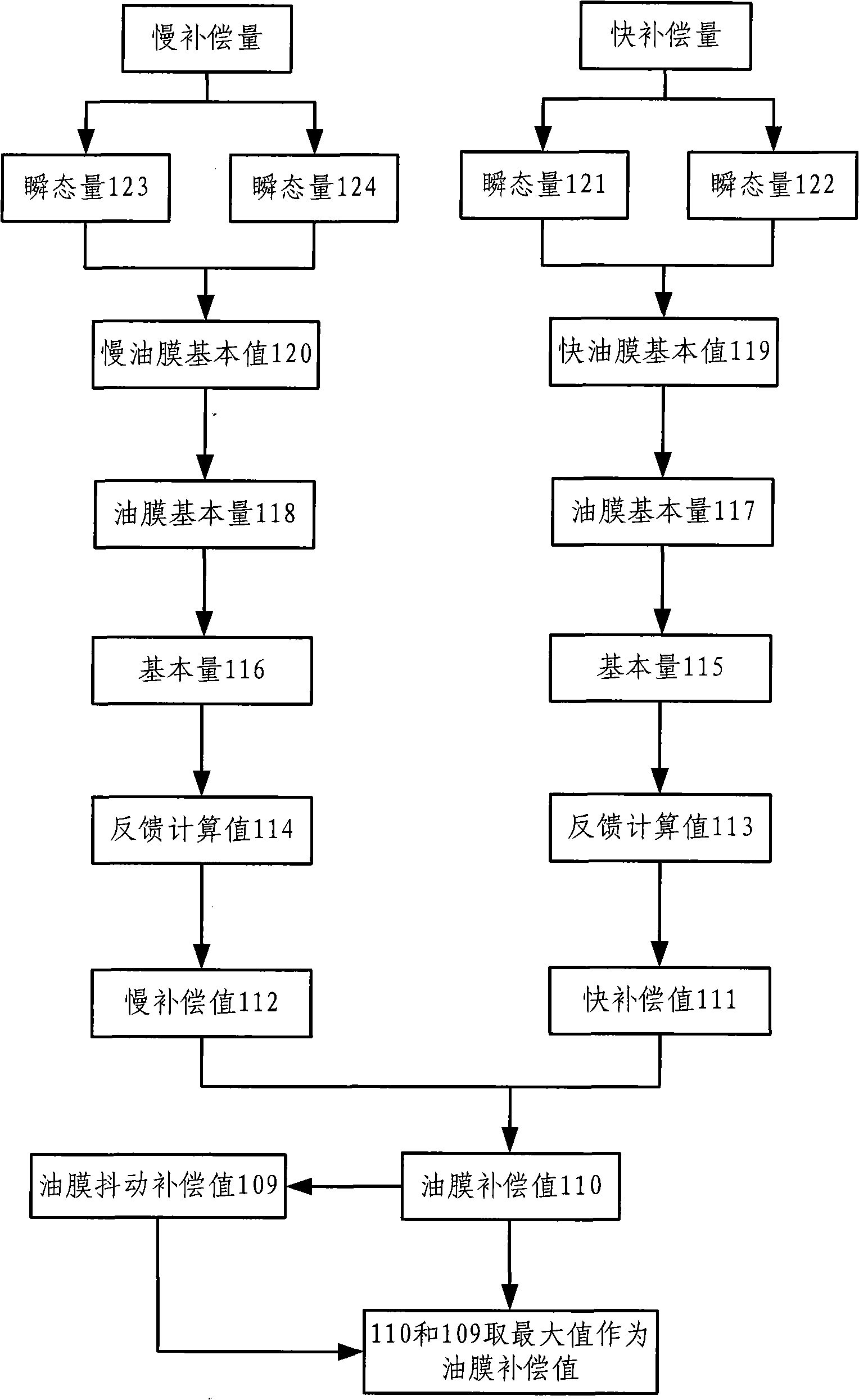

Oil film compensation process when fuel oil injection

A technology of fuel injection and compensation method, which is applied in the direction of fuel injection control, engine control, machine/engine, etc., and can solve problems such as high fuel consumption and unstable acceleration and deceleration performance of automobiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

[0018] First introduce the calibration and calibration data table. Calibration, the English expression is Calibration, which means calibration. An engine cannot be matched to only one vehicle type, and different vehicle types have different performance requirements: sports cars require high-speed and high-power, SUV models require low-speed and high-torque, ordinary cars require balanced performance, etc., one engine achieves Different performance is achieved through calibration. The main contents of calibration include: fuel injection quantity, ignition timing, electronic throttle opening, idle speed control valve duty cycle, exhaust gas circulation, turbocharger bleed valve opening timing and ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com