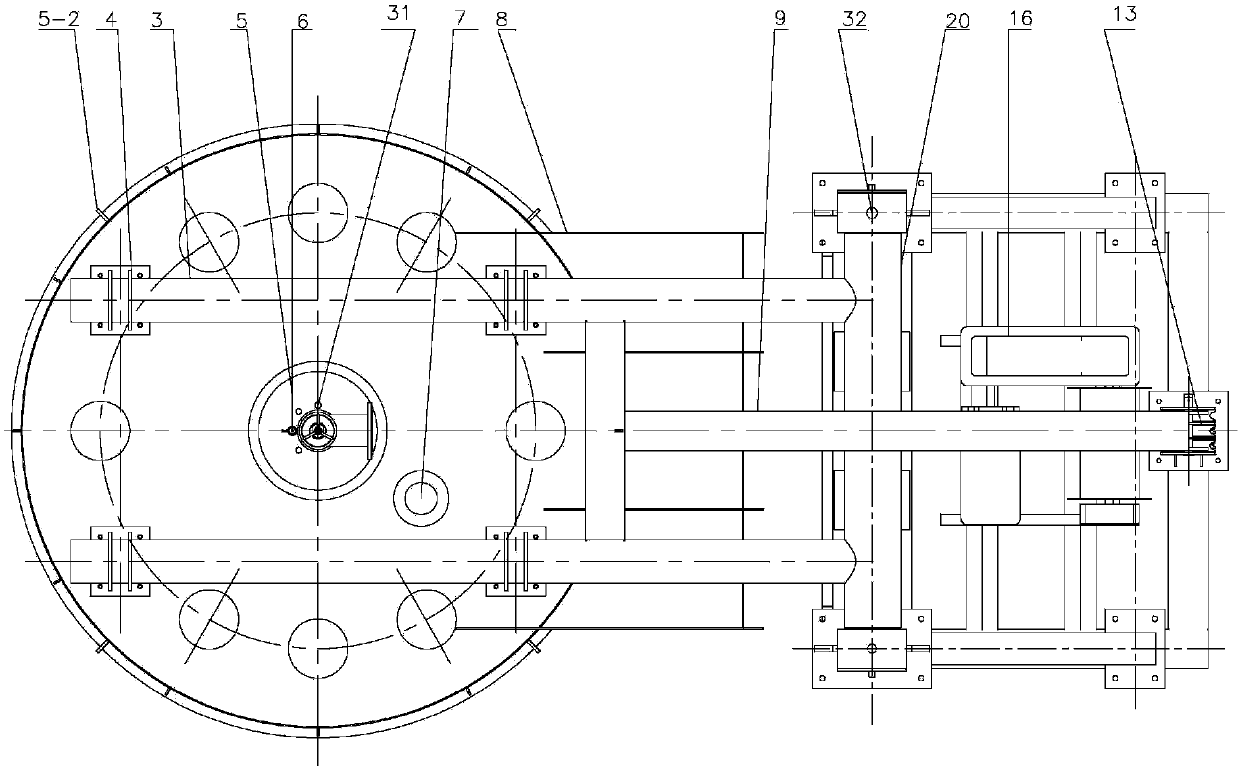

[0047] like Figure 1 to Figure 4 , the energy-saving premixed internal combustion type blast furnace gas ladle baking device, its mechanical body structure consists of a cover 2, a rocker arm 3, a burner 5, a fire baffle 8, a tie bar 9, a bearing seat 11, and a boom 12 , movable pulley 13, wire rope 14, winch device 16, fixed pulley device 17, frame device 18, rotating shaft 20 (details are as described in the summary of the invention part, omitted here).

[0048] In the energy-saving premixed internal combustion type blast furnace gas ladle baking device, the ladle cover 2 has a safe distance from the ladle 1, and the safe distance is agreed to be 20 centimeters.

[0049] The cover 2 is a self-suction structural model, on the one hand, it heats the combustion air, on the other hand, it uses zirconium-containing refractory cotton material 2-6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com