Patents

Literature

63results about How to "Good air-fuel ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

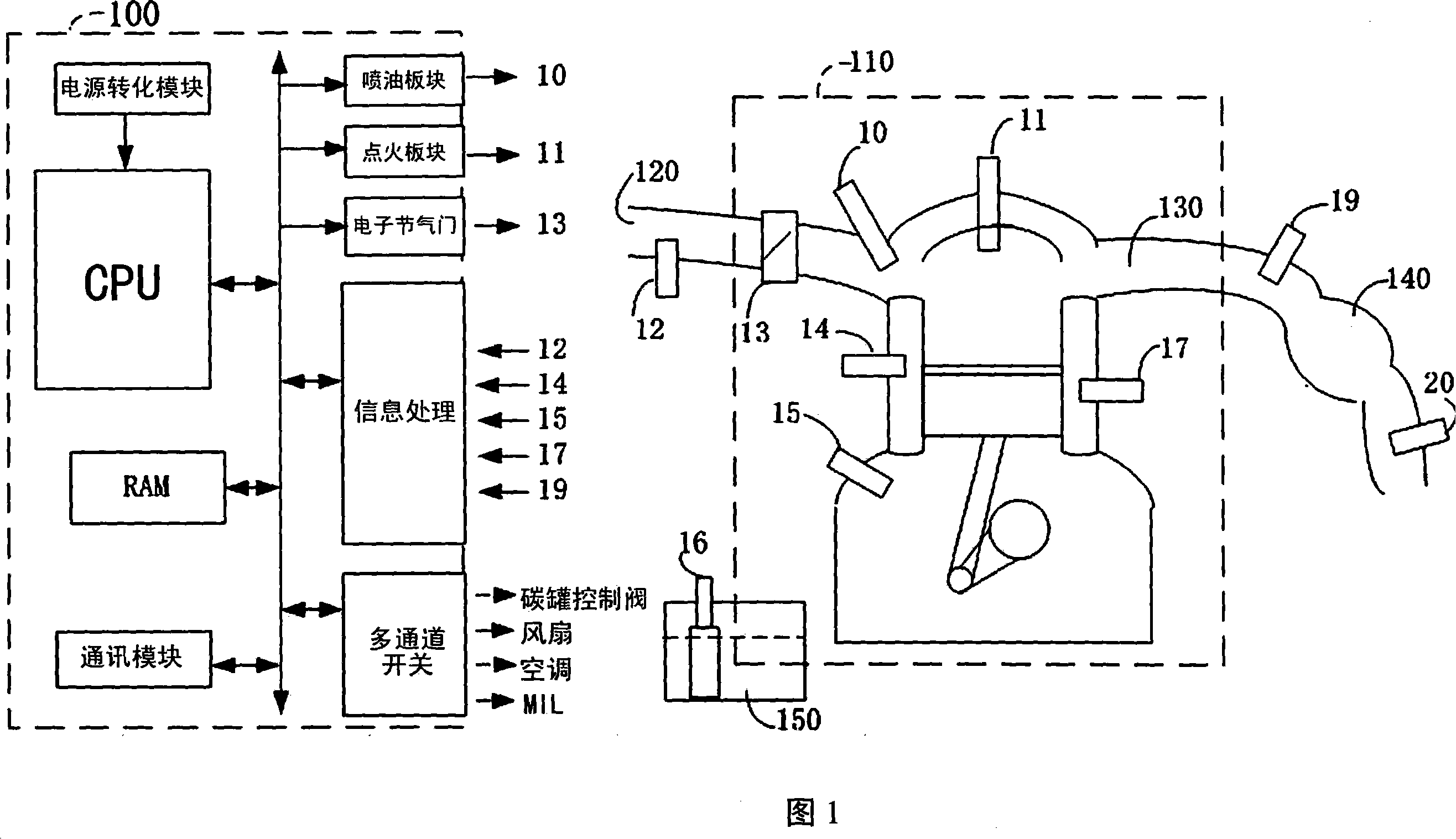

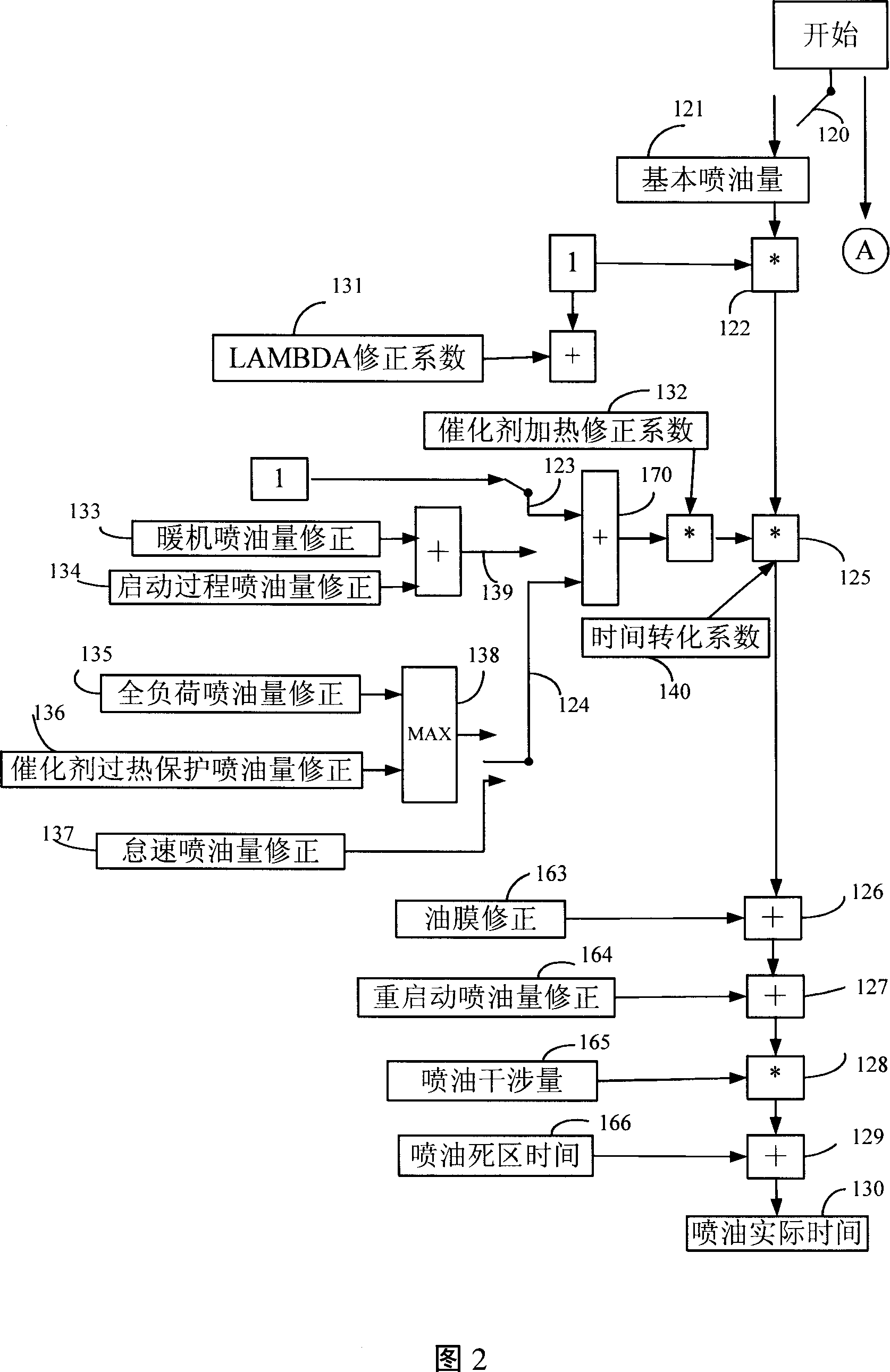

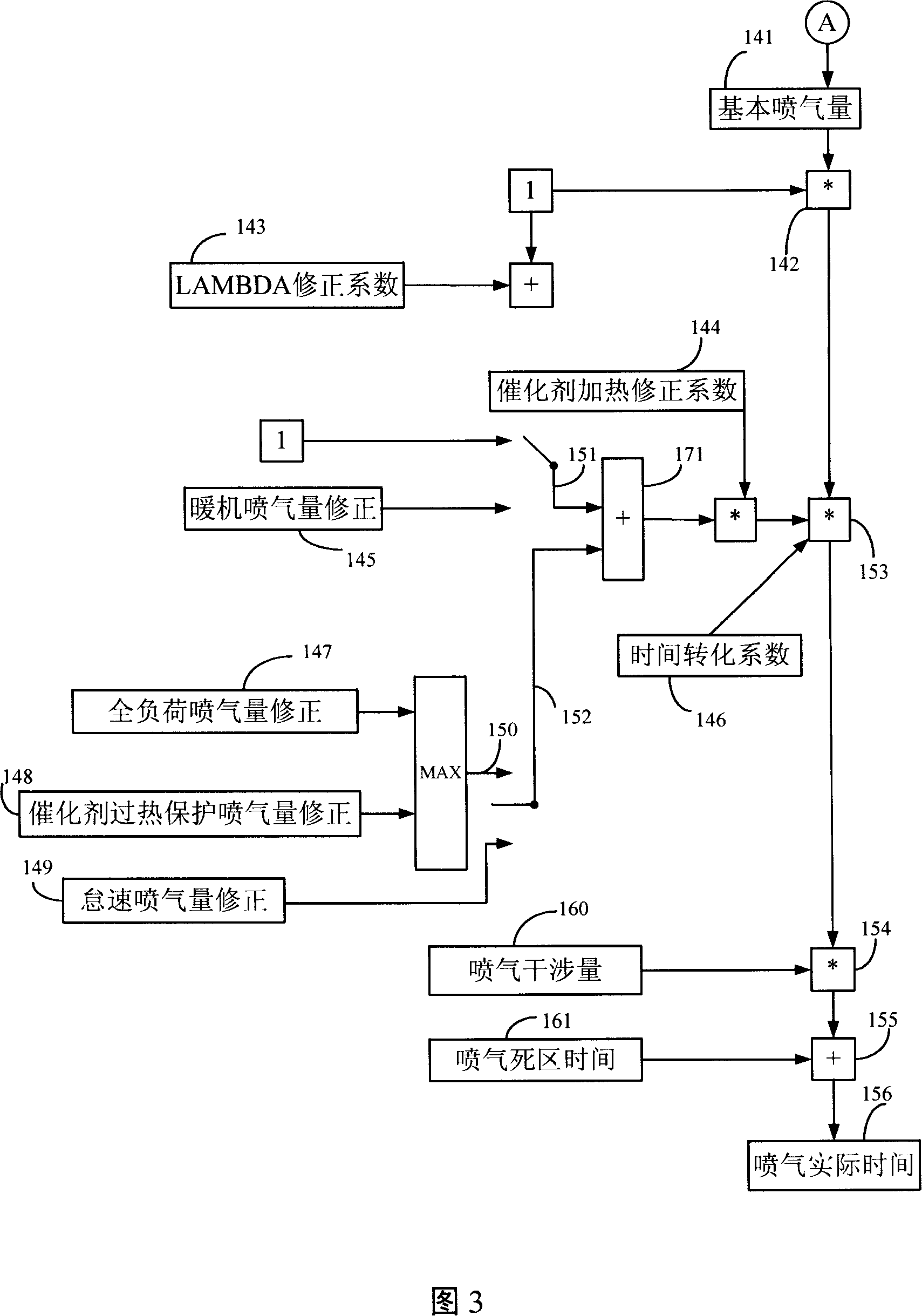

Engine oil gas mixing ECU control method

InactiveCN101105155AImprove performanceImprove powerElectrical controlMachines/enginesOxygen sensorClosed loop

The invention relates to a controlling method of fuel-air mixture electronic control unit (ECU) of engine. In the controlling method, through acquisition of air inlet temperature and pressure, water temperature, engine rotational speed, throttle position and oxygen sensor signal, the ECU accurately controls the oil (gas) spraying quantity and ignition angle; the oil (gas) spraying adopts multipoint grouping or multipoint sequential technique, and the ECU calculates the actual oil (gas) spraying quantity and actual oil (gas) spraying time with one same algorithm and two sets of rating data in the same hardware platform; the ECU performs closed-loop control to air fuel ratio; the oil (gas) spraying is controlled based on the torque of an electronic air throttle, and ECU acquires the air throttle pedal position signal and calculates the maximal torque at that time to control the opening extent of the air throttle. The controlling method can remarkably improve the performance of engine, obtain the optimal air fuel ratio under various operating conditions, and make the automobile to achieve the optimal dynamic force.

Owner:CHINA VAGON AUTOMOTIVES HLDG CO LTD

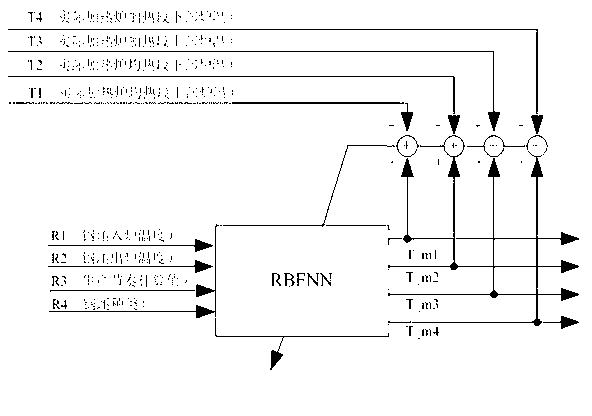

Optimal control system for steel rolling heating furnace

ActiveCN103019097AGuaranteed control accuracyGuaranteed stabilityAdaptive controlFurnace temperatureOptimal control system

The invention discloses an optimal control system for a steel rolling heating furnace, relating to the technical field of steel rolling of a heating furnace. Firstly, an on-line furnace temperature setting device is established according to different billet types, production rhythm, billet initial temperature and billet tapping temperature; the billet tapping temperature is controlled by controlling the temperature of the furnace; based on heat efficiency models under various working conditions, the loading variation of the heating furnace is calculated and taken as a feedforward value of the furnace temperature, and the high-accuracy control on the temperature of the heating furnace under loading fluctuation is realized; and on the basis, an optimal air-fuel ratio is found by establishment of an air-fuel ratio optimal control model, so that the heating furnace achieves an optimal burning condition and the aims of saving fuel and lowering steel loss are achieved.

Owner:北京和隆优化科技股份有限公司

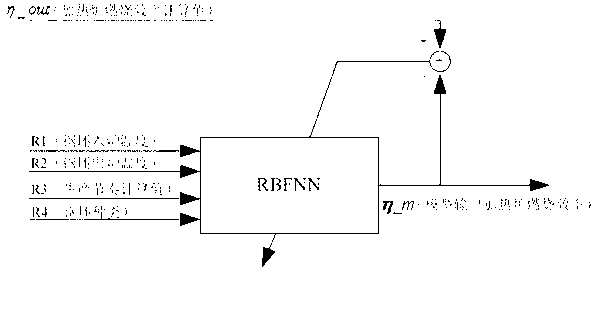

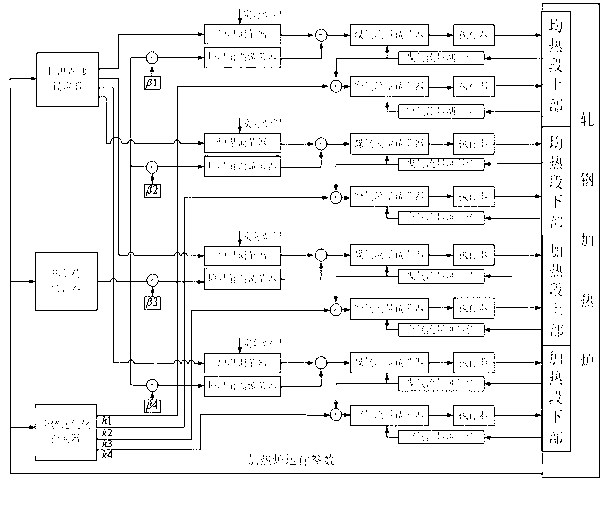

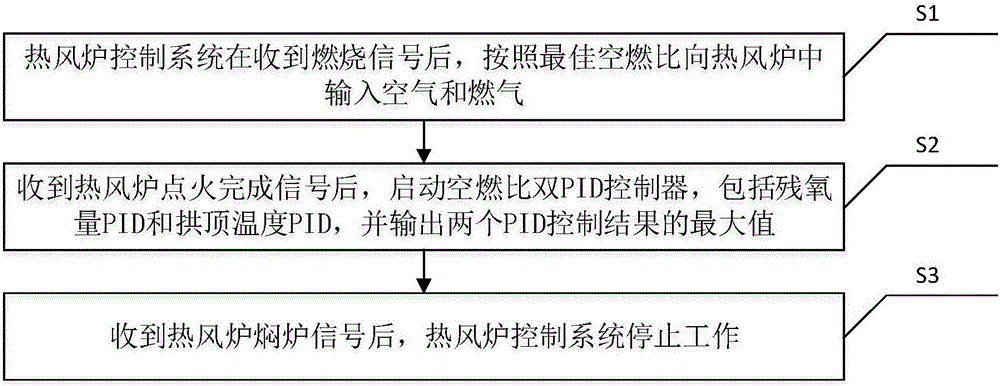

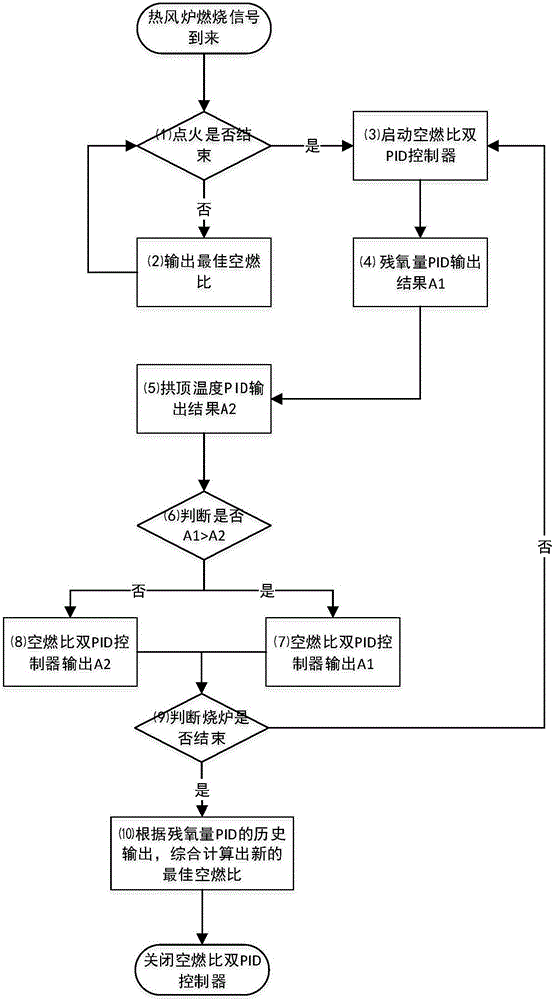

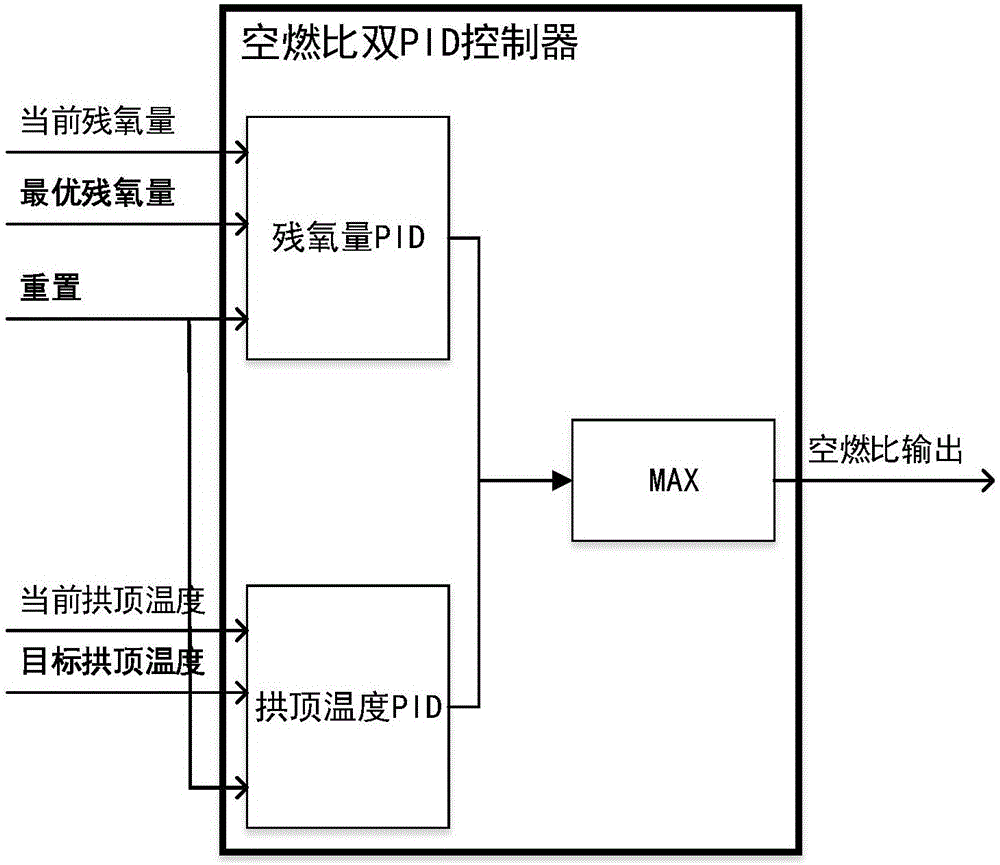

Automatic control method for air-fuel ratio of hot-blast stove

InactiveCN105783024ABurn fullySmooth switchingFuel supply regulationBlast furnace detailsAutomatic controlHot blast

The invention discloses an automatic control method for the air-fuel ratio of a hot-blast stove. The method includes the following steps that S1, in the ignition stage, after a control system of the hot-blast stove receives a combustion signal, air and fuel gas are input into the hot-blast stove according to the optimal air-fuel ratio; S2, after a signal indicating that ignition of the hot-blast stove is completed is received, an air-fuel ratio dual-PID controller is started, dual PID includes remaining oxygen PID and arch crown temperature PID, and maximum values of the two PID control results are output; and S3, after a banking signal of the hot-blast stove is received, the control system of the hot-blast stove stops working. By means of the automatic control method for the air-fuel ratio of the hot-blast stove, the optimal air-fuel ratio can be output all the time, and it is guaranteed that coal gas is efficiently and fully combusted; the arch crown temperature is controlled to be stabilized at the a target arch crown temperature, and it is guaranteed that the combustion process is safe and stable; and automatic and stable switch for different requirements of the air-fuel ratio in various stages can be achieved.

Owner:WISDRI ENG & RES INC LTD

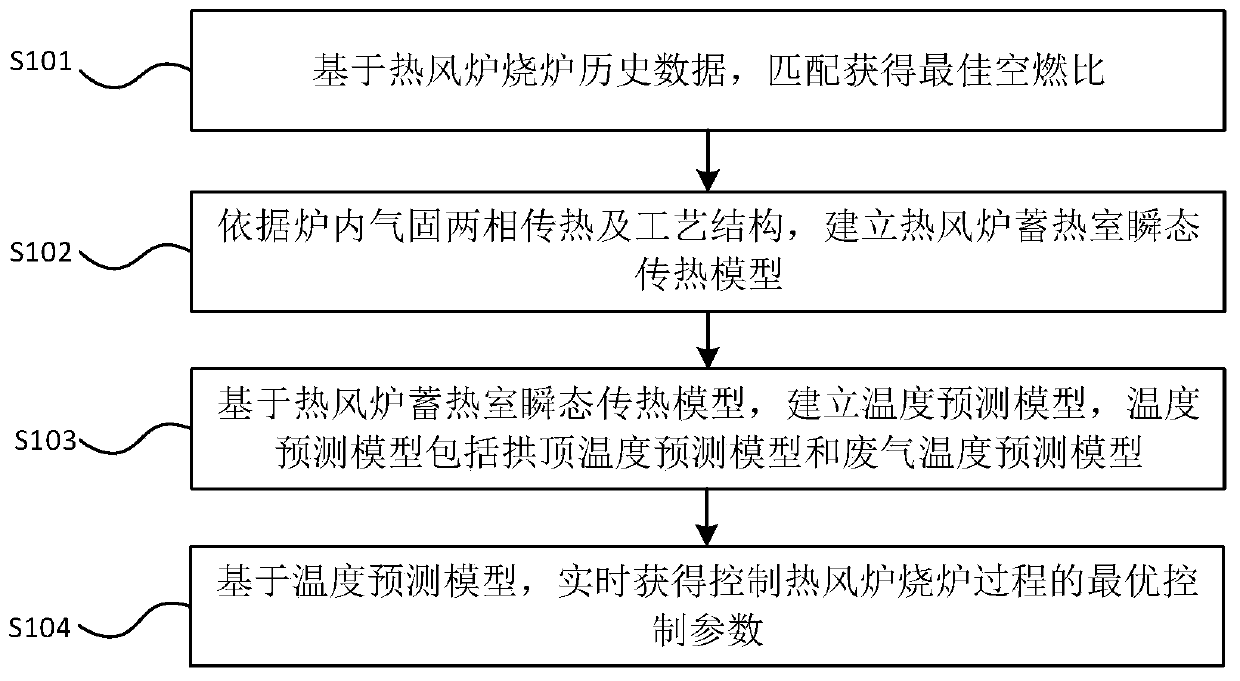

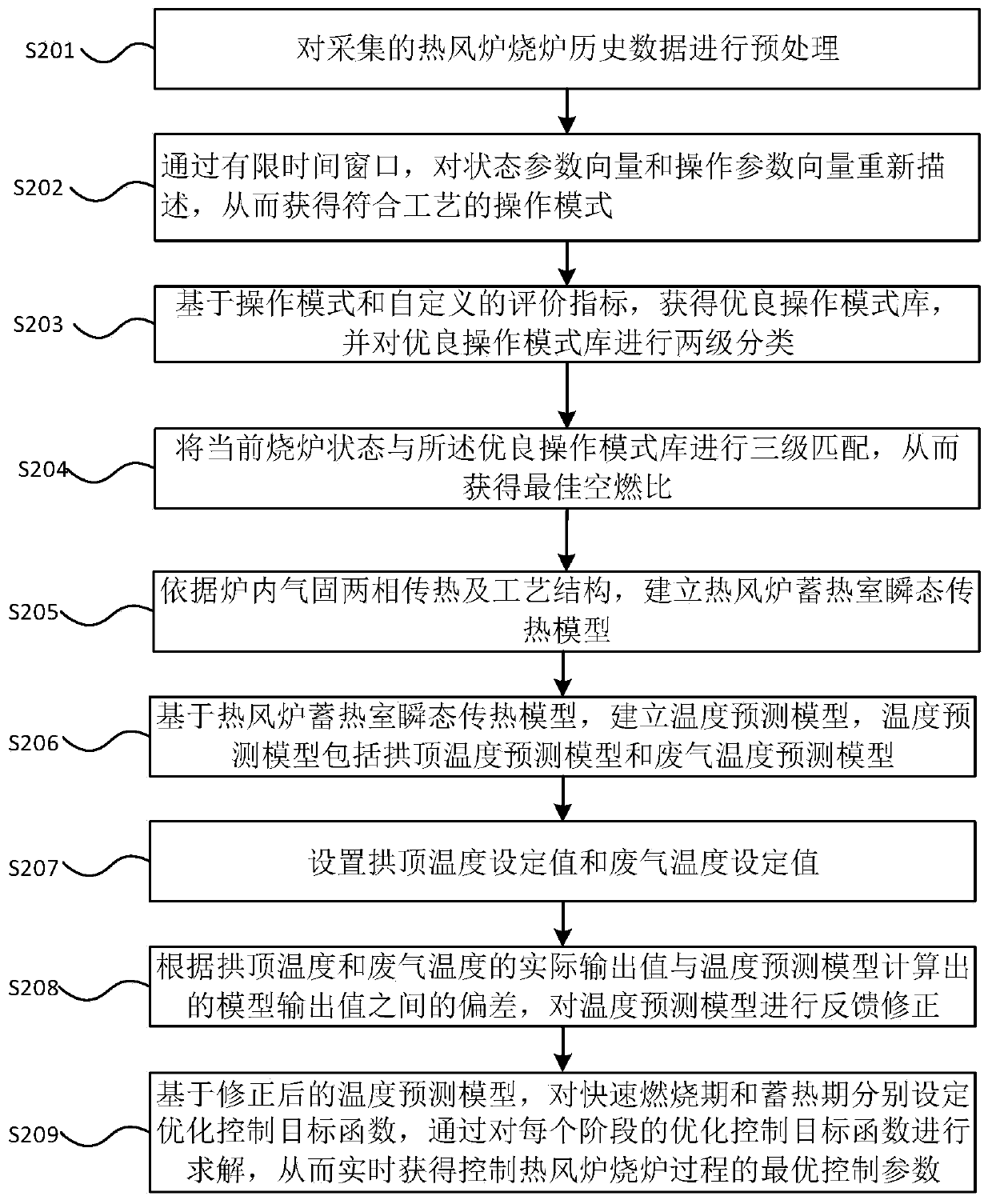

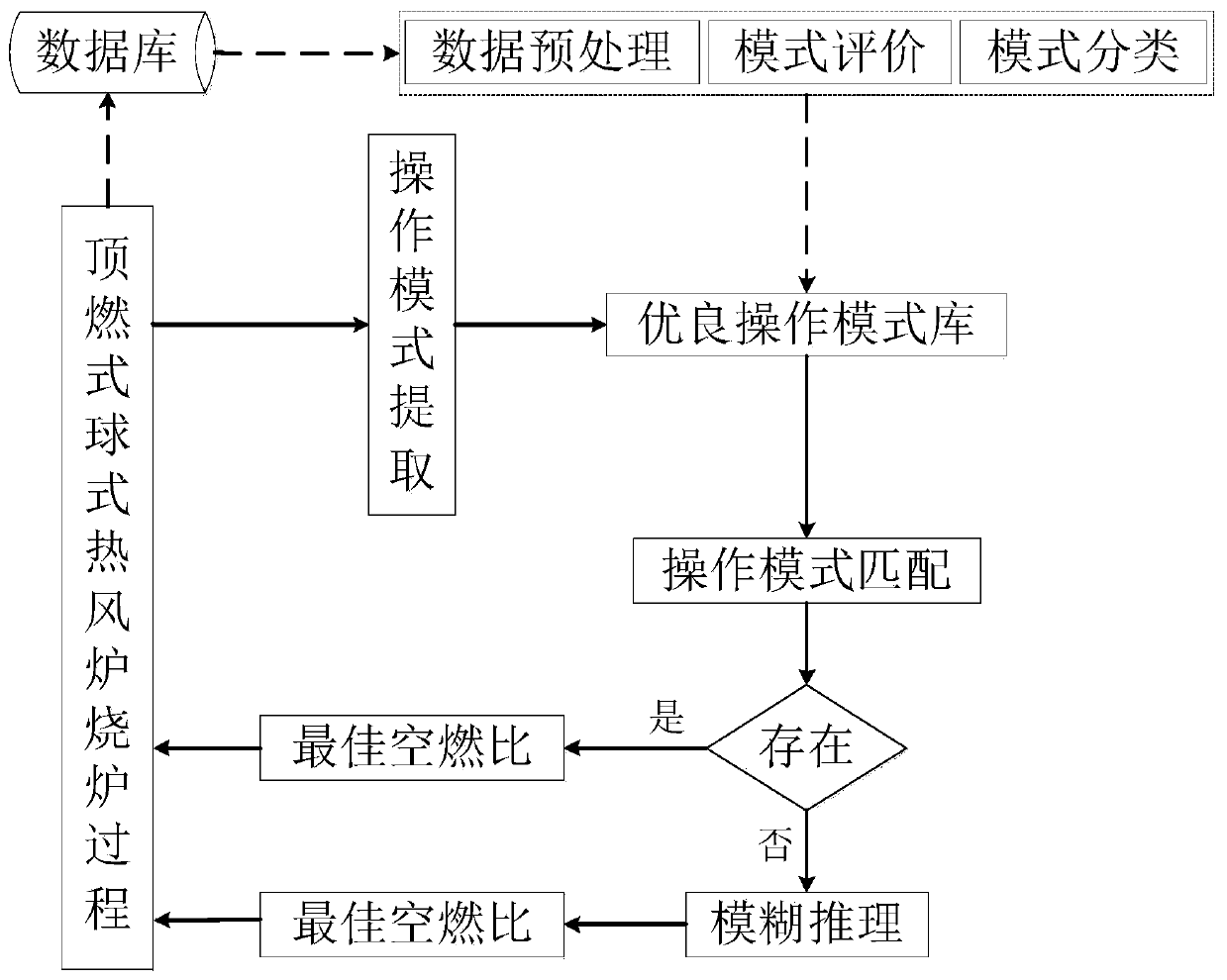

Ball type hot blast stove burning process control method and system

ActiveCN110257577AGood air-fuel ratioOptimal Control ParametersSteel manufacturing process aspectsBlast furnace detailsOptimal controlProcess engineering

The invention discloses a ball type hot blast stove burning process control method and system. The method comprises the steps that the optimal air-fuel ratio is obtained through matching based on hot blast stove burning historical data; a hot blast stove regenerative chamber transient heat transfer model is established according to stove inner gas-solid two-phase heat transfer and a process structure; temperature predicting models are established based on the hot blast stove regenerative chamber transient heat transfer model and include the vault temperature predicting model and the waste gas temperature predicting model; and the optimal control parameters for controlling the hot blast stove burning process are obtained in real time based on the temperature predicting models. The technical problem that the hot blast stove burning process is hard to control precisely in real time in the prior art is solved. By analyzing the ball type hot blast stove burning process, the air-fuel ratio is controlled from the data perspective according to a field process, the coal gas flow rate is controlled form the mechanical perspective, the air-fuel ratio and the coal gas flow rate are caused to reach the optimal values at the same time, in addition, the optimal coal gas flow rate is optimized in real time based on the matched optimal air-fuel ratio, and the hot blast stove burning process can be precisely controlled in real time.

Owner:CENT SOUTH UNIV

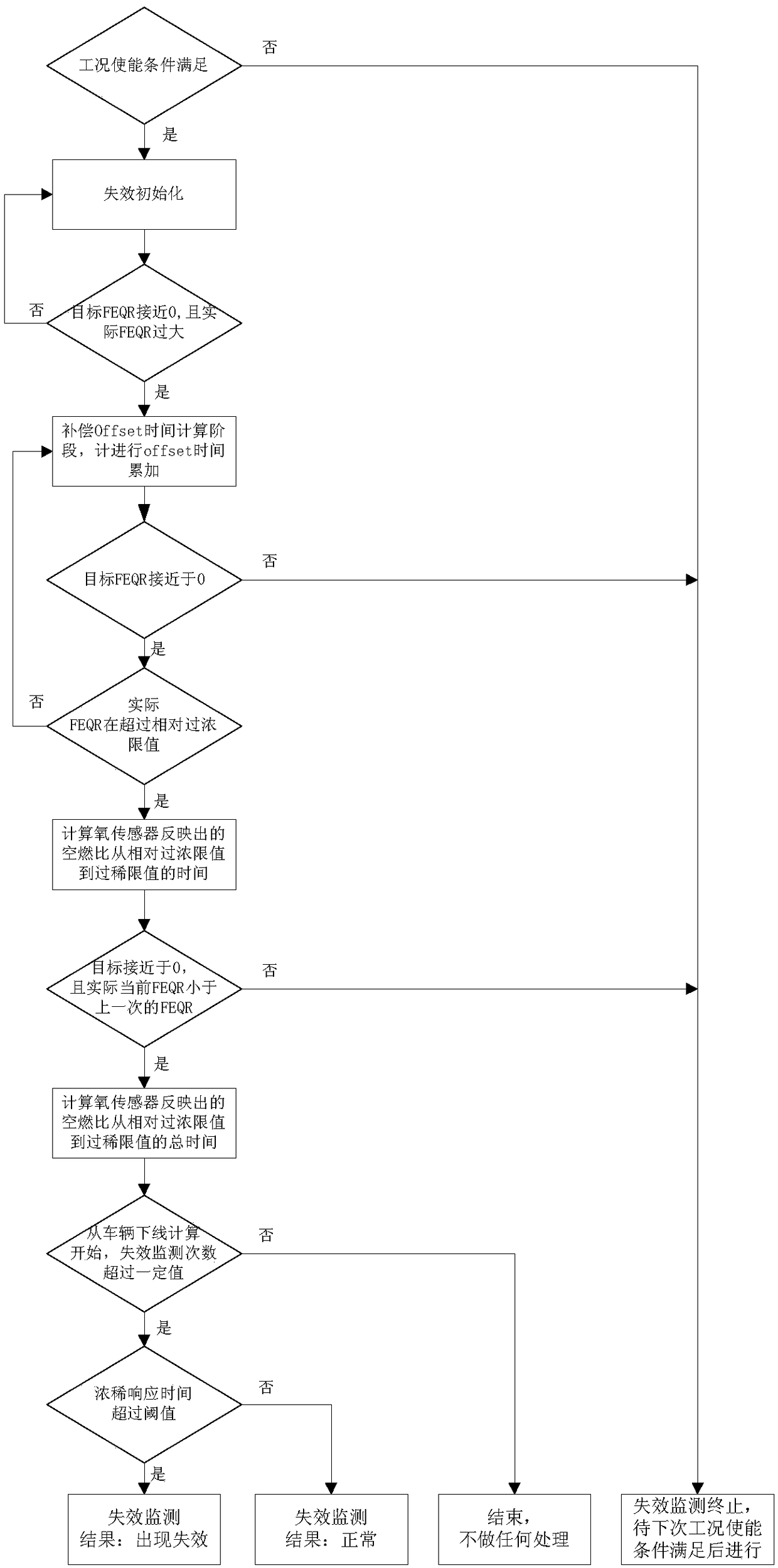

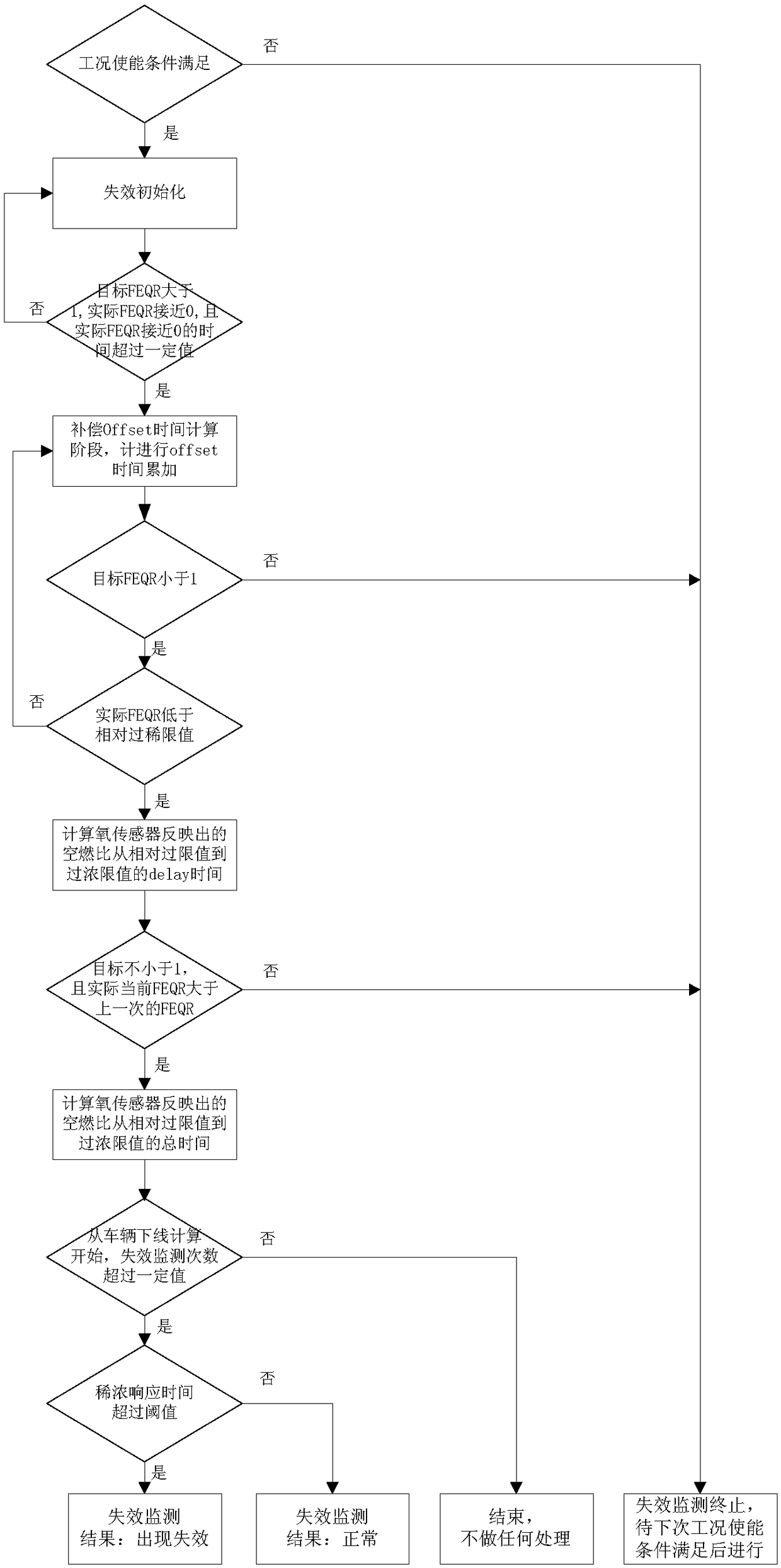

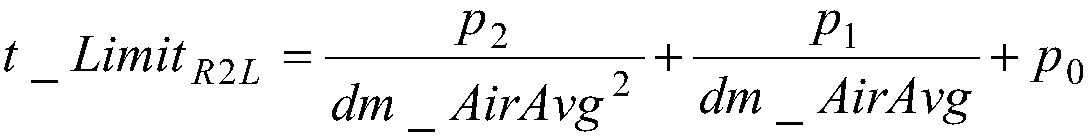

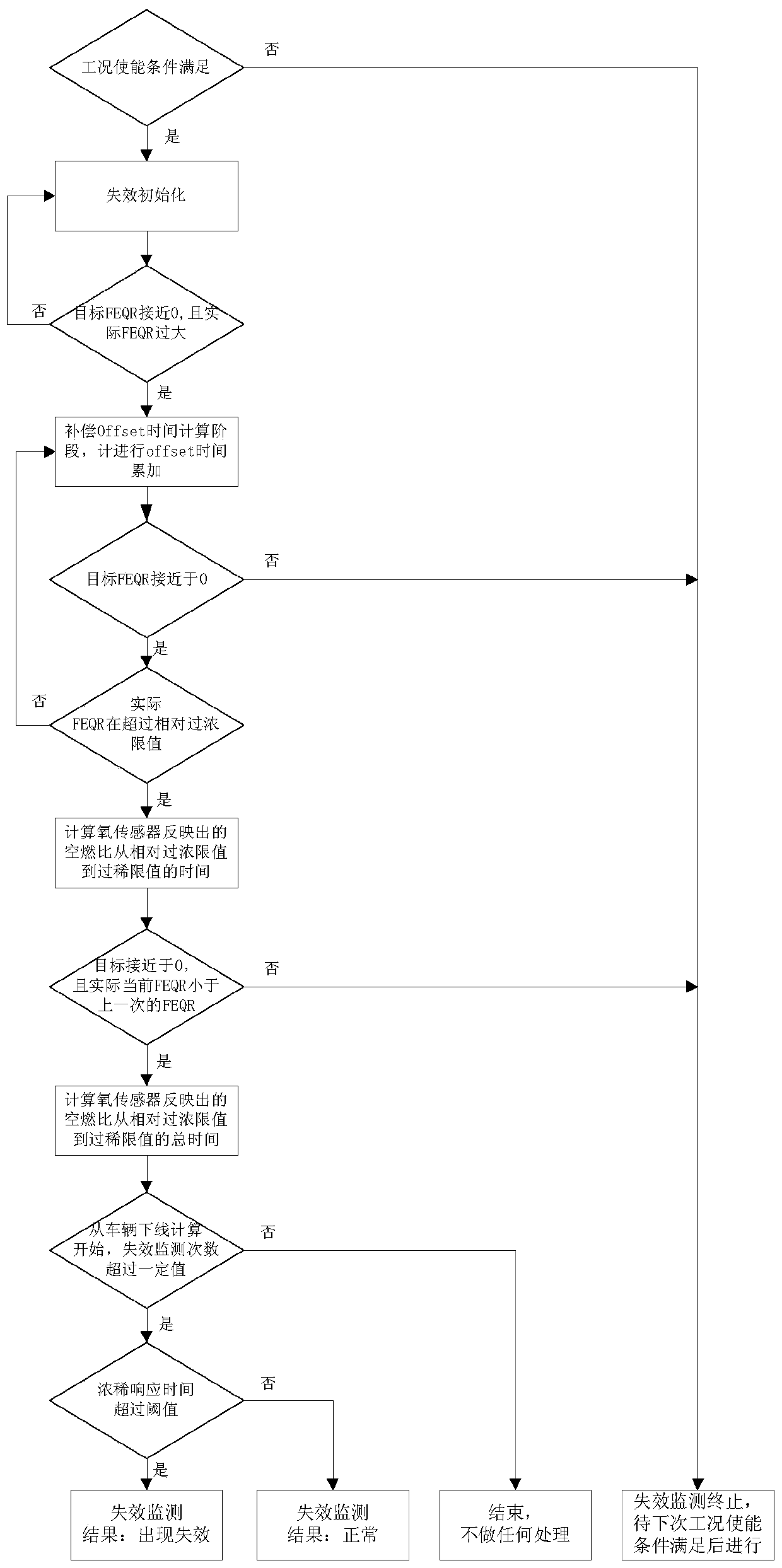

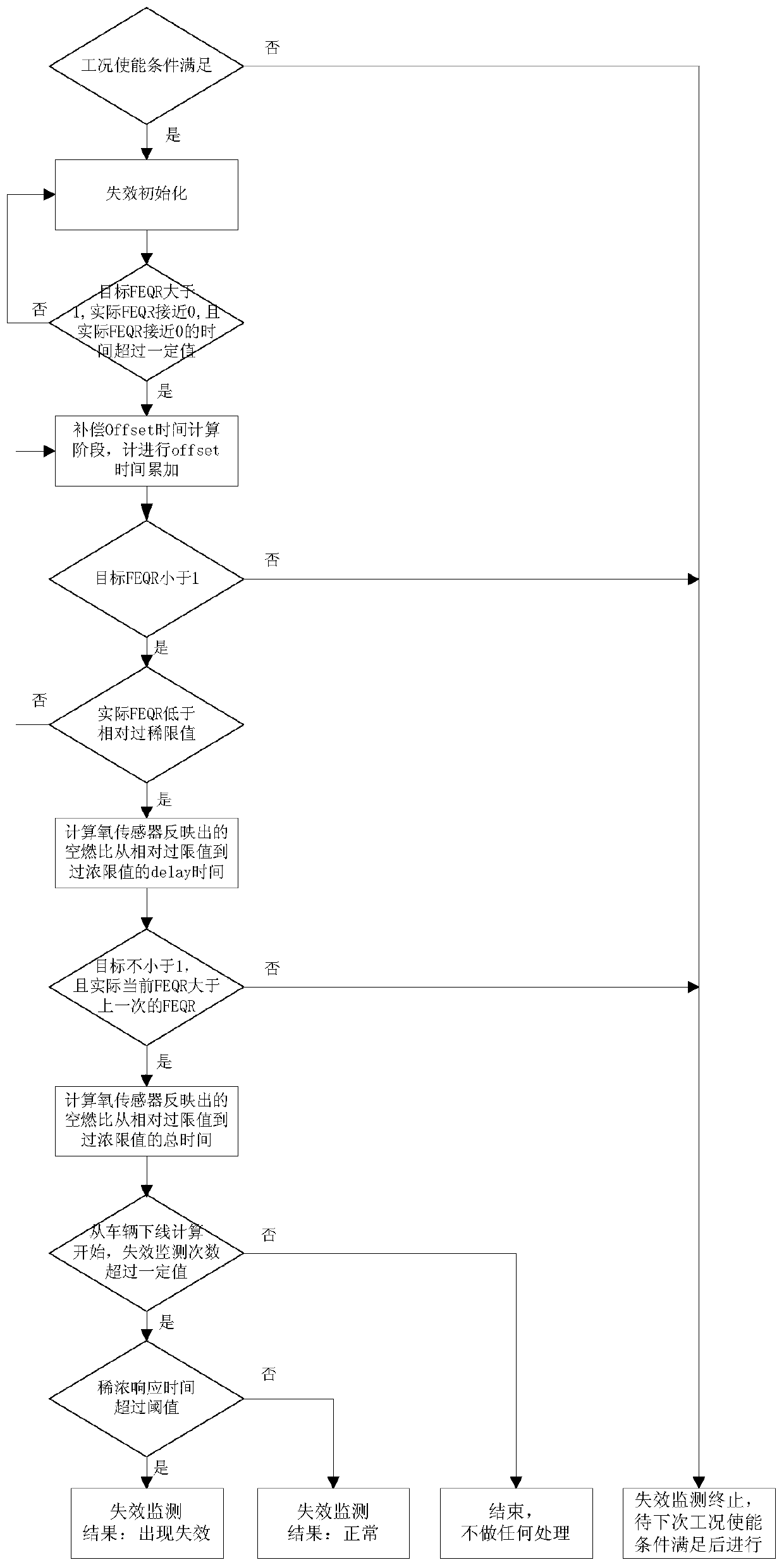

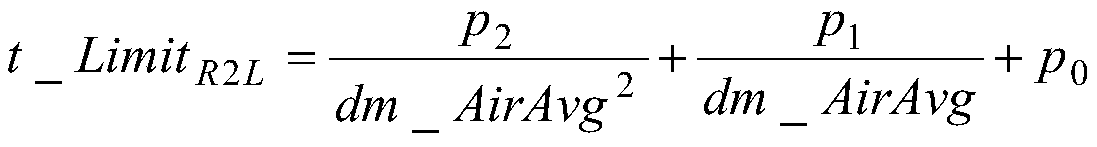

Vehicle wide area oxygen sensor lose-efficacy monitoring method

ActiveCN109372618AAccurate monitoringGood air-fuel ratioElectrical controlInternal combustion piston enginesWide areaOxygen sensor

The invention discloses a vehicle wide area oxygen sensor lose-efficacy monitoring method. According to the vehicle wide area oxygen sensor lose-efficacy monitoring method, wide area oxygen sensor lose-efficacy monitoring comprises response delay monitoring from thick to thin and response delay monitoring from thin to thick in an air exhaust system, and the monitoring processes both comprise a lose-efficacy initialization stage, a waiting stage, an offset time calculation stage, a response delay time calculation stage, a final response time calculation stage and a lose-efficacy monitoring evaluating stage. By means of the vehicle wide area oxygen sensor lose-efficacy monitoring method, the vehicle wide area oxygen sensor lose-efficacy monitoring can be rapidly and accurately realized.

Owner:DONGFENG MOTOR CORP HUBEI

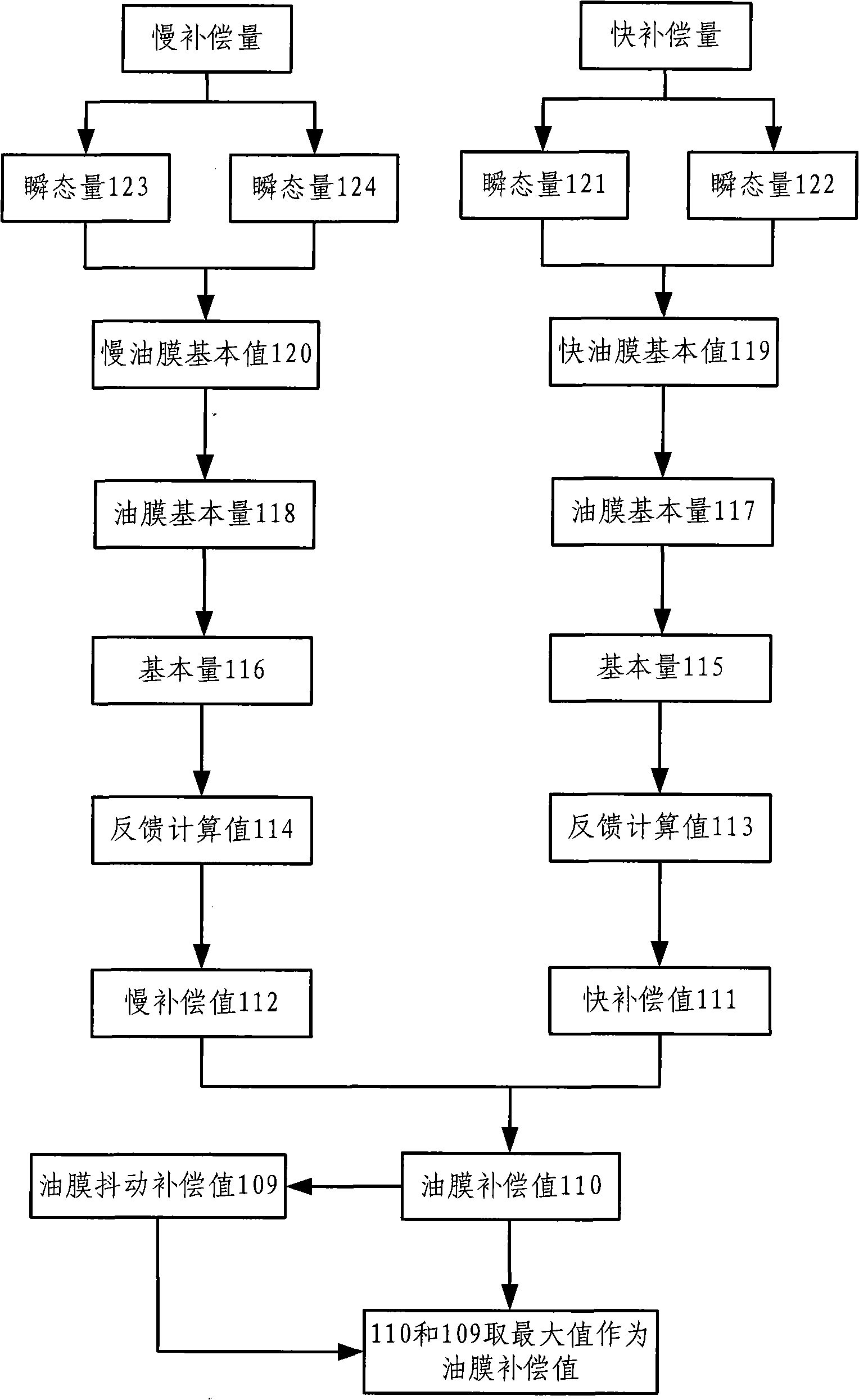

Oil film compensation process when fuel oil injection

InactiveCN101493052AEnhanced power output performanceAdjust drivingElectrical controlMachines/enginesFuel oilAir–fuel ratio

The invention discloses an oil film compensation method used in fuel oil injection. The method comprises the following steps: collecting air inflow signal and crankshaft rotating speed signal; confirming basic injecting time (TIB) of an engine according to the crankshaft rotating speed signal and the air inflow signal; judging that the engine is in sharp accelerating state or sharp decelerating state according to the TIB; inquiring a marking data table of the engine to obtain fast compensation amount and slow compensation amount of an intake manifold of the engine according to the state of the engine; and acquiring the oil film compensation value in the engine oil injection process according to the fast compensation amount and slow compensation amount of the intake manifold of the engine. The method can accurately compensate the oil injection amount by precisely calculating the oil film compensation value in fuel oil injection, thus greatly improving the power output performance in acceleration and deceleration, obtaining the optimal air-fuel ratio of an automobile in accelerating or decelerating working condition, and adjusting the running performance of the automobile by changing oil injection sum.

Owner:CHINA VAGON AUTOMOTIVES HLDG CO LTD

Ceramic kiln burner

ActiveCN103925595AAvoid wastingEasy to adjustOperating means/releasing devices for valvesLift valveCombustion chamberAir volume

The invention discloses a ceramic kiln burner. The burner comprises a controller, an air adjusting device, a fire observing device and a nozzle. The nozzle comprises an air distribution head and a nozzle sleeve. The nozzle sleeve is an integrated member composed of a premixing chamber, a combustor and an accelerating ring. The air distribution head is positioned at a junction, between the premixing chamber and the combustor, in the premixing chamber. The air adjusting device comprises a transmission mechanism and air valve blades. During working, a fixed air valve blade is fixed and motionless, and a rotating air valve blade can rotate relative to the fixed air valve blade to adjust supply air rate of the ceramic kiln burner. The burner further comprises a flameout protection device arranged in the combustor and a tempering protection device arranged in a vortex tube of the air distribution head. The burner can burn stably, has impulsive force, and is high in heat efficiency, capable of accurately adjusting the supply air rate to achieve an optimum air-fuel ratio and capable of effectively preventing flameout and tempering.

Owner:SHANGHAI YIDE TECH

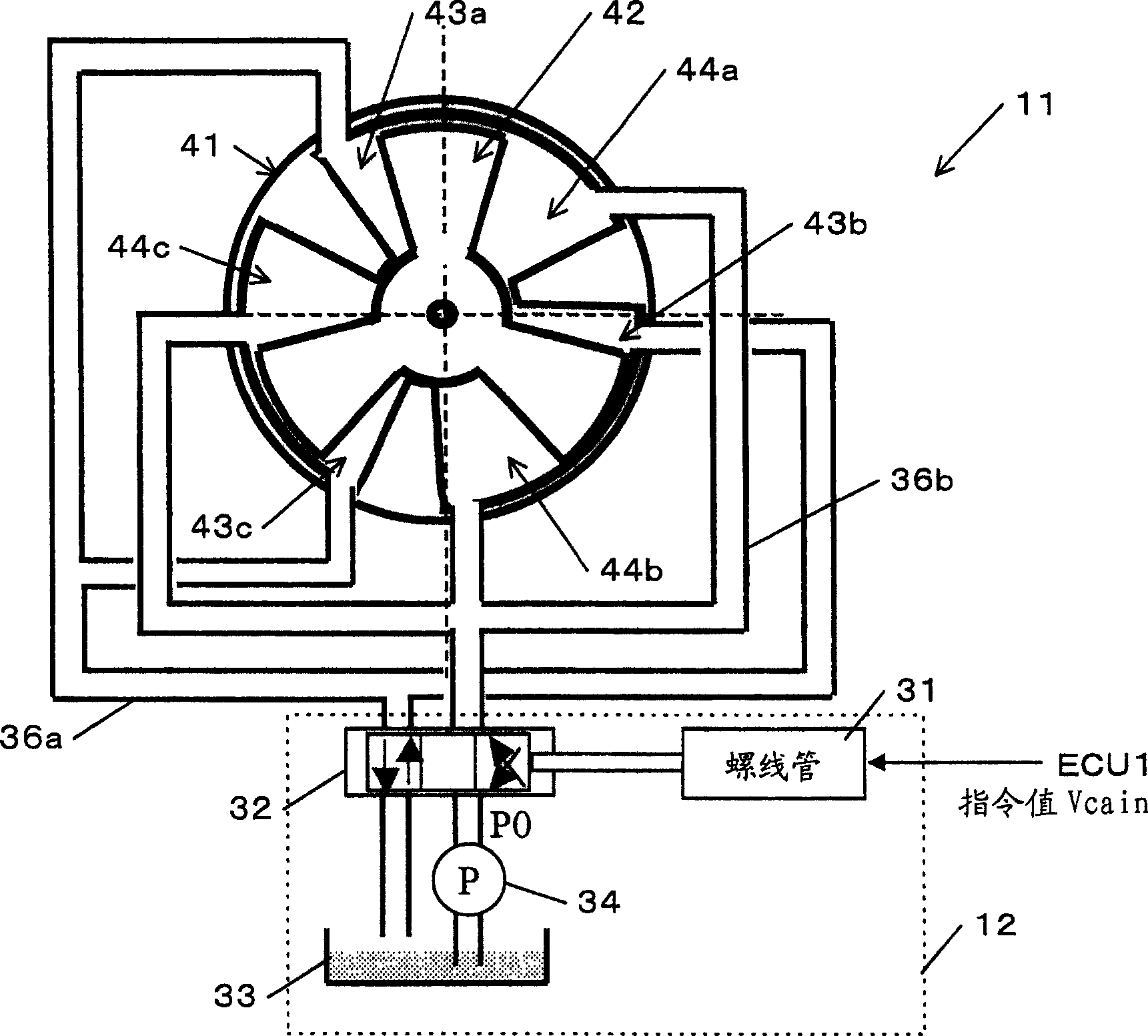

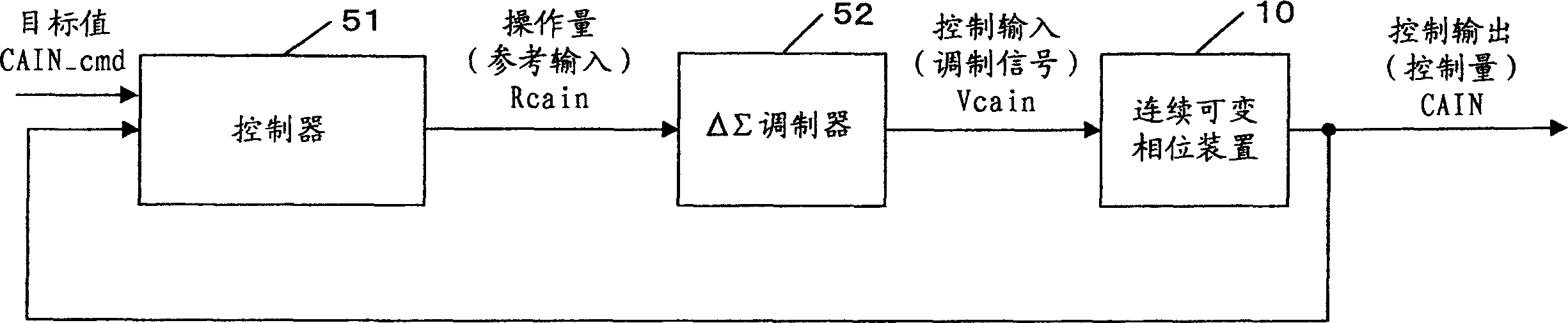

A control apparatus for controlling a plant by using a delta-sigma modulation algorithm

InactiveCN1667530AReduce surgeGood air-fuel ratioValve arrangementsElectrical controlControl theorySigma delta modulation

The invention provides a control apparatus comprising a controller for determining a manipulated variable for manipulating a controlled object so that an output of the controlled object converges to a desired value and a modulator for modulating the manipulated variable by using one of a delta-sigma modulation algorithm, a sigma-delta modulation algorithm and a delta modulation algorithm to generate a modulated signal to be applied to the controlled object. The modulator generates the modulated signal so that a center value of an amplitude of the modulated signal follows a change of the manipulated variable. Thus, the modulated signal in which the manipulated variable is reflected without any loss can be generated even when the manipulated variable changes.

Owner:HONDA MOTOR CO LTD

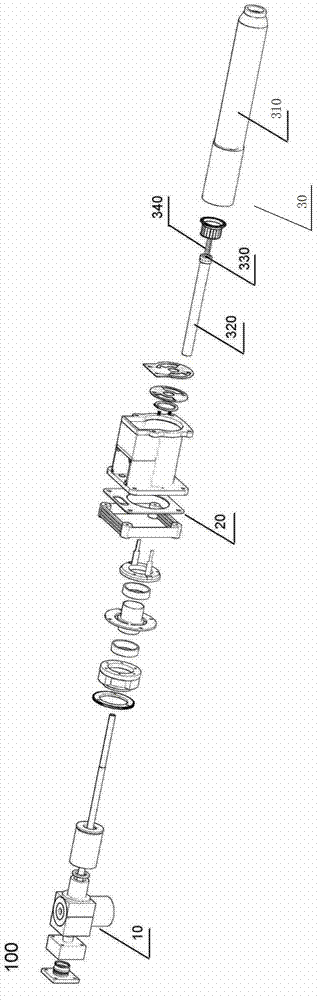

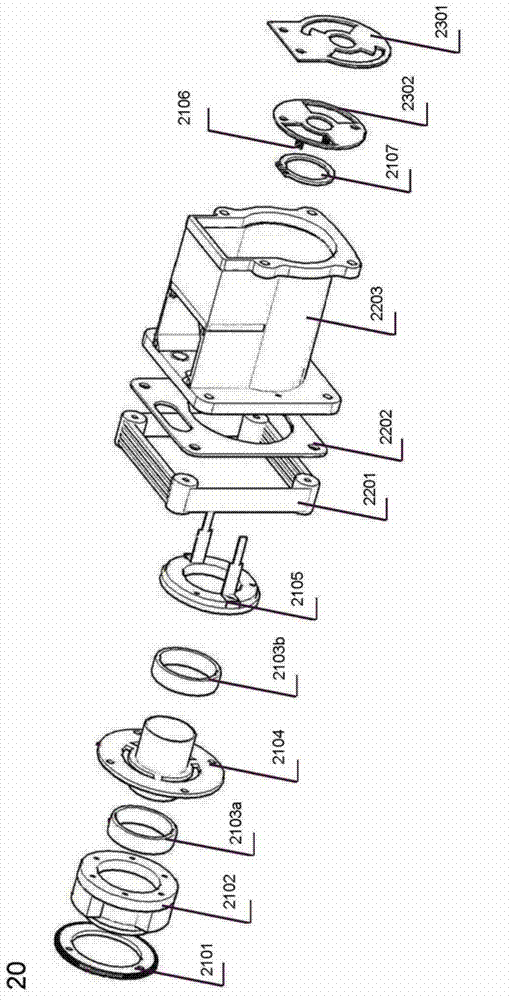

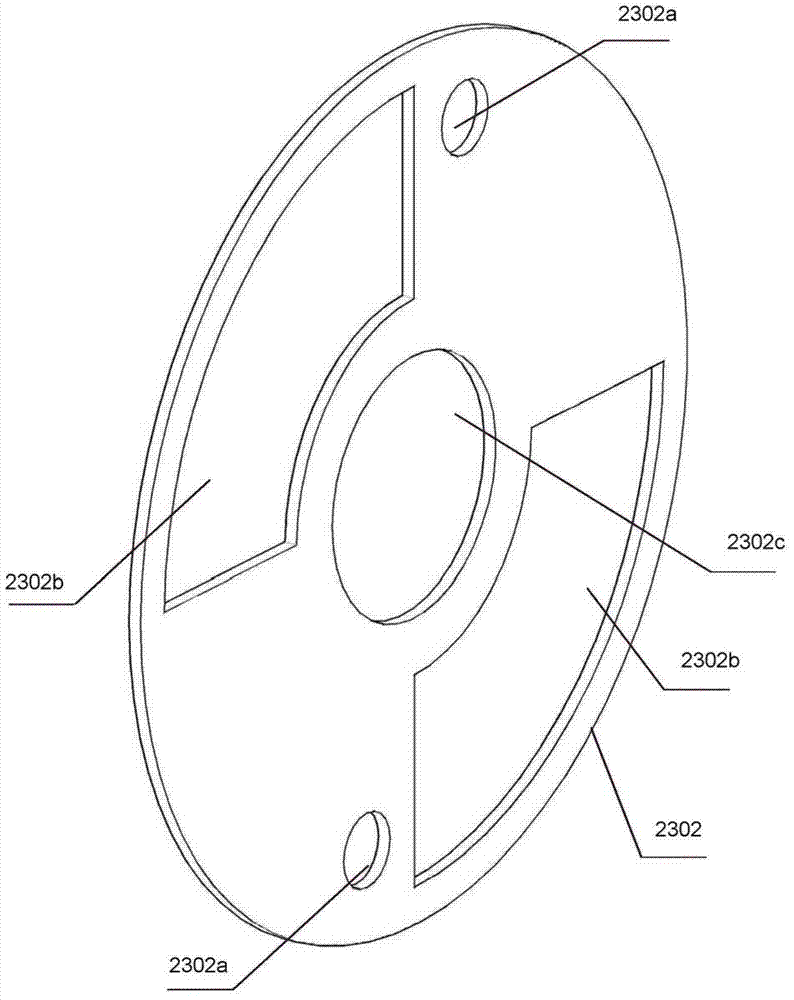

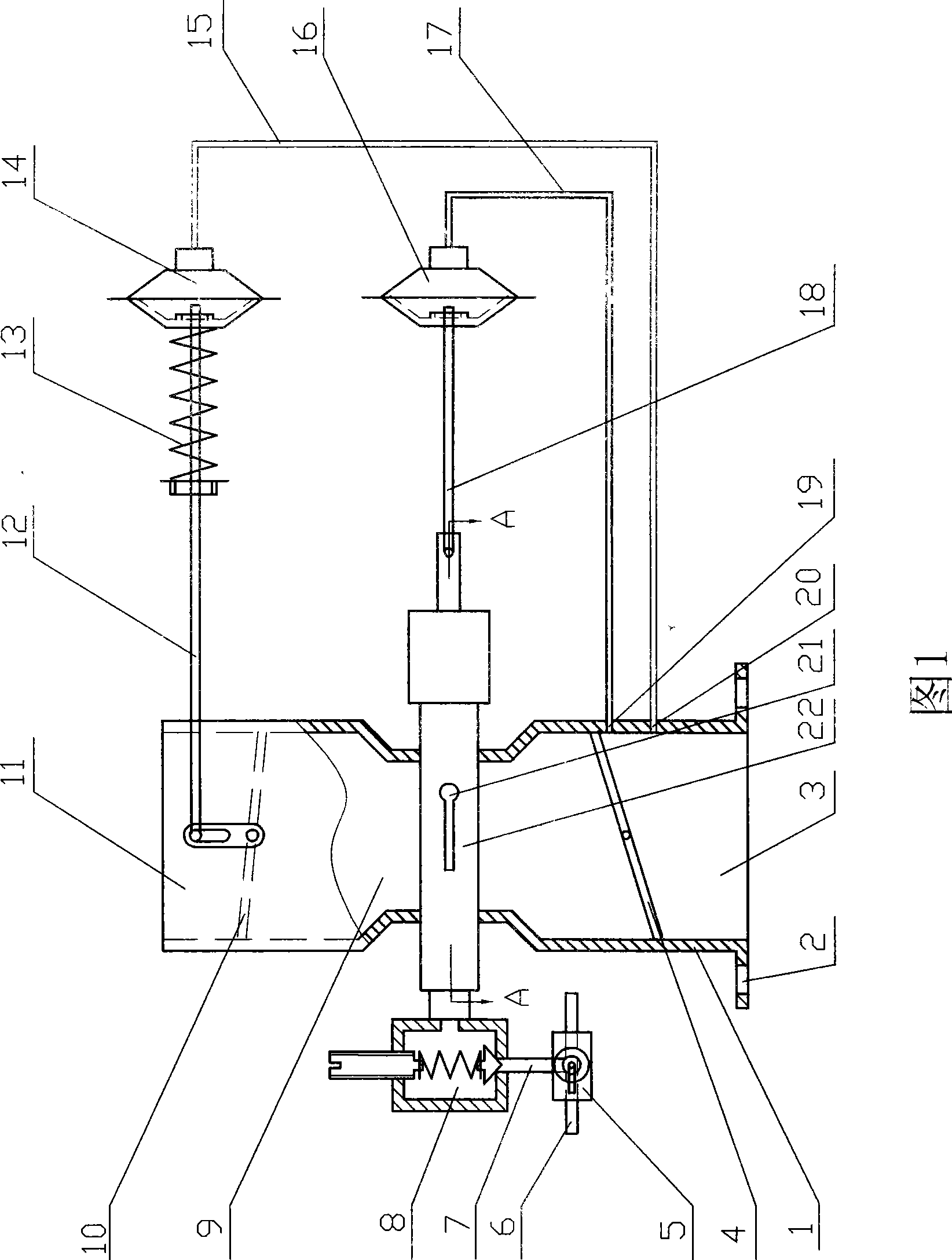

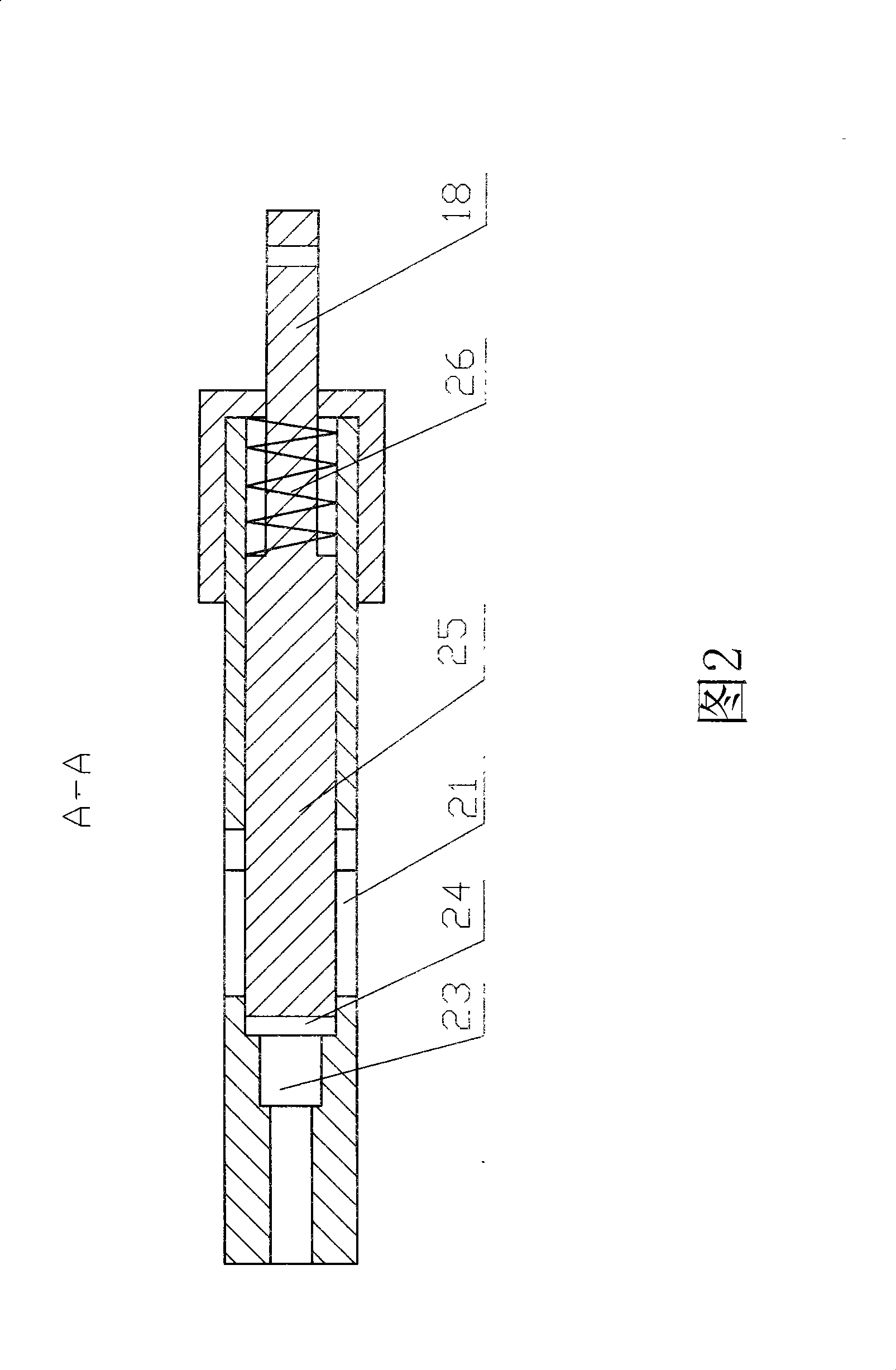

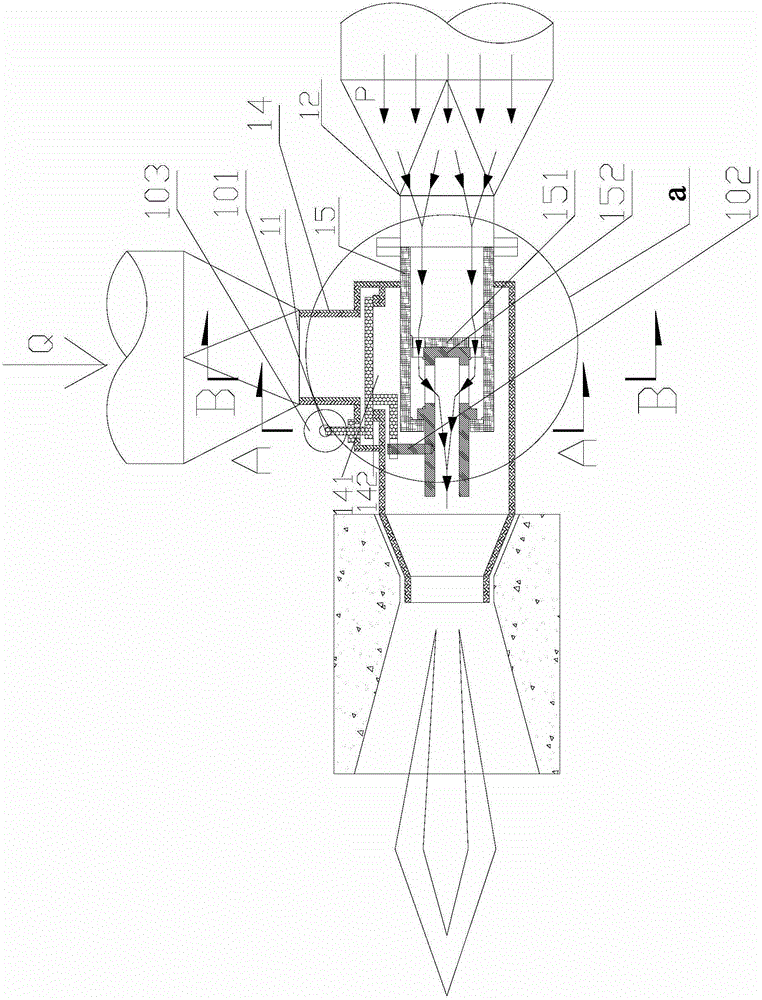

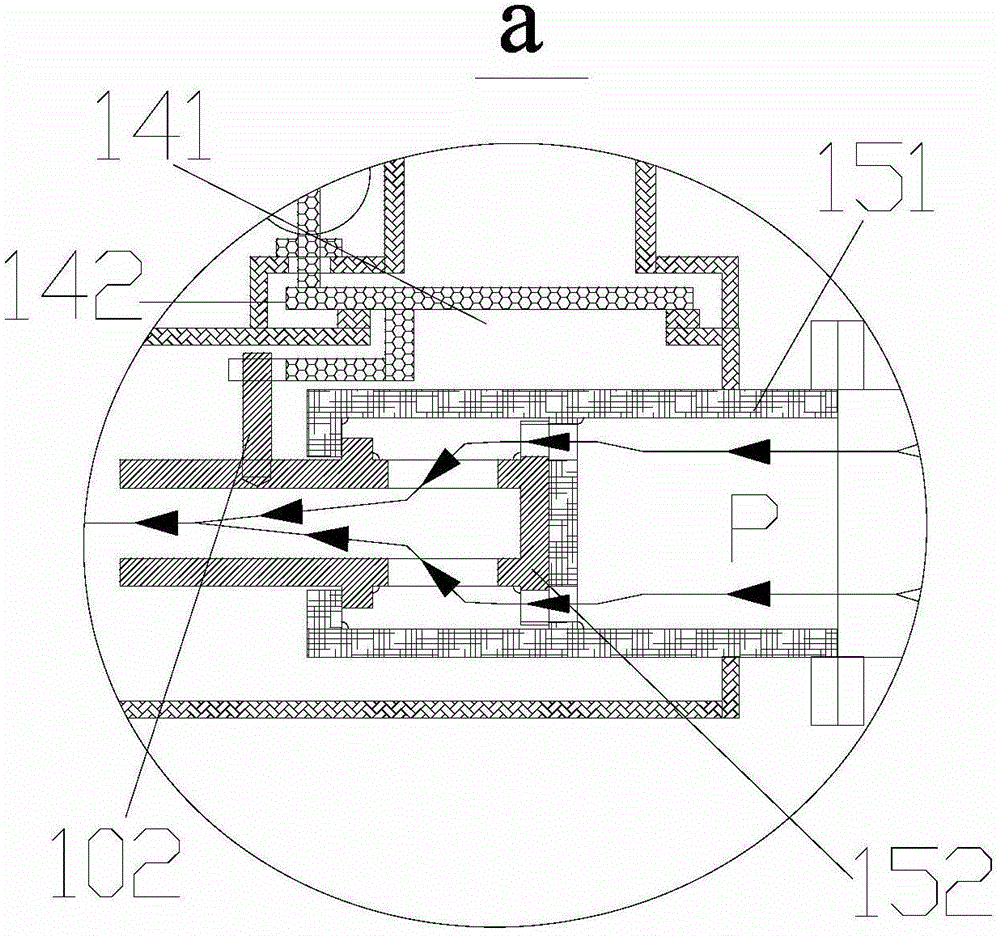

Automatic feeding device of engine fuel

InactiveCN101435370AGood air-fuel ratioImprove ergonomicsInternal combustion piston enginesFuel supply apparatusEngineeringMixed gas

The invention relates to an engine fuel automatic feeding device which comprises a mixer and a fuel control valve. The mixer consists of a gas inlet, a mixing chamber and a mixed fuel outlet, wherein a chock valve is arranged on the gas inlet; and a throttle is arranged on the mixed fuel outlet. The device is characterized in that the fuel control valve is a change-over valve which has an input port for different fuels and a fuel output port; the fuel output port is communicated with a pressure regulation valve communicated with a fuel chamber of a fuel distribution valve; a plunger cavity communicated with the fuel chamber is arranged on the distribution valve; the cavity wall is provided with a fuel outlet which is arranged inside the mixing chamber; a plunger is arranged in the plunger cavity; the motion of the plunger controls the opening and closing of the fuel outlet; two vacuum holes are reserved on the mixer body outside the throttle, and are communicated with vacuum valves through communication pipes respectively; the execution end of one vacuum valve controls the opening and closing of the chock valve; and the execution end of the other vacuum valve controls the motion of the plunger. The engine fuel automatic feeding device can automatically adjust the air-fuel ratio, the mixed gas intake and the supply of different fuels.

Owner:牟利民

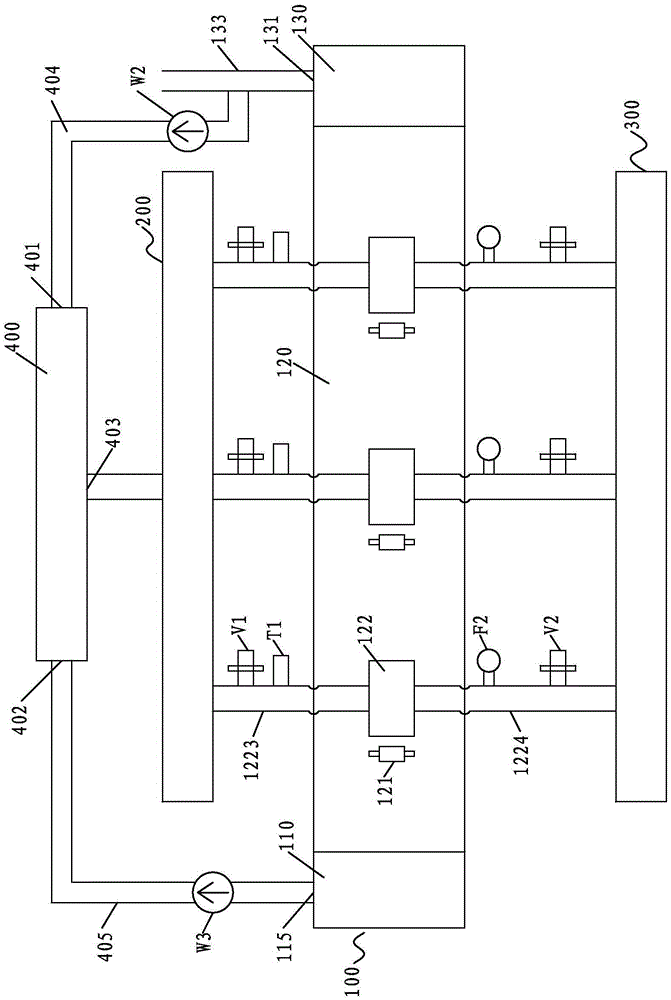

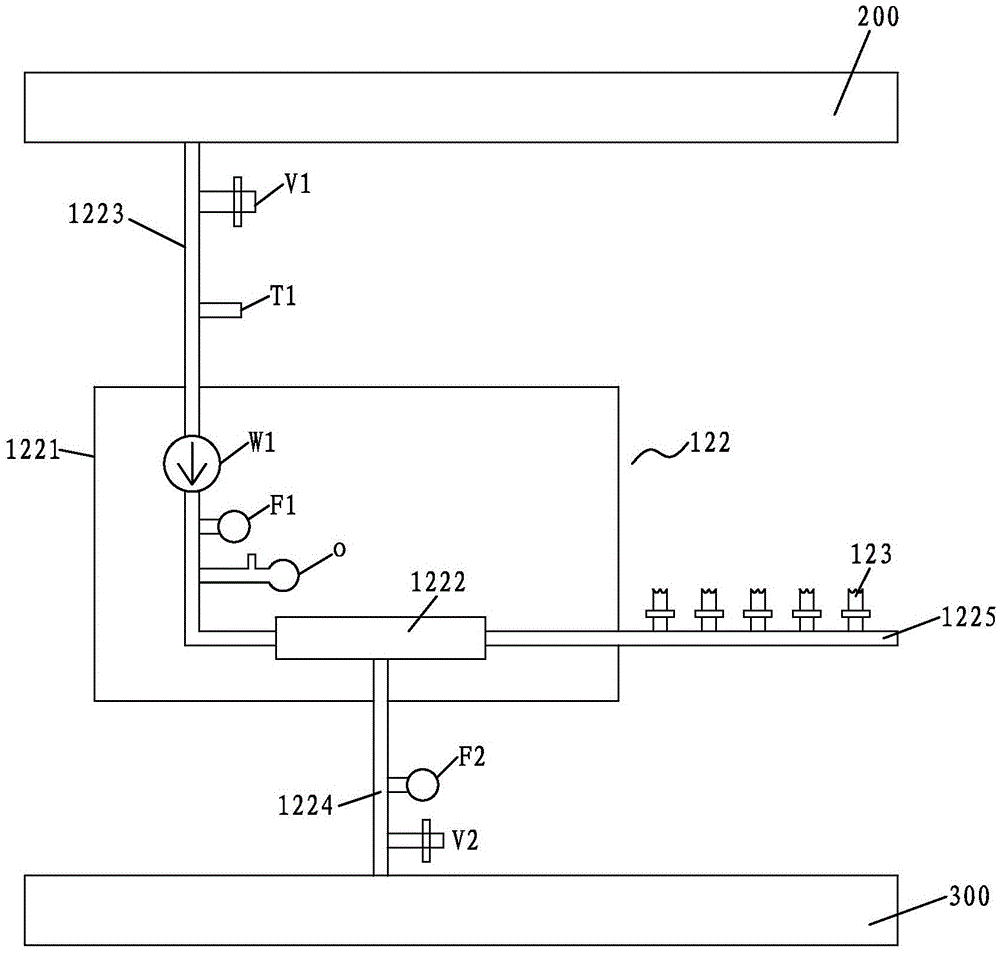

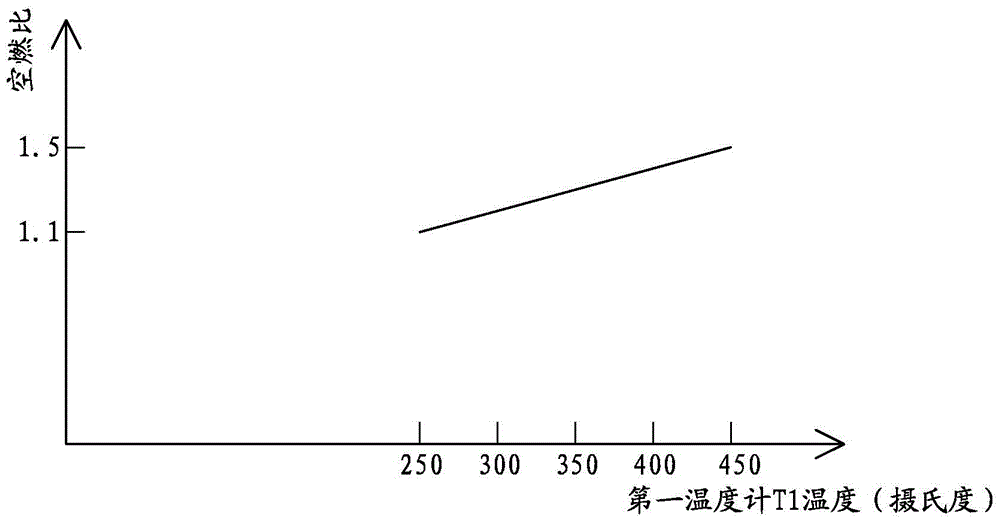

High-temperature air and high-temperature low-oxygen smoke mixed combustion-supporting type full-automatic control ceramic kiln

ActiveCN105650673AEmission reductionQuality assuranceFuel supply regulationAutomatic controlControl engineering

The invention discloses a high-temperature air and high-temperature low-oxygen smoke mixed combustion-supporting type full-automatic control ceramic kiln which comprises a combustion-supporting gas main pipe, a fuel gas main pipe and a kiln body. The kiln body is divided into a cooling section, a combustion section and a preheating section in the longitudinal direction. The combustion section comprises at least three control subareas, and each control subarea comprises a thermocouple, at least five nozzles and a control box. Each control box is provided with a box body, a first mixer contained in the box body, a combustion-supporting gas control branch pipe penetrating one side wall of the box body to be connected between the first mixer and the combustion-supporting gas main pipe, a fuel gas control branch pipe penetrating the other side wall of the box body to be connected between the first mixer and the fuel gas main pipe, and a mixed gas branch pipe penetrating one end wall of the box body from the first mixer to extend to the outside of the box body. First electric valves, first thermometers and first flowmeters are arranged on the combustion-supporting gas control branch pipes. Second electric valves and second flowmeters are arranged on the fuel gas control branch pipes. Each mixed gas branch pipe is connected with the at least five nozzles in the corresponding subarea.

Owner:广州汇锦能效科技有限公司

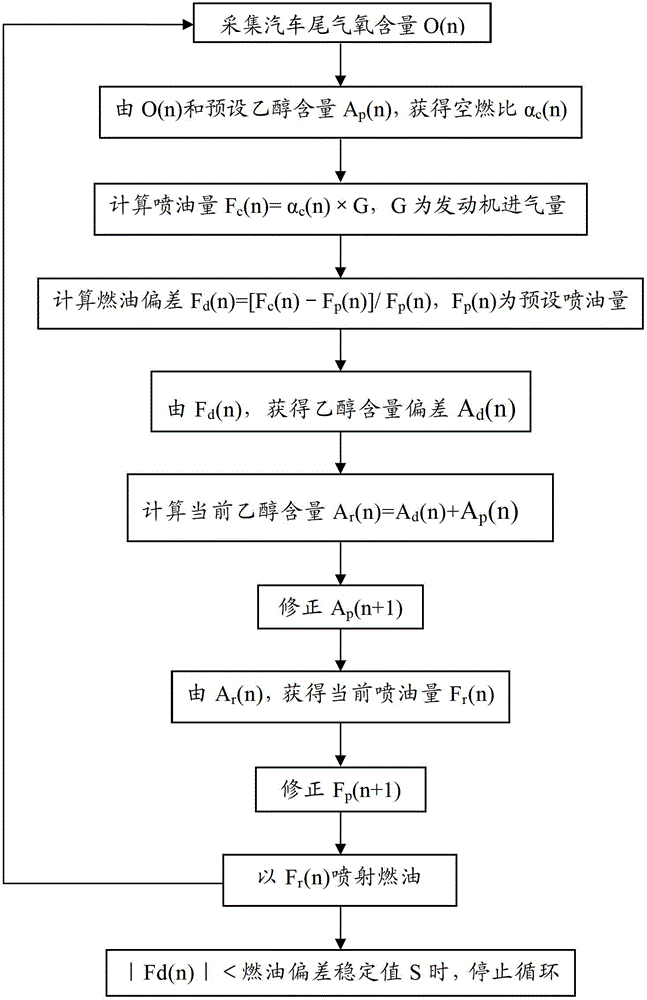

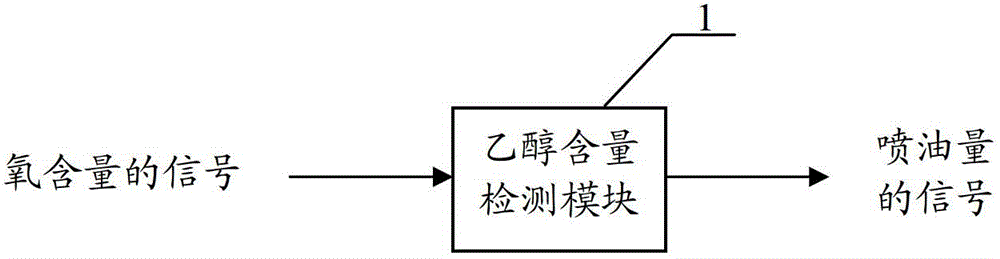

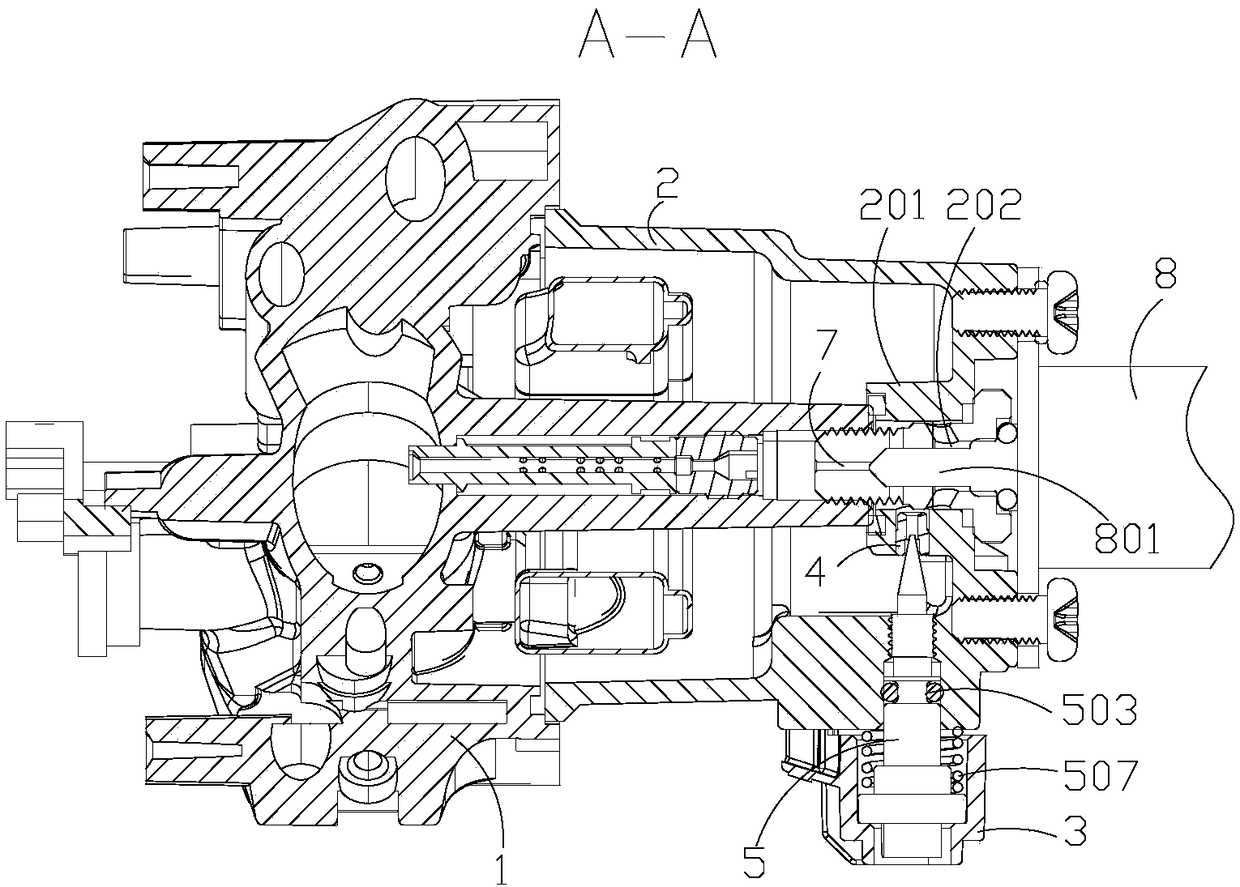

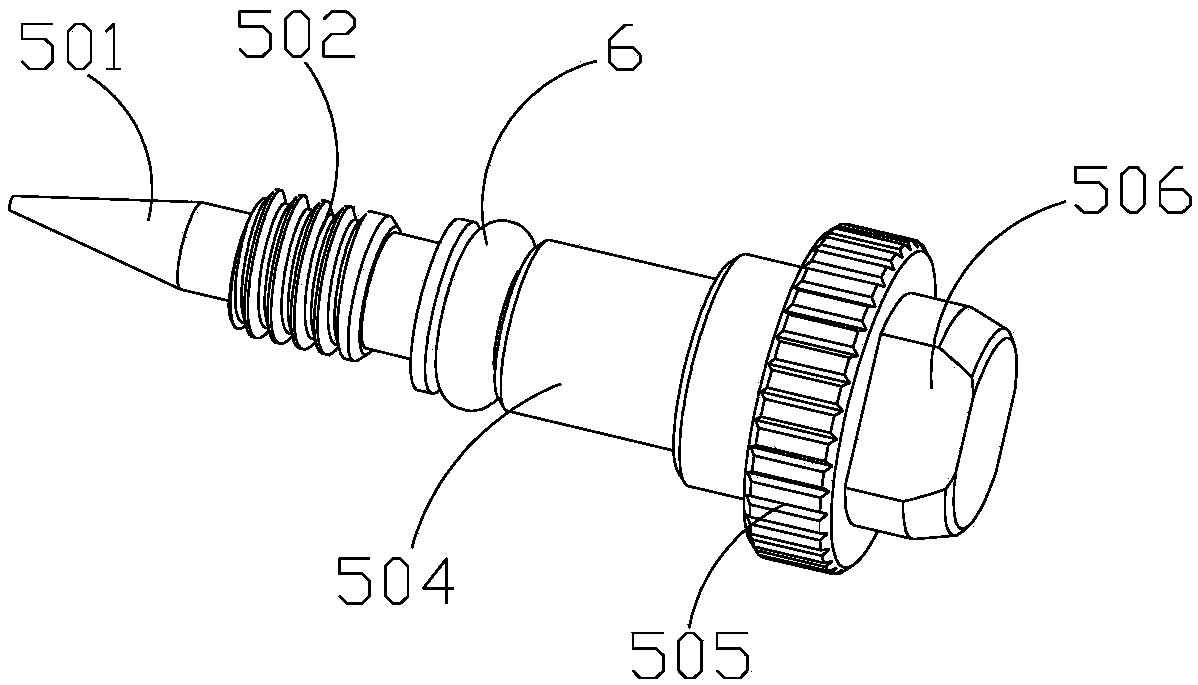

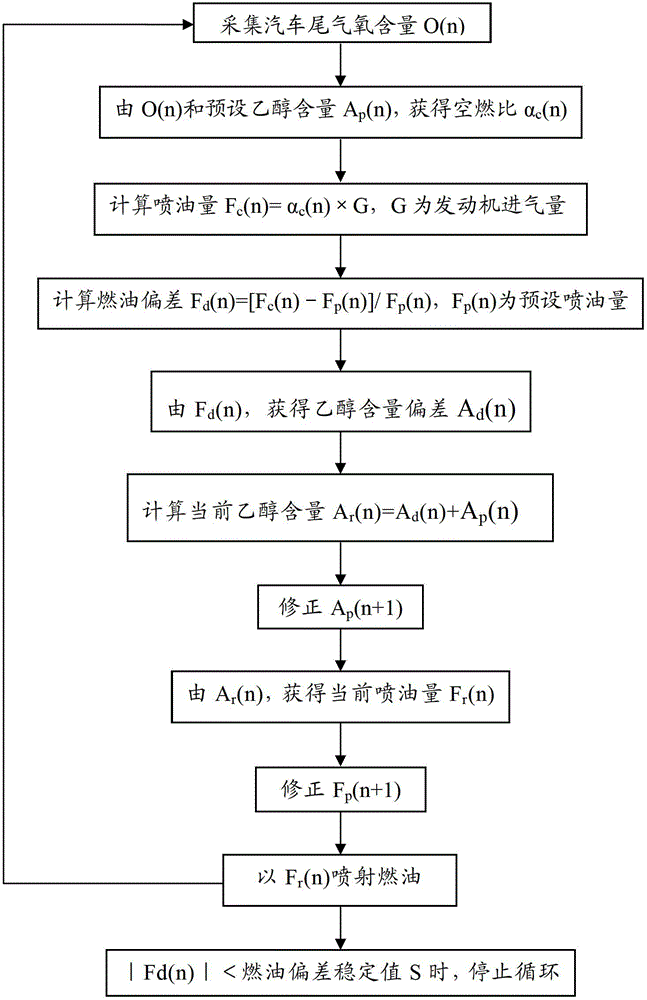

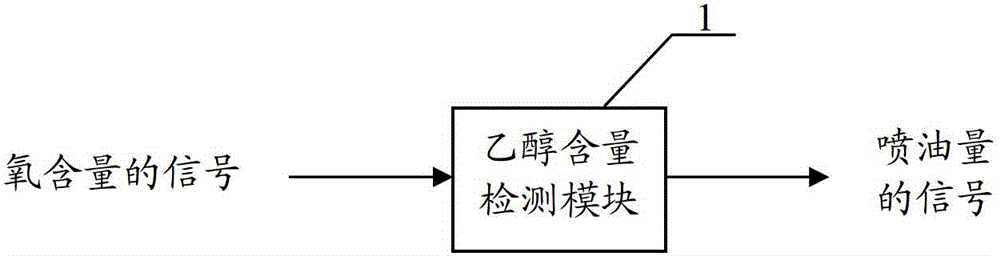

Alcohol fuel alcohol content detection method and module

ActiveCN102877971AAlcohol content can be easily obtainedEmission reductionElectrical controlInternal combustion piston enginesAlcohol contentAlcohol fuel

The invention discloses an alcohol fuel alcohol content detection method and module for alcohol fuel automobiles. The method comprises the following steps of: collecting oxygen content O(n) of automobile tail gas; acquiring an air-fuel ratio alpha c (n) according to O (n) and the preset alcohol content Ap (n); acquring oil injection quantity Fc(n) according to alpha c(n) and engine air input G; calculating the fuel deviation Fd(n)=[Fc(n)-Fp(n)] / Fp(n), wherein Fp(n) is the preset oil injection quantity; acquring the alcohol content deviation Ad(n) according to Fd(n); calculating the current alcohol content Ar(n)=Ad(n)+Ap(n); amending Ap(n+1); acquring the current oil injection quantity Fr(n) according to Ar(n); amending Fr(n+1); injecting fuel according to Fr(n) and repeating the steps; and stopping repeating when the absolute value of Fd(n) is less than the fuel deviation stabilized value S. The alcohol fuel alcohol content detection method disclosed by the invention can detect the alcohol content in the fuel, and improves the using performance of fuel automobiles.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

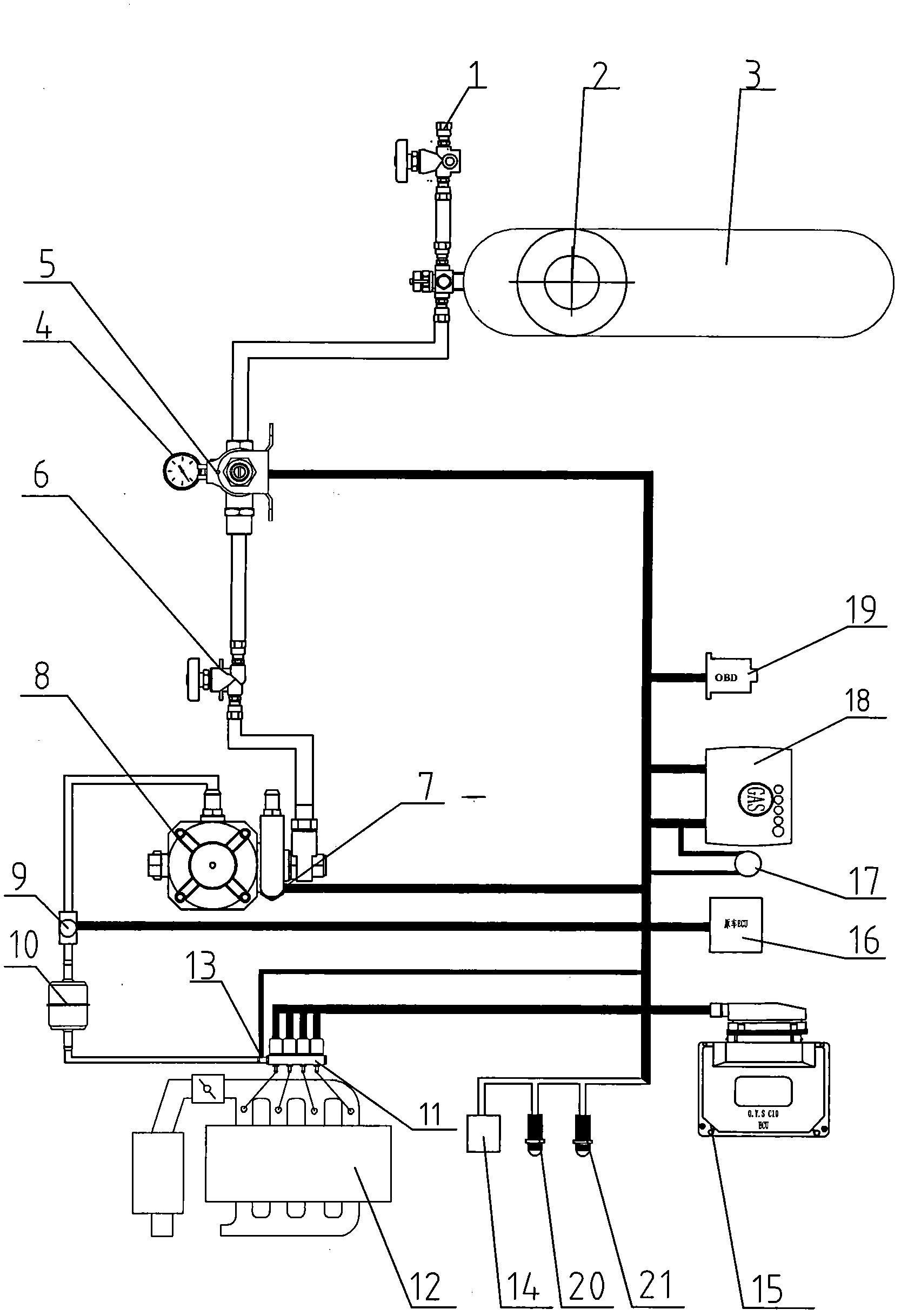

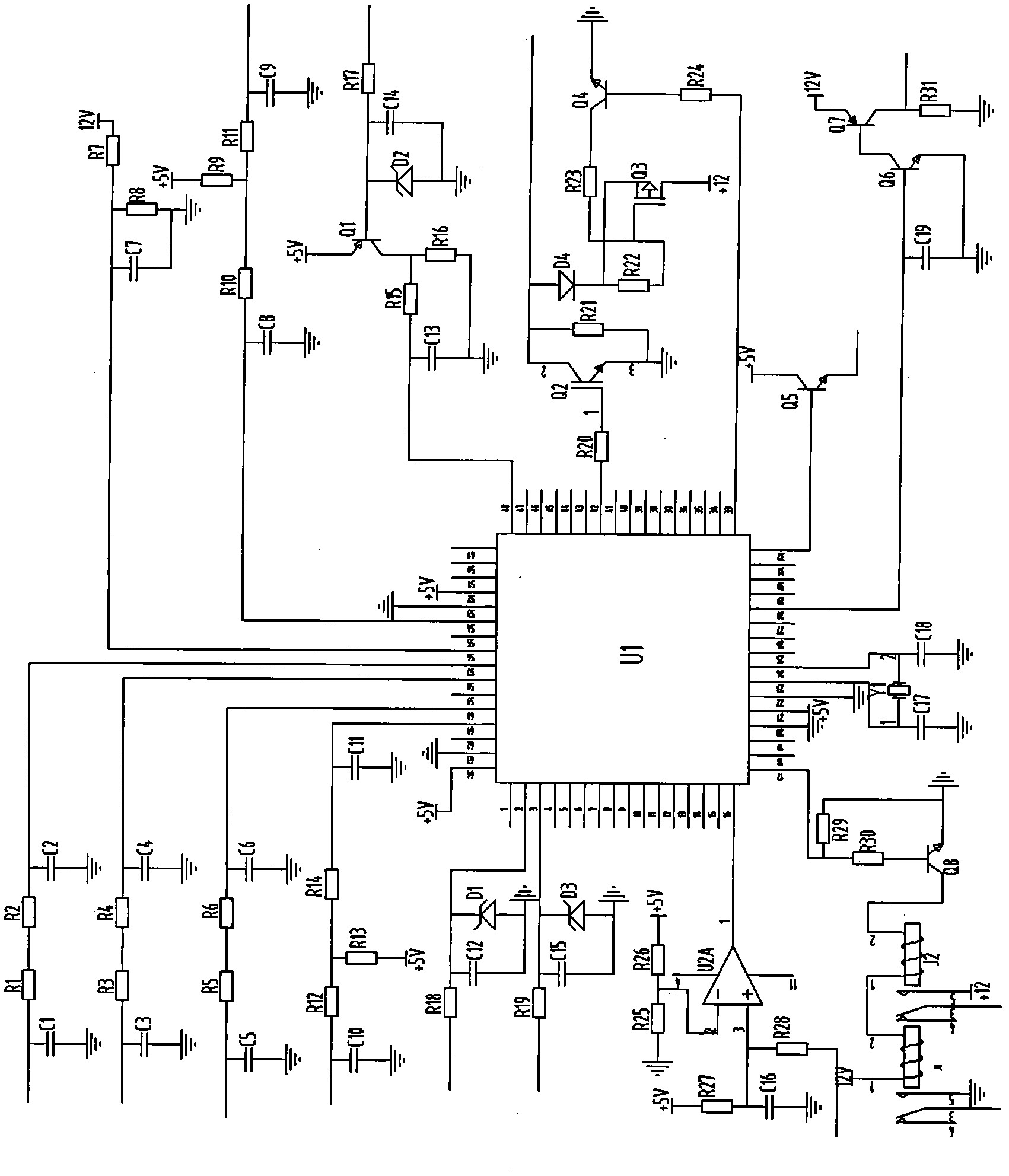

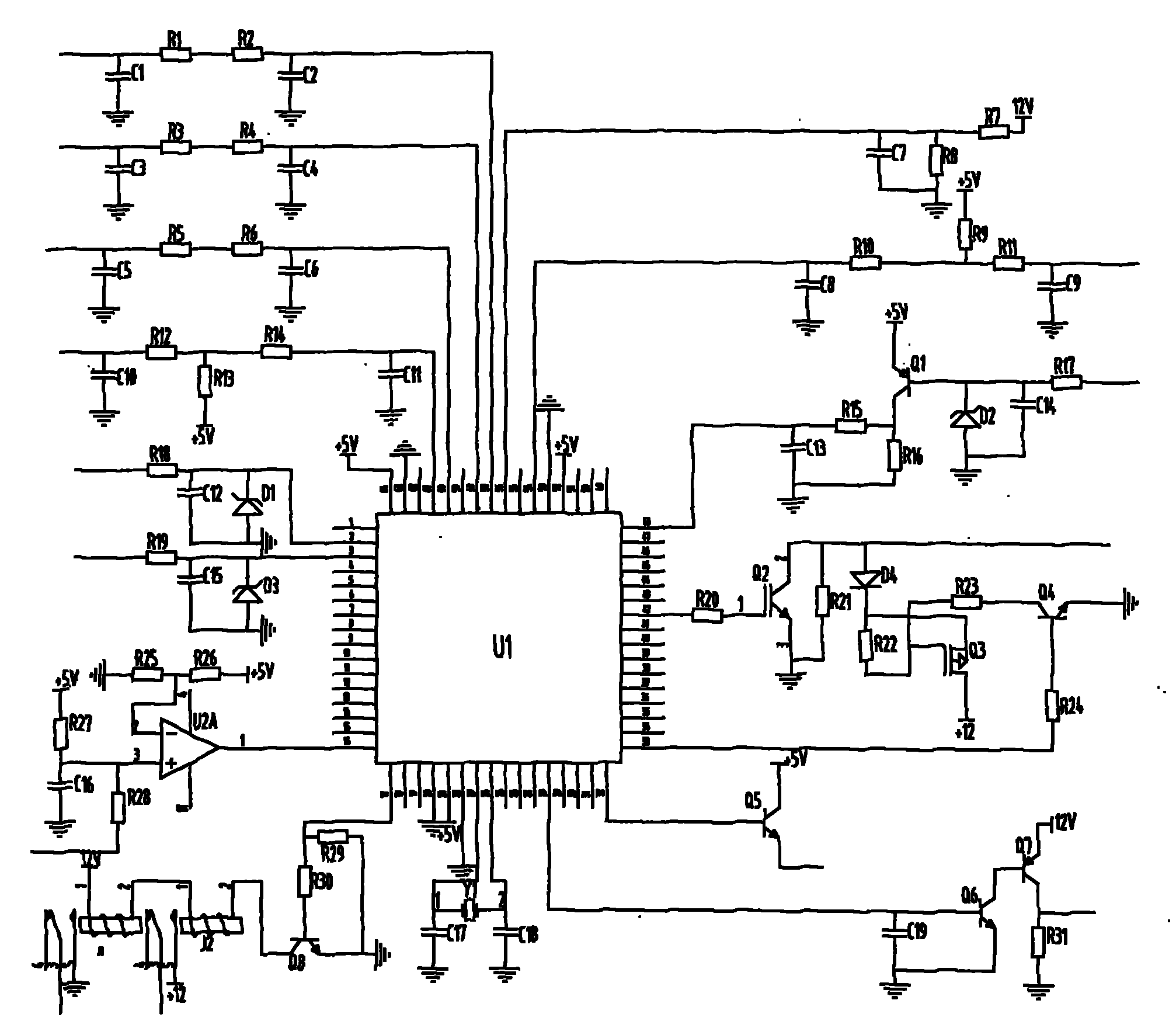

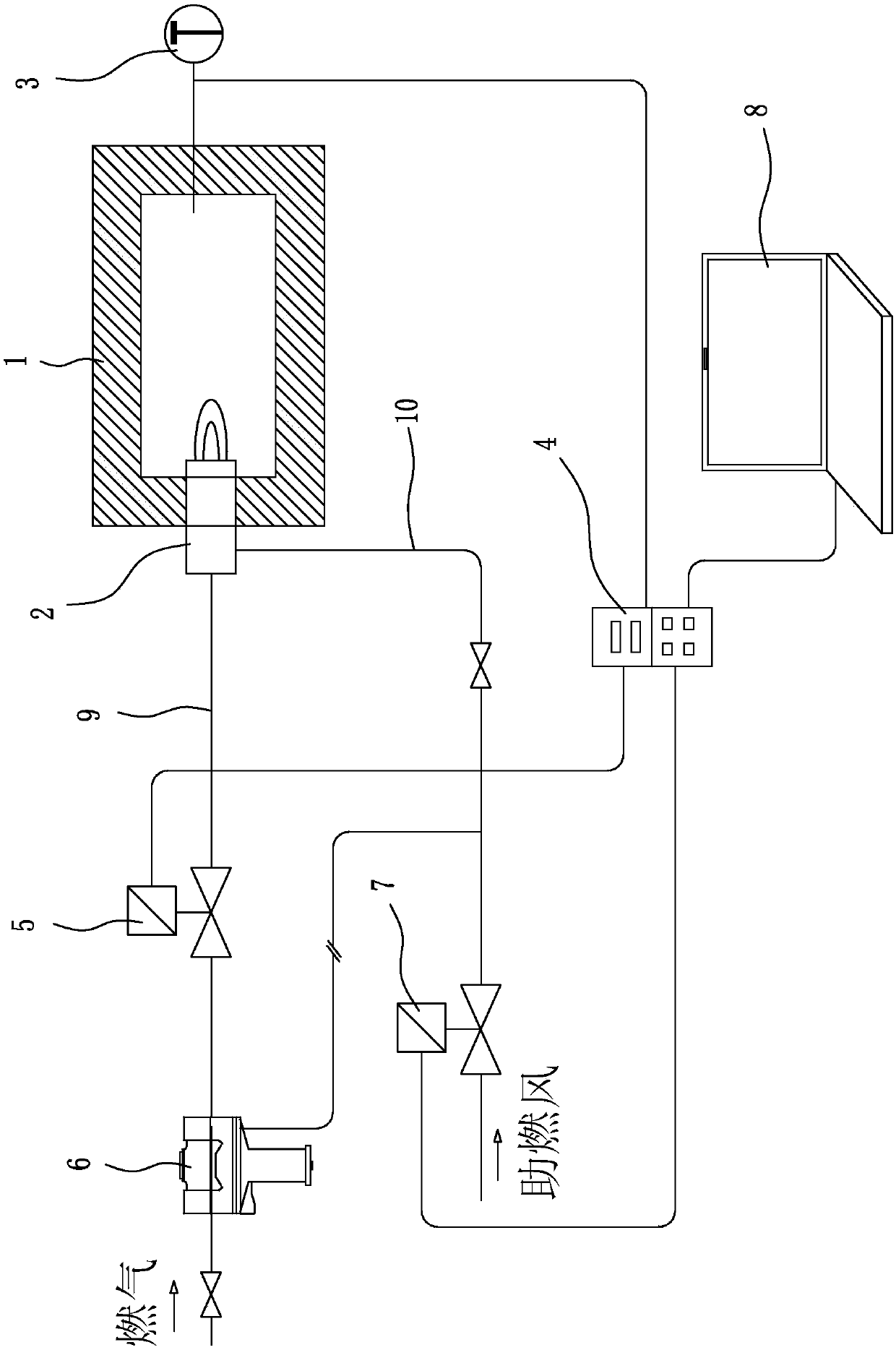

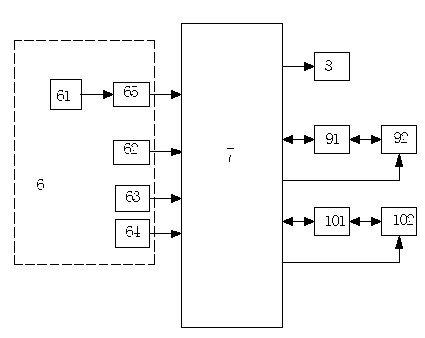

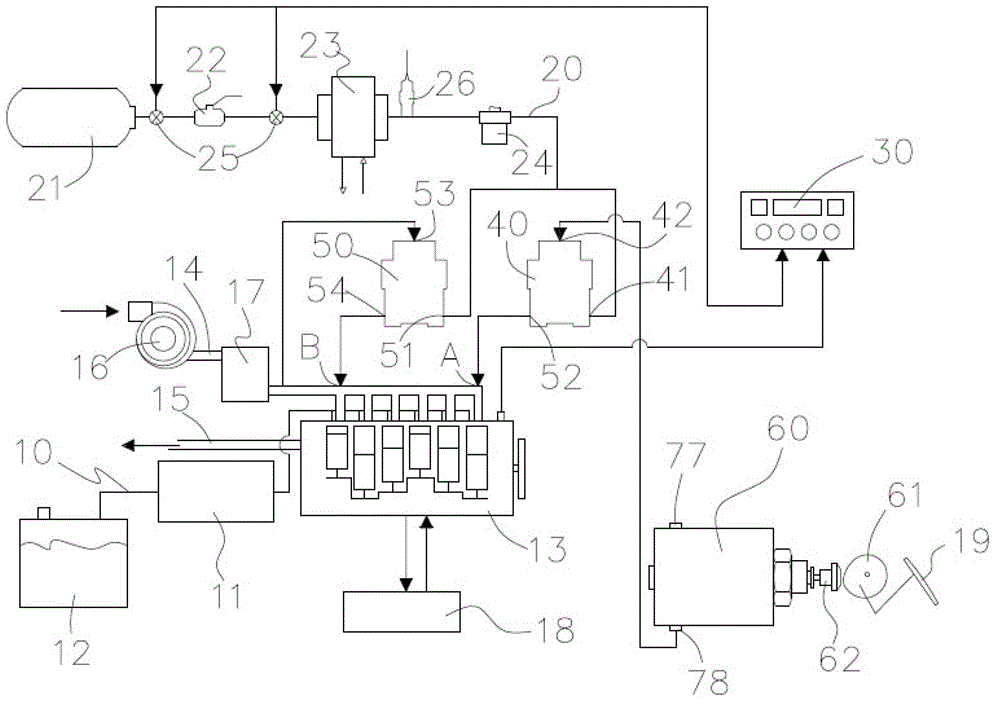

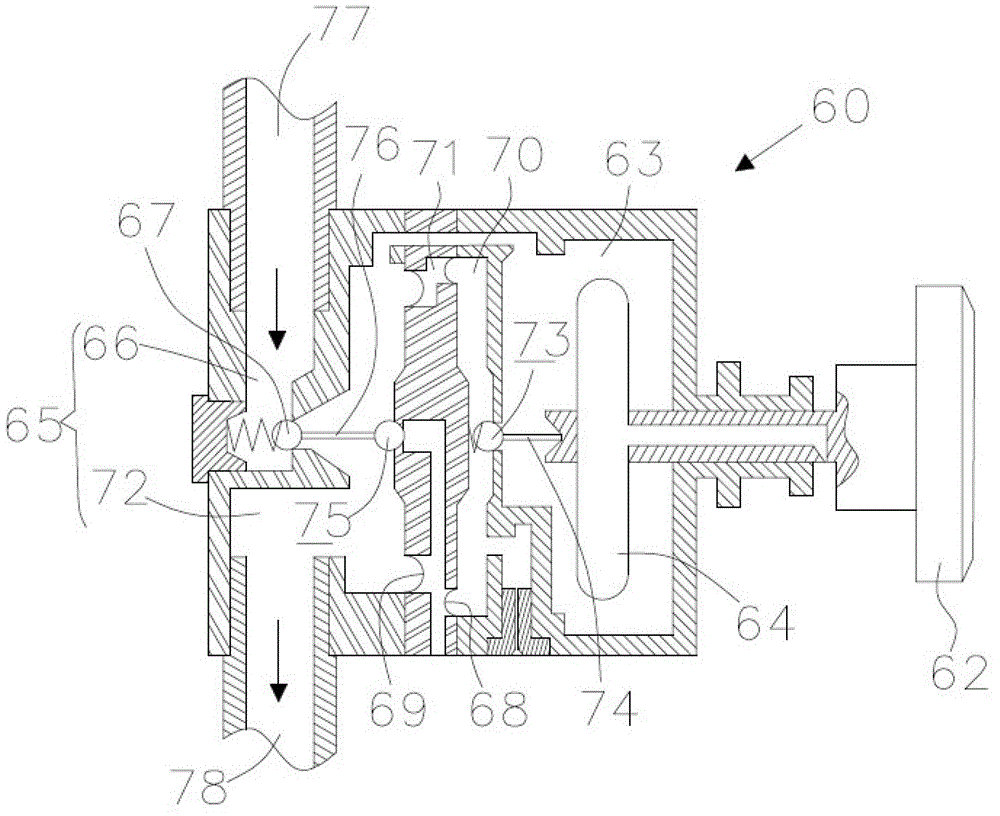

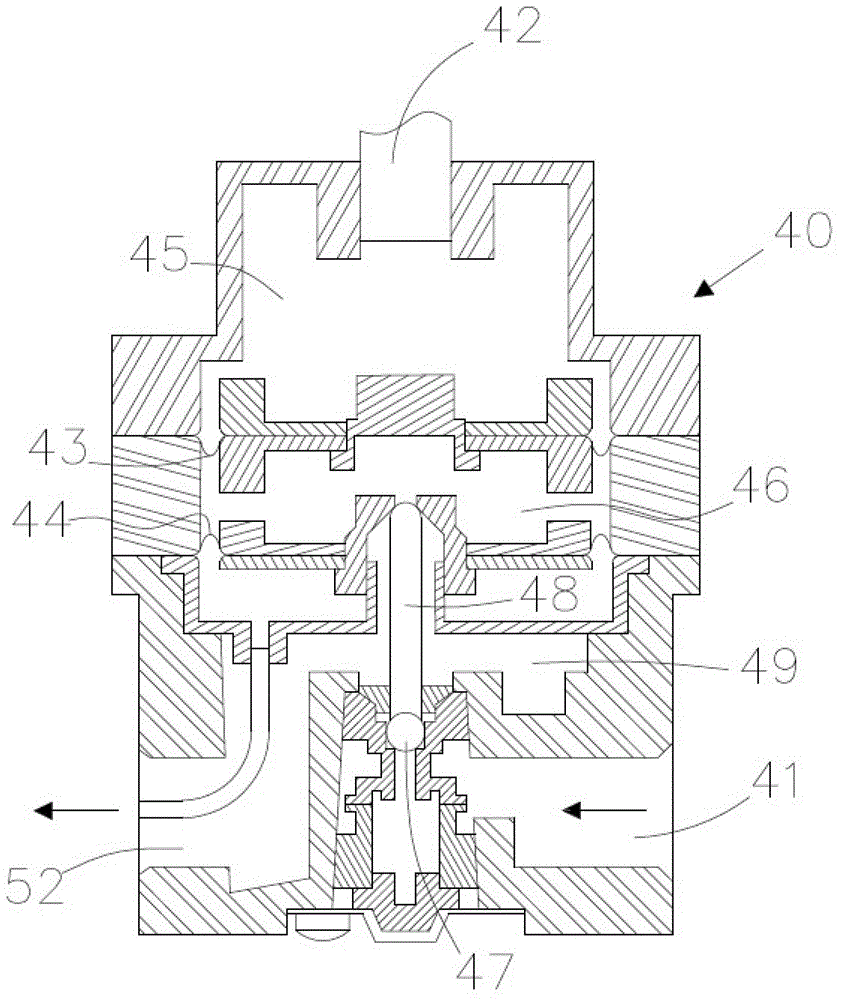

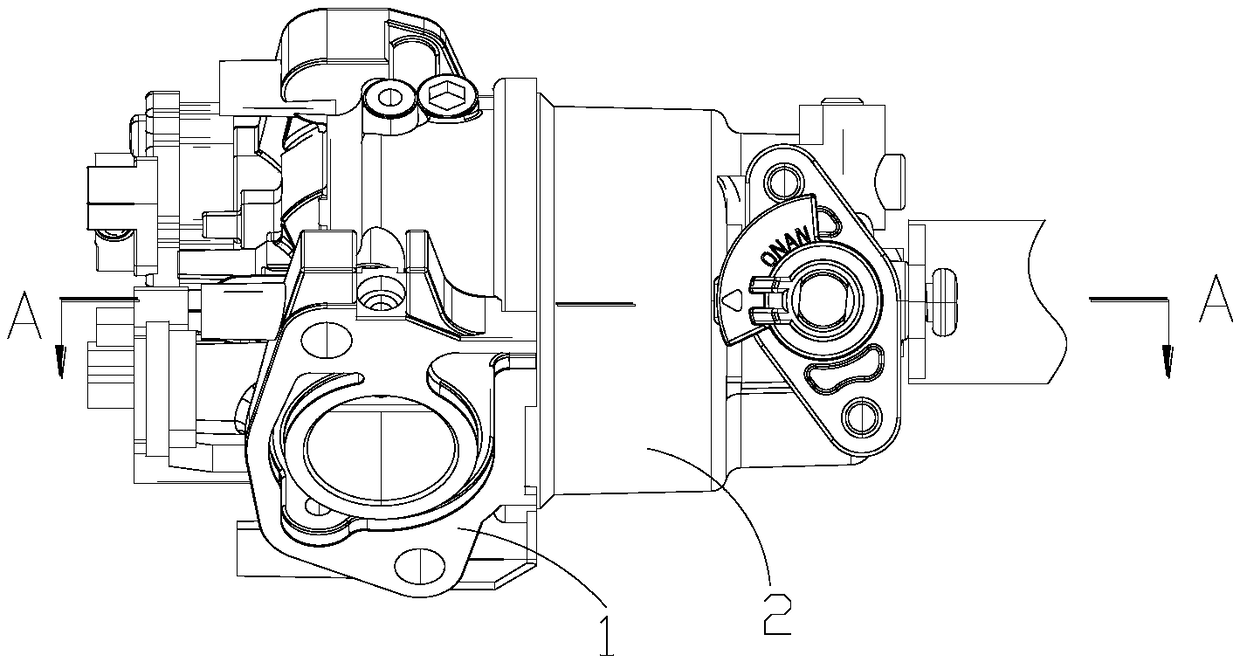

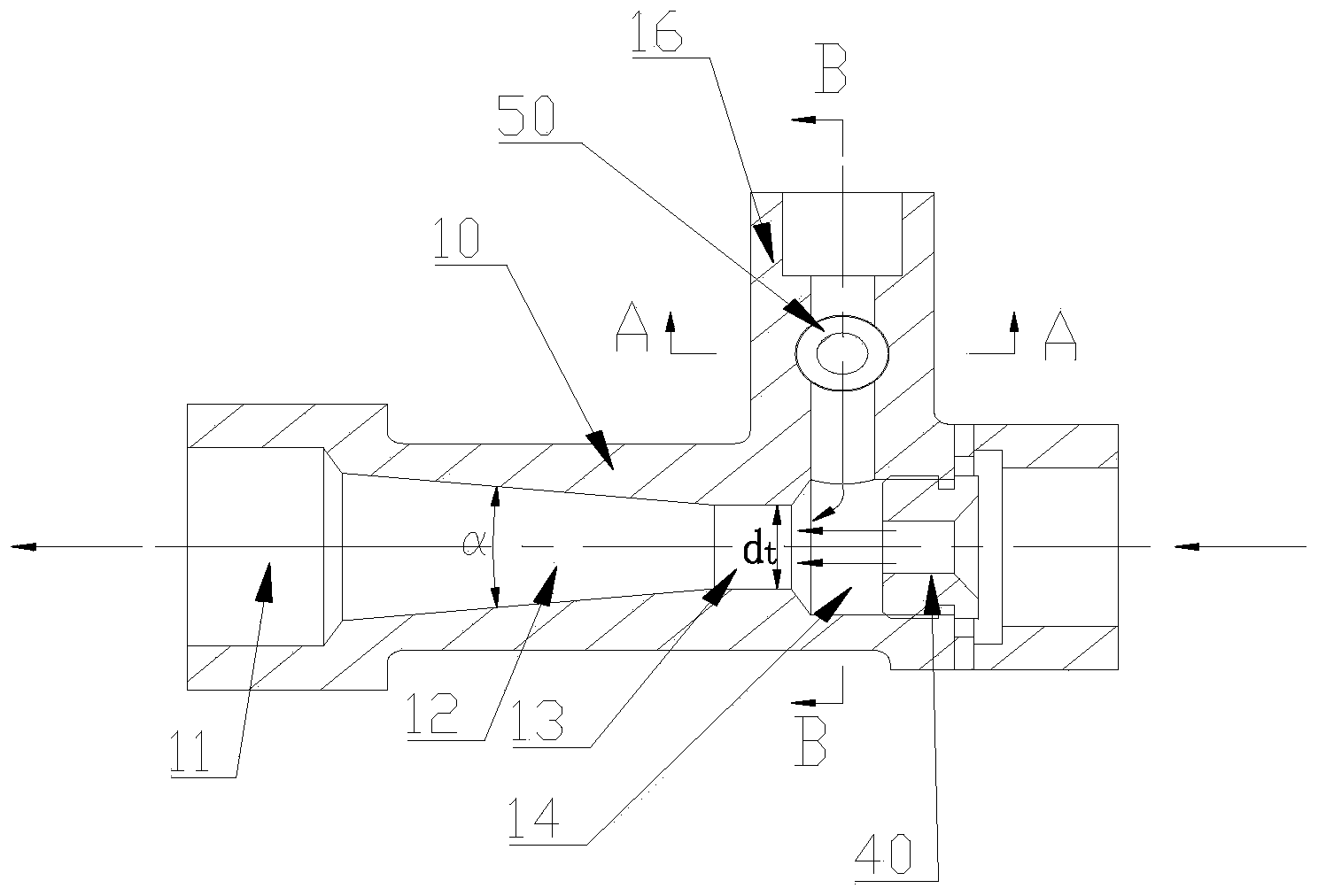

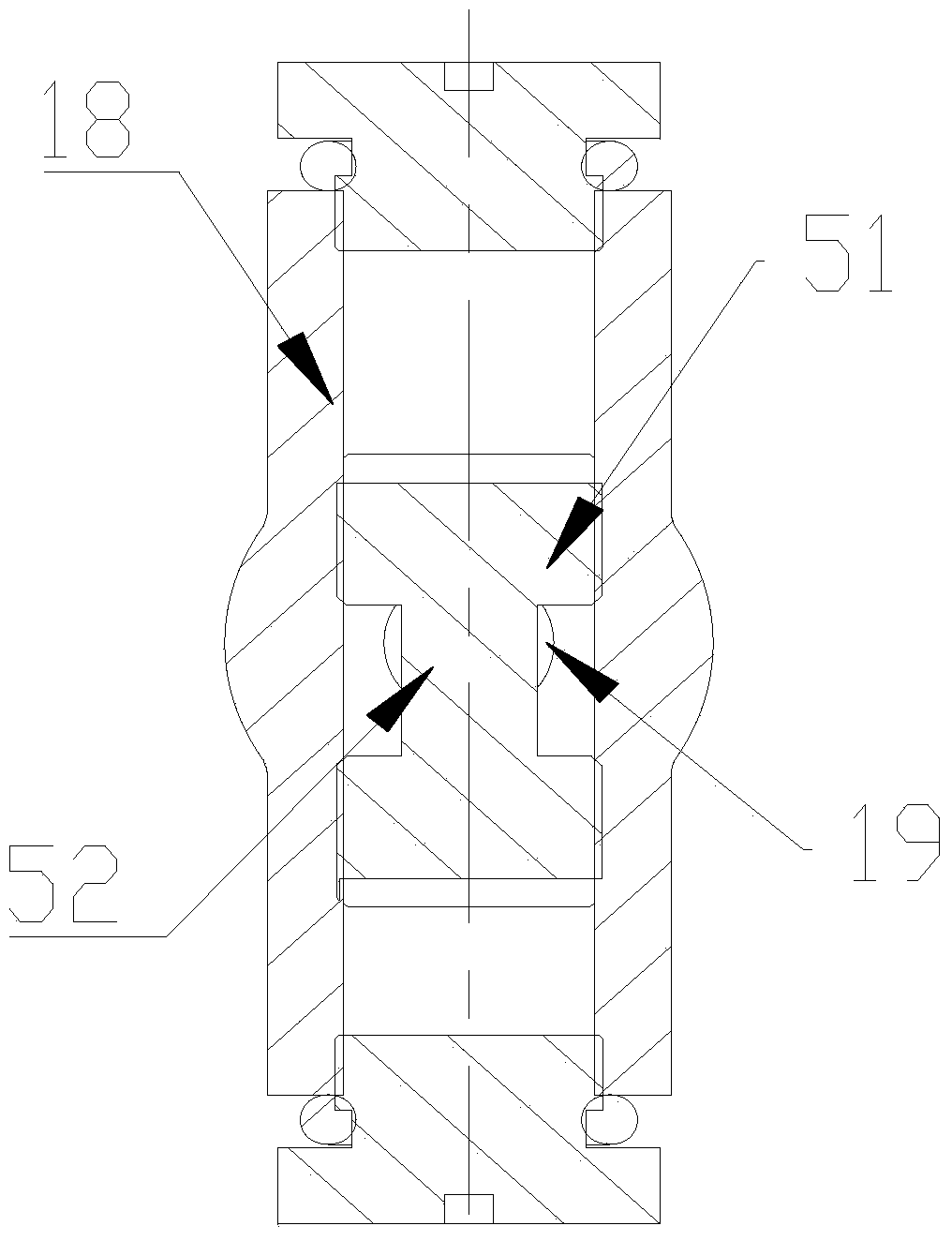

Sequential fuel gas injection system with on-board diagnostics (OBD) system for automobile

ActiveCN102072033AGood air-fuel ratioImprove driving performanceElectrical controlInternal combustion piston enginesHigh pressureElectric control

The invention relates to a sequential fuel gas injection system with an on-board diagnostics (OBD) system for an automobile. The sequential fuel gas injection system comprises a fuel gas supply system, wherein in the fuel gas supply system, a gas storage steel cylinder is connected with a high-pressure electromagnetic valve; a pressure sensor is arranged on the high-pressure electromagnetic valve; the high-pressure electromagnetic valve is connected to a manual cutoff valve through a steel pipe, and is connected to a pressure reducer through a steel pipe; the pressure reducer is connected with one end of a gas filter through a rubber hose; the other end of the gas filter is connected with a gas injection valve through a rubber hose; a nozzle of the gas injection valve is connected with a corresponding engine cylinder through a rubber hose; the gas storage steel cylinder is provided with a steel bottle angle valve; a gas outlet pipe of the gas storage steel cylinder is provided with a gas charging valve; and an electric control system consists of a water temperature sensor which is arranged on the pressure reducer, a gas temperature sensor which is arranged on the gas injection valve, a change-over switch, a buzzer, a manifold pressure sensor, a fuel gas pressure sensor, an oxygen sensor, an engine rotating speed sensor, an OBD adapter and a fuel gas electronic control unit (ECU). In the fuel gas multi-point sequential injection control system with OBD function, optimal air-fuel ratio of the engine and optimal traveling performance of the automobile are ensured under various working conditions, and economical efficiency is improved by over 10 percent compared with the conventional fuel gas system for the automobile.

Owner:河南欧意机械设备有限公司

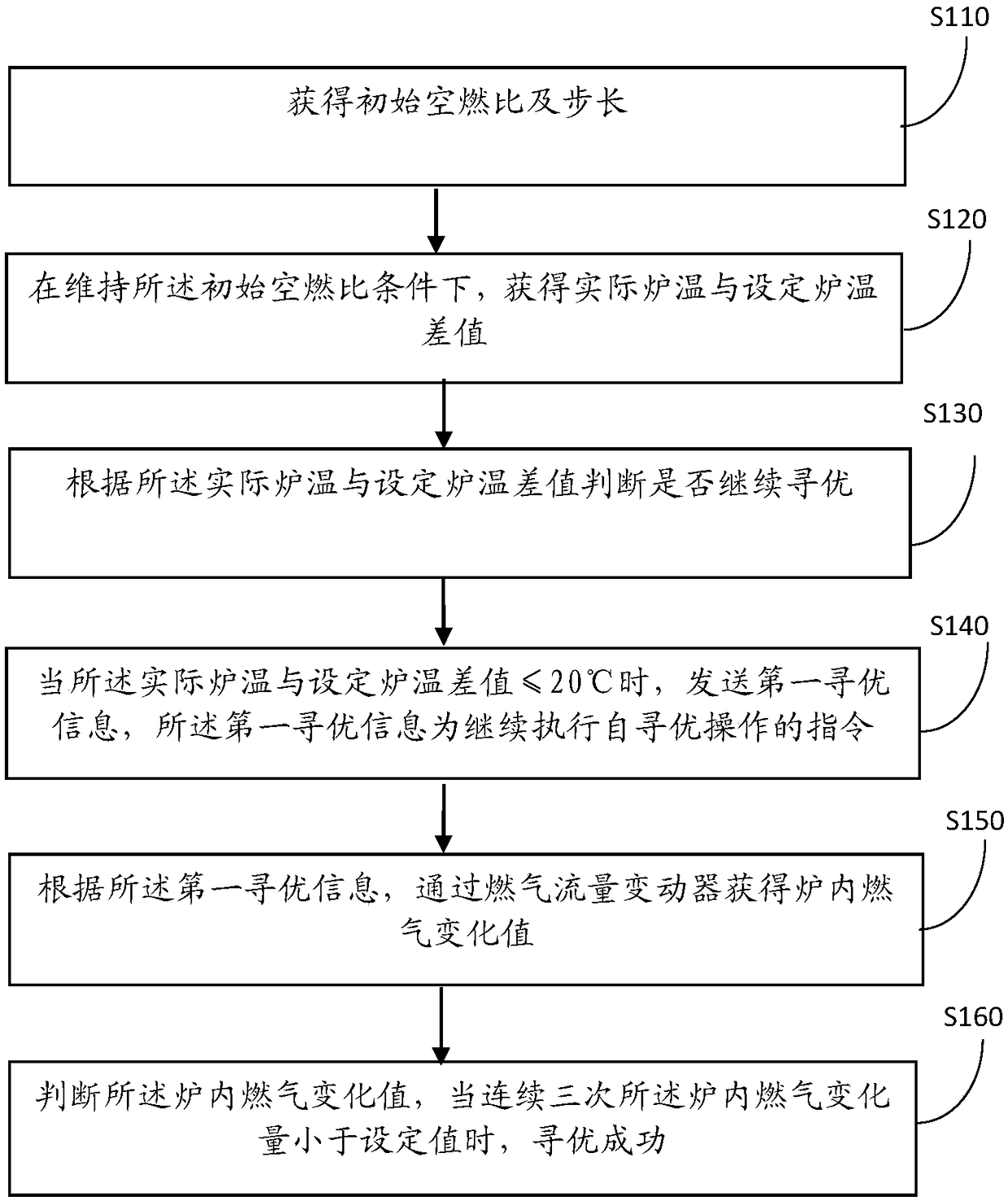

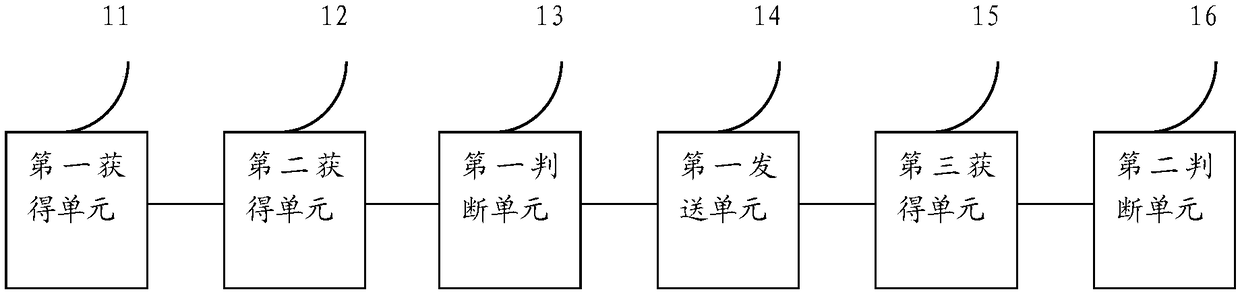

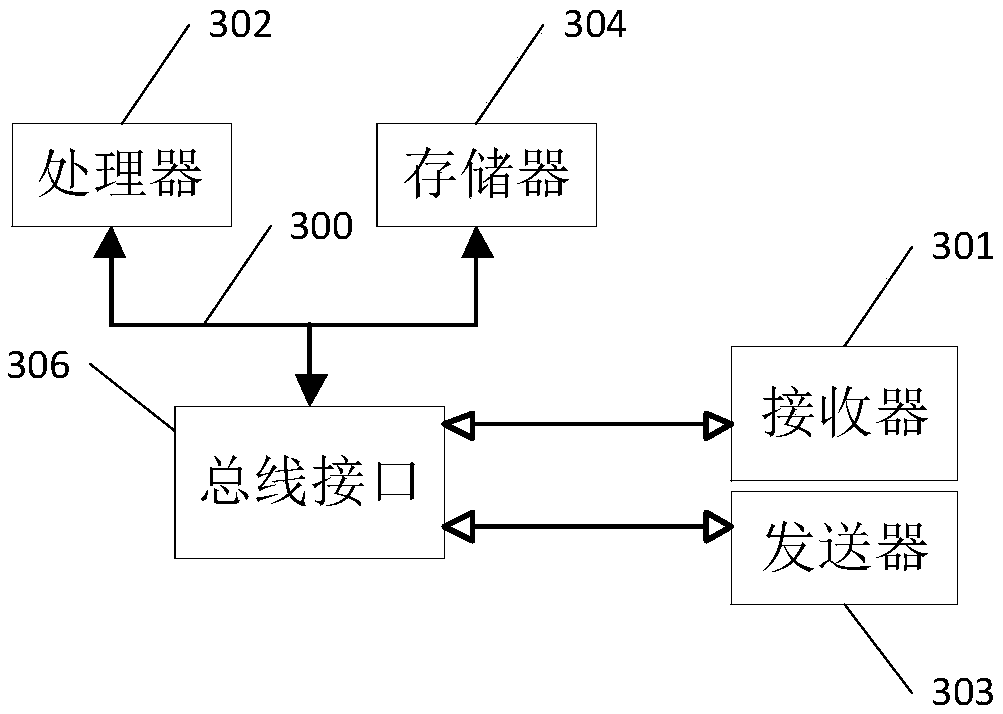

Annealing furnace air-fuel ratio self-optimizing method and device

ActiveCN109055700ASmall temperature fluctuations in the furnaceReduce gas consumptionFurnace typesHeat treatment process controlAir–fuel ratioThermal load

The invention provides an annealing furnace air-fuel ratio self-optimizing method and device. The method comprises the following steps that initial air-fuel ratio and step size are obtained; the difference value between the actual furnace temperature and the set furnace temperature is obtained; whether optimizing is performed continuously or not is judged according to the difference value betweenthe actual furnace temperature and the set furnace temperature; when the difference between the actual furnace temperature and the set furnace temperature is less than or equal to 20 DEG C, first optimizing information is sent; according to the first optimizing information, an in-furnace fuel gas change value is obtained through a fuel gas flow changing device; and the in-furnace fuel gas change value is judged, when the in-furnace fuel gas change quantity is smaller than a set value for three times continuously, optimizing is completed. The technical problems that in the prior art, due to thefact that the control of the air-fuel ratio is not good in annealing furnace combustion control, heat loss, unstable system combustion and the like exist are solved; and the technical effects that the proper air-fuel ratio can still be kept under the working condition that thermal load changes, then the combustion condition is optimized, the optimal combustion control is achieved, the product quality is ensured, the heating quality is improved, the fuel gas consumption is reduced, and the economic benefits are obvious are achieved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

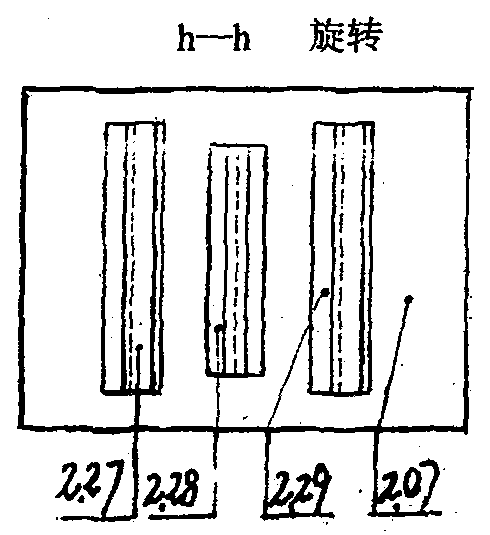

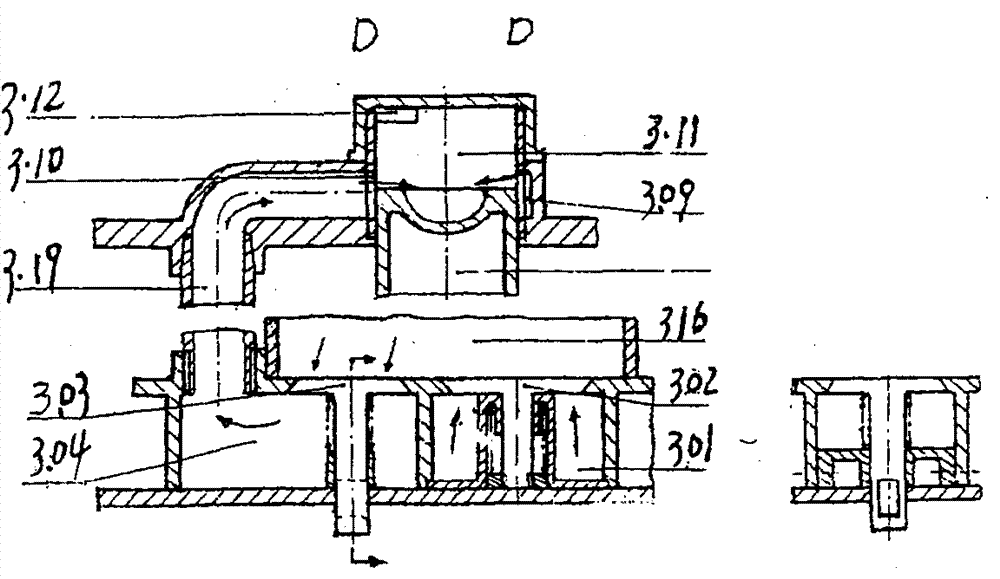

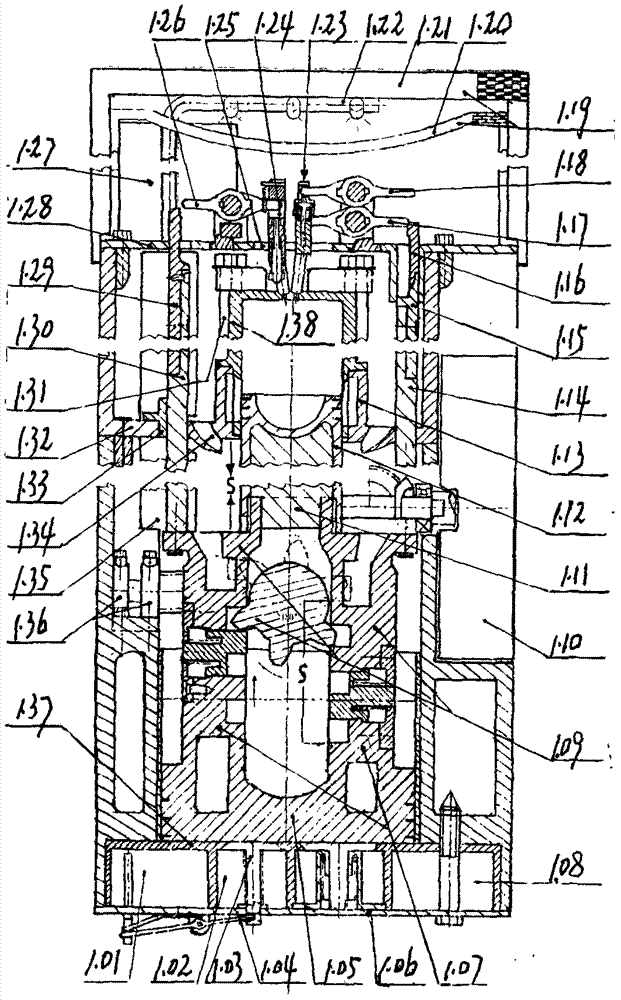

Piston reciprocating-type single-cylinder high-speed internal combustion engine

InactiveCN104775904AIncrease speedIncreased maximum allowable valueMachines/enginesExternal combustion engineEngineering

The invention discloses a piston reciprocating-type single-cylinder high-speed internal combustion engine which adopting a gear and rack mechanism of a third embodiment of the invention patent ZL200710147446.7 (the Publication No: CN101144524B) in China as an actuating mechanism. The piston reciprocating-type single-cylinder high-speed internal combustion engine consists of a power mechanism and inventions made in invention patents ZL200710193938.X (the Publication No:CN101289956B), ZL200710193940.7 (the Publication No: 101205861B), ZL200810169739.X (the Publication No: 101434419B) and ZL201112083190.9 (the Publication No: CN102562339B), and the patent applications 200710193939.4, 20131043603.X, 201410020453.0 and 201410208643.5. The piston reciprocating-type single-cylinder high-speed internal combustion engine is capable of completely eliminating the defects and the shortcomings of an existing conventional internal combustion engine, has the thermal efficiency reaching about 70% and the specific weight relatively reduced by about 30 times, and has an active effect of basically eliminating various inefficiently combusted pollutants to the atmosphere.

Owner:肖光宇

Multi-nozzle type gas burner

ActiveCN104421942AReduce manufacturing costImprove operational reliabilityGaseous fuel burnerEngineeringGas burner

The invention discloses a multi-nozzle type gas burner. The multi-nozzle type gas burner comprises an air box body, a gas box body, at least one main nozzle and at least two auxiliary nozzles, the main nozzle is communicated with the air box body through a main nozzle air valve and communicated with the gas box body through a main nozzle gas valve; the main nozzle air valve comprises a first half-open state and a second fully-open state; the main nozzle gas valve comprises a first half-open state and a second fully-open state; every auxiliary nozzle is communicated with the air box body through an auxiliary nozzle air valve and communicated with the gas box body through an auxiliary nozzle gas valve; every auxiliary nozzle air valve comprises a first fully-closed state and a second fully-open state; every auxiliary nozzle gas valve comprises a first fully-closed state and a second fully-open state; the number of the auxiliary nozzles is larger than that of the main nozzle; the auxiliary nozzles are arranged on the periphery of the main nozzle; the main nozzle air valve, the auxiliary nozzle air valves, the main nozzle gas valve and the auxiliary nozzle gas valves are synchronously driven by a driving device to be switched between the corresponding first states and the corresponding second states.

Owner:SHEN KAN QINHUANGDAO GENERAL ENG DESIGN & RES INST CORP MCC

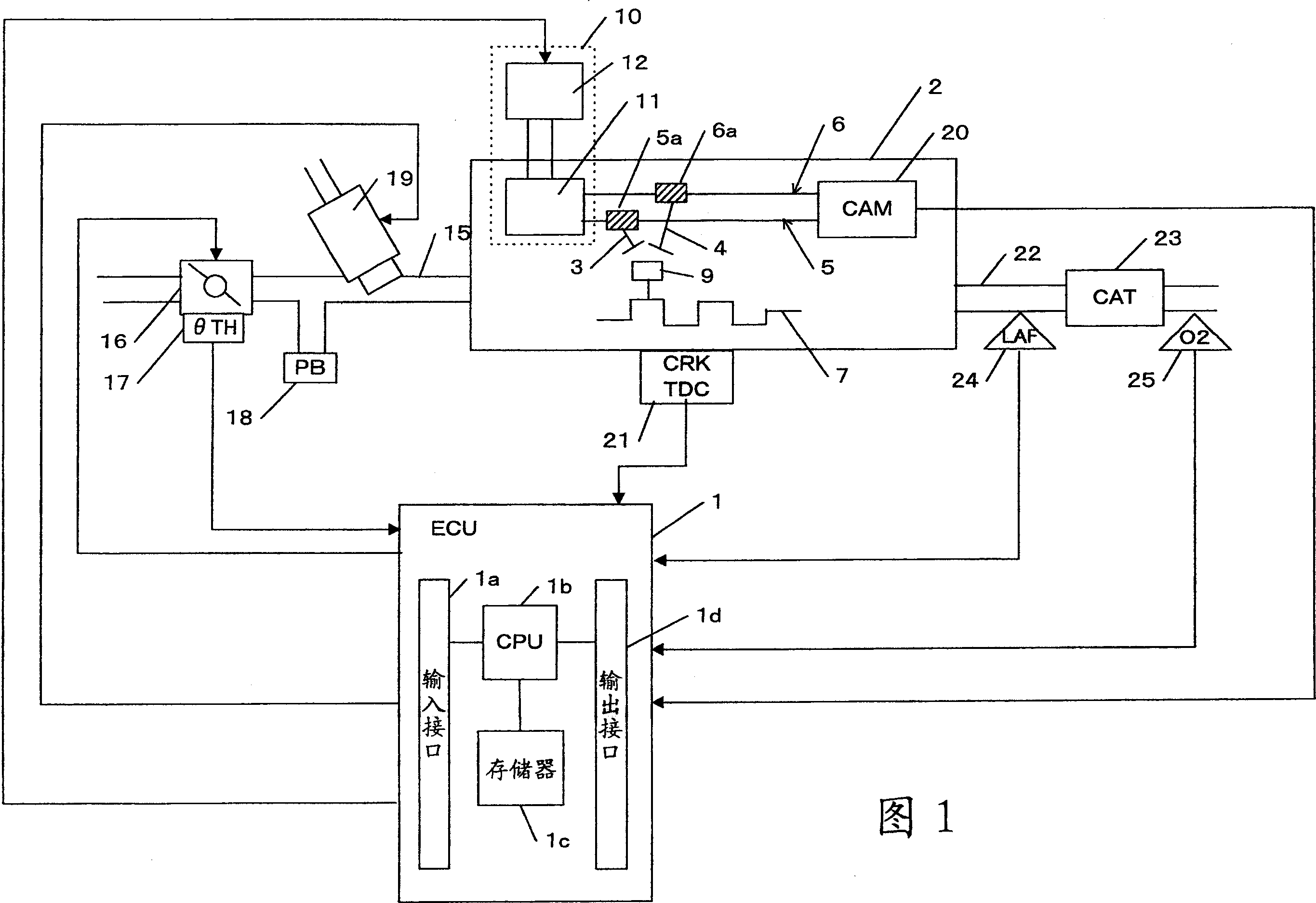

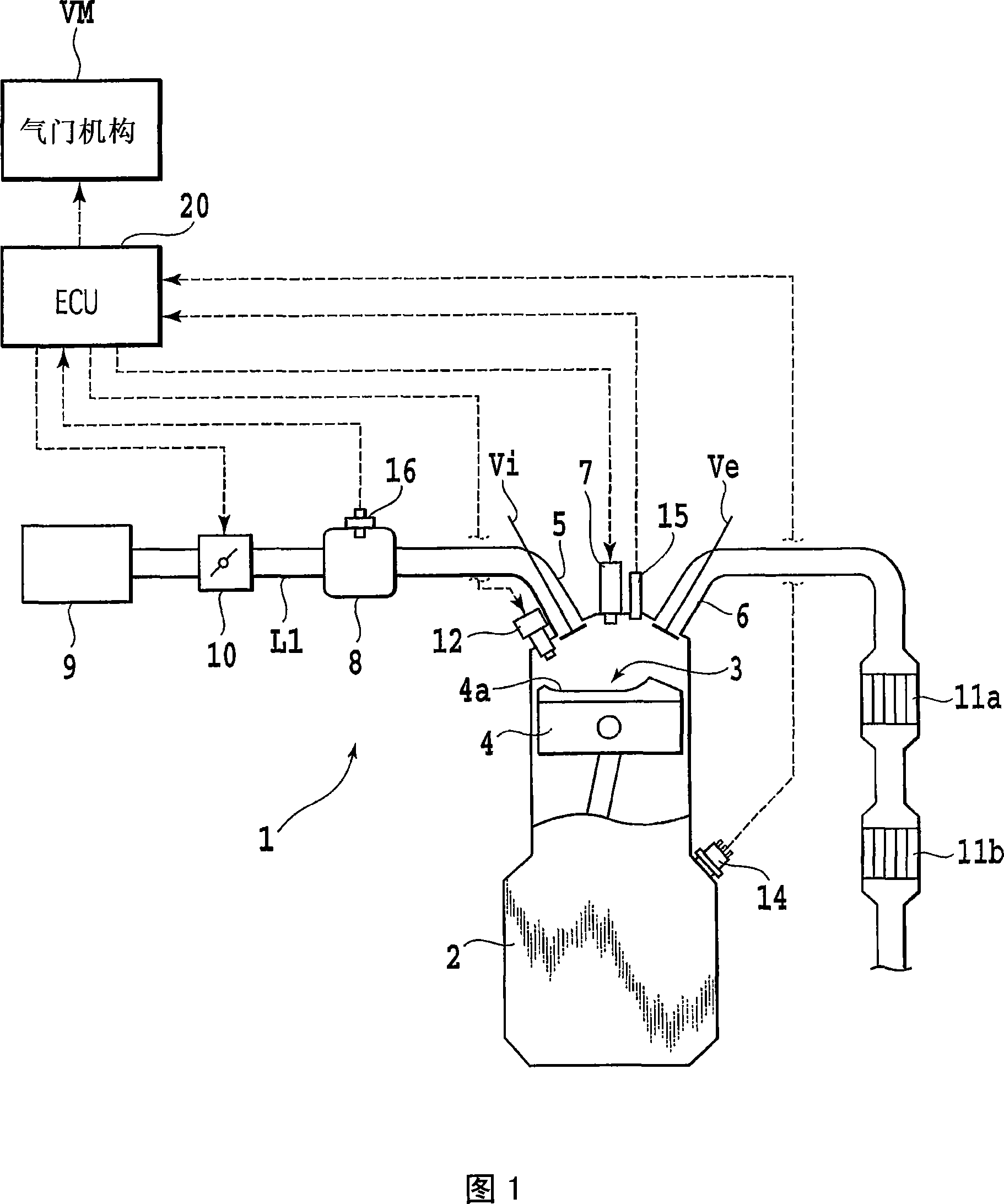

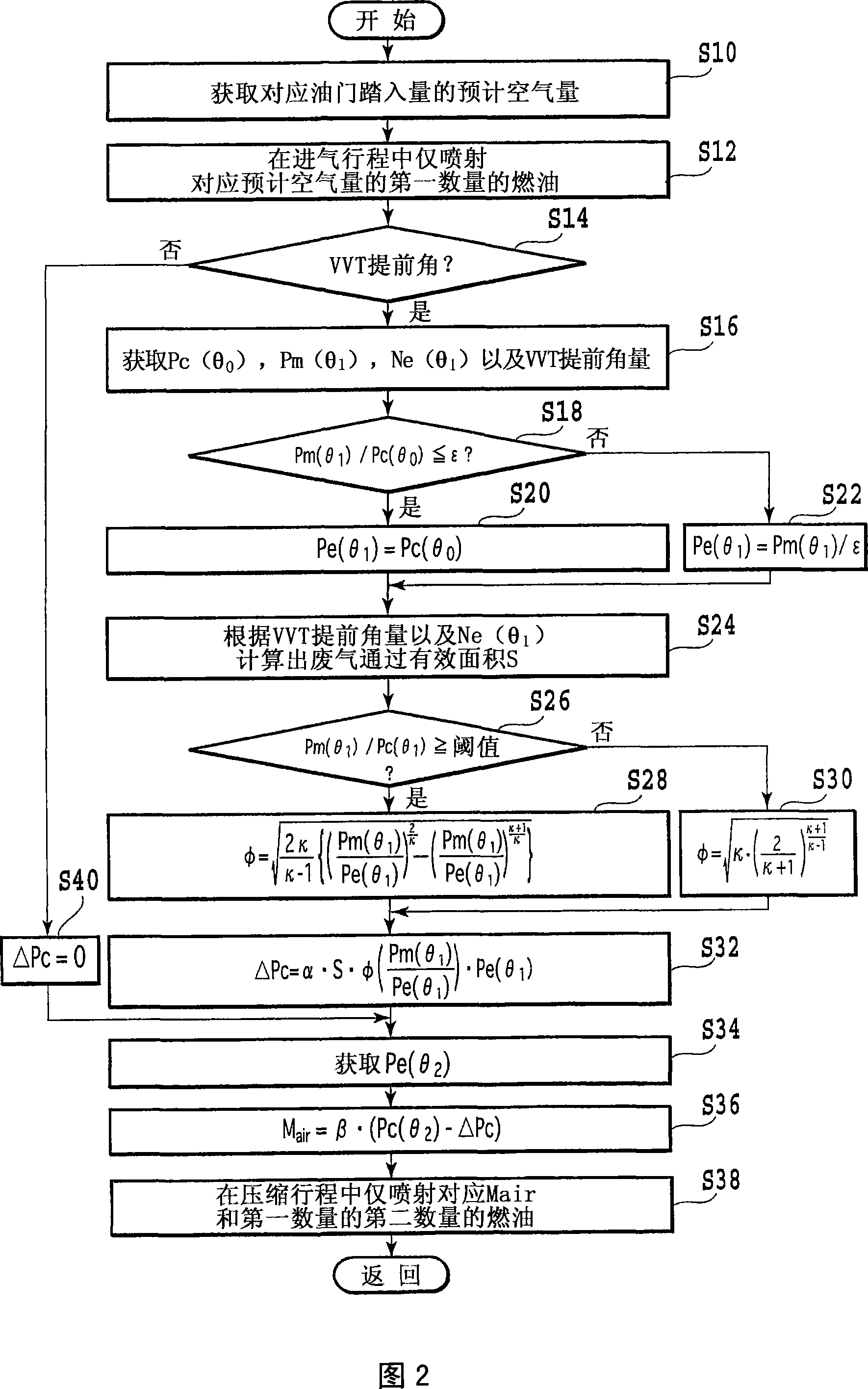

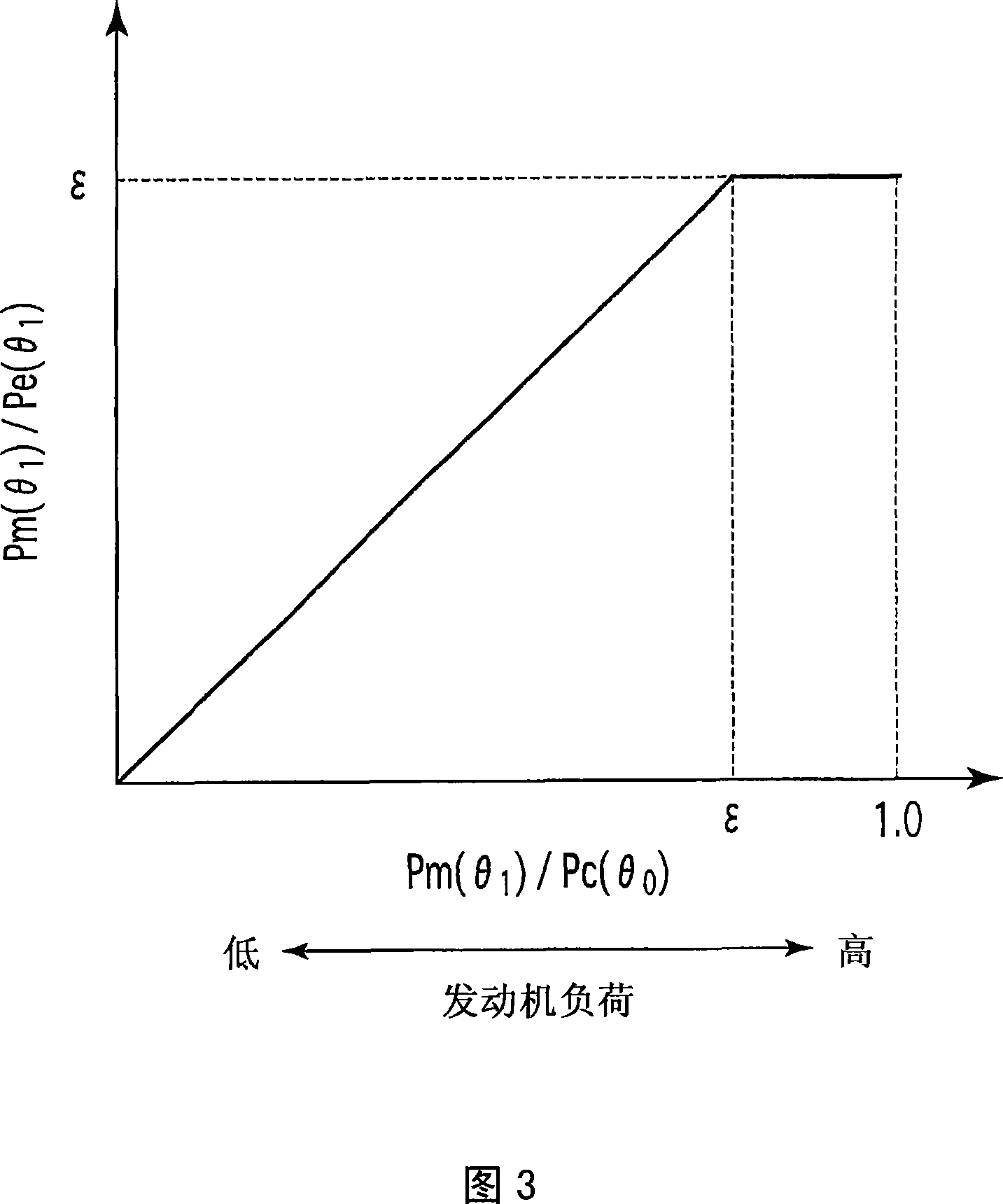

Internal combustion engine control device and methd

InactiveCN101061298AGood air-fuel ratioElectrical controlInternal combustion piston enginesCombustion chamberAir–fuel ratio

The ECU (20) of an internal combustion engine (1) estimates the quantity of air corresponding to the demand on the internal combustion engine (1), controls an injector (12) to inject an initial injection quantity of fuel determined such that the air / fuel ratio of the mixture in a combustion chamber (3) is a target level or less depending on the estimated quantity of air, calculates the quantity of air sucked into the combustion chamber (3) from the cylinder pressure in the combustion chamber (3) at a predetermined timing during the compression stroke before the ignition, and controls the injector (12) to inject a corrected injection quantity of fuel determined according to the calculated quantity of sucked air and the initial injection quantity such that the air / fuel ratio of the mixture in the combustion chamber (3) agrees with a target air / fuel ratio.

Owner:TOYOTA JIDOSHA KK

Excess air coefficient management system for kiln

PendingCN107655029AStable furnace temperatureImprove firing efficiencyFuel supply regulationControl devices for furnacesHearthPressure detection

The invention discloses an excess air coefficient management system for a kiln. The excess air coefficient management system comprises a burner arranged in the kiln, a thermocouple, a temperature control instrument, a fuel gas actuator, a fuel gas proportional valve, an air actuator and an industrial personal computer. The fuel gas actuator and the fuel gas proportional valve are connected to a fuel gas pipeline of the burner in series one after another. The air actuator is connected to an air pipeline of the burner in series. An air pressure detection device of the fuel gas proportional valveis connected with the air pipeline of the burner. The thermocouple, the industrial personal computer, the fuel gas actuator and the air actuator are connected with the temperature control instrument.According to the baking technology of green bricks, burner sets have different optimal air-fuel ratios during the different firing stages. Meanwhile, when the kiln is not in operation, the burner isin a low fire state, combustion-supporting wind can achieve automatic adjustment and the optimal ratio of fuel gas. The whole process is completely controlled by the program edited in advance, precisecontrol over excess air coefficients is achieved, the stability of temperature of the hearth is ensured, the firing efficiency is improved, and energy consumption is reduced.

Owner:MODENA TECH LTD

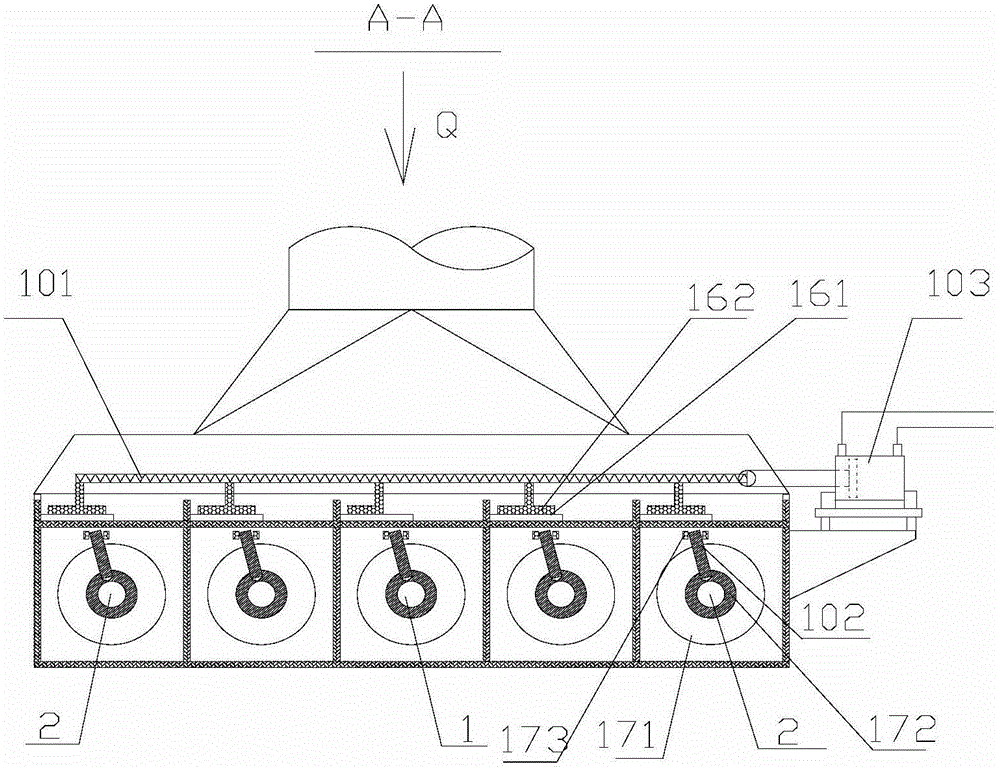

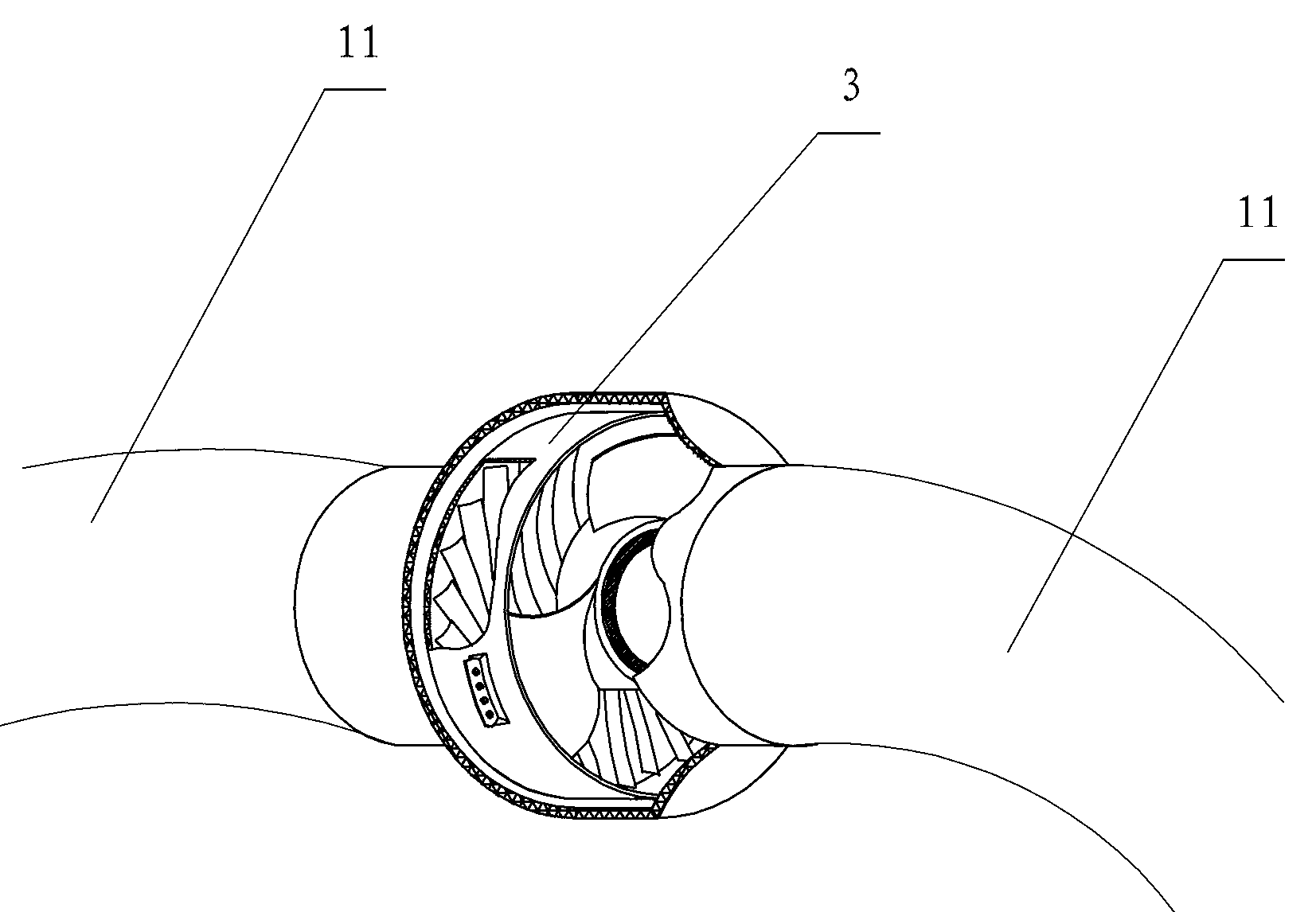

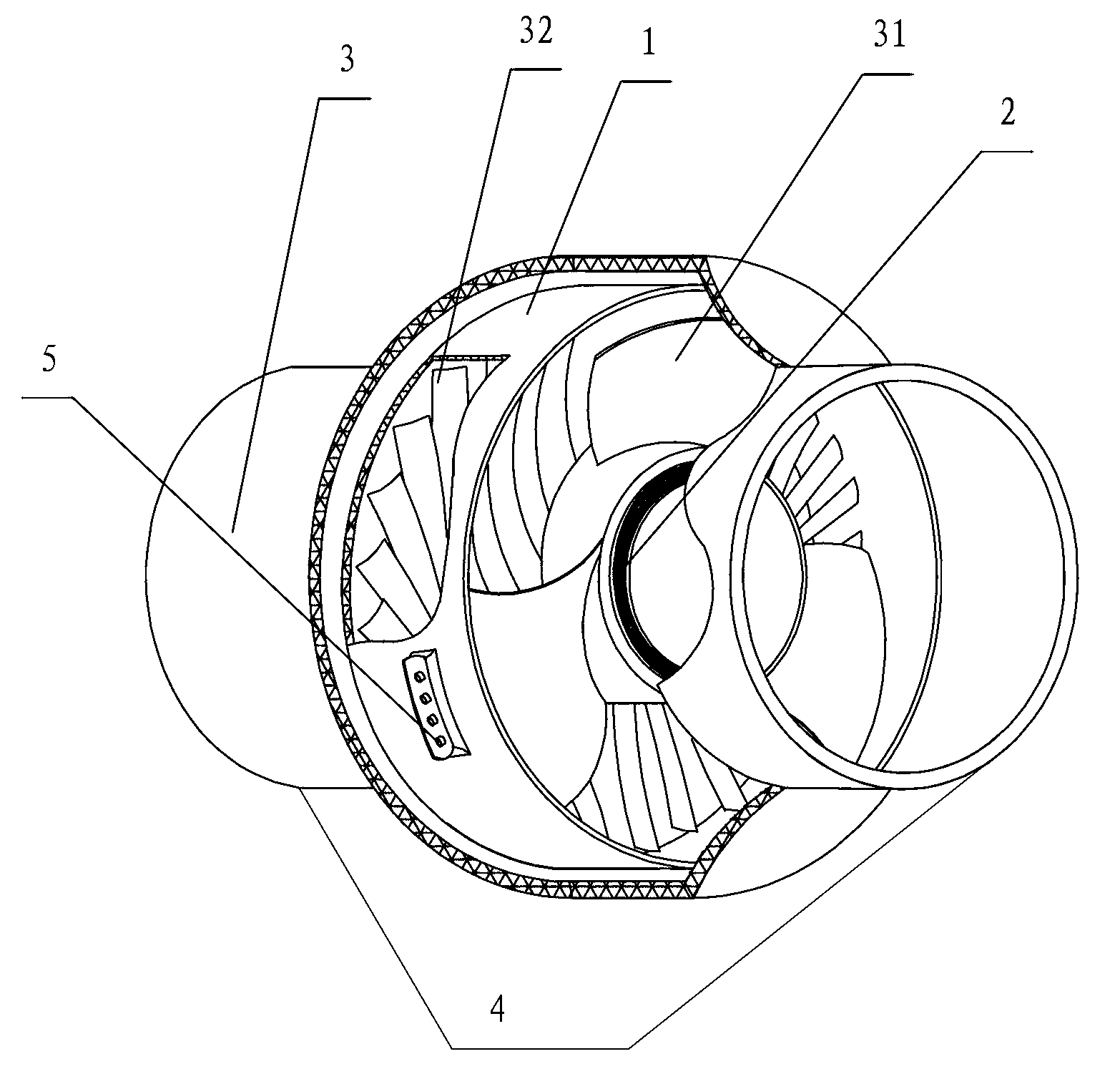

Engine transient air-intake control system and control method

ActiveCN102852625AIncrease intake speedControl air supplyInternal combustion piston enginesEngine controllersControl systemMixing effect

The invention discloses an engine transient air-intake control system. The engine transient intake control system comprises a fan (3) and a control device, wherein the fan (3) is arranged above an air-intake pipeline (11) between an air inlet and an air-intake manifold and is used for adjusting the air flow strength of intake air and converting the air flow into vortex; and the control device is used for acquiring the state information of a vehicle and controlling the running speed of the fan (3) based on the state information of the vehicle. The invention also discloses a method for controlling such engine transient air-intake control system. The method comprises the steps of acquiring and processing the running state information of the vehicle through the control system, and sending out a command to control and adjust the rotating speed of the fan based on the current running state of the vehicle. With the adoption of the method provided by the invention, the air intake speed of an engine is increased, the vortex strength in a cylinder is improved, and the effect of mixing the oil and gas is improved; on the other hand, the air quality in the air-intake pipeline is regulated, the air supply of the engine under different working conditions is controlled, and the air-fuel ratio of the engine under different working conditions is precisely controlled, therefore, the combustion process is improved; and moreover, the fuel consumption and the exhaust emission are reduced while improving the power of the engine.

Owner:姜添棋

Diesel oil/liquefied petroleum gas co-firing system

InactiveCN104373227AExcellent mixed firing effectOptimum Gas Injection QuantityInternal combustion piston enginesFuel supply apparatusPetroleumFuel tank

The invention provides a diesel oil / liquefied petroleum gas co-firing system. The diesel oil / liquefied petroleum gas co-firing system comprises a diesel oil engine, a diesel oil delivery pipeline and a liquefied petroleum gas delivery pipeline, wherein the diesel oil engine is connected with a gas intake manifold, diesel oil of a diesel oil tank is delivered to the diesel oil engine through the diesel oil delivery pipeline, and the liquefied petroleum gas delivery pipeline is connected with a liquefied petroleum gas storage barrel. The liquefied petroleum gas in the gas storage barrel is delivered to the corresponding positions of the gas intake manifold through two air compression type flow control valves, and the optimum gas injection is obtained, so that the diesel oil / liquefied petroleum gas can be co-fired excellently, and energy conservation and carbon emission reduction are realized.

Owner:游素月

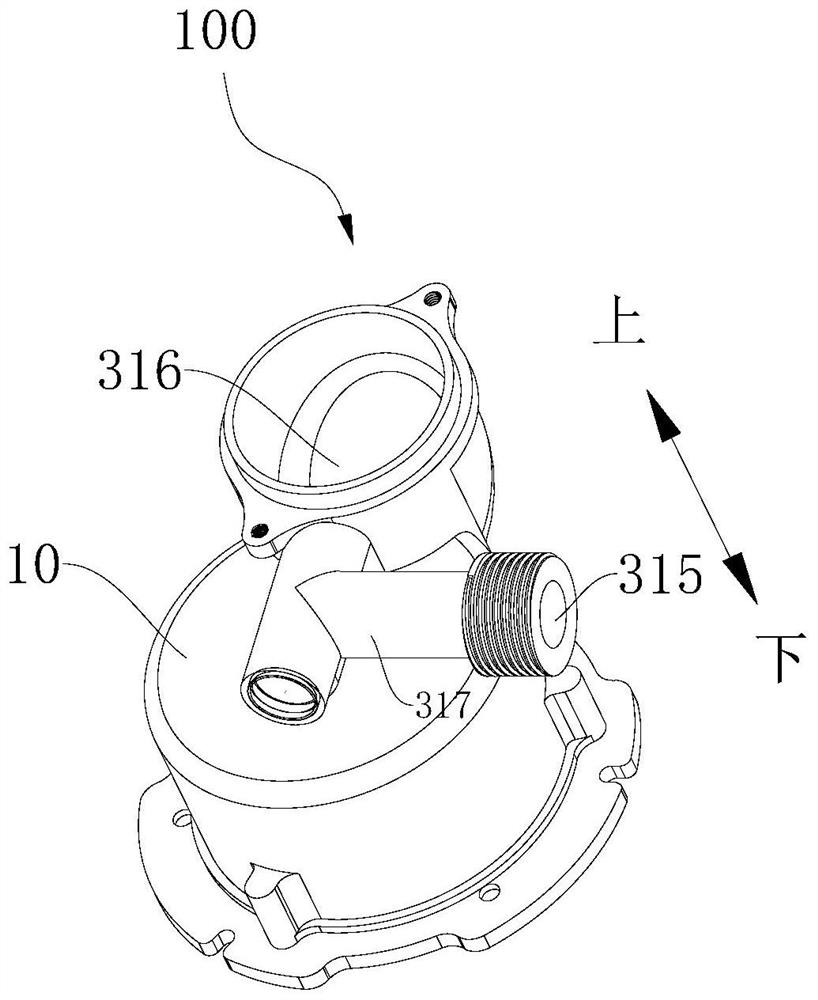

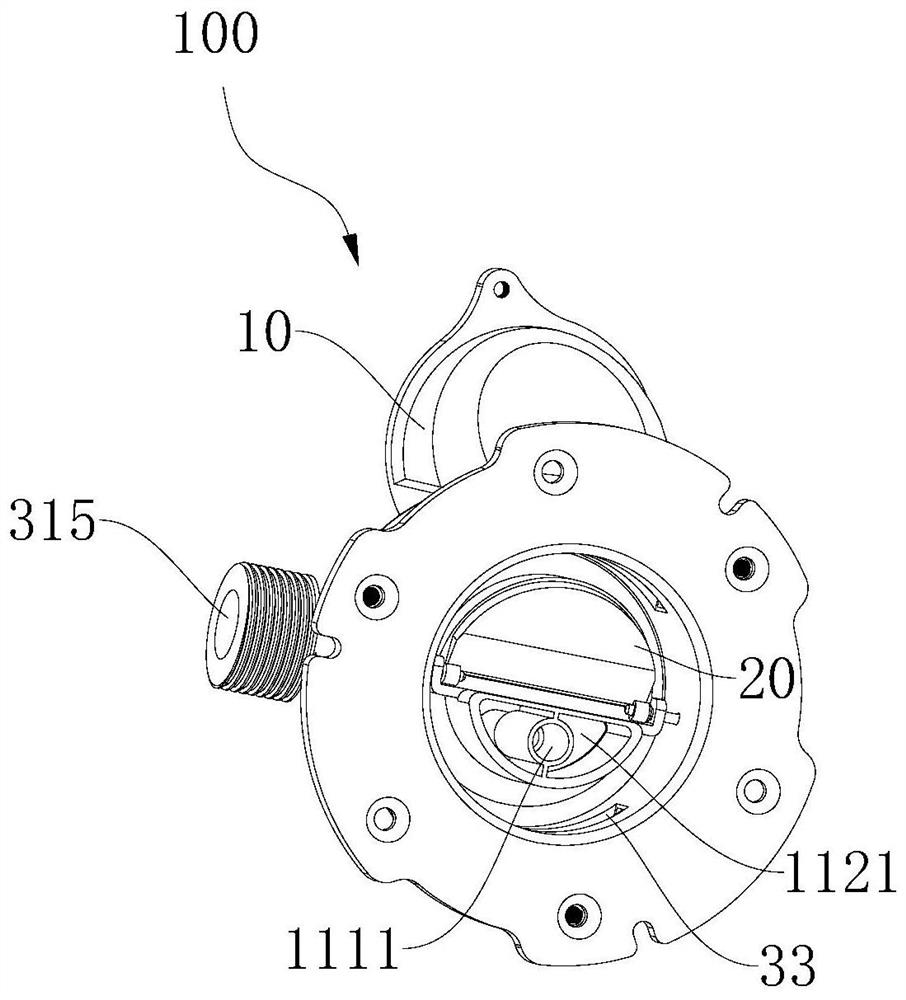

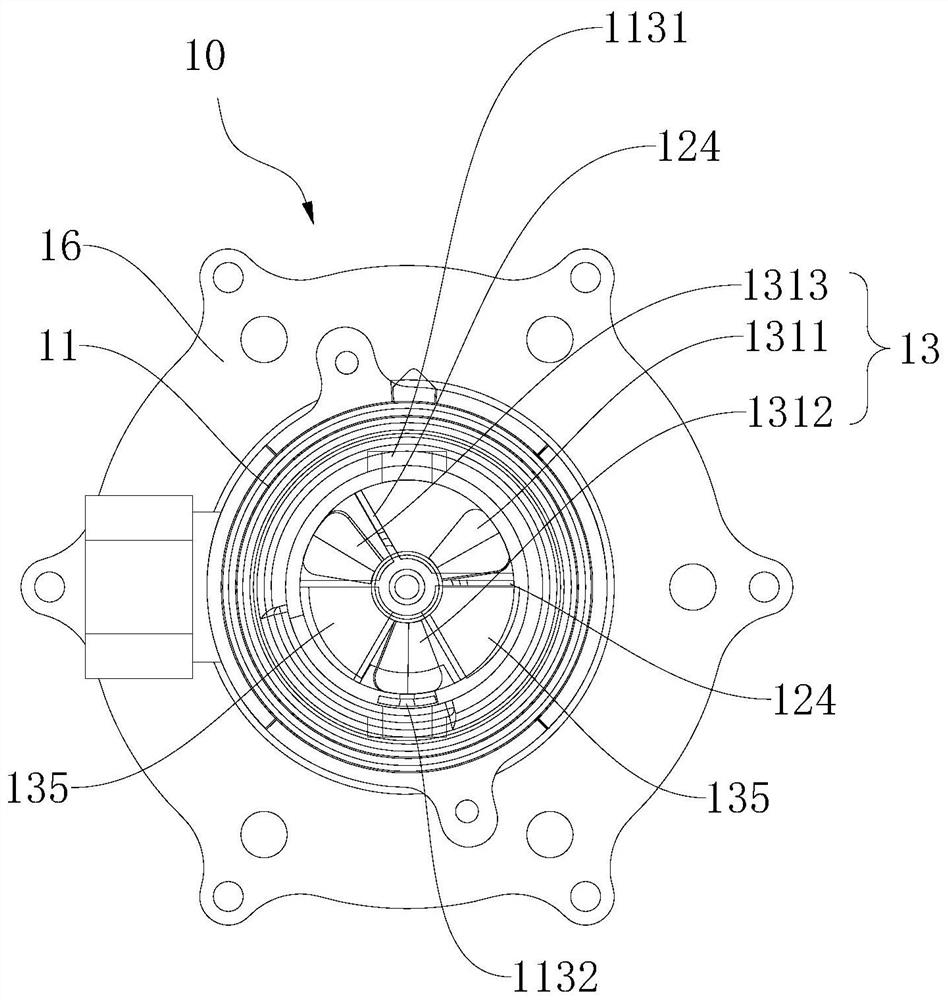

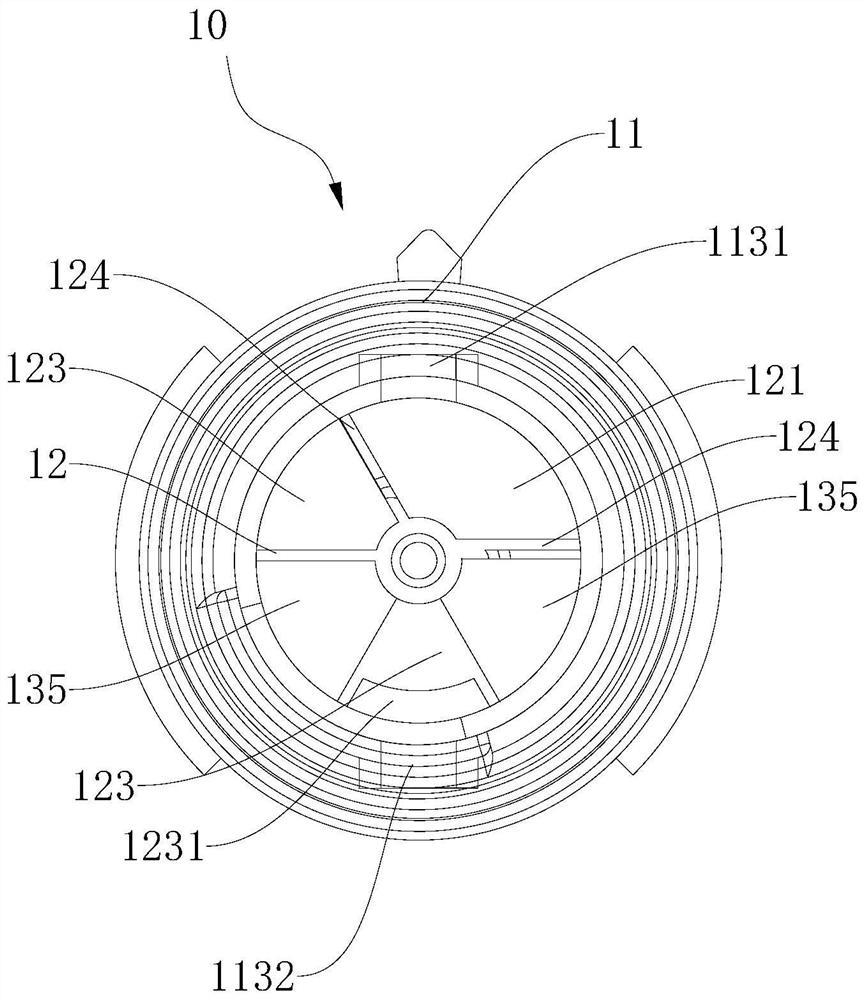

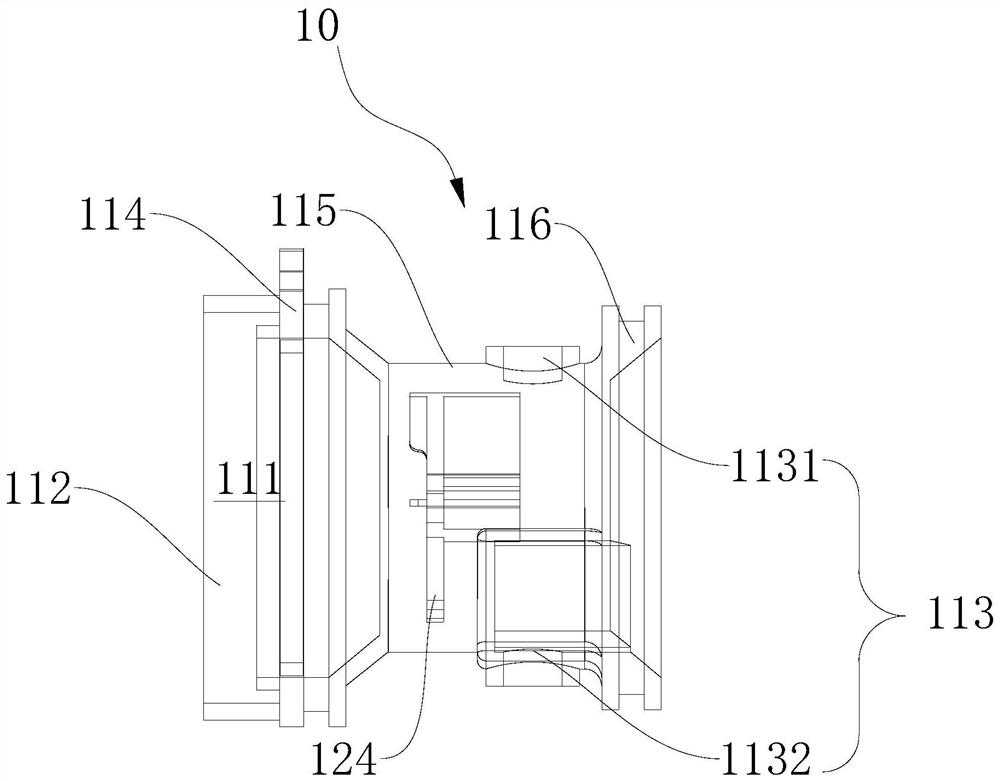

Fuel gas mixer and fuel gas equipment

PendingCN112128750AMeet different load requirementsGood air-fuel ratioGaseous fuel burnerThermodynamicsMechanics

The invention discloses a fuel gas mixer and fuel gas equipment. The fuel gas mixer comprises a shell and a valve; the shell defines a gas flow channel, the gas flow channel is divided into an independent fuel gas flow channel and an independent air flow channel, and the fuel gas flow channel is in communication with the outlet of the air flow channel; and the valve is arranged in the gas flow channel and used for selectively cutting off a part of the fuel gas flow channel and / or the air flow channel. According to the fuel gas mixer, one part of the fuel gas flow channel and / or the air flow channel are / is selectively cut off through the valve in the gas flow channel, so that the amount of air and the amount of fuel gas entering the gas flow channel are controlled, a better air-fuel ratio is obtained, and different load requirements of the fuel gas equipment are met.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD

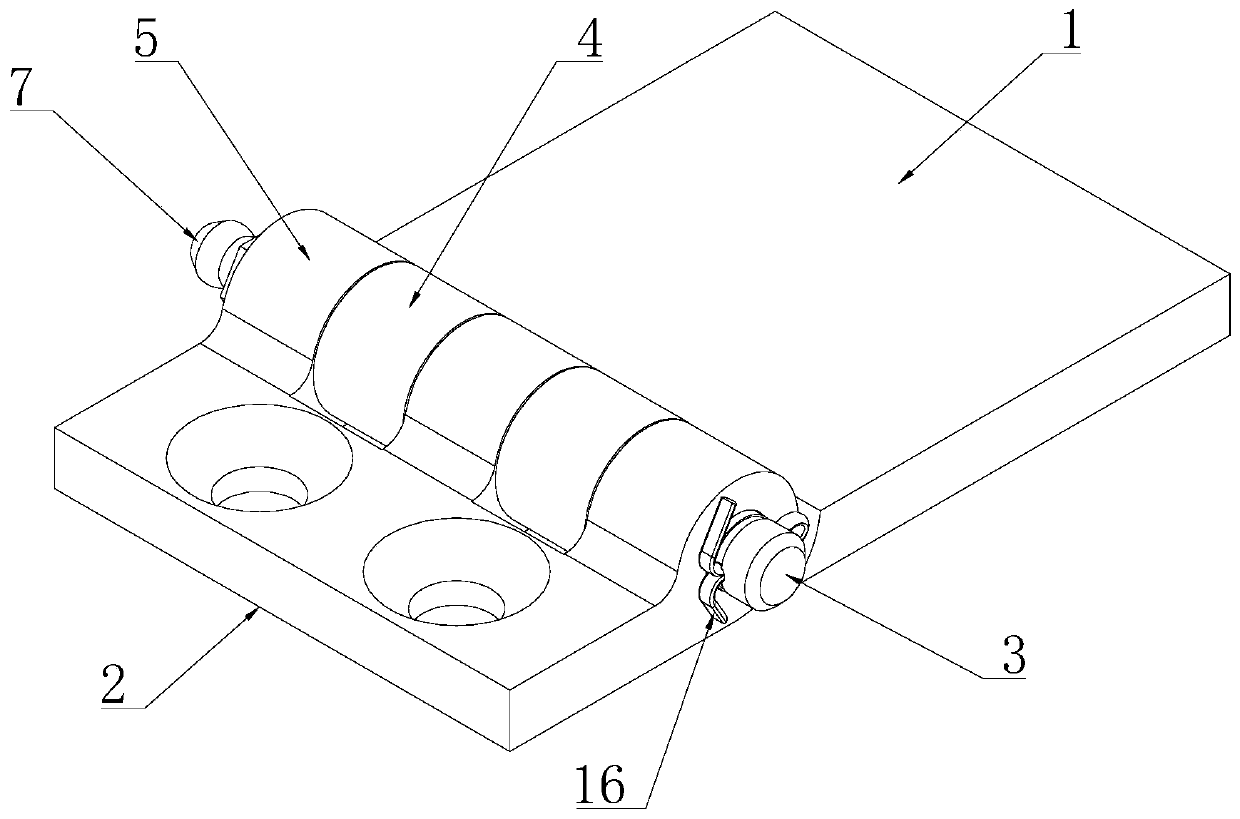

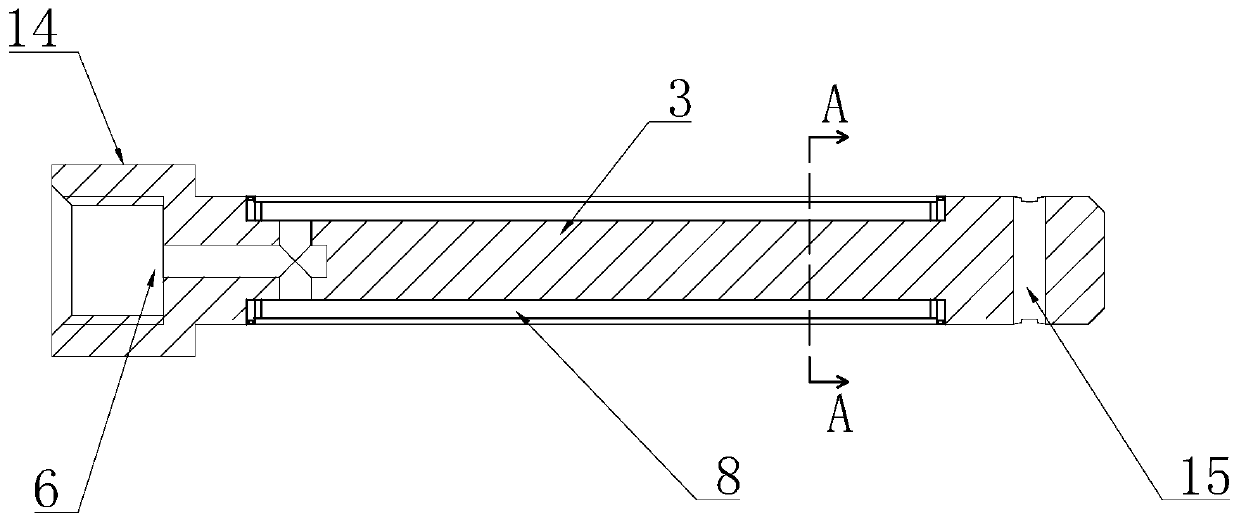

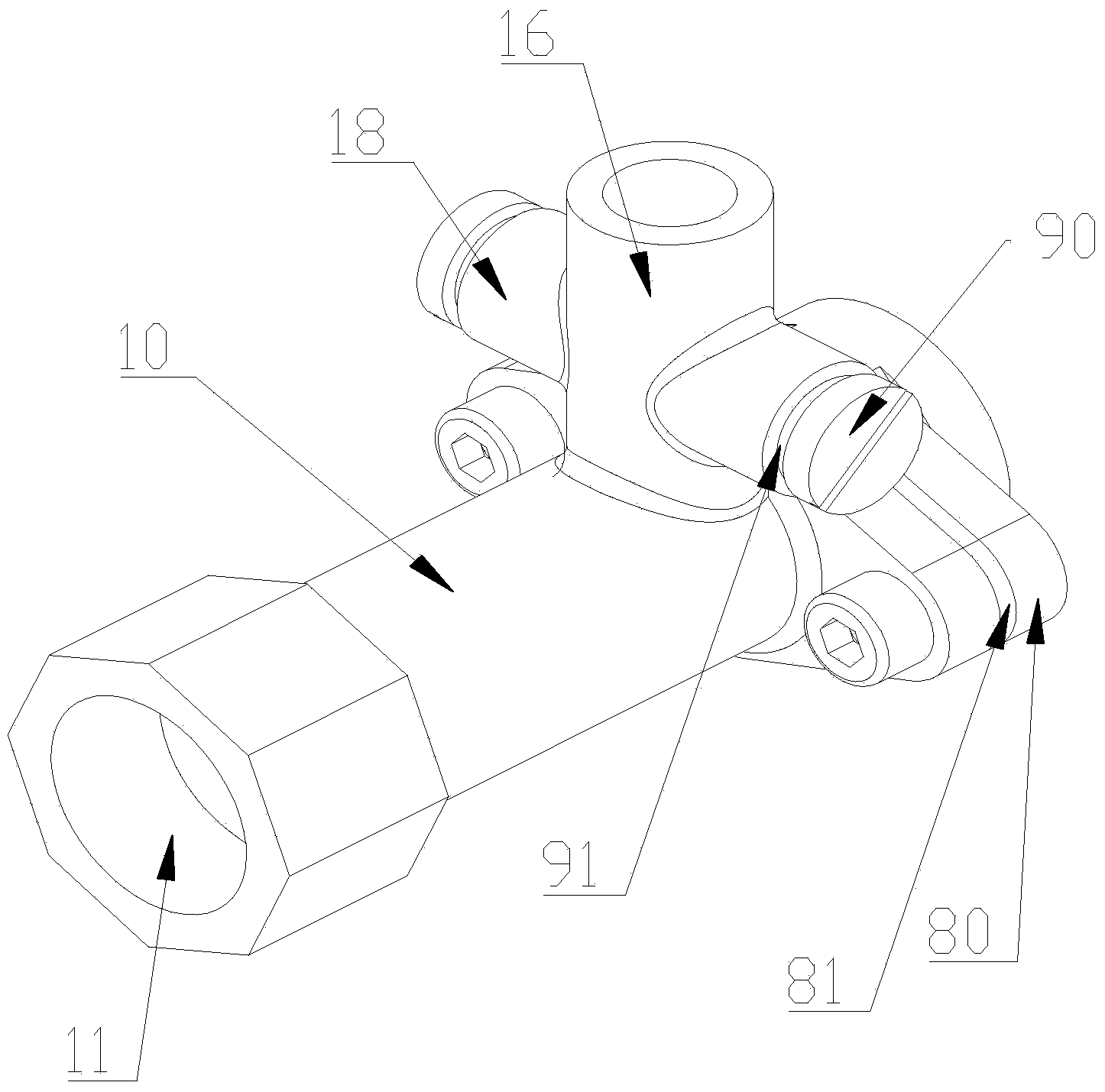

Engineering vehicle door hinge and manufacturing process thereof

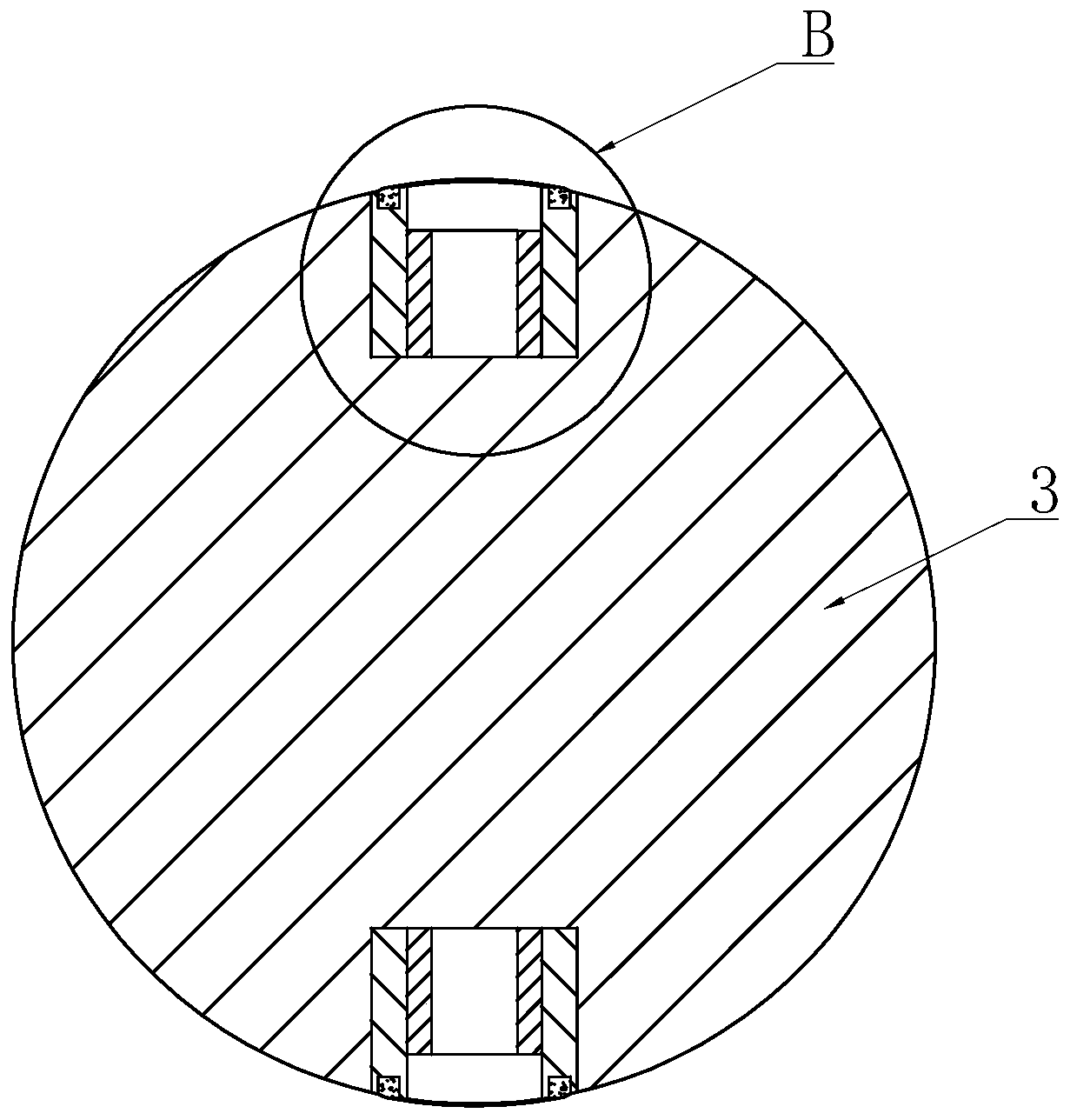

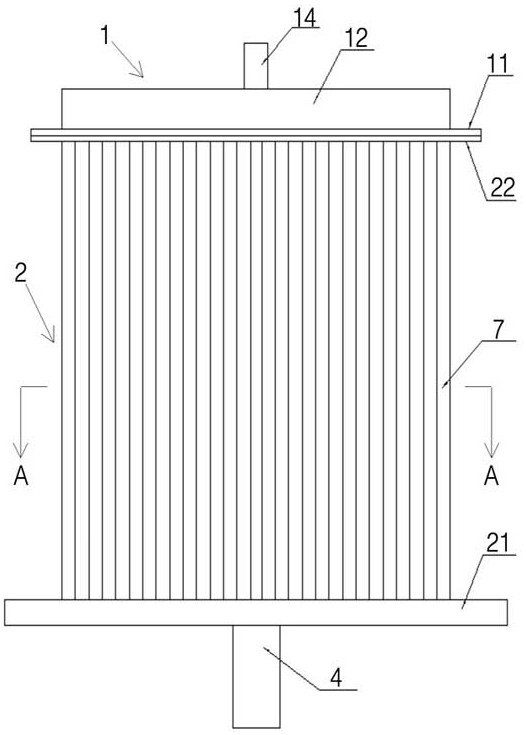

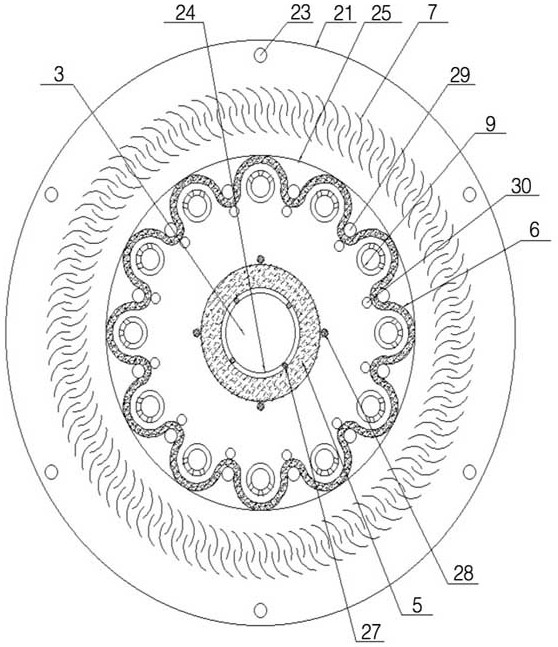

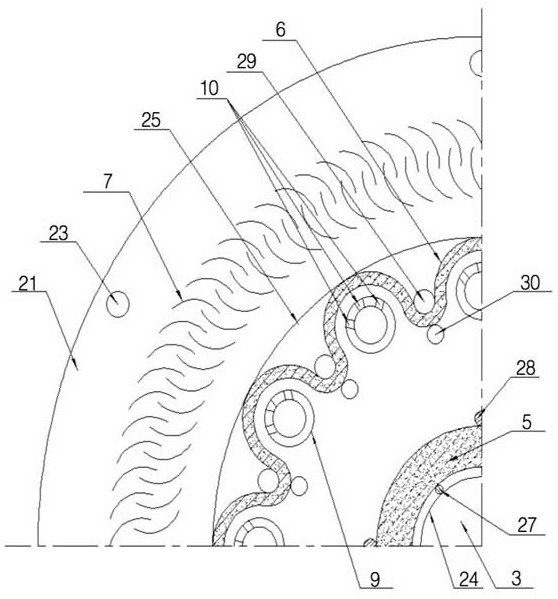

ActiveCN111456575AImprove the lubrication effectImprove wear resistanceWing accessoriesPin hingesManufacturing technologyCar door

The invention discloses an engineering vehicle door hinge and a manufacturing process thereof. The hinge has the advantages of being reliable in structural strength and good in abrasion resistance. According to the main points of the technical scheme, the hinge comprises a first hinge piece, a second hinge piece and a rotating shaft, wherein first movable sleeves are arranged on one side of the first hinge piece, second movable sleeves are arranged on one side of the second hinge piece, the first movable sleeves and the second movable sleeves are all arranged on the rotating shaft and rotationally connected, an oil hole is formed in one end of the rotating shaft, an oil nozzle communicating with the oil hole is formed in the rotating shaft, a plurality of strip-shaped oil grooves are formed in the peripheral wall of the rotating shaft, the oil grooves are annularly distributed at equal intervals, oil guide holes communicating with the oil hole are formed in the bottoms of the oil grooves, sealing sleeves and steel rings are arranged in the oil grooves, the steel rings are arranged on the inner sides of the sealing sleeves, and the sealing sleeves are fixed in the oil grooves through the steel rings. The hinge and the method are suitable for the technical field of hinges.

Owner:台州欧力得汽车部件股份有限公司

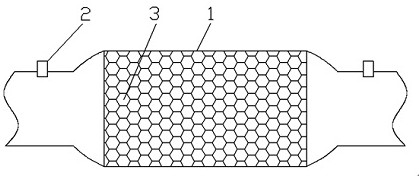

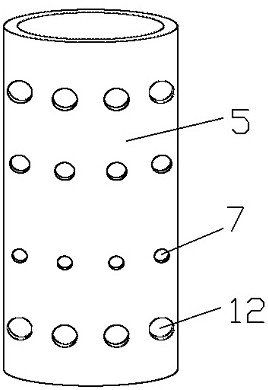

Automobile air filter

ActiveCN113357060ARealize reverse sootblowing treatmentImprove filtering effectMachines/enginesAir cleaners for fuelAir filterStructural engineering

The invention discloses an automobile air filter. The automobile air filter comprises an upper cover body and a lower shell, wherein the lower shell comprises a bottom plate and an annular flange plate; an air outlet hole is formed in the center of the bottom plate; a cylindrical first filter element is arranged at the periphery of the air outlet hole in the top of the bottom plate; a cylindrical second filter element is arranged at the periphery of the first filter element; a plurality of plate sheets are arranged at the periphery of the second filter element in the circumferential direction; the top ends and the bottom ends of the plate sheets are connected with the annular flange plate and the bottom plate respectively; a gap between the two adjacent plate sheets forms an air inlet channel; the upper cover body comprises a cover plate, a cover shell and a circular lug boss; the circular lug boss is arranged at the bottom of the cover plate; a first clamping groove and a second clamping groove, which are correspondingly matched with the top ends of the first filter element and the second filter element, are formed in the circular lug boss; and the cover shell is arranged at the top of the cover plate. According to the automobile air filter, two layers of filtering structures are arranged so that the air filtering effect and efficiency are improved; the two layers of filtering structures have a large filtering area and a low pressure difference, so that an automobile engine keeps the optimal air-fuel ratio and the service life of the filter elements in the air filter is effectively prolonged.

Owner:YANGZHOU POLYTECHNIC INST

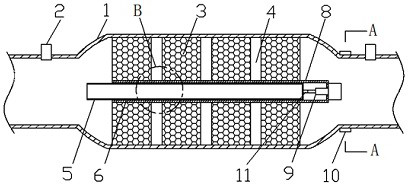

Automobile exhaust treatment device

InactiveCN112145264AReduce energy consumptionLow exhaust pressure requirementExhaust apparatusSilencing apparatusPtru catalystProcess engineering

The invention discloses an automobile exhaust treatment device, and belongs to the technical field of environmental protection equipment. According to the technical scheme, the automobile exhaust treatment device is characterized by comprising a shell internally provided with a heat preservation interlayer and a catalyst carrier arranged in the shell, wherein the catalyst carrier is divided into aplurality of blocks by circulation gaps, and a fixing sleeve communicating with the circulation gaps is assembled at the axis of the catalyst carrier. A control sleeve directly conveys exhaust to themiddle and lower reaches of a catalyst through commnuicating holes, the distance of part of the exhaust penetrating through the catalyst gaps is shortened, and the exhaust resistance is reduced; meanwhile, the amount of harmful pollutants making contact with catalysts at different positions is relatively uniform, and the conversion strength is relatively consistent; when the temperature is too high, an ECU controls a telescopic piece to contract, thus part of the exhaust is directly exhausted through an exhaust opening, the strength of the oxidation reaction in the catalyst is reduced, and the temperature in the catalyst is controlled; and when the blocking pressure in a three-way catalyst is too large, the control sleeve moves, part of the exhaust is directly exhausted, and the pressureof the exhaust end of an engine is reduced.

Owner:深圳市亚环环保科技有限公司

High-altitude-area carburetor device

In order to solve the problem that engine power of a carburetor in the high altitude area is affected, the invention provides a high-altitude-area carburetor device. The high-altitude-area carburetordevice comprises a carburetor body, the carburetor body comprises a float chamber and a float chamber cover, a main jet is arranged in the float chamber, a protrusion is arranged on the inner side ofthe float chamber cover, a channel is arranged in the protrusion, an electromagnetic valve is arranged on the outer side of the float chamber cover, and is connected with a first needle valve, an oilinlet is formed in the side wall of the channel, an opening is formed in the float chamber cover, a fuel oil adjusting device is further included, and comprises a needle valve part, the needle valve part comprises a second needle valve, the second needle valve is matched with the oil inlet, and a valve cover is arranged at the tail end of the second needle valve. Through the electromagnetic valve,the main oil inlet amount of the main jet can be rapidly controlled, the opposite position of the second needle valve and the oil inlet can be adjusted, the oil inlet amount of the main jet can be controlled, the valve cover is arranged at the tail end of the second needle valve, according to the air thinning degree, the positions of the second needle valve and the oil inlet can be precisely adjusted, and the air-fuel ratio of an engine is optimal.

Owner:CHONGQING DAJIANG POWER EQUIP MFG

Alcohol fuel alcohol content detection method and module

ActiveCN102877971BAlcohol content can be easily obtainedEmission reductionElectrical controlInternal combustion piston enginesAlcohol contentAlcohol fuel

Disclosed are an alcohol fuel alcohol content detection method and module for alcohol fuel automobiles. The method comprises the following steps: collecting oxygen content O(n) of automobile tail gas; acquiring an air-fuel ratio alpha c(n) according to O(n) and the preset alcohol content Ap(n); acquiring oil injection quantity Fc(n) according to alpha c(n) and engine air input G; calculating the fuel deviation Fd(n)=[Fc(n)-Fp(n)] / Fp(n), wherein Fp(n) is the preset oil injection quantity; acquiring the alcohol content deviation Ad(n) according to Fd(n); calculating the current alcohol content Ar(n)=Ad(n)+Ap(n); amending Ap(n+1); acquiring the current oil injection quantity Fr(n) according to Ar(n); amending Fr(n+1); injecting fuel according to Fr(n) and repeating the steps; and stopping repeating when the absolute value of Fd(n) is less than the fuel deviation stabilized value S. The alcohol fuel alcohol content detection method disclosed by the invention can detect the alcohol content in the fuel, and improve the using performance of fuel automobiles.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Failure monitoring method of wide-area oxygen sensor for vehicle

ActiveCN109372618BAccurate monitoringGood air-fuel ratioElectrical controlInternal combustion piston enginesWide areaOxygen sensor

The invention discloses a vehicle wide area oxygen sensor lose-efficacy monitoring method. According to the vehicle wide area oxygen sensor lose-efficacy monitoring method, wide area oxygen sensor lose-efficacy monitoring comprises response delay monitoring from thick to thin and response delay monitoring from thin to thick in an air exhaust system, and the monitoring processes both comprise a lose-efficacy initialization stage, a waiting stage, an offset time calculation stage, a response delay time calculation stage, a final response time calculation stage and a lose-efficacy monitoring evaluating stage. By means of the vehicle wide area oxygen sensor lose-efficacy monitoring method, the vehicle wide area oxygen sensor lose-efficacy monitoring can be rapidly and accurately realized.

Owner:DONGFENG MOTOR CORP HUBEI

Adjuster with accurate mixing ratio

ActiveCN104234873AIncrease inhalationIncrease volumeInternal combustion piston enginesFuel supply apparatusSpray nozzleMixing effect

The invention relates to an adjuster with accurate mixing ratio. The adjuster comprises a casing and an air spray nozzle, wherein the casing is provided with a mixing air outlet, a diffusion mixing cavity, a mixing cavity, a negative pressure cavity and an air inlet which are sequentially communicated from left to right, the air spray nozzle is arranged in the air inlet, the top wall of the casing is provided with a gas inlet pipe, and the gas inlet pipe is communicated with the negative pressure cavity. The adjuster has the advantages that the structure is simple, the weight is light, the accurate and proper air and gas ratio is guaranteed, the utilization rate of air and gas is effectively improved, the mixing effect is optimized, the adjusting is convenient, the maintenance by professional workers is not needed, and the production cost and maintenance cost are low.

Owner:GUANGZHOU BAKE OVEN MACHINERY

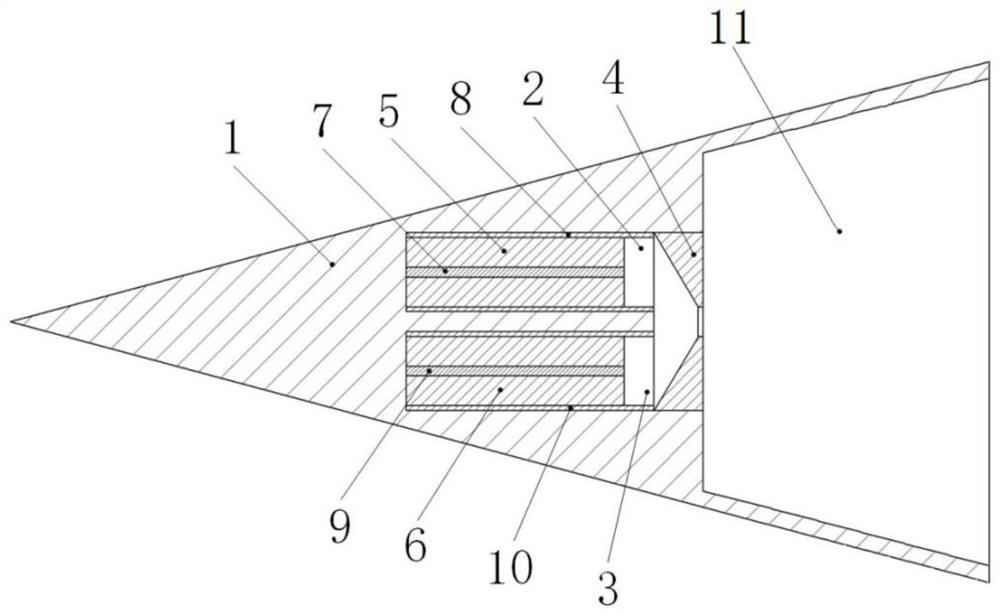

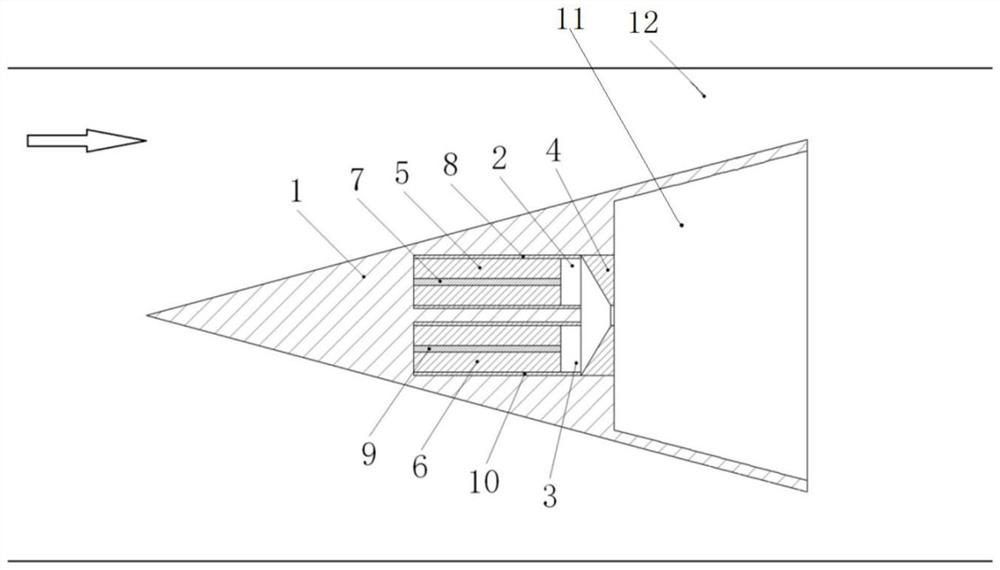

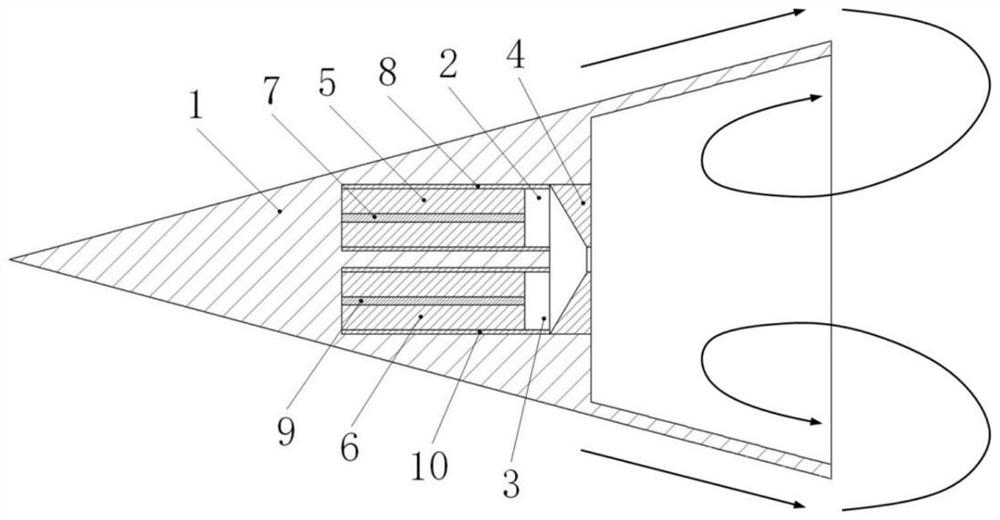

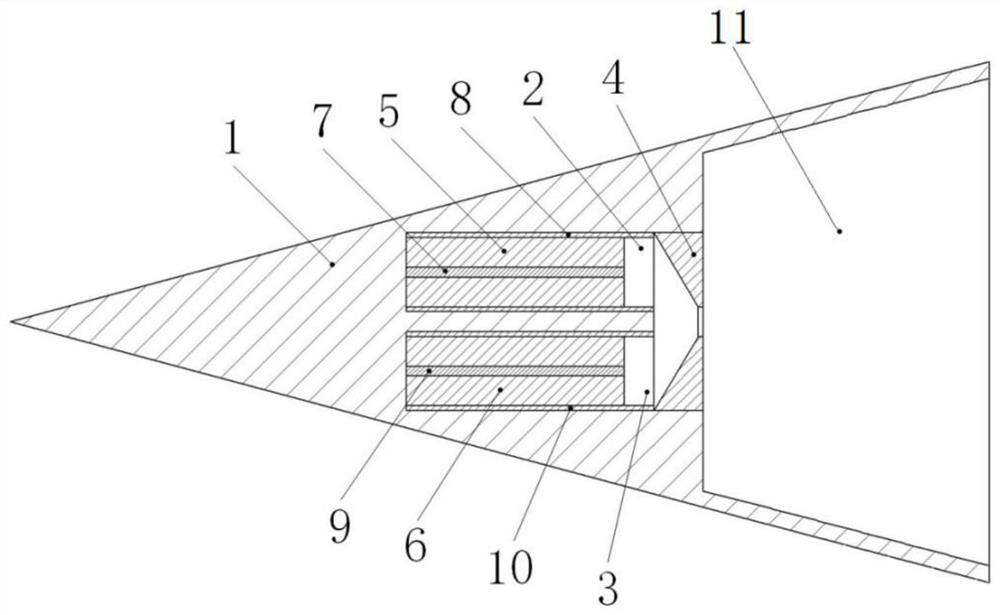

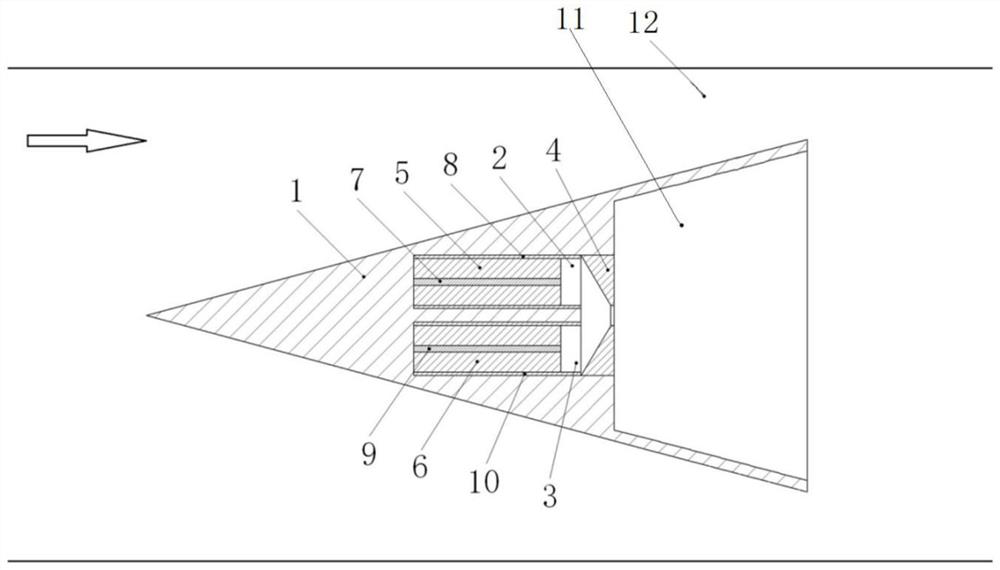

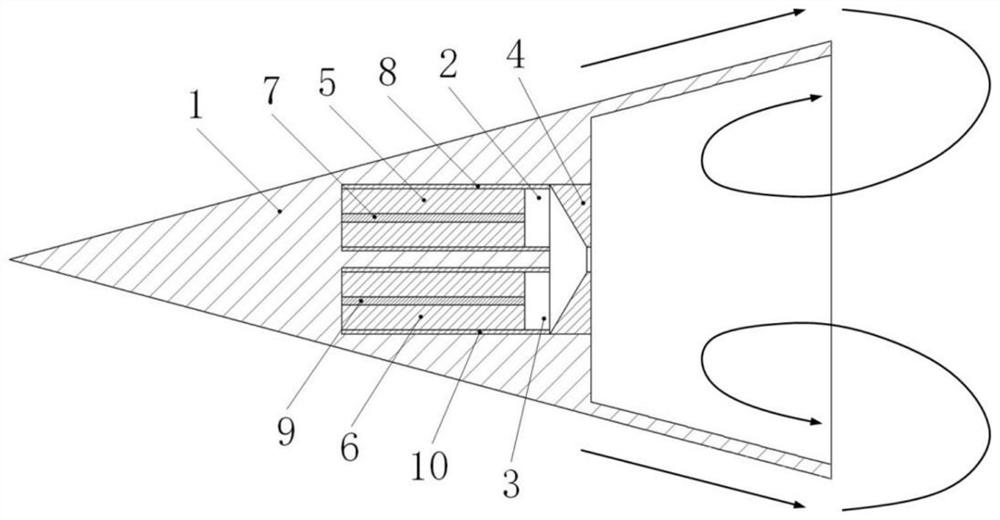

Controllable flame stabilizer, engine and aircraft

ActiveCN113432150AStable combustion boundary wideningIncrease the ambient temperatureContinuous combustion chamberIndirect carbon-dioxide mitigationCombustion chamberFlight vehicle

The invention discloses a controllable flame stabilizer, an engine and an aircraft. The controllable flame stabilizer is installed in an engine combustion chamber and comprises a shell, an electric control fuel gas generator and a spray pipe are arranged in the shell, and the electric control fuel gas generator comprises a fuel-rich electric control solid propellant combustion chamber and an oxygen-rich electric control solid propellant combustion chamber; one end of the fuel-rich electronic control solid propellant combustion chamber and one end of the oxygen-rich electronic control solid propellant combustion chamber are respectively a fuel-rich storage cavity used for containing a fuel-rich electronic control solid propellant and an oxygen-rich electronic control solid propellant storage cavity used for containing an oxygen-rich electronic control solid propellant; and independently-controlled electric ignition mechanisms are respectively arranged in the fuel-rich electric control solid propellant combustion chamber and the oxygen-rich electric control solid propellant combustion chamber. The fuel-rich propellant and the oxygen-rich propellant can be ignited and combusted separately or simultaneously according to the flight working condition and the maneuvering requirement of the engine, so that the air-fuel ratio is kept in a better state, and the stable combustion boundary and the engine performance are improved.

Owner:NAT UNIV OF DEFENSE TECH

Controllable flame holders, engines and aircraft

ActiveCN113432150BStable combustion boundary wideningIncrease the ambient temperatureContinuous combustion chamberIndirect carbon-dioxide mitigationCombustion chamberFlight vehicle

A controllable flame stabilizer, an engine and an aircraft. The controllable flame stabilizer is installed in the combustion chamber of the engine. Controlled solid propellant combustion chamber, oxygen-enriched electronically controlled solid propellant combustion chamber; one end of the fuel-rich electronically controlled solid propellant combustion chamber and oxygen-enriched electronically controlled solid propellant combustion chamber is respectively a and the fuel-rich storage chamber of the oxygen-enriched electronically controlled solid propellant and the oxygen-enriched electronically controlled solid propellant storage chamber; the fuel-enriched electronically controlled solid propellant combustion chamber and the oxygen-enriched electronically controlled solid propellant combustion chamber are respectively equipped with independently controlled electrical ignition mechanism. According to the flight conditions and maneuvering requirements of the engine, the fuel-enriched propellant and the oxygen-enriched propellant can be ignited and burned separately or simultaneously to maintain the air-fuel ratio in a better state, thereby improving the stable combustion boundary and engine performance.

Owner:NAT UNIV OF DEFENSE TECH

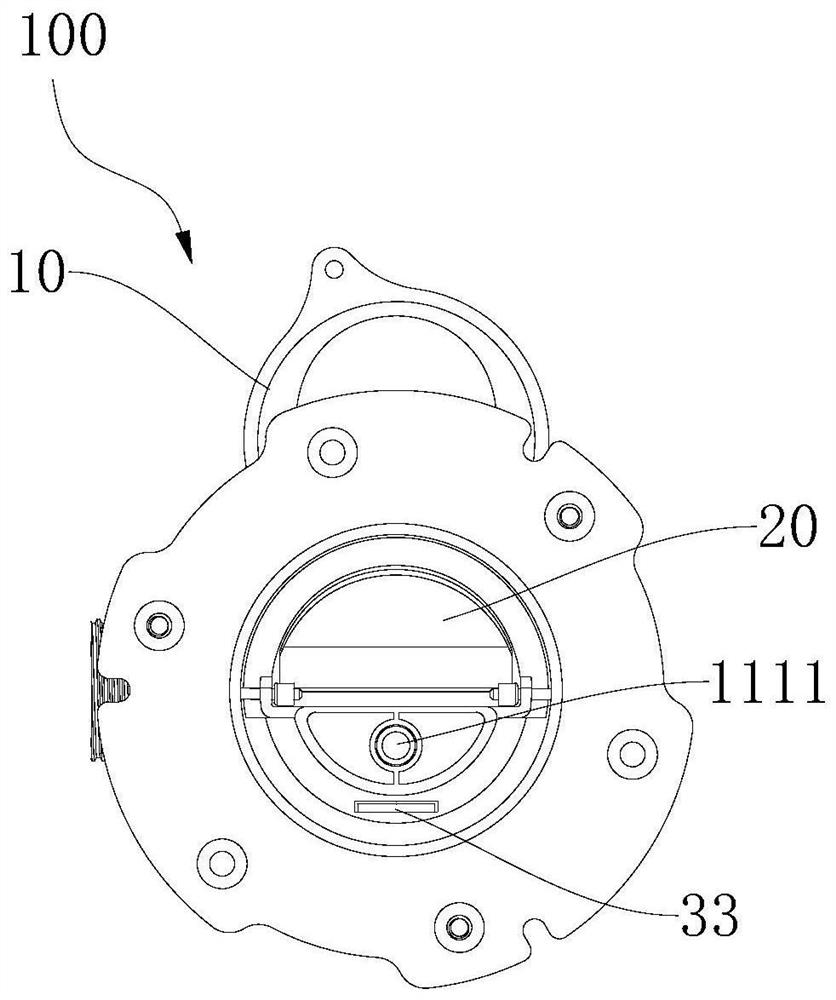

Premixing device and gas equipment

PendingCN112128757AGood air-fuel ratioWide adjustment range of air-fuel ratioGaseous fuel burnerPhysicsImpeller

The invention discloses a premixing device and gas equipment. The premixing device comprises a body which defines a gas flow channel with an air inlet and a gas nozzle; an air volume adjusting plate arranged in the air flow channel, and a plurality of normally-closed air openings and normally-open air openings which are opposite to the air inlet are formed in the air volume adjusting plate; an impeller assembly including a rotating shaft penetrating through the air volume adjusting plate and a plurality of impellers arranged on the rotating shaft, and at least one impeller is always at least partially overlapped with the projection of the normally-open air openings in the direction perpendicular to a paper surface, so that the impeller assembly is driven to rotate by virtue of air pressure; and a valve plate. According to the premixing device disclosed by the embodiment of the invention, the air volume adjusting plate with the normally-closed air openings and the normally-open air openings is arranged in the air flow channel, and the impeller assembly is driven by the air pressure to rotate so as to drive the valve plate to rotate synchronously, so that the opening degree of the normally-closed air openings is changed through the valve plate, the air inflow participating in mixing is adjusted, and a better air-fuel ratio is obtained.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com