Patents

Literature

47results about How to "Easy unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

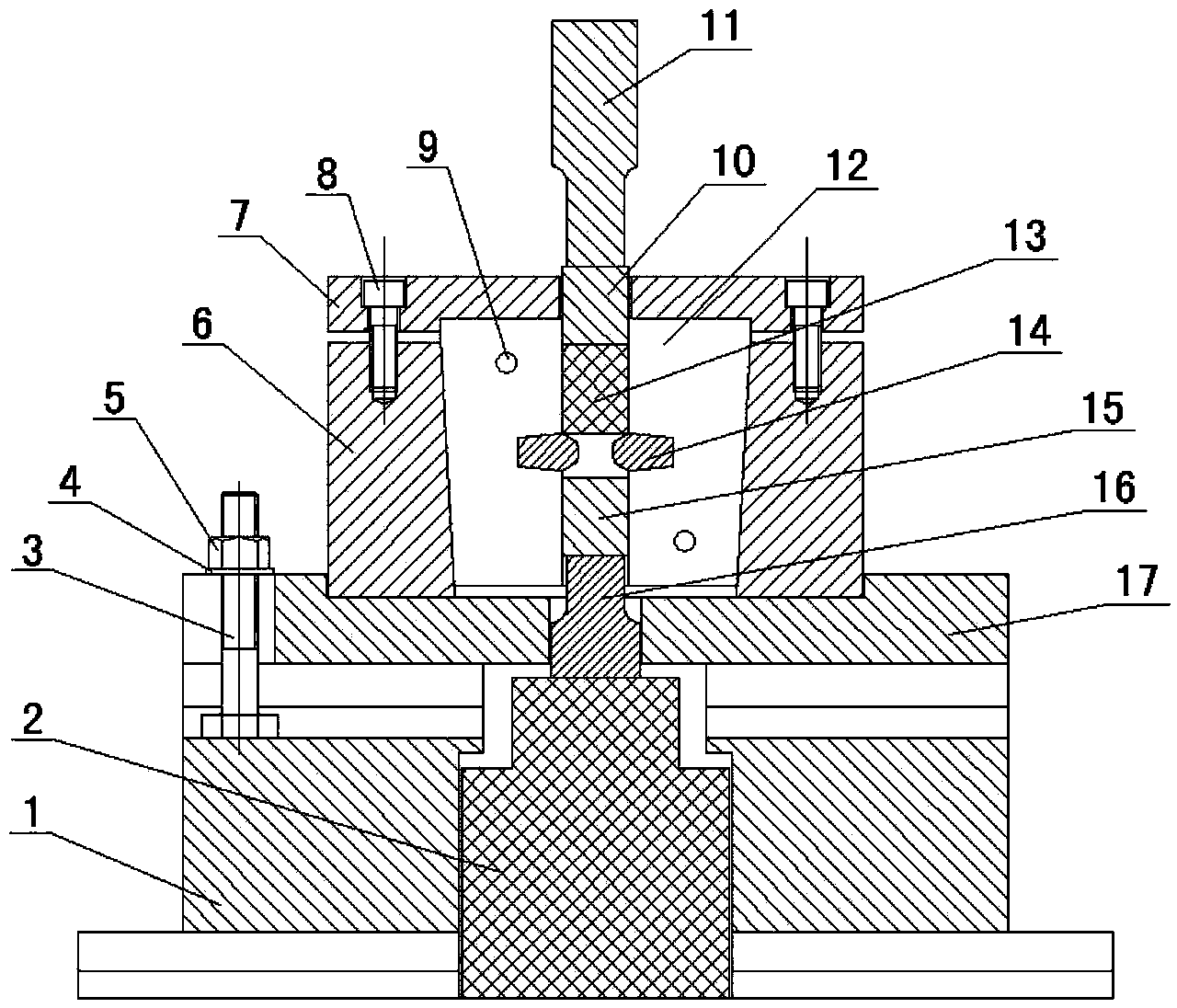

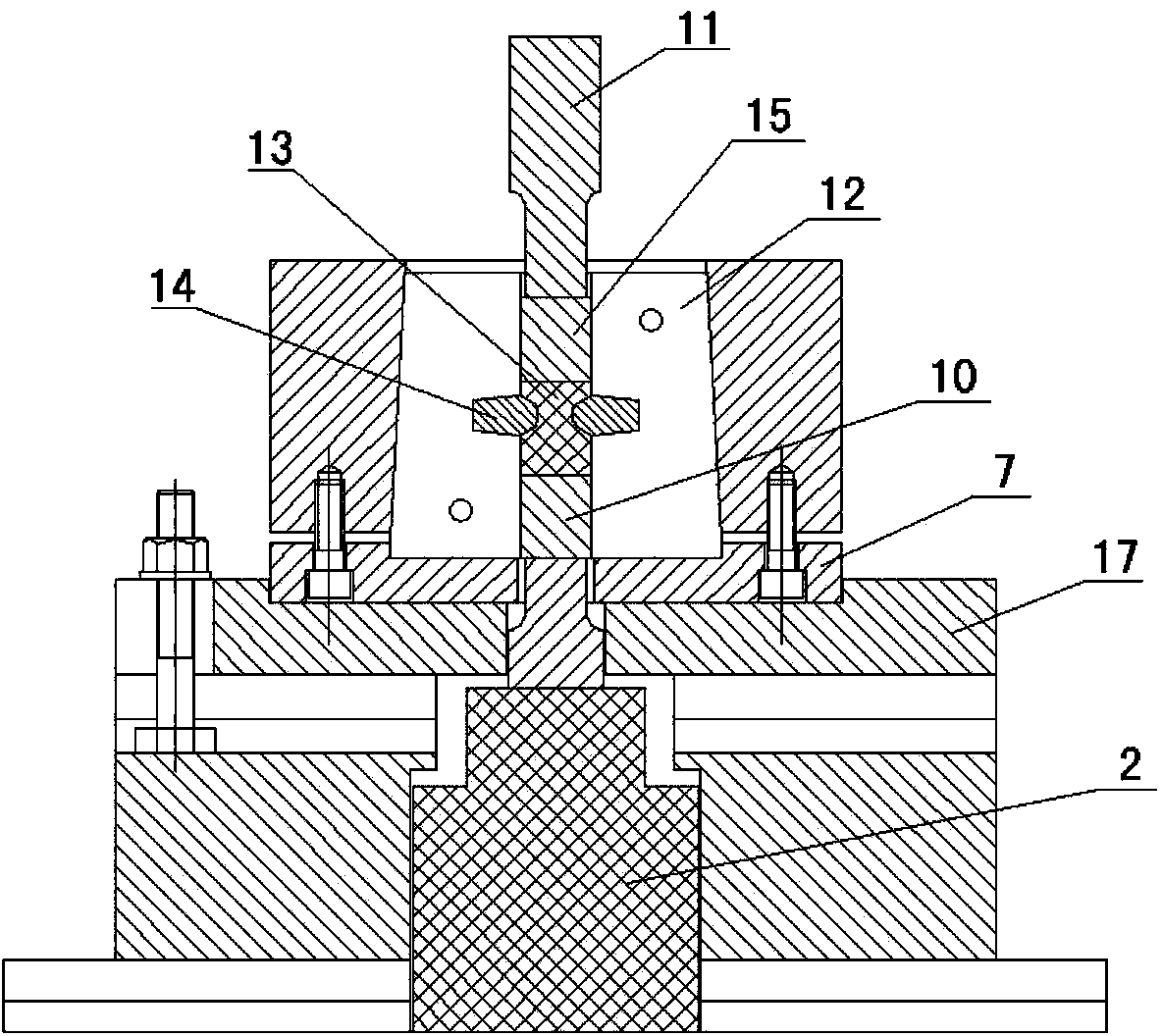

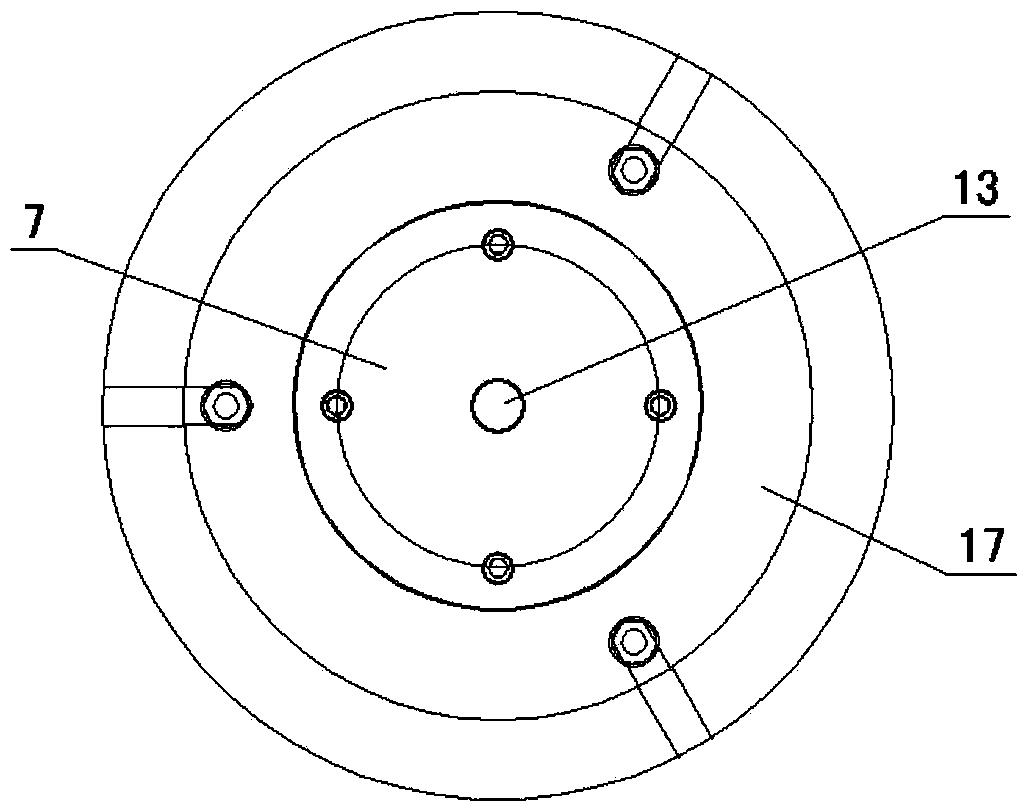

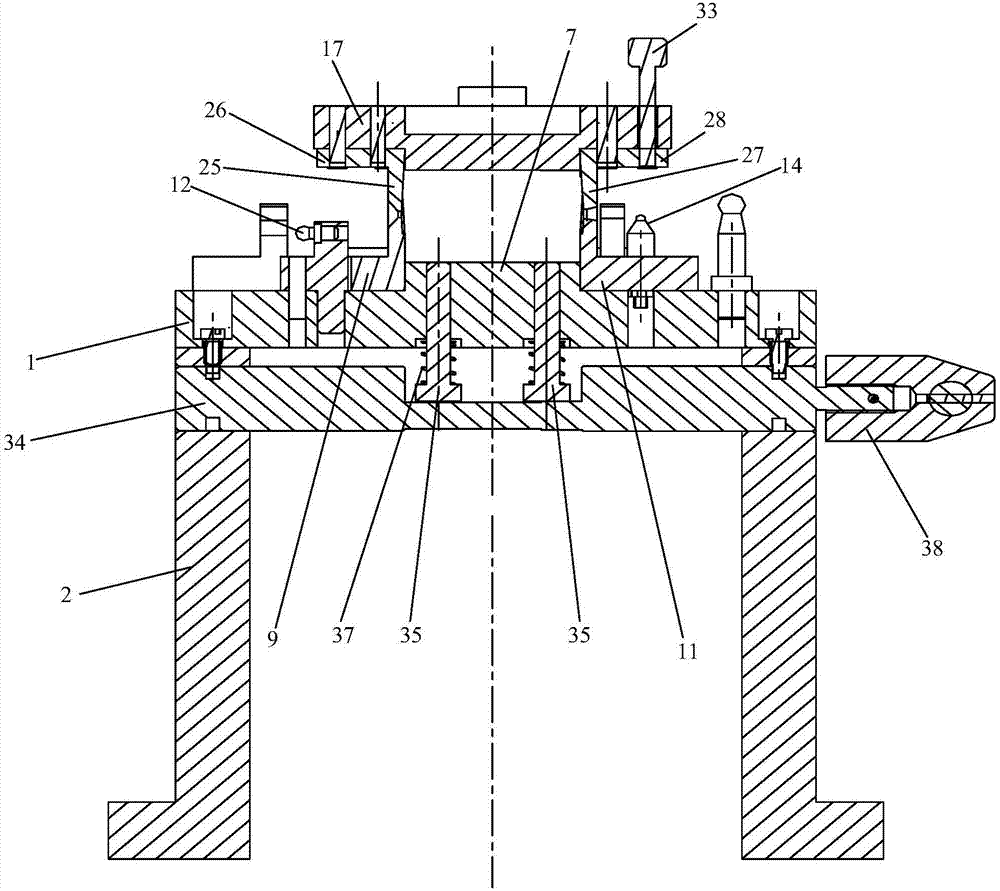

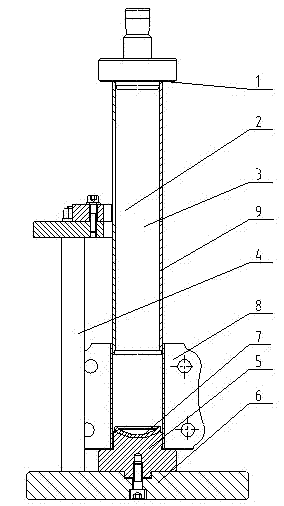

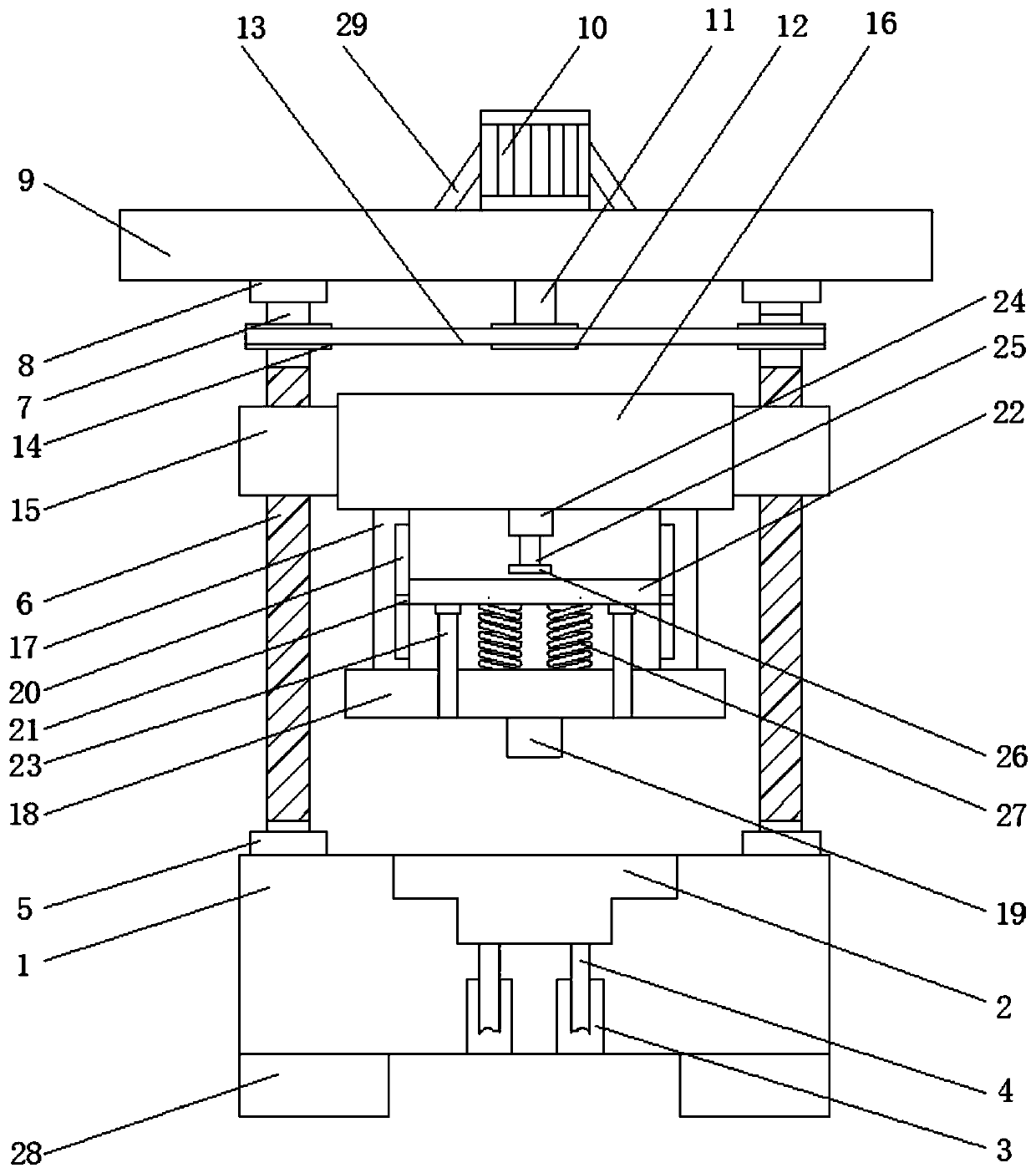

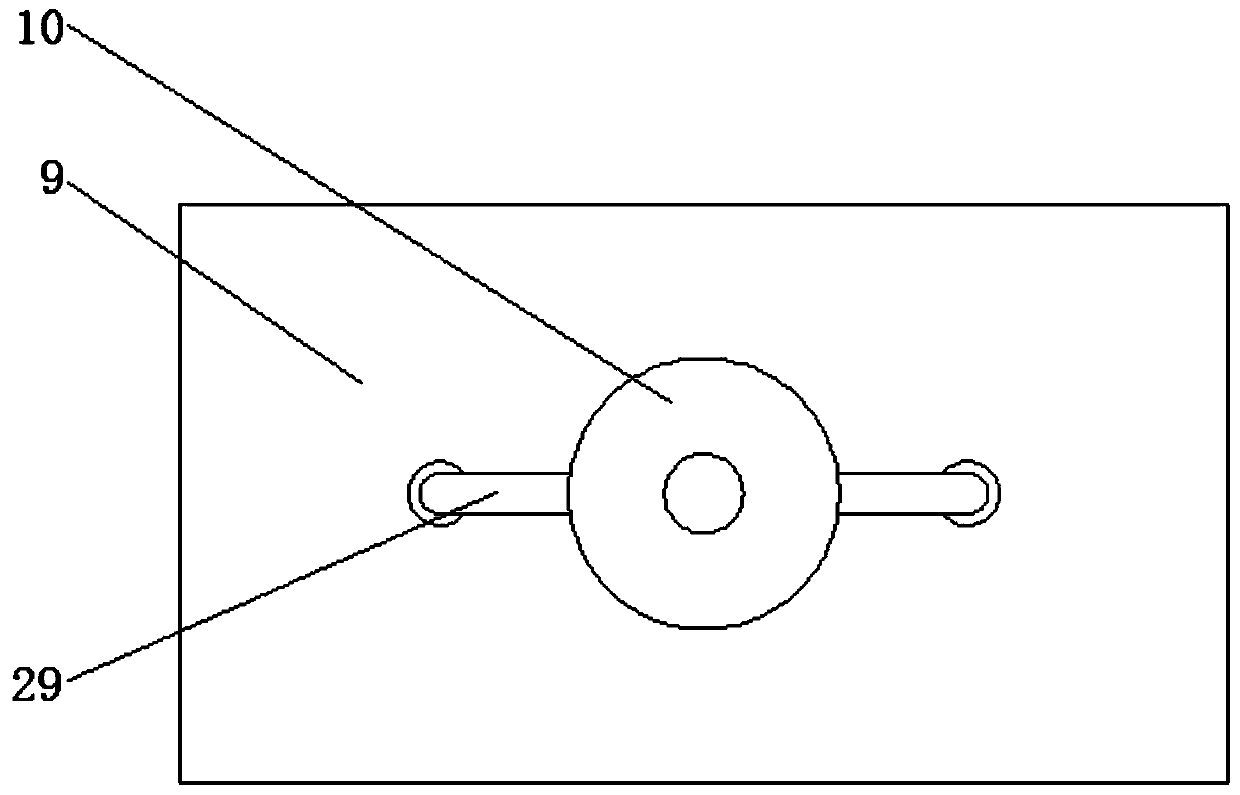

Device for realizing reciprocating extrusion process on one-way hydraulic press

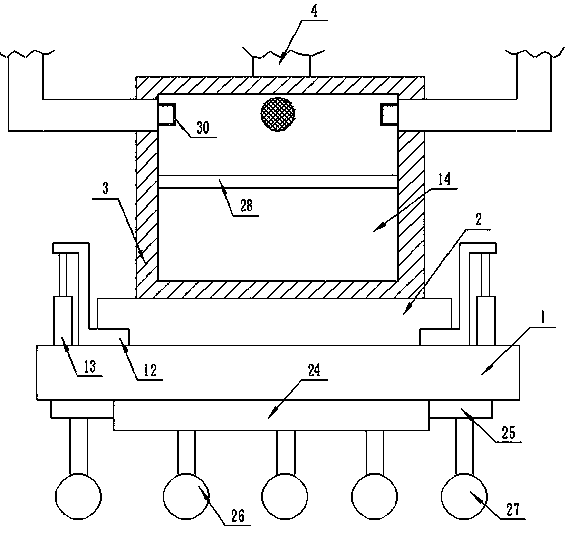

The invention discloses a device for realizing a reciprocating extrusion process on a one-way hydraulic press. The device is characterized in that a hollow cylindrical cavity is formed in an annular extrusion cylinder; an upper male die and a lower male die which can be in axial sliding in the hollow cylindrical cavity are respectively arranged at the top and the bottom of the hollow cylindrical cavity; a cylindrical blank is placed in the hollow cylindrical cavity; a die core inserted block is clamped and embedded into a groove in the inner cylinder wall of the annular extrusion cylinder to form an annular reduced section; the circumference of the annular extrusion cylinder is fixedly sleeved with a pre-tightening ring; a female die pressing plate is fixedly connected to the top of the pre-tightening ring and is propped against the top surface of the annular extrusion cylinder; a female die composed of the annular extrusion cylinder, the female die pressing plate, the pre-tightening ring and the die core inserted block is formed in the manner that the bottom surface of the pre-tightening ring or the top surface of the female die pressing plate is placed in a downward-concave platform on the top surface of a female die fixing plate to form an upright-placing or inverted state; an nitrogen spring in the hollow cavity of a base forms underpropping to the lower male die. According to the invention, the reciprocating extrusion technology on the one-way hydraulic press is realized in an assisting way, reciprocating extrusion deformation under different extrusion ratios can be satisfied, and the fine and equiaxed fine-grain tissues can be achieved.

Owner:HEFEI UNIV OF TECH

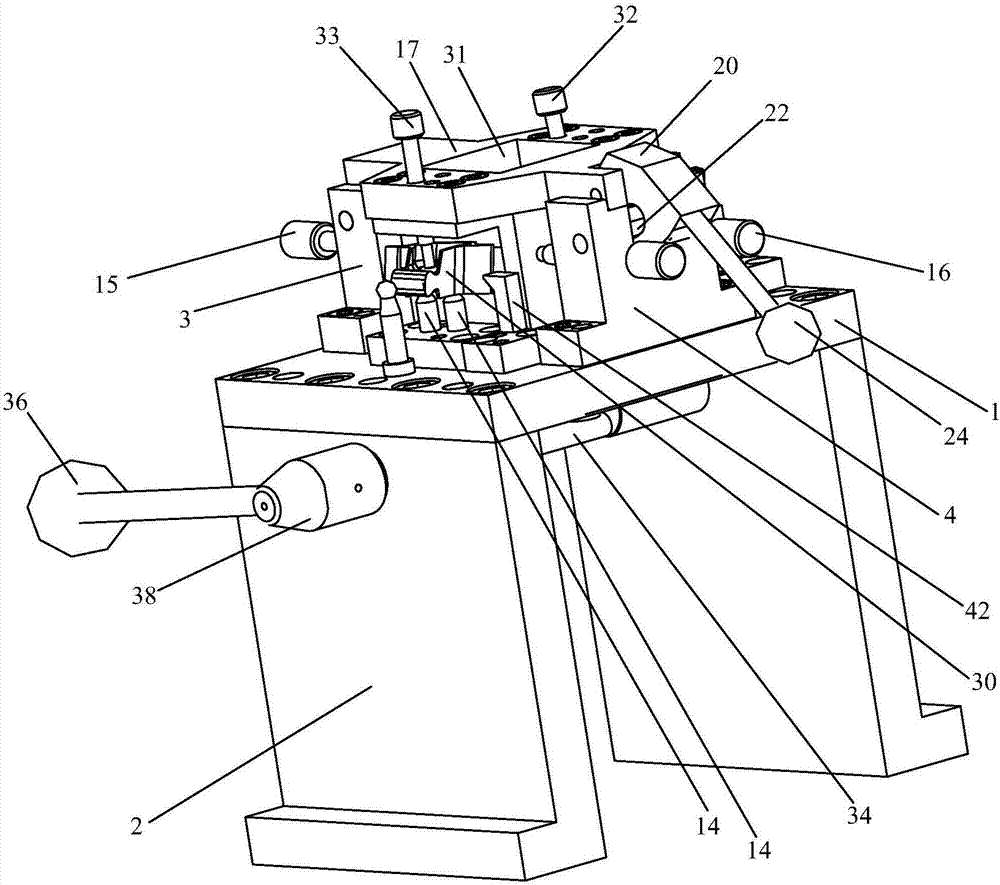

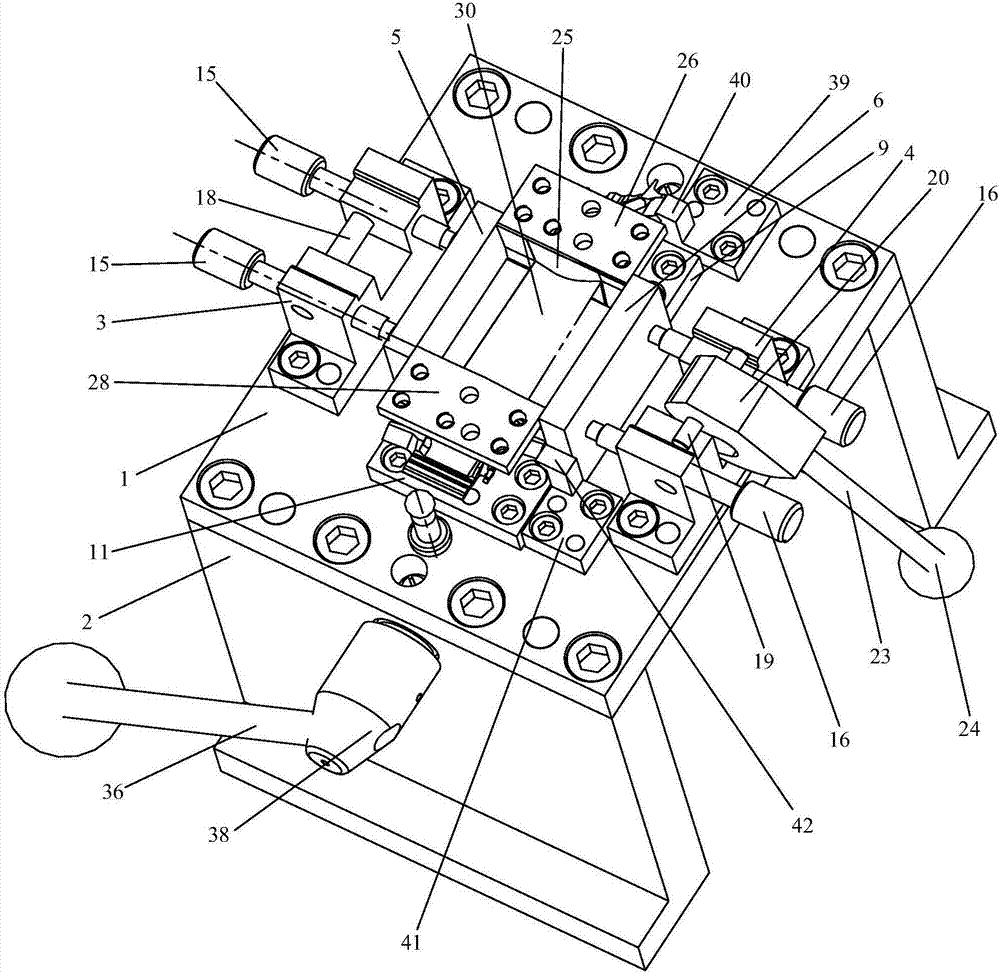

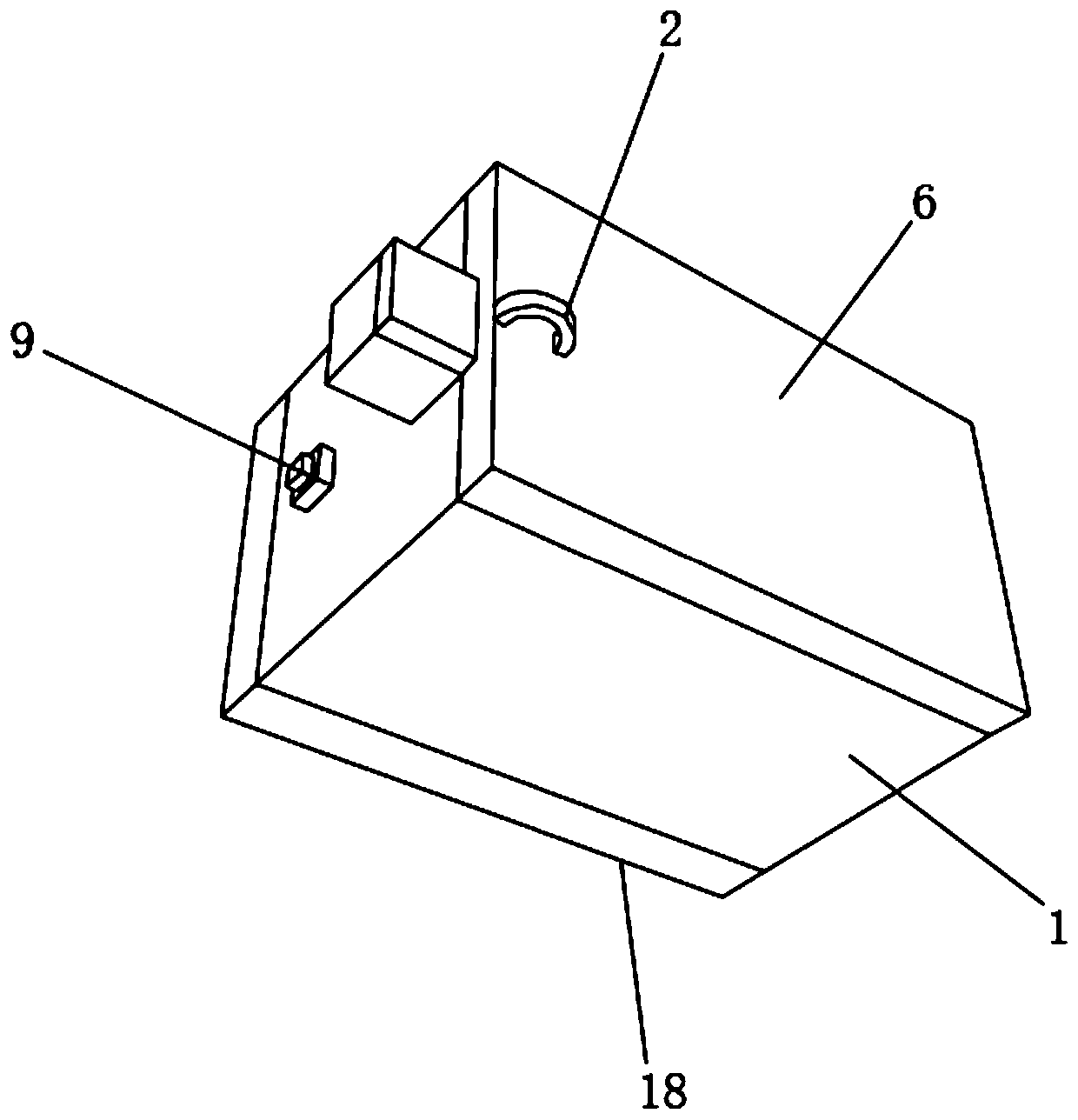

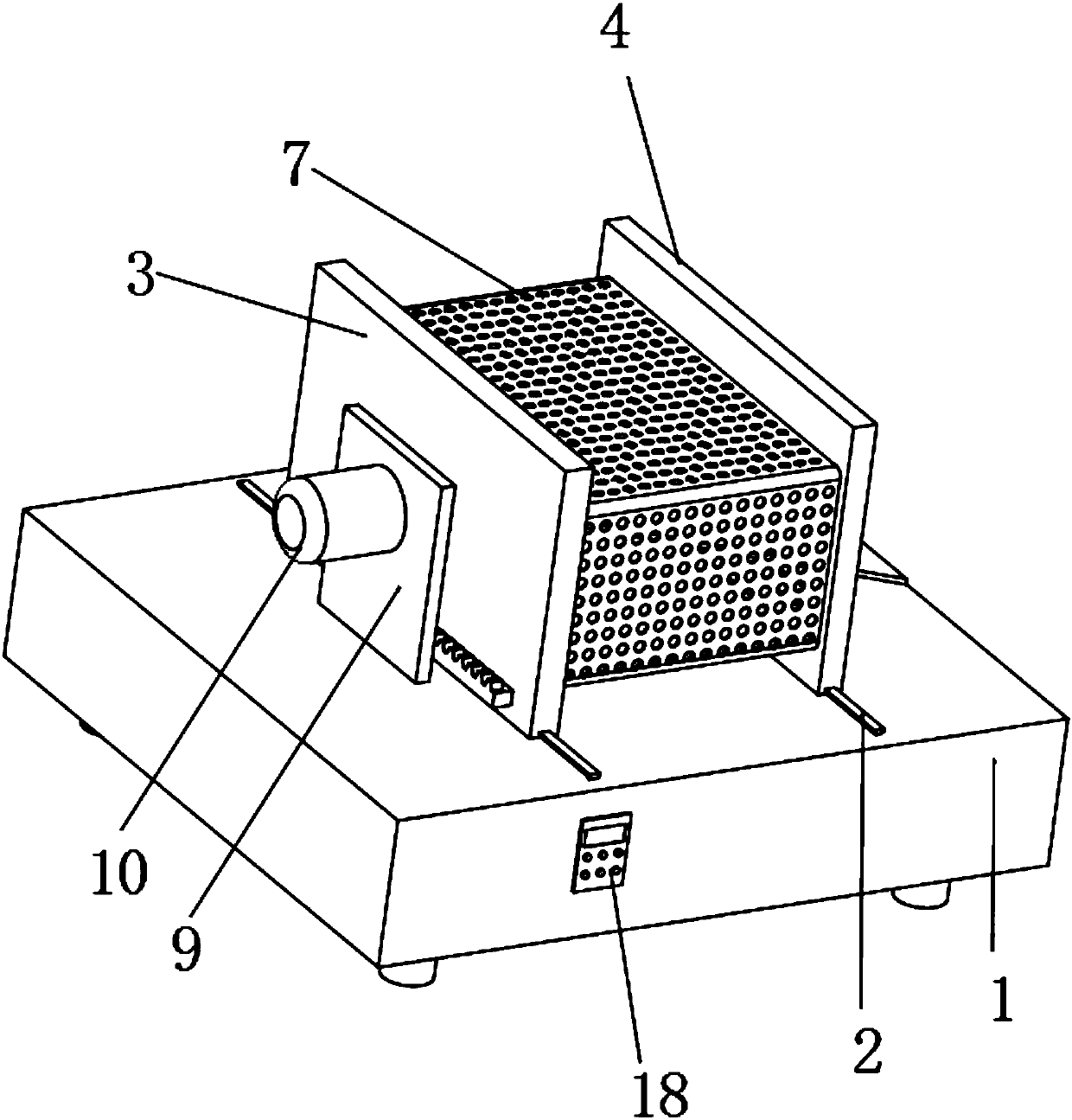

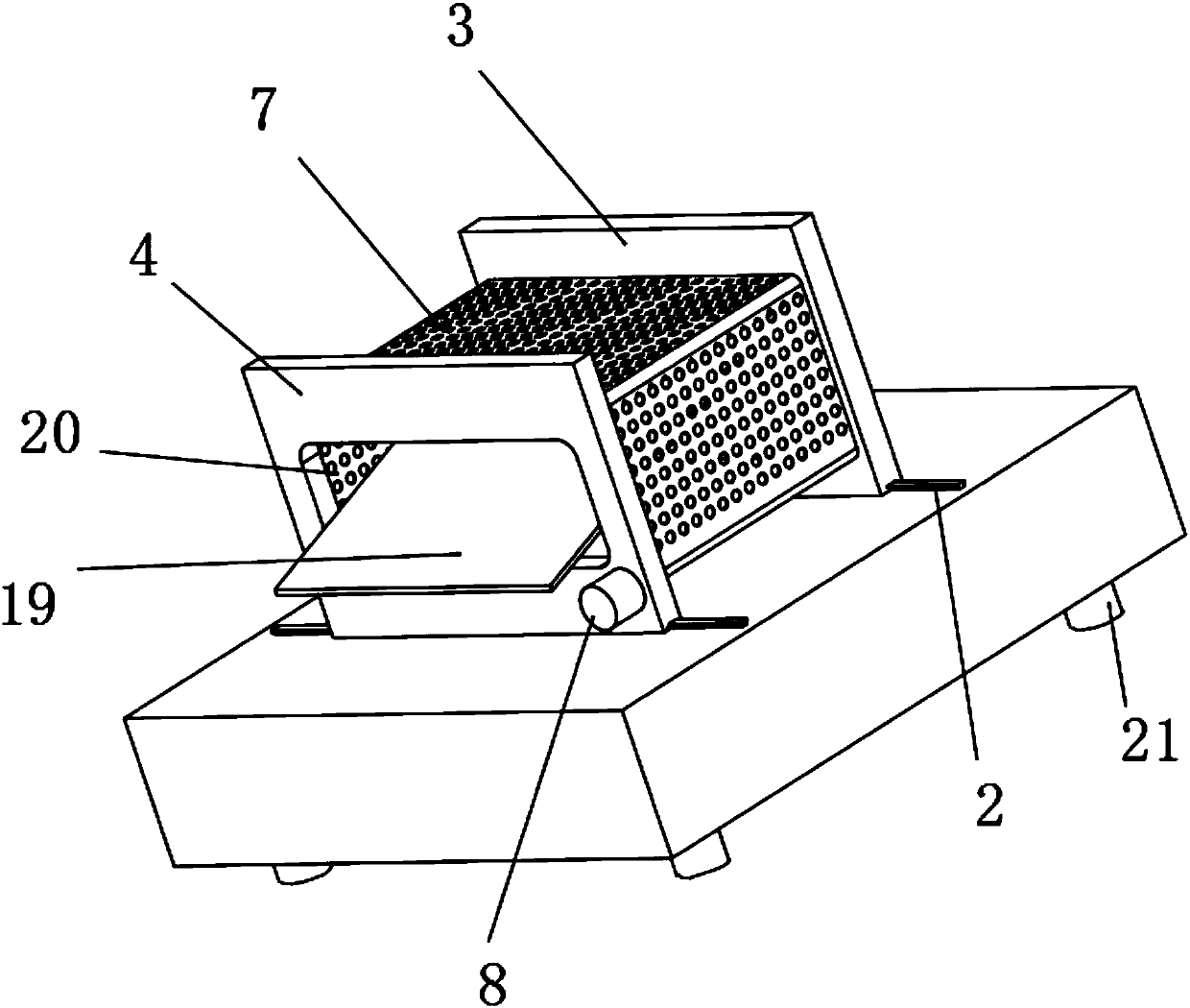

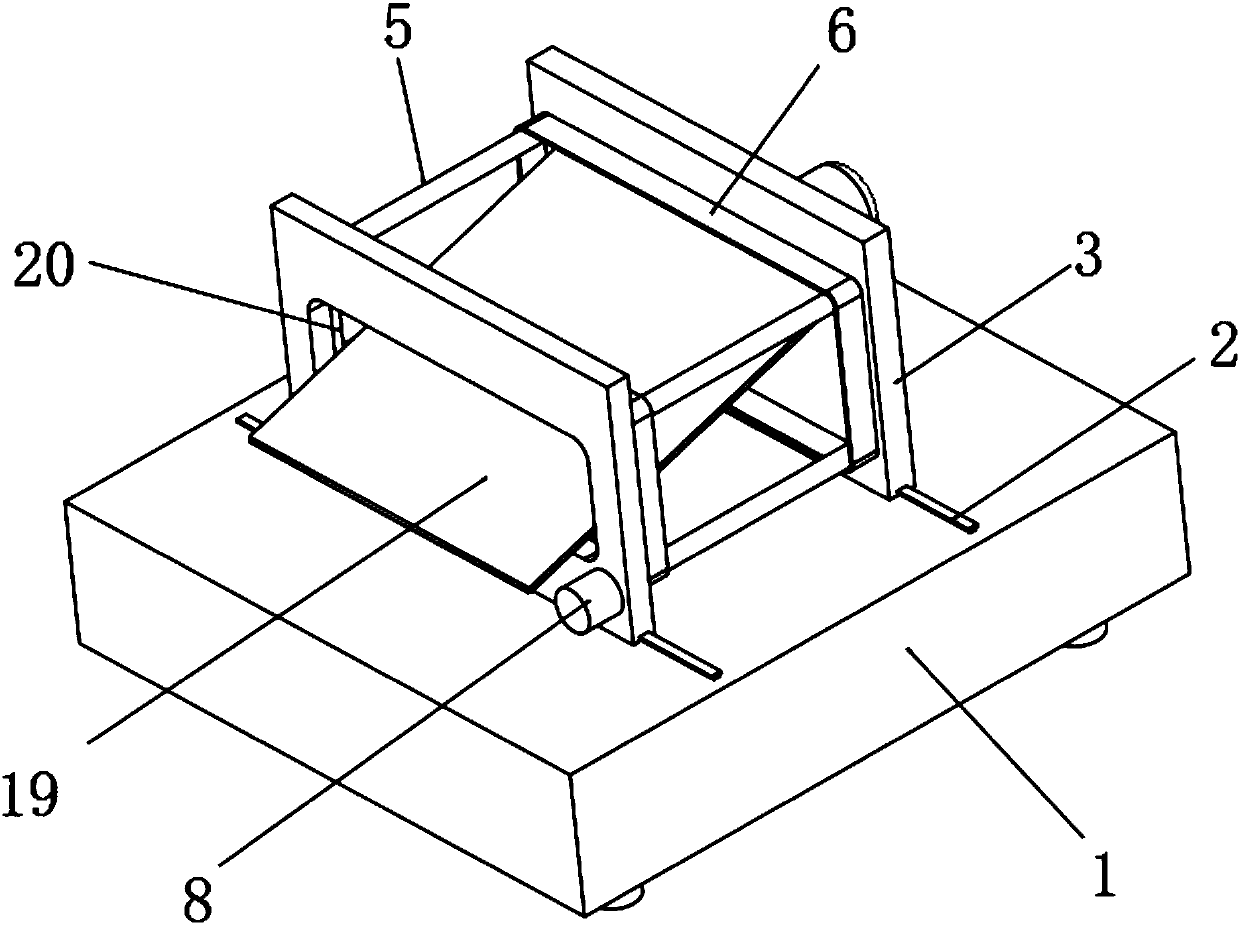

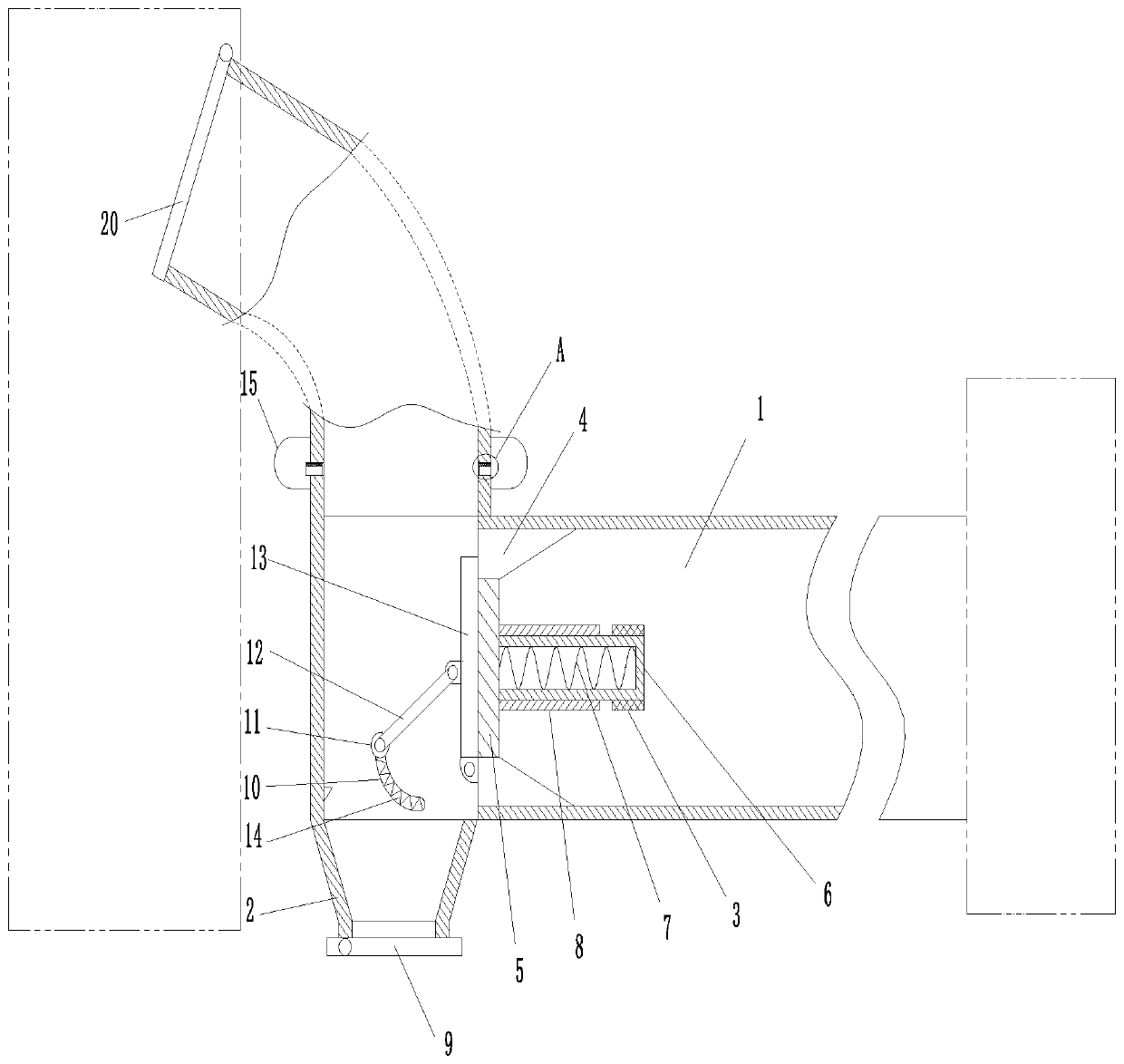

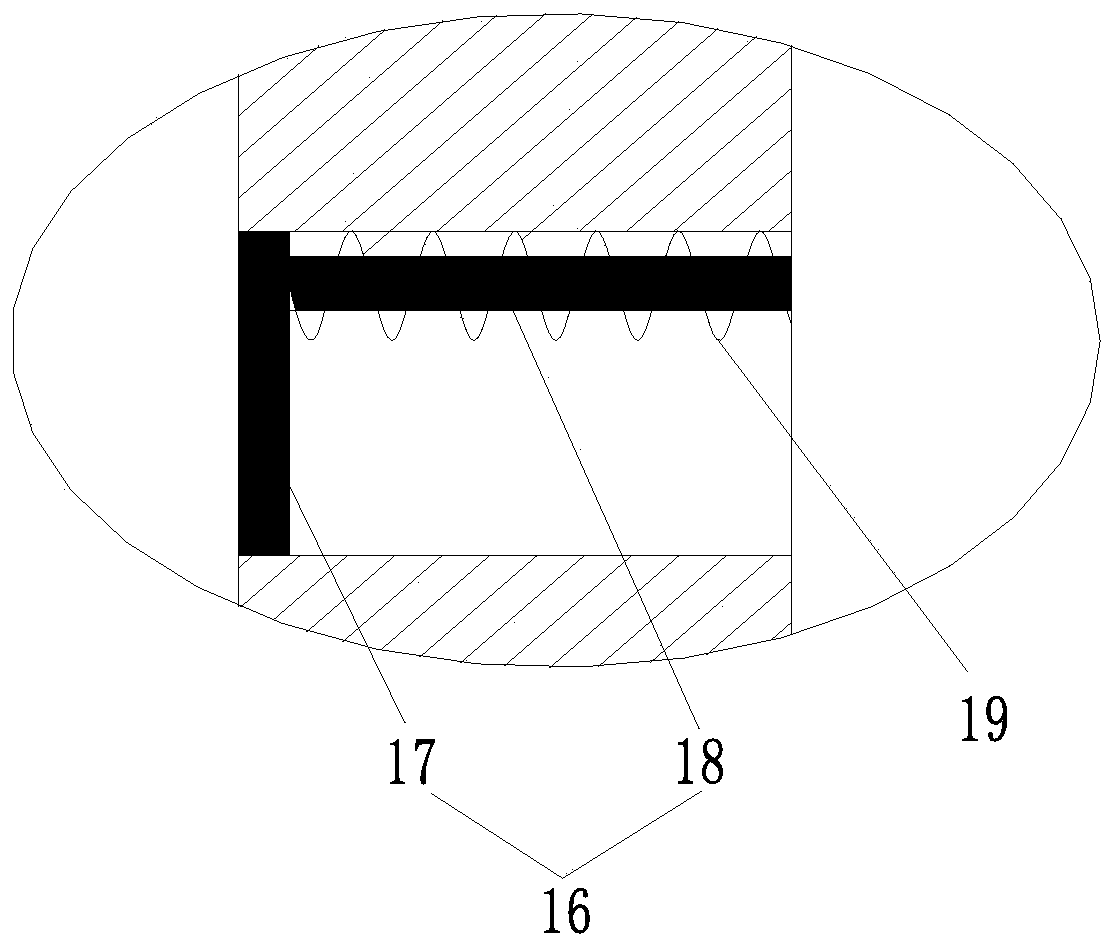

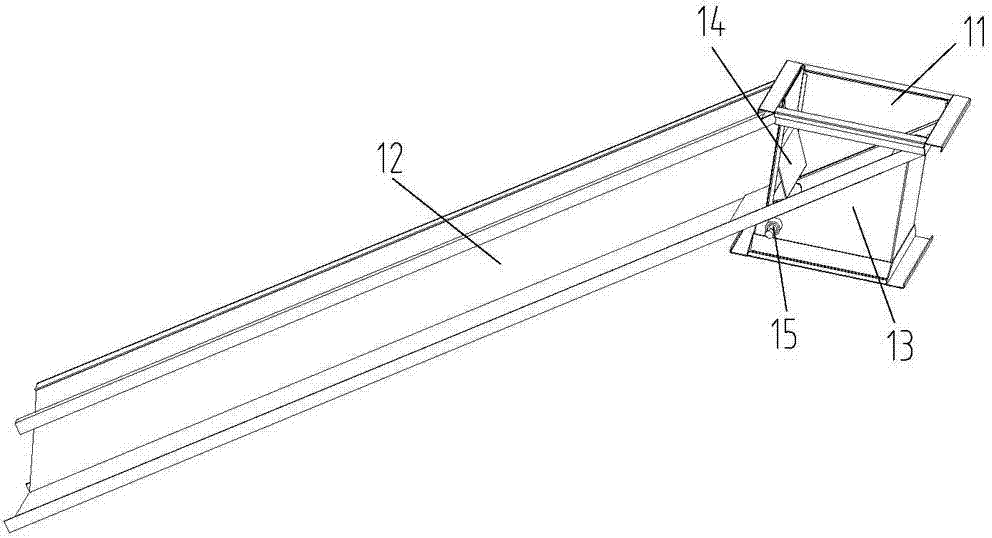

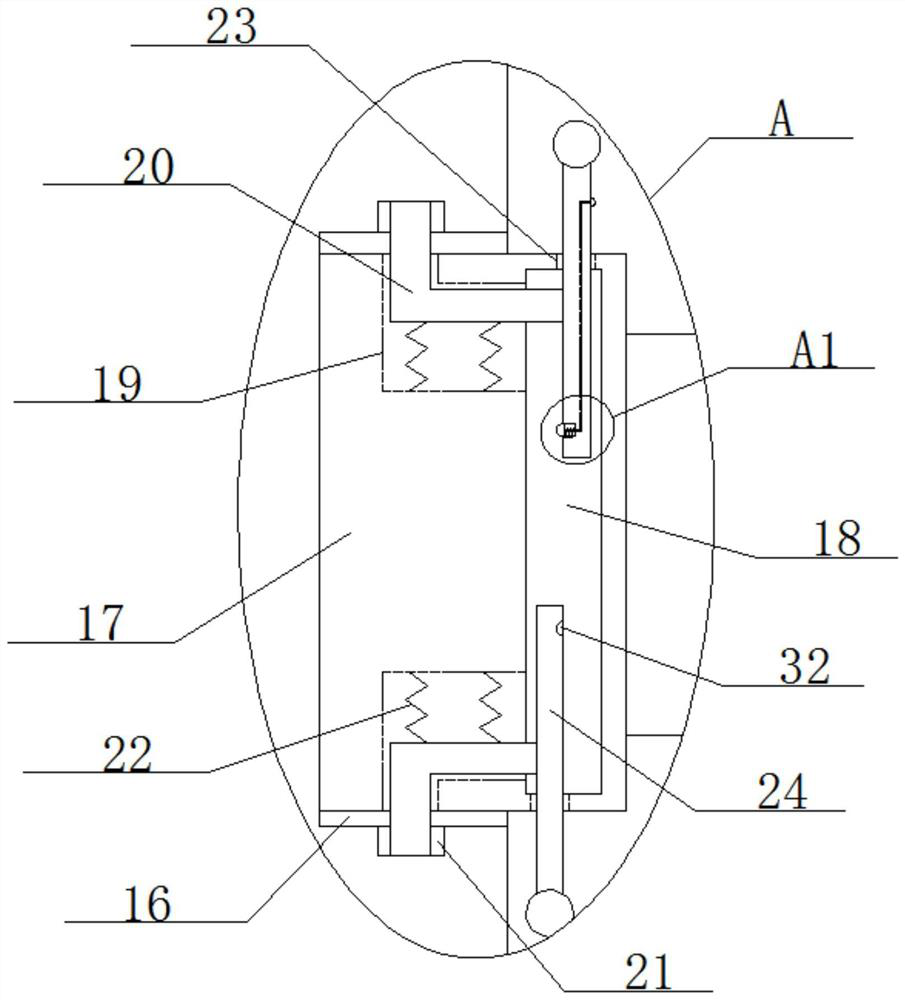

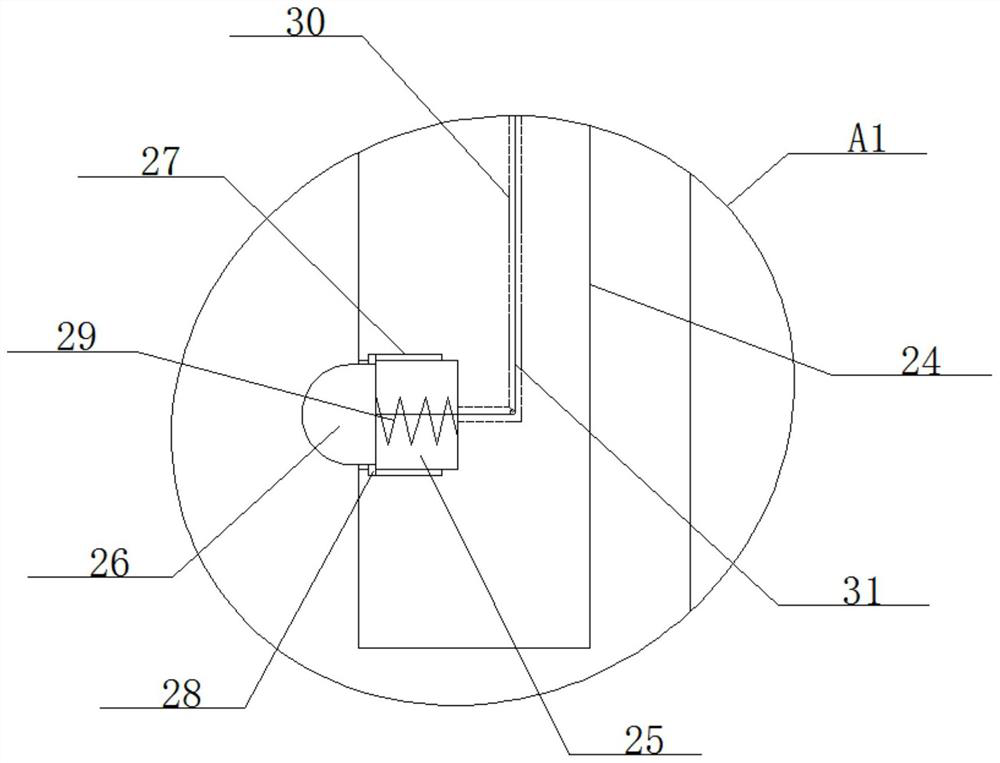

Precision casting blade tenon tooth machining front reference conversion clamp and using method thereof

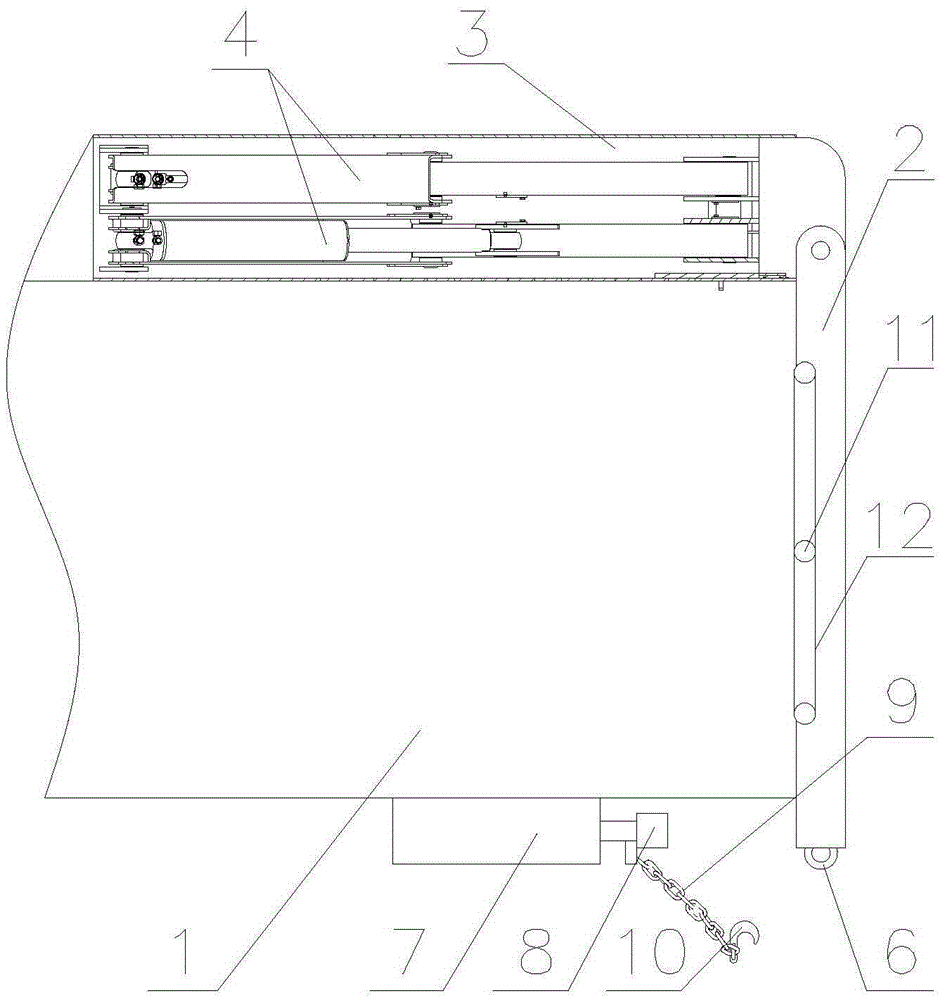

ActiveCN107984340ACompact structureEasy unloadingGrinding machinesGrinding work supportsHinge angleEngineering

The invention provides a precision casting blade tenon tooth machining front reference conversion clamp and a using method thereof, and belongs to the technical field of machining of high-low-pressureturbine blades. The precision casting blade tenon tooth machining front reference conversion clamp comprises a support plate, support legs, a first hinge support, a second hinge support, a first lateral baffle, a second lateral baffle, a turnover cavity and a discharging mechanism, wherein the supporting legs are arranged below the supporting plate, the center of the support plate is provided with a square protrusion, and the first hinge support and the second hinge support are installed on the support plate. The turnover cavity comprises a turnover cover, wherein the discharging mechanism comprises a cam shaft, lifting pins and a handle, wherein the cam shaft is arranged on the supporting legs and is positioned below the supporting plate, the lifting pins are arranged in the square protrusion of the supporting plate and are in contact with the cam shaft, springs are arranged at the part, below the supporting plate, of the lifting pins in a sleeved mode, and the handle is arranged onthe cam shaft and can drive the cam shaft to rotate. The clamp is simple in operation process, the tenon teeth can be positioned stably and reliably during machining, the damage to the precision casting blades is avoided, the machining quality is guaranteed, and the production efficiency is improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

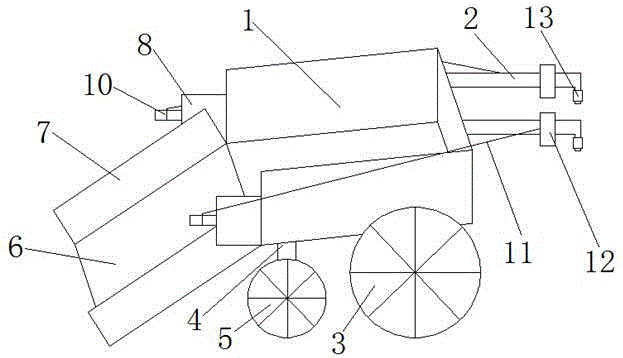

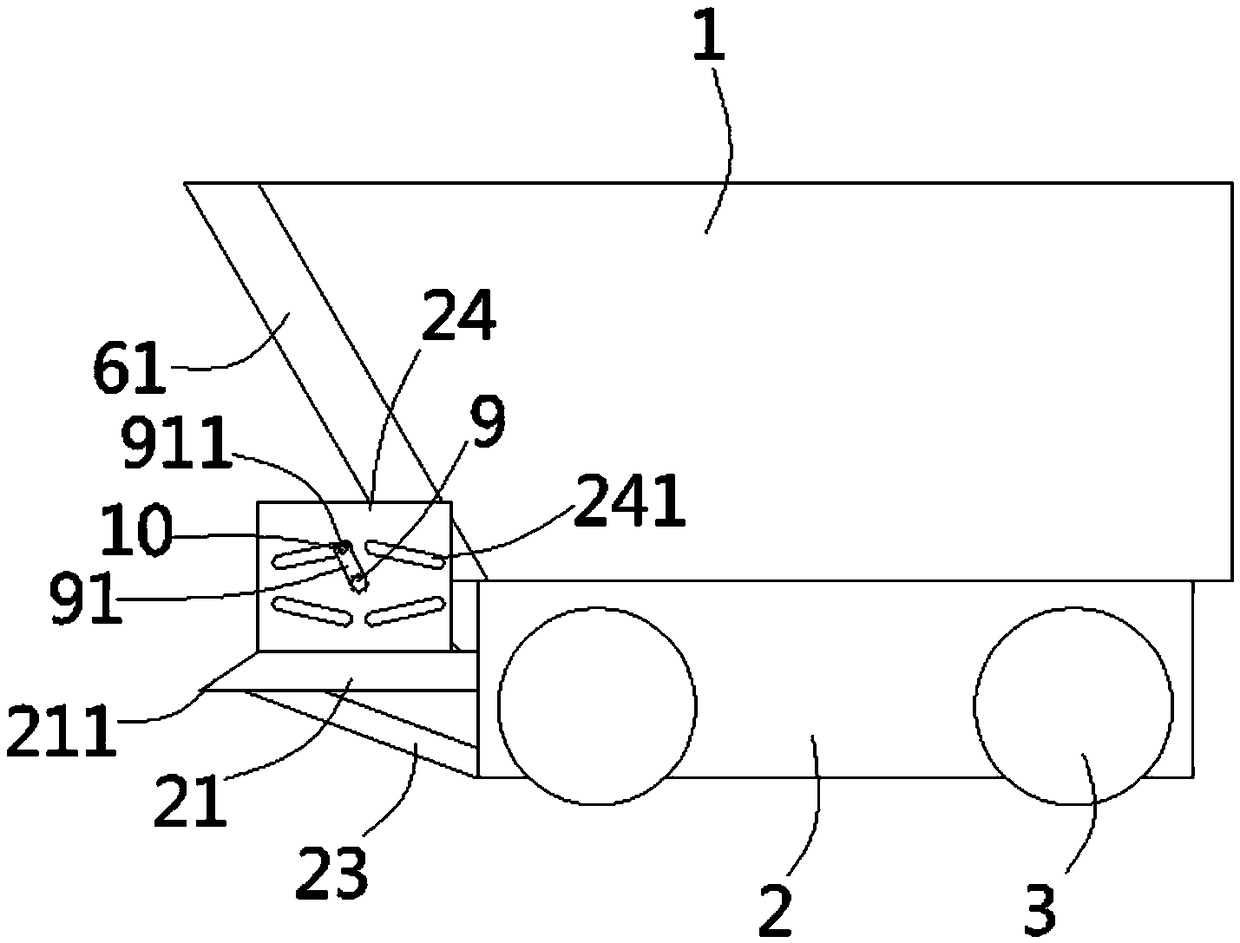

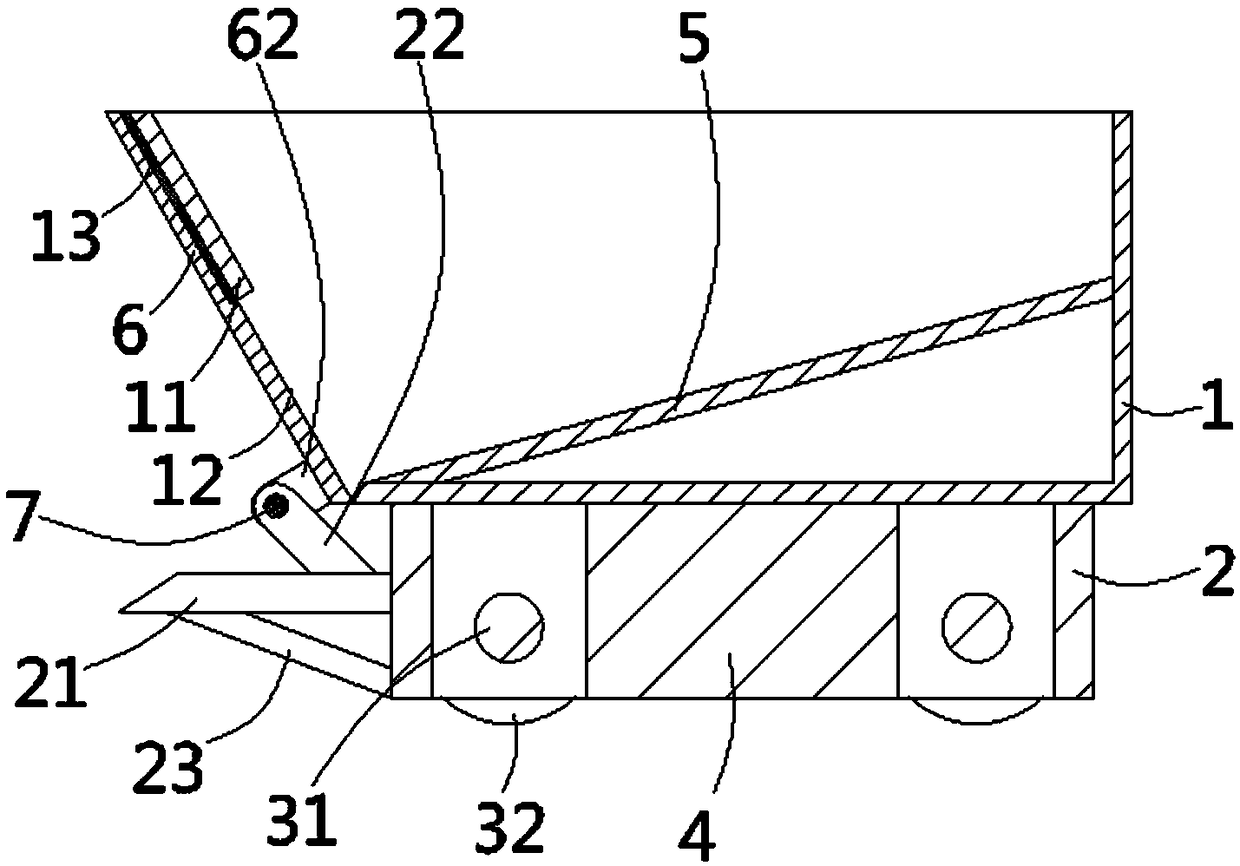

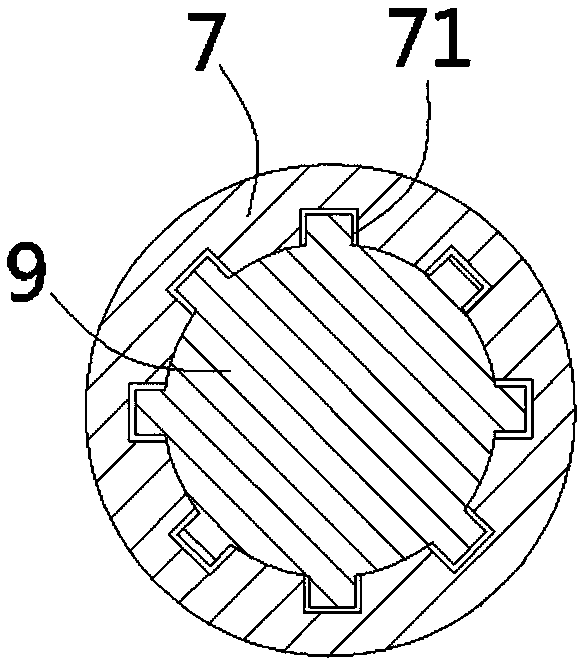

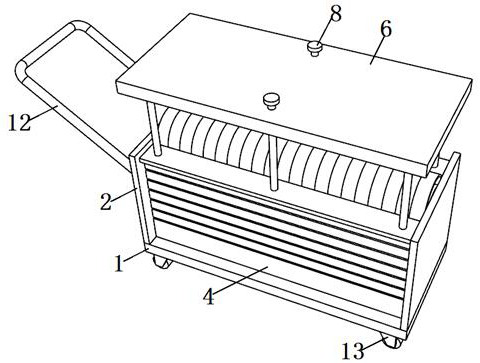

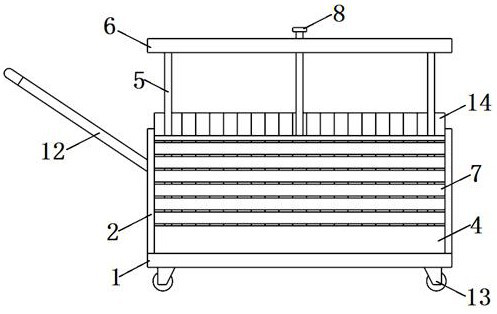

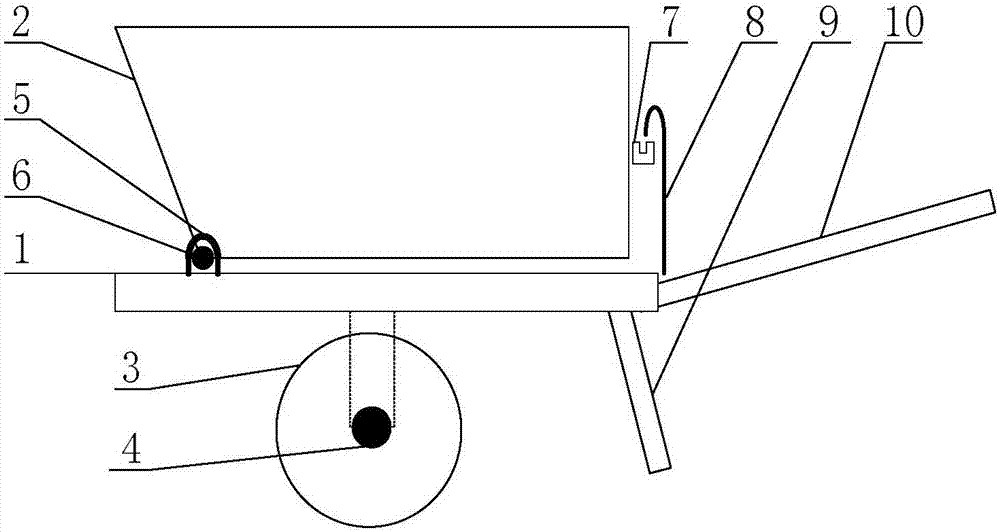

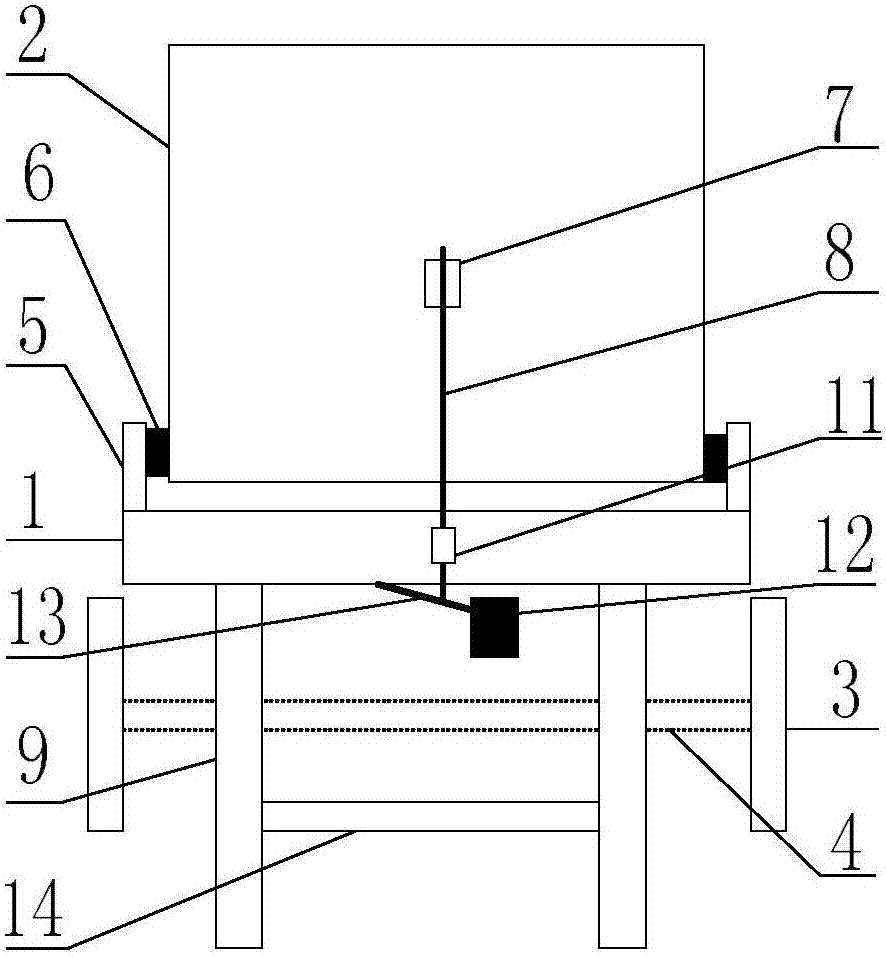

Trolley for conveying concrete

InactiveCN105857366AEasy unloadingSave manpower and timeFluid steeringHand carts with multiple axesEngineering

The invention discloses a trolley for conveying concrete, comprising a trolley body and a handle disposed at the rear end of the trolley body. The trolley body is in the shape of forwardly oblique rectangle, left and right sides of the trolley body are each provided with a wheel, a support rod is disposed on the lower portion of the trolley body, one end of the support rod is fixedly connected with the trolley body, the other end of the support rod is provided with a small wheel, the front end of the trolley body is provided with a moving retainer, the moving retainer is hinged to the trolley body, left and right ends of the moving retainer are bent up, forming discharge side retainers, left and right front ends of the trolley body are provided with fixed retainers, and the fixed retainers are hinged to the trolley body. The trolley enables simple and clean discharging during usage, saves discharging time and labor, and is also very easy to clean before replacing material to be conveyed.

Owner:刘瑞

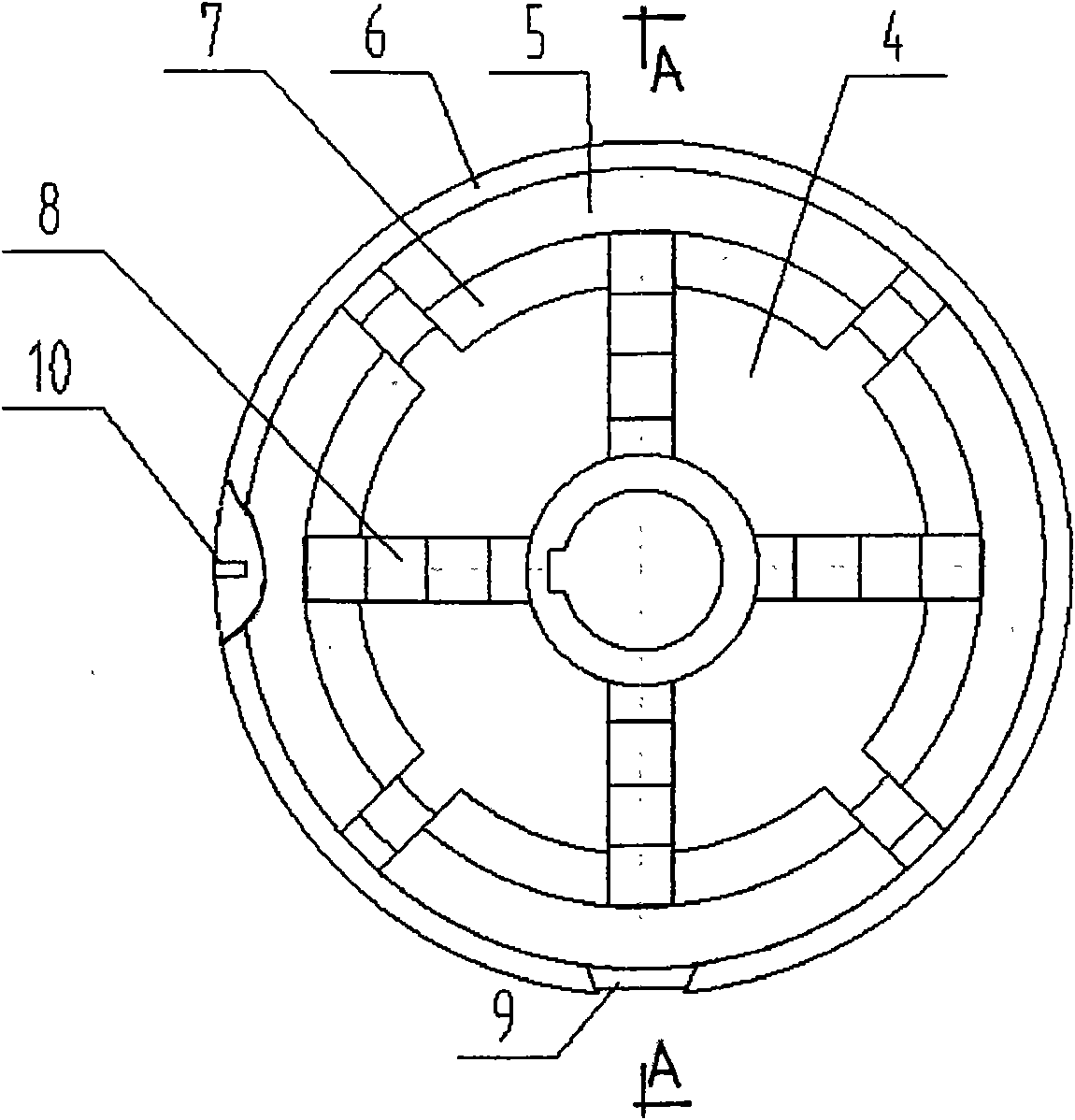

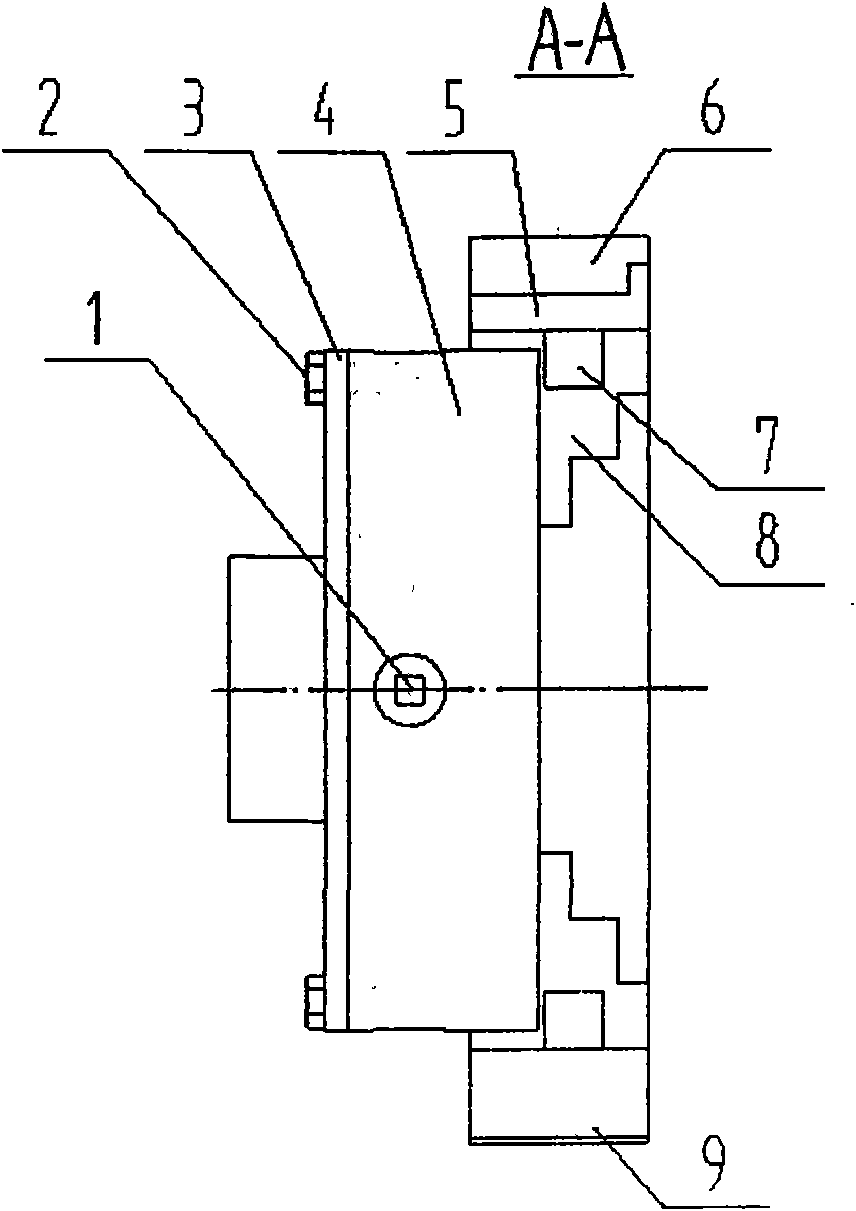

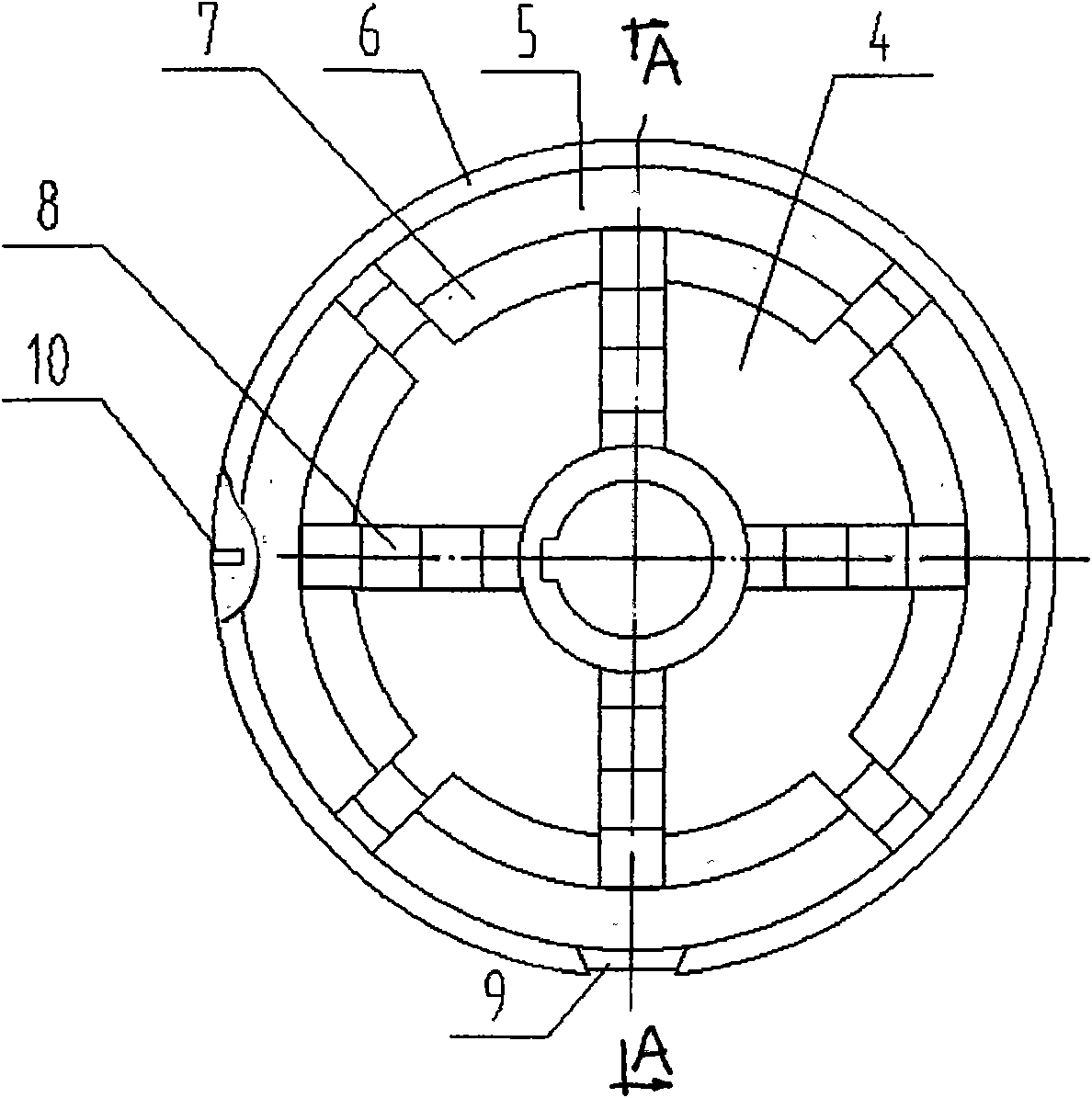

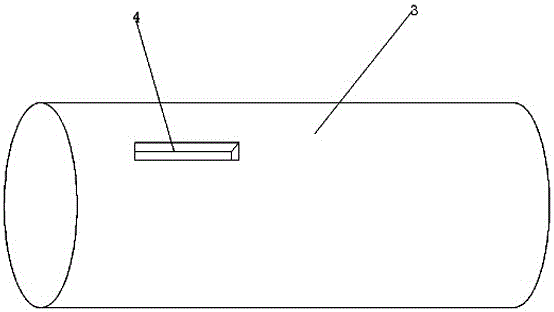

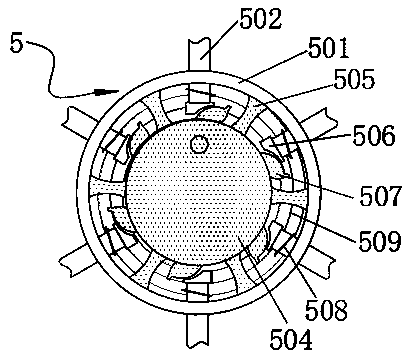

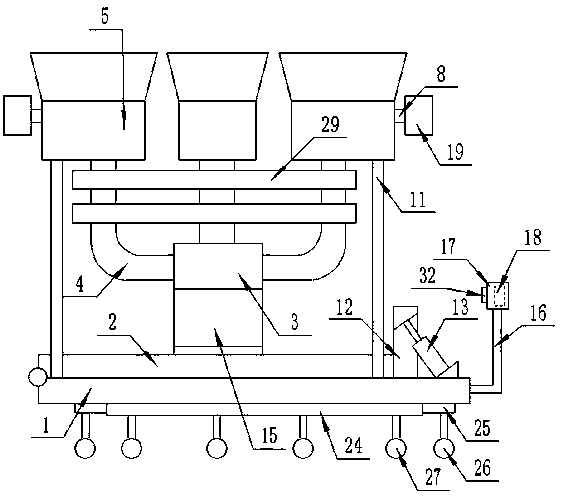

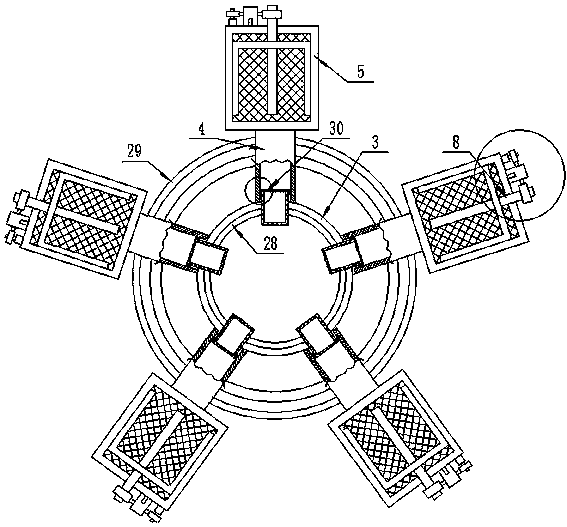

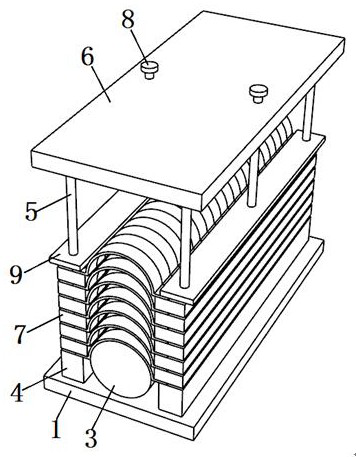

Strip expanding drum device

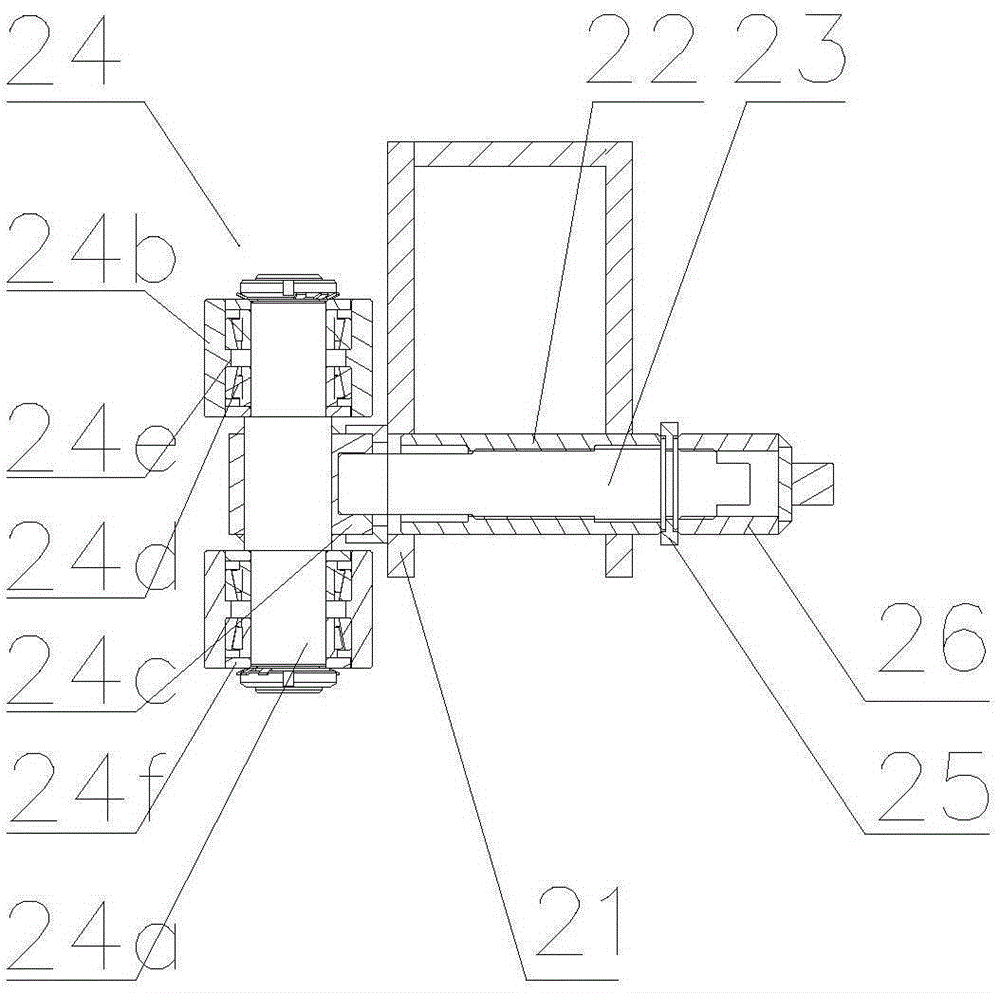

The invention discloses a strip expanding drum device with the width of less than 100mm. The conventional drum devices are connecting rod and wedge type mechanical drums mostly due to small structure size, and when the drums discharge coils, an expanding mechanism is difficult to act because of large radial pressure of the strip coils, a screw thread pair wears severely, and great troubles are brought to the coil discharging work. The technical scheme provides an expanding drum device with simple structure and convenient coil discharge; a multiple-jaw automatic centering chuck for a common lathe is utilized; each external jaw of the chuck is fixed with an arch block to form a drum; the arch block is sleeved with an elastic ring of which the periphery is provided with a wedge-shaped notch; a wedge is fixed on any arch block; and the wedge is in fit with the wedge-shaped notch on the elastic ring during coiling, so the radial pressure of a strip coil acts on the elastic ring; and during coil discharge, the elastic ring shrinks inwards under the action of internal force and generates a clearance with the internal diameter of the strip coil, so the shrinkage of the drum is easy.

Owner:上海格林赛高新材料有限公司

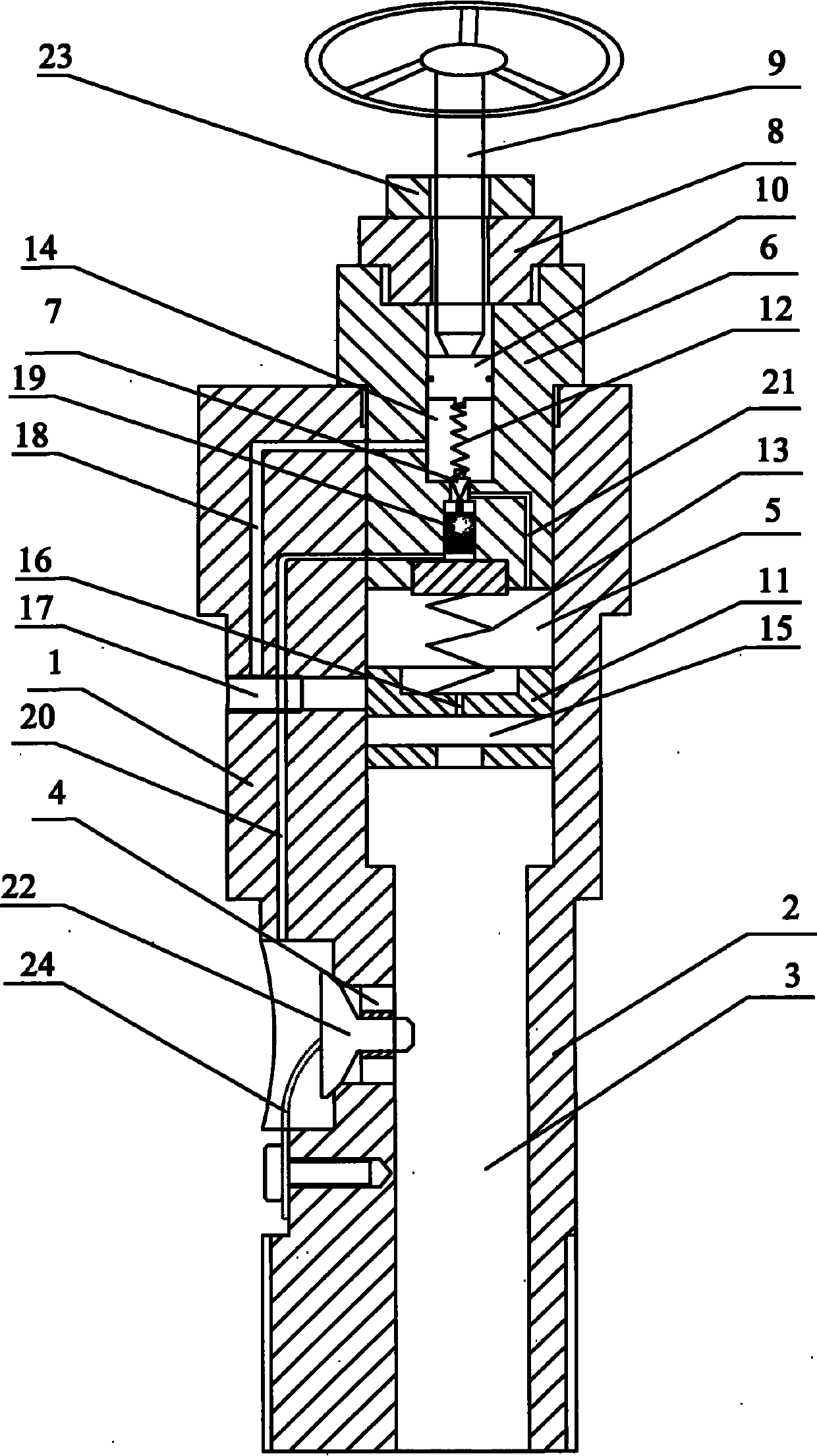

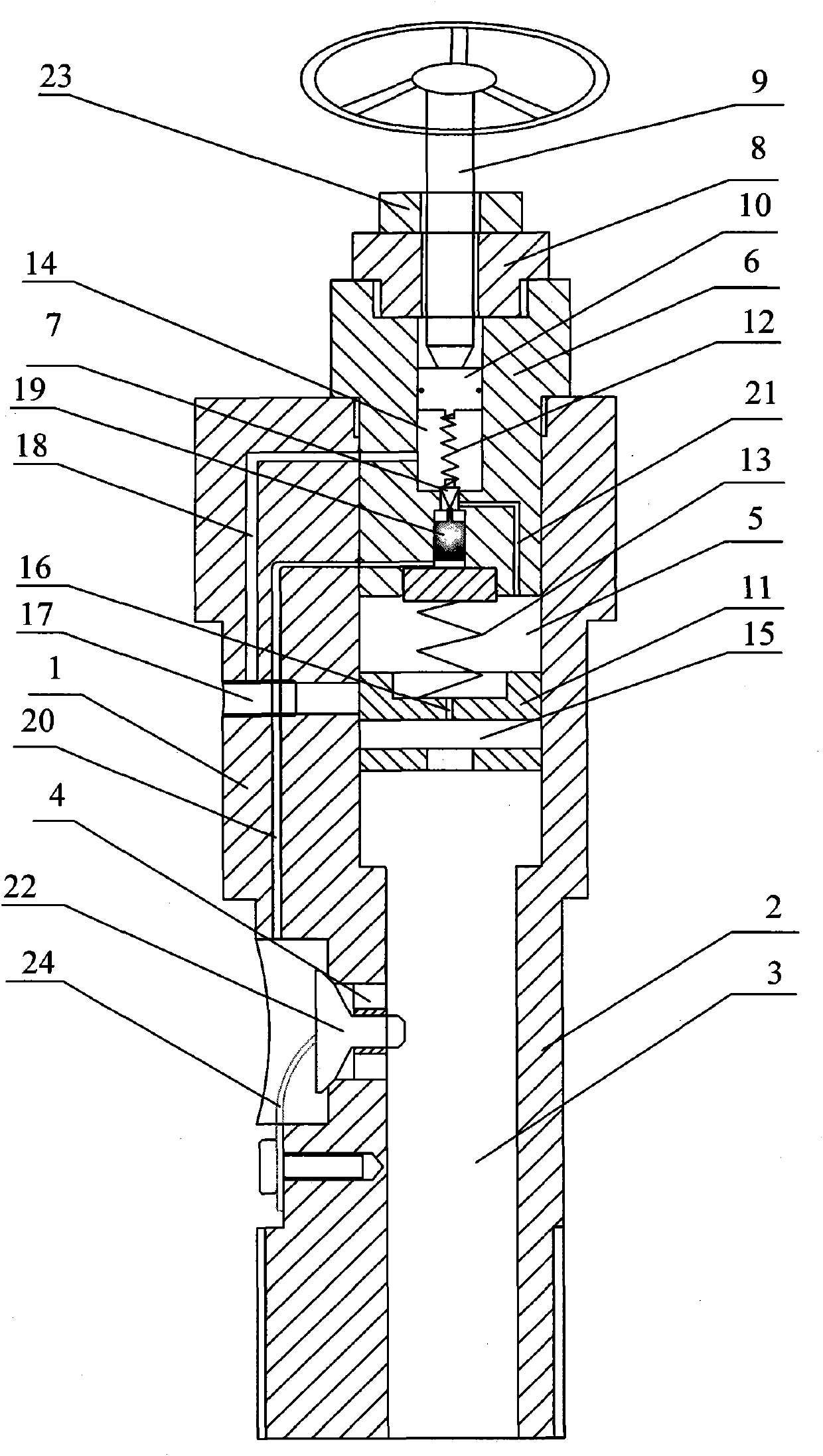

Link bolt with unloading overflow valve

ActiveCN101907119AStable pressureLow failure rateFluid-pressure actuator safetyEqualizing valvesFuel tankDecreased pressure

The invention discloses a link bolt with an unloading overflow valve, which is formed by additionally arranging an unloading overflow valve on the prior link bolt. The function of unloading overflow valve is integrated with the function of the link bolt. An outlet of a cross passage is communicated with a hydraulic system, and when the liquid pressure of the hydraulic system is larger than the threshold value of the overflow valve, liquid enters a passage I to exert pressure to a control piston, then the control piston pushes a cone valve open so as to enable liquid in the link bolt to enter a cavity through a passage II, liquid in the cavity enters an oil return hole through an oil drain hole, an adjusting spring can move up along a mounting passage because the pressure between a gland and the adjusting spring is reduced, and the liquid in the link bolt can enter an oil tank through the oil return hole to realize the unloading overflow when a high-pressure passage ascends to the oil return hole. By cooperating the unloading overflow valve and the link bolt, the liquid pressure can be stabilized, and the unloading effect can be realized. The link bolt with the unloading overflow valve has obvious effect, convenient installation and low failure rate.

Owner:林友根

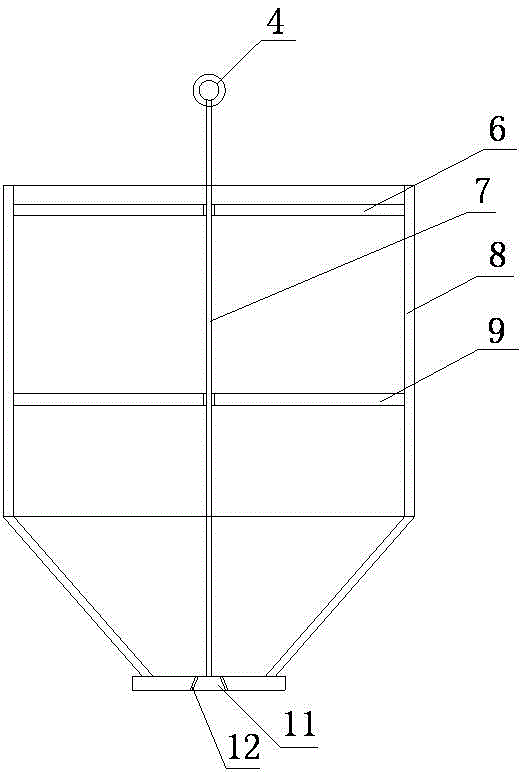

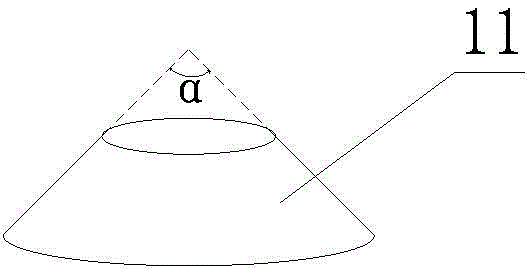

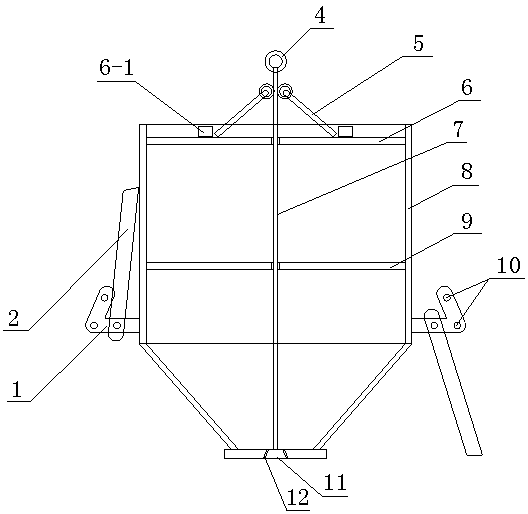

Self-unloading type material shifting and transporting hopper

The invention provides a self-unloading type material shifting and transporting hopper and belongs to the technical field of material storage or transportation devices. The self-unloading type material shifting and transporting hopper comprises a hopper body with the lower portion of a conical structure. A guide support is arranged in the hopper body. A suspension rod penetrates the center of the guide support movably. A suspension ring is arranged at the top end of the suspension rod, and a plug is arranged at the lower end of the suspension rod. A frustum-shaped through hole is formed in a base plate of the hopper body, and the plug is matched with the frustum-shaped through hole so as to seal the hopper body. The self-unloading type material shifting and transporting hopper is novel in structure and reasonable in design; and by researching the falling character of materials, the hopper is subjected to a series of structural improvements in consideration of material airtightness, operation convenience, operation efficiency and the like of the hopper, so that loading and unloading are more convenient, the material airtightness is better, operation is safer and more reliable, the operation efficiency is improved, and the labor intensity is relieved.

Owner:NANYANG FUSEN MAGNESIUM POWDER CO LTD

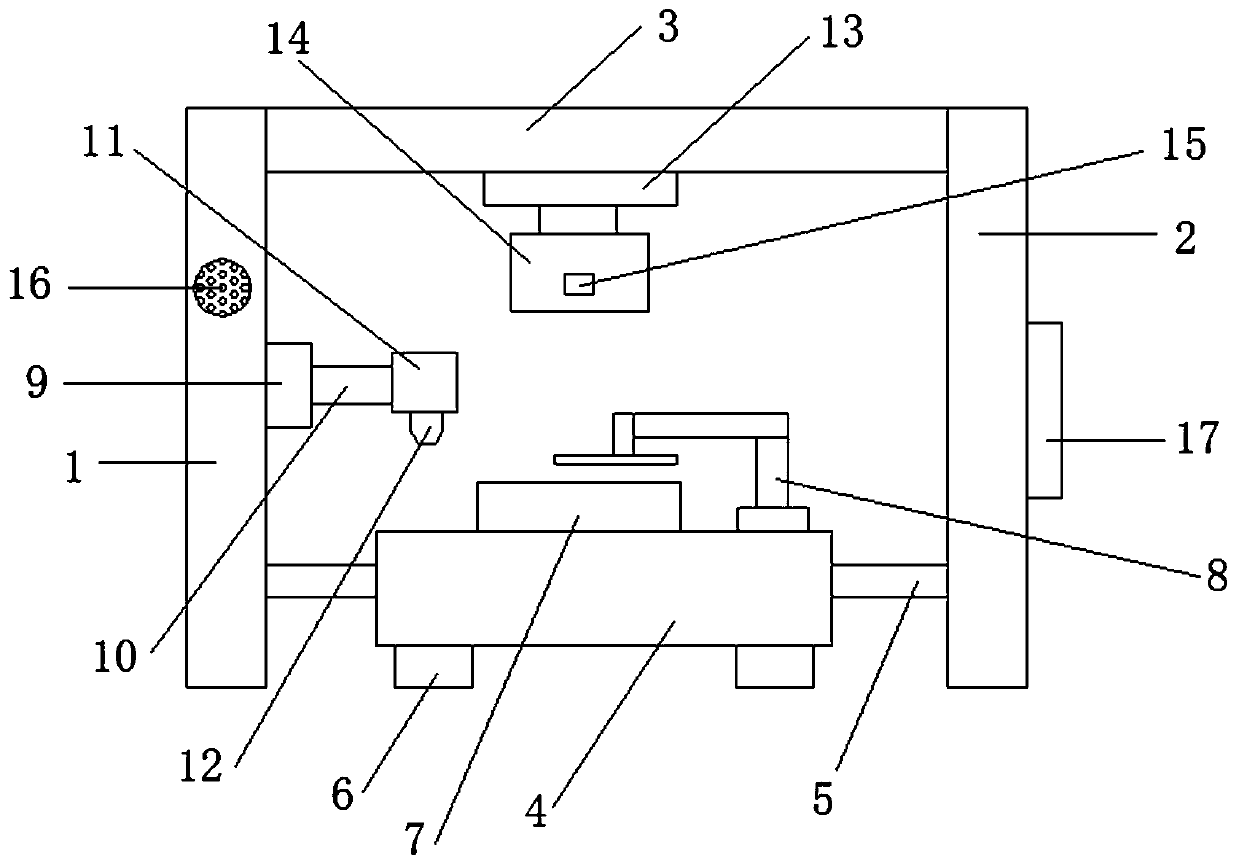

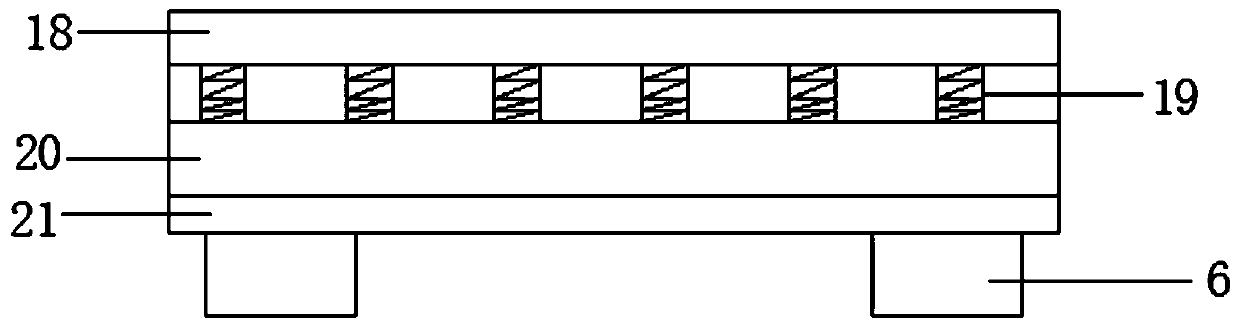

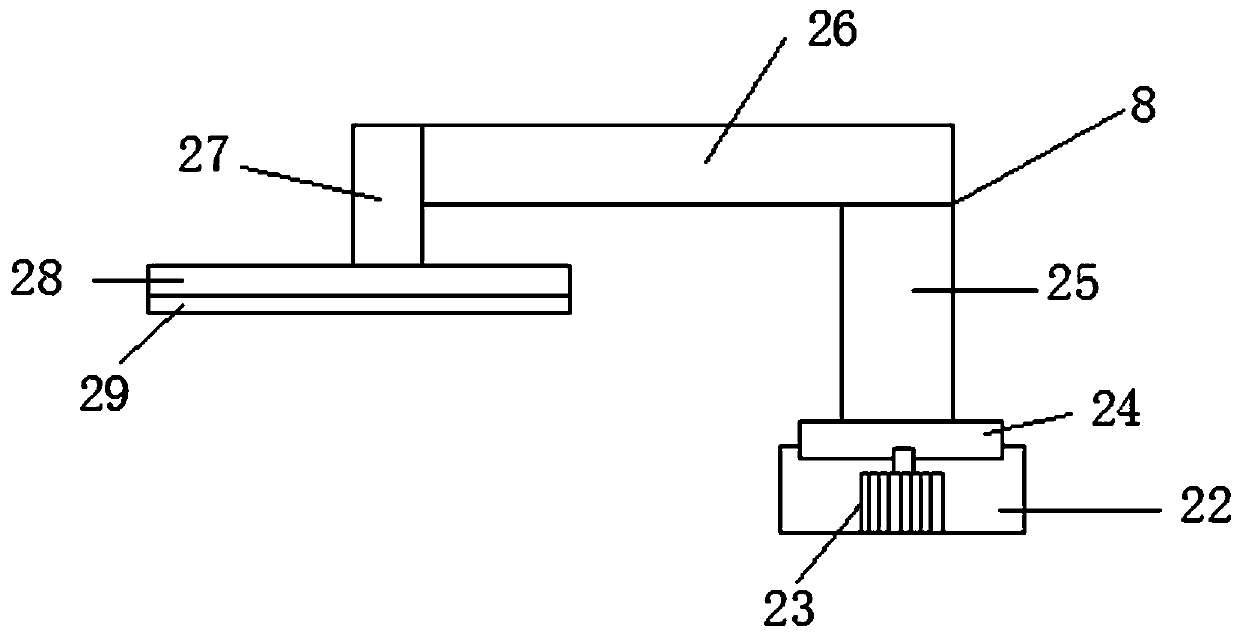

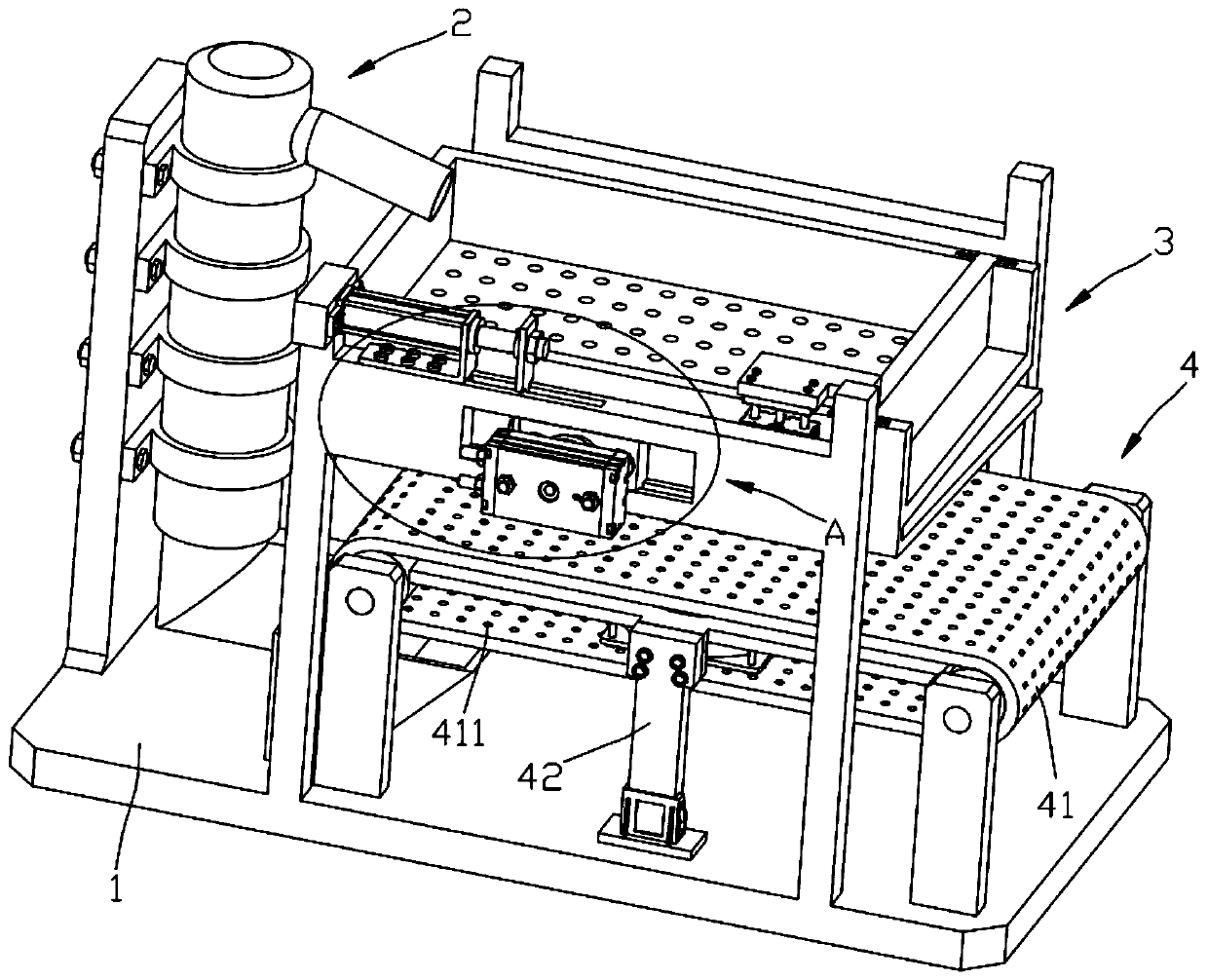

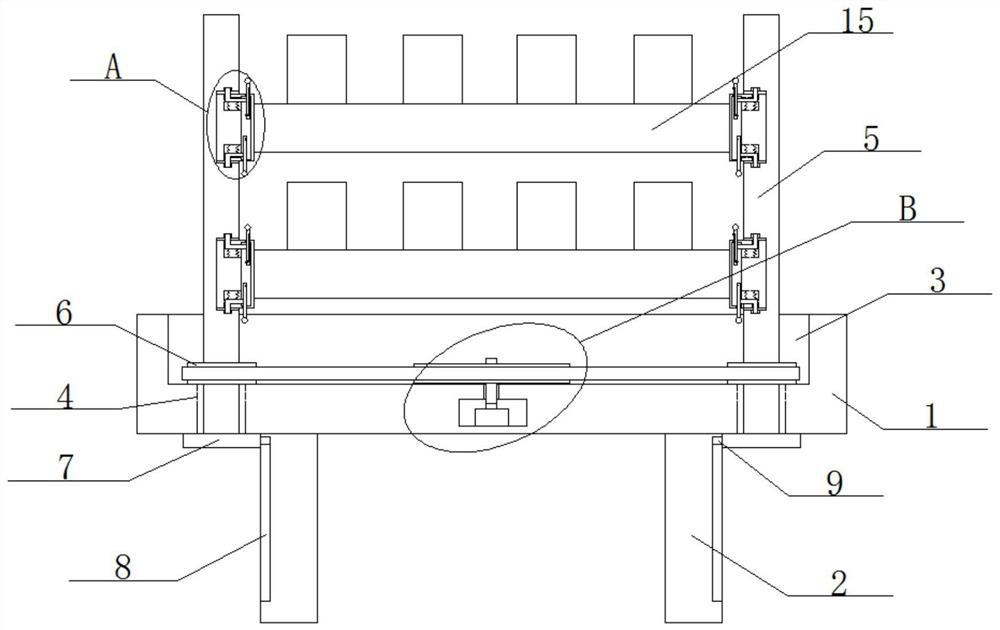

Composite material forming equipment

InactiveCN110815845AImprove securityEasy unloadingLiquid surface applicatorsCoatingsAdhesive glueManufacturing engineering

The invention relates to composite material forming equipment. The composite material forming equipment comprises a first supporting frame and a second supporting frame; the first supporting frame isarranged on the left side of the second supporting frame; a cross beam is fixedly connected between the first supporting frame and the second supporting frame, and is fixedly connected to the tops ofthe first supporting frame and the second supporting frame; the first supporting frame and the second supporting frame are fixedly connected with a supporting table through a reinforcing rod; supporting feet are fixedly connected to the bottom of the supporting table; the top of the supporting table is fixedly connected with a punching die table; a uniform applying device is arranged on the rightside of the punching die table; the right end of the first supporting frame is fixedly connected with a first hydraulic cylinder; the output end of the first hydraulic cylinder is fixedly connected with a first telescopic rod; and the right end of the first telescopic rod is fixedly connected with a glue storage box. The whole composite material forming equipment facilitates uniformly applying glue, rapid drying of the glue is facilitated, the automation degree of composite plate production is improved, the discharging after plate forming is facilitated, and the production efficiency is improved.

Owner:户玉珠

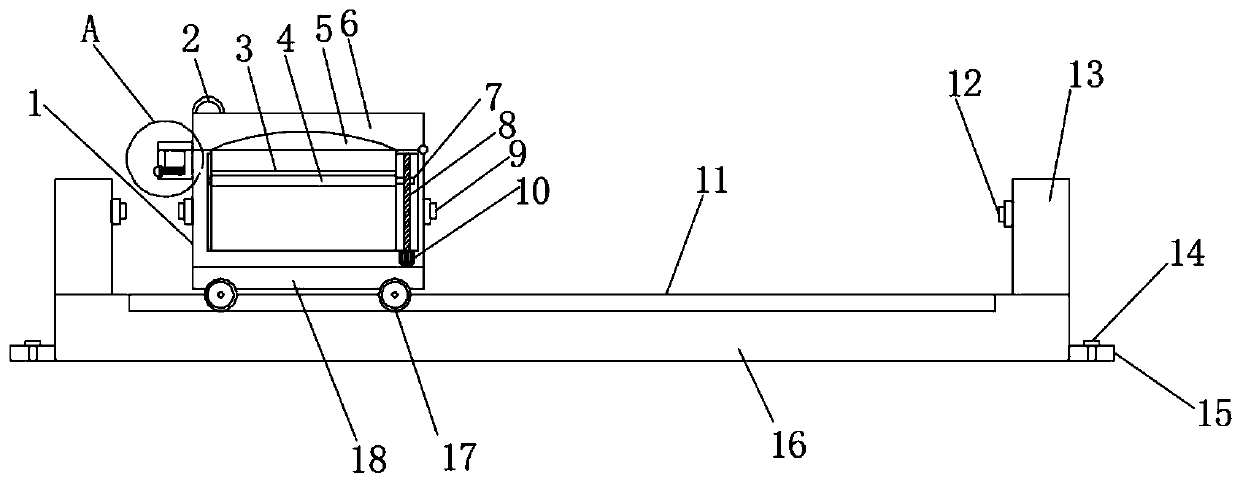

Intelligent unmanned transportation vehicle applied to workshops

ActiveCN110921229AHigh degree of intelligenceEasy unloadingMechanical conveyorsAutomotive engineeringAerospace engineering

Owner:聊城西科自动化设备有限公司

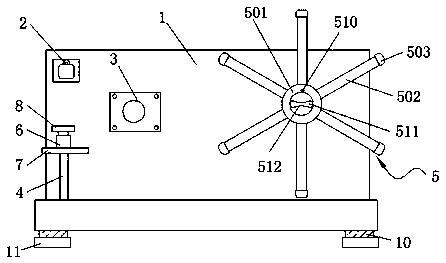

Tea leaf dewatering and air-drying device

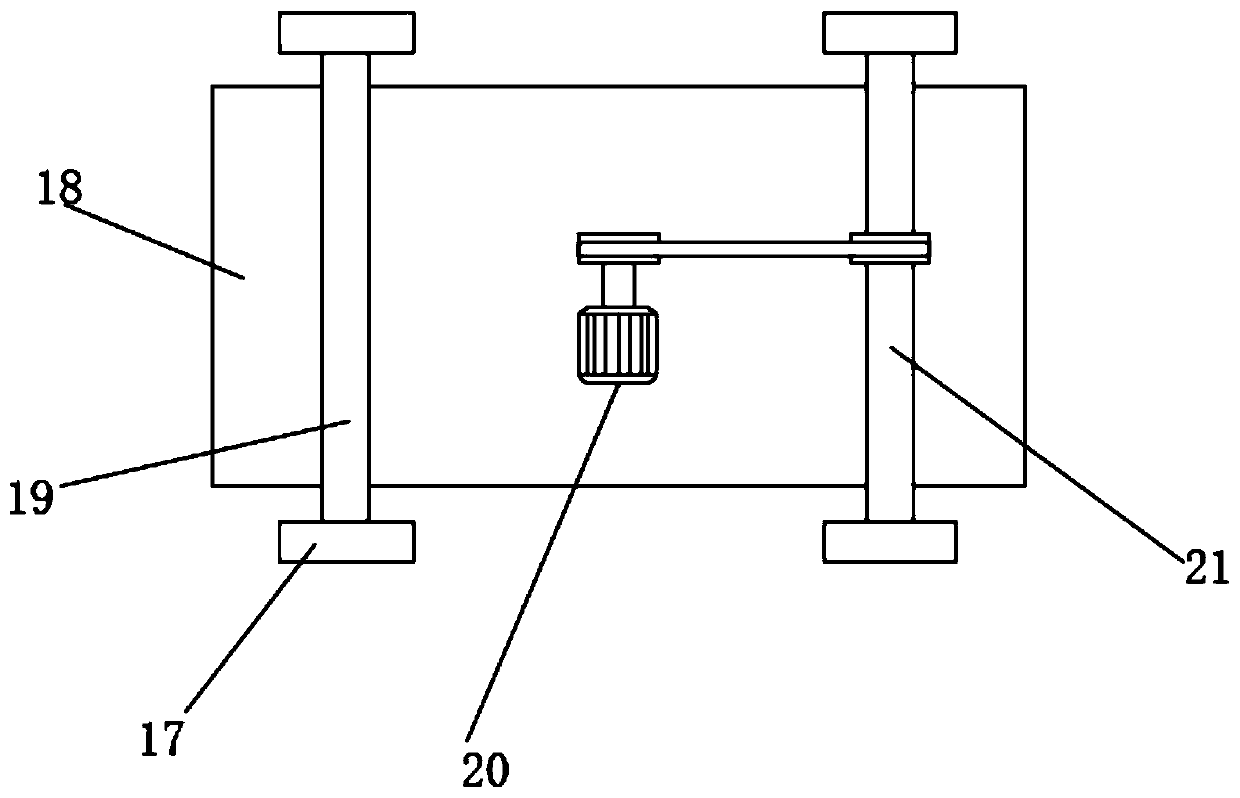

InactiveCN109974431AAccelerate moisture dryingEasy unloadingTea dryingDrying gas arrangementsEngineeringTea leaf

The invention provides a tea leaf dewatering and air-drying device which comprises a support frame, an elevating conveyer, a primary air-drying mechanism and a secondary air-drying mechanism. The elevating conveyer is fixedly arranged on the support frame; the primary air-drying mechanism comprises a water filtering tank, a sliding block, a baffle plate, a double-shaft air cylinder, a rotating aircylinder, a connecting plate and a single-shaft air cylinder; the water filtering tank is arranged on the support frame through the sliding block; the baffle plate is movably arranged in the water filtering tank through the double-shaft air cylinder; the rotating air cylinder is in power connection with the water filtering tank; the sliding block is in power connection with the single-shaft air cylinder through the connecting plate; the secondary air-drying mechanism comprises a conveyer belt, support legs, a bottom plate and a fan; the conveyer belt is arranged on the support frame; the bottom plate is arranged on the support frame through the two support legs; and the fan is arranged on the bottom plate. The sliding block is pulled back and forth through the single-shaft air cylinder soas to further drive tea leaves on the water filtering tank to shake back and forth and accelerate moisture air-drying, the rotating air cylinder drives the water filtering tank to rotate so as to realize convenience in unloading, and the fan aligns at the conveyer belt and blows air for drying.

Owner:淮南三创机器人科技有限公司

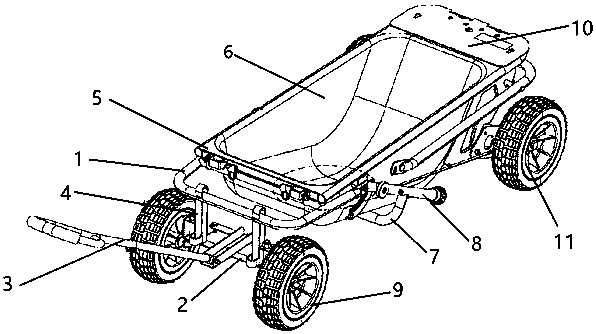

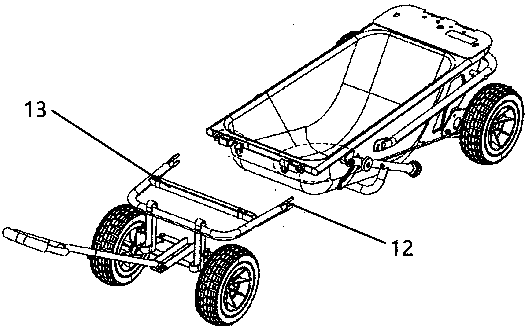

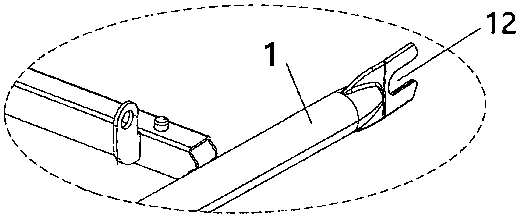

Mineral turnover car capable of discharging conveniently

InactiveCN108706025AEasy unloadingReduce labor intensityHand carts with multiple axesHand cart accessoriesTorsion springEngineering

The invention discloses a mineral turnover car capable of discharging conveniently. The mineral turnover car comprises a car hopper and a bottom frame. A discharge opening is formed in the car hopper,and the discharge opening is covered with a cover plate. Support lugs are formed on both side of the lower end of the cover plate, and support rods are formed on the side walls of the bottom frame. Hinged supports are formed on the support rods, and the support lugs are hinged to the hinged supports by hinged shafts. The hinged shafts are sleeved with torsion springs in an inserting mode, and thetwo ends of the torsion springs are separately fixed to the hinged shafts and the hinged supports. Spline holes are formed in one ends of the hinged shafts, and the spline holes are internally connected with spline shafts which are in spline fit with the spline holes in an inserting mode. Limiting plates are formed on the support rods, and one ends of the spline shafts penetrate through the limiting plates and folding plates are formed at the ends. The folding plates abut against the limiting plates in a pressing mode, and a plurality of inclined grooves are formed in the limiting plates around the spline shafts. Limiting holes corresponding to the inclined grooves are formed in the limiting plates, and hinge pins are connected into the limiting holes and the inclined grooves in an inserted mode. The mineral turnover car is capable of discharging minerals conveniently and reducing the labor intensity of staff.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Straw impurity removal device

InactiveCN107812706AGood effect of removing impuritiesEasy unloadingSievingScreeningDrive motorScrap

A straw impurity removal device, comprising a base, a guide rail, a first side plate, a second side plate, a roller, a conveyor belt, an annular filter, a motor, a mounting plate, a driving motor, a turntable, a positioning rod, a rocker arm, a half gear, Rack, limit rod, waist hole, control panel and waste guide plate, guide rails are installed on both sides of the top of the base, the guide rails on both sides of the top of the base are respectively installed with the first side plate and the second side plate, the first side plate The corresponding four corners of the second side plate are connected by rollers, and the joints of the rollers and the first side plate and the second side plate are all connected by bearing rotation, and the first side plate and the second side plate are symmetrical A conveyor belt is provided, and the conveyor belt is set on the outer side of the roller, and the outer side of the conveyor belt is set with an annular filter. The miscellaneous effect is good, and it is easy to unload, thereby improving the efficiency of impurity removal.

Owner:建始惠万农生物科技有限公司

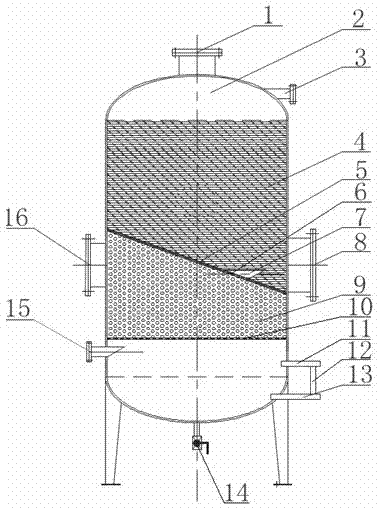

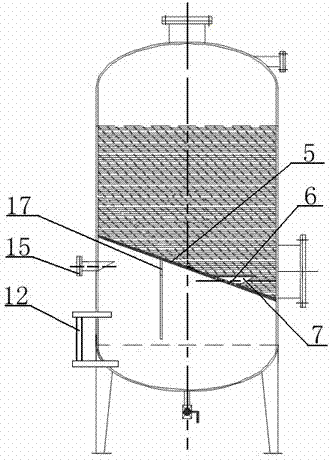

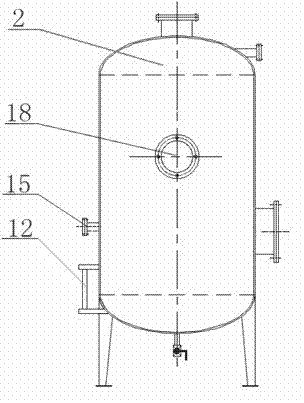

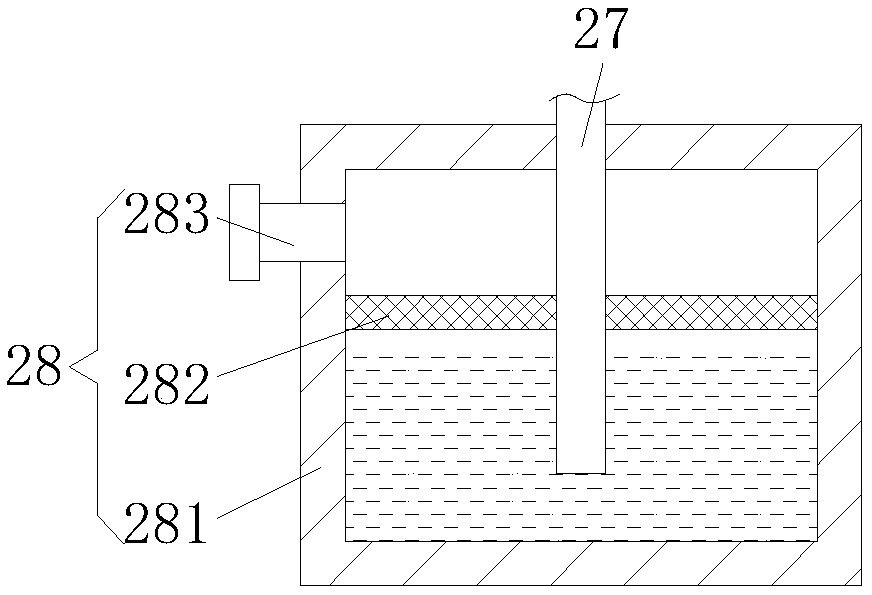

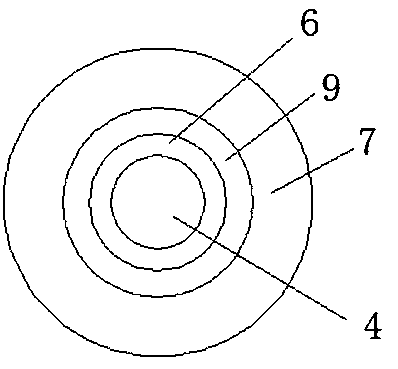

Desulfuration water filtering tower

ActiveCN102641662AEasy unloadingFast unloading speedDispersed particle filtrationGas passingFiltration

The invention discloses a desulfuration water filtering tower, belonging to a sulfurous gas desulfuration and dehydration purifying device. An aslant-arranged partition plate (5) is arranged between a desulfuration chamber (4) and a water filtering chamber (9), a gas passing channel (7) for communicating the desulfuration chamber (4) with the water filtering chamber (9) is arranged on the partition plate (5), and a discharging hole (8) is correspondingly arranged in the tank wall of the desulfuration chamber (4) at the lower end of the partition plate (5). A saturated desulfurizing agent can be immediately discharged more conveniently without local failure at a higher speed, and automatic management of feeding and discharging and control of continuous feeding and discharging of the desulfurizing agent are conveniently realized. The desulfuration water filtering tower has the advantages of simple structure, novel design, simpleness in processing and long service life, can be used for water filtration and desulfuration of methane, and can also be widely applied to a desulfuration and dehydration purification treatment process of various kinds of sulfurous gas.

Owner:湖北蓝焰生态能源有限公司

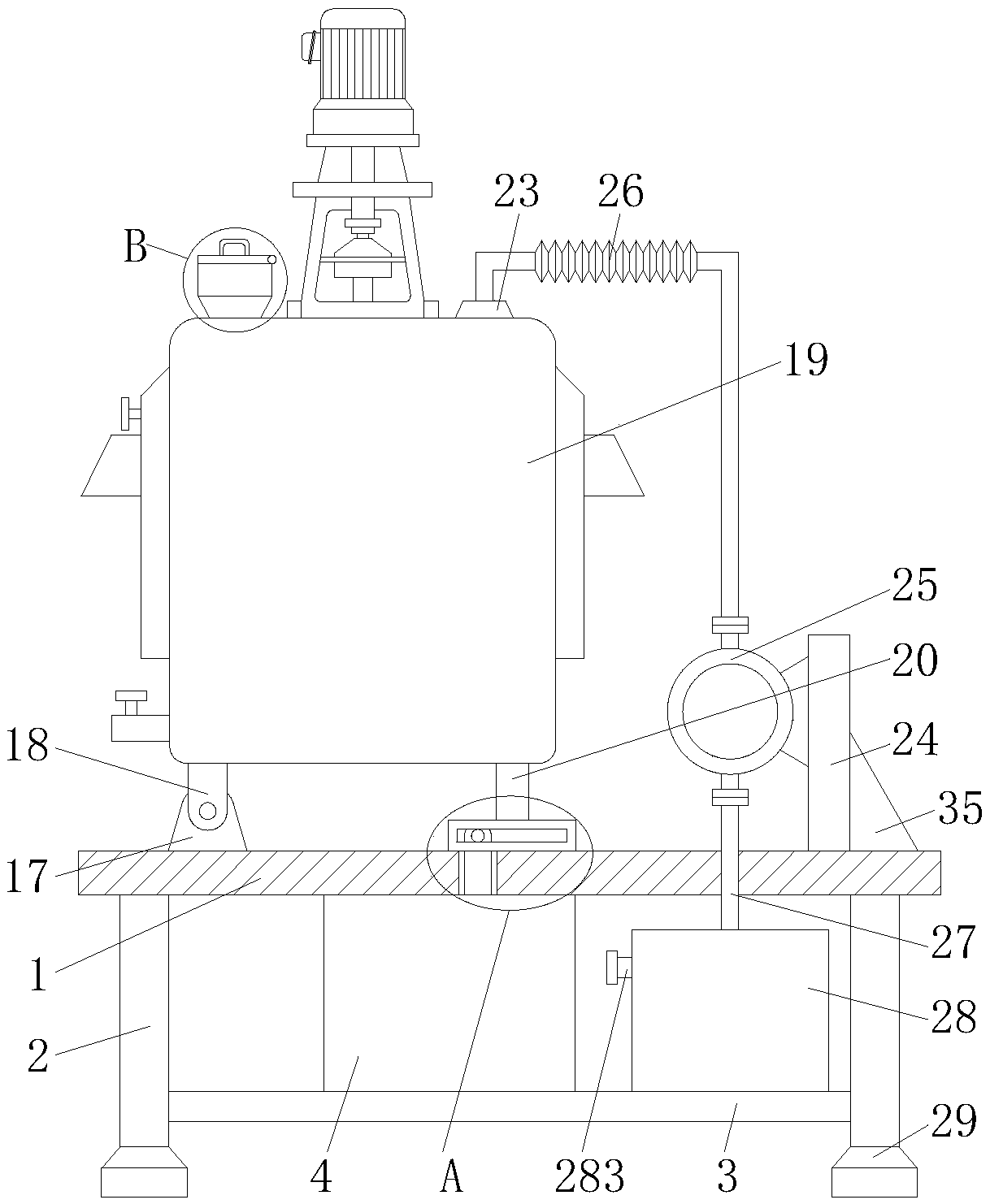

Mixing device for graphene waterproof paint

InactiveCN109499469AEasy unloadingShorten the timeRotary stirring mixersTransportation and packagingPetroleum engineering

The invention discloses a mixing device for a graphene waterproof paint. The mixing device comprises a bottom plate, wherein supporting legs are fixedly connected with the two sides of the bottom of the bottom plate; a cross plate is fixedly connected with the bottom of the inner side of each supporting leg; a box body is fixedly connected with the left side of the top of the cross plate. The mixing device solves the problem that the conventional mixing device is horizontally arranged and inconvenient for users to perform unloading through the matching of the bottom plate, the supporting legs,the cross plates, the box body, an air cylinder, a moving block, a connecting plate, a fixed block, a rotating plate, a connecting block, a transmission rod, a positioning rod, a positioning ring, atransmission frame, a top plate, a transmission column, a fixed seat, a moving plate, a mixing device, a supporting plate, a lifting frame, a feeding hopper, a dust hood, a vertical plate, an exhaustfan, an extension hose, an air pipe and a filtering mechanism, has the advantage of high convenience in unloading, saves a large amount of time for the users, and improves the practicability.

Owner:饶玉明

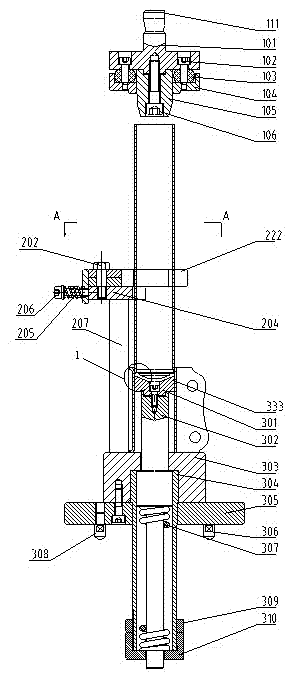

Vertical pumping anti-backflow controlling device and using method

PendingCN110608299AEasy unloadingEasy to disassemble and cleanHollow article cleaningCheck valvesBackflowControl engineering

The invention discloses a vertical pumping anti-backflow controlling device, and belongs to the field of concrete construction auxiliary devices. According to the device, an anti-backflow structure isarranged in a pumping pipe, the anti-backflow structure comprises a fixing seat, a guiding seat and a baffle, wherein the fixing seat is fixedly connected to the middle of the pumping pipe, a fixingsleeve is fixedly connected to the fixing seat, a first spring is arranged in the fixing sleeve, the guiding seat is fixedly connected to the inner wall of the pumping pipe, a through hole is formed in the middle of the guiding seat, the baffle is arranged in the through hole, a sleeve is fixedly connected to the baffle, the sleeve is movably connected to the outer side of the fixing sleeve, the baffle located in the sleeve is connected with the first spring located in the fixing sleeve, an adapter pipe is detachably connected to the discharging port of the pumping pipe and communicates with the pumping pipe, a door plate is hinged to the bottom of the adapter pipe, and the top of the adapter pipe extends into a steel pipe column. The device is reasonable in structure, convenient to use and safe and reliable, and it is guaranteed that after a vertical pump stops mechanical operation, the influence of backflow cannot be generated under the action of gravity.

Owner:CHINA MCC17 GRP

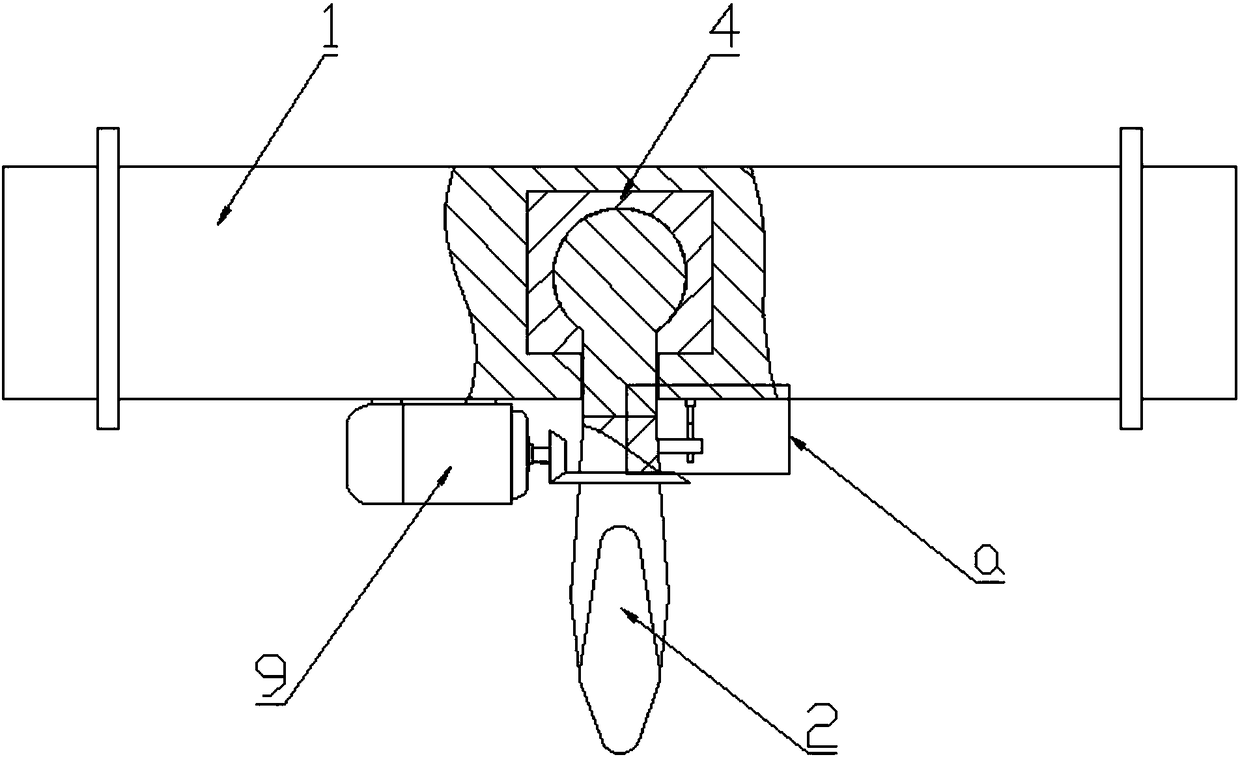

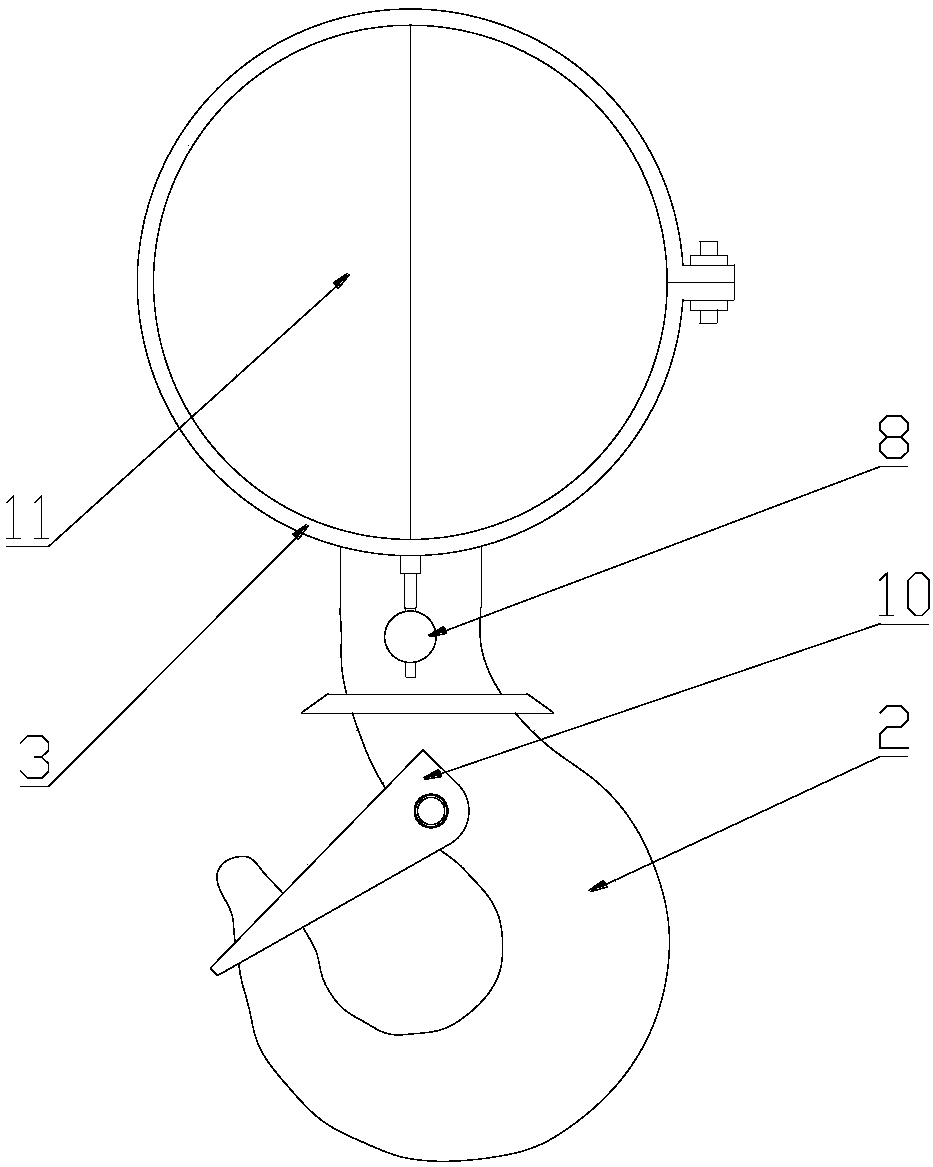

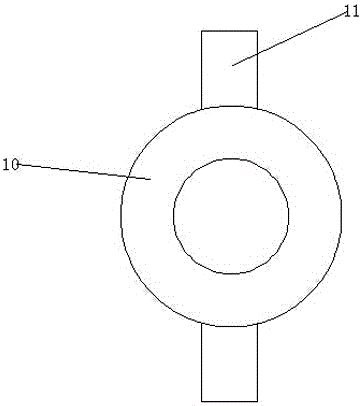

Rotary combined lifting sling for metallurgy

InactiveCN108100859AEasy unloadingPrevent the hook from swingingLoad-engaging elementsEngineeringHeavy load

The invention discloses a rotary combined lifting sling for metallurgy. The combined lifting sling comprises a balance beam, wherein a ball joint is arranged in the balance beam, a ball pin of the ball joint extends out of the balance beam to be connected with a lifting hook, a lifting hook rotating motor is arranged on the balance beam, an output end of the lifting hook rotating motor is connected with a hook handle of the lifting hook through a bevel gear pair, and a rotary locking mechanism is arranged between the lifting hook and the balance beam. The combined lifting sling has the benefits that after the lifting sling lifts a weight to an assigned place, the lifting hook rotating motor can drive the lifting hook to rotate to adjust the angle of the lifting sling, and discharging is facilitated; the rotary locking mechanism is arranged between the lifting hook and the balance beam, so that the lifting hook can be prevented from swinging in the lifting process by the aid of the rotary locking mechanism, and the lifting safety is improved.

Owner:CHONGQING CRANE WORKS

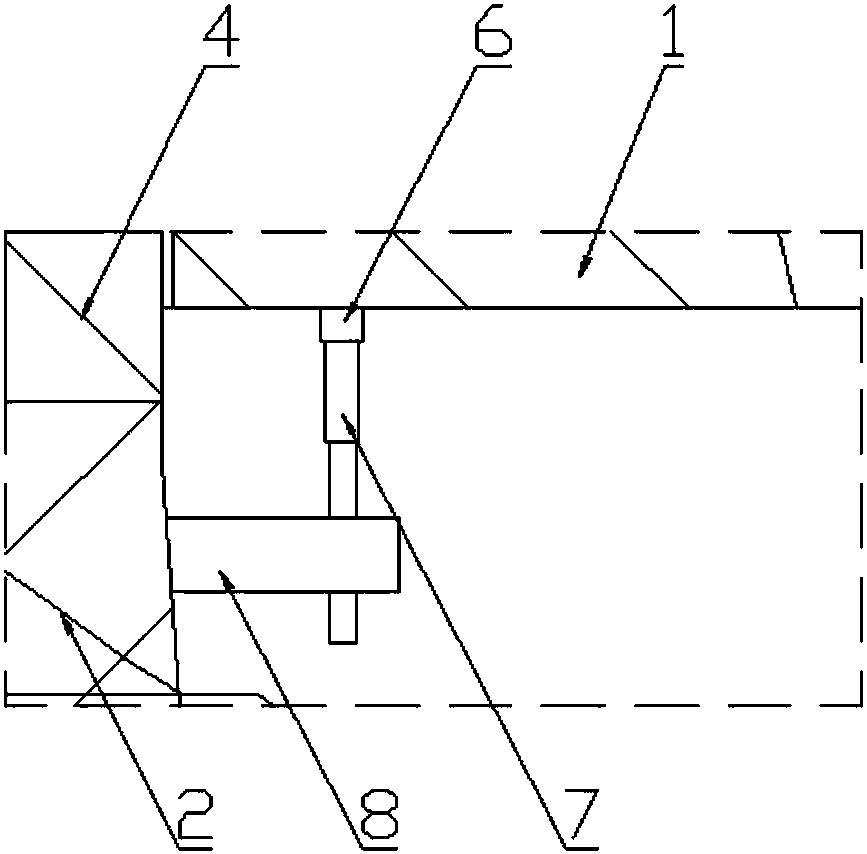

Loading and unloading dual-purpose mechanical arm

InactiveCN106393093AEasy loadingEasy unloadingProgramme-controlled manipulatorEngineeringDual purpose

The invention discloses a loading and unloading dual-purpose mechanical arm. The loading and unloading dual-purpose mechanical arm comprises a base of a hollow structure. An electromotor is mounted on the inner wall of the top of the base. The outer wall of one side of the base is connected with a screw rod through a bearing. The screw rod is located below the electromotor. The screw rod extends into the base. The screw rod is in transmission connection with an output shaft of the electromotor through a belt. The outer wall of the screw rod is provided with two grooves. The two grooves are located on the outer side of the base. The two grooves are in axial symmetry. The symmetry axis of the two grooves is the diameter of the screw rod. A mother rod of a hollow structure is rotatably connected to the end, far from the base, of the screw rod. A son rod is slidably mounted in the mother rod. An iron hook is connected to the end, far from the mother rod, of the son rod. The loading and unloading dual-purpose mechanical arm has a loading state and an unloading state and can be freely switched between the loading state and the unloading state. The investment cost of loading and unloading is lowered in different forms, and the time is saved.

Owner:NANLING ZINGIBER MIOGA ROSE IND ASSOC

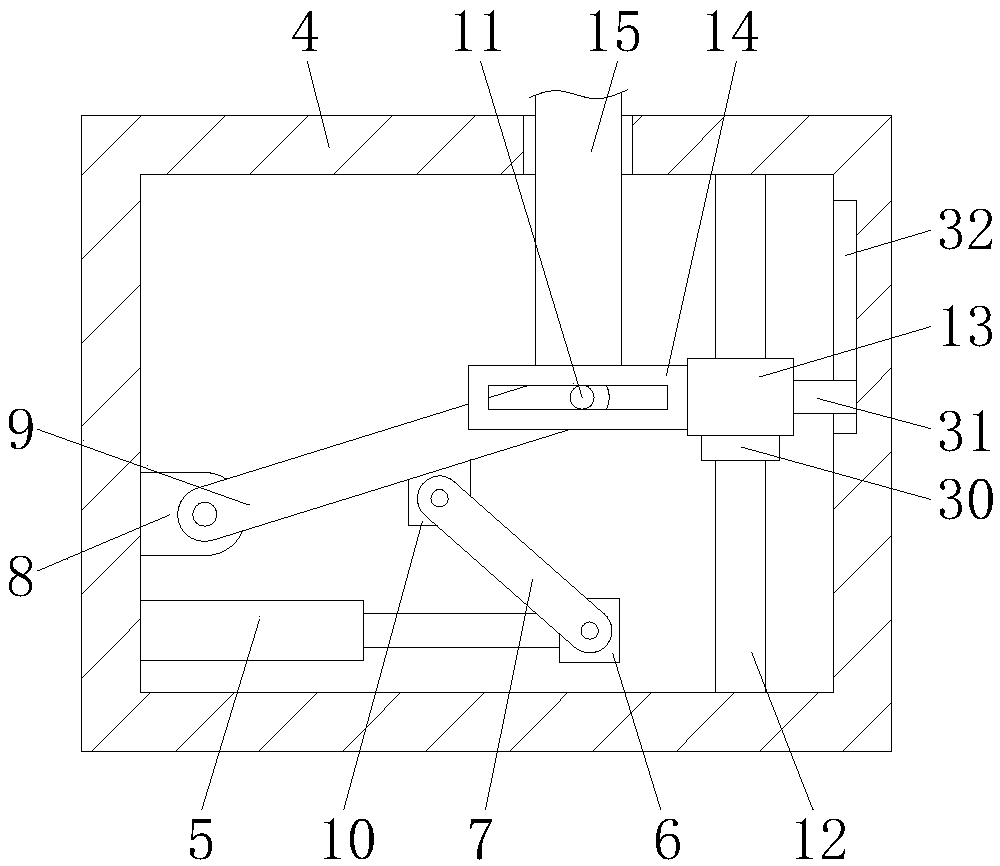

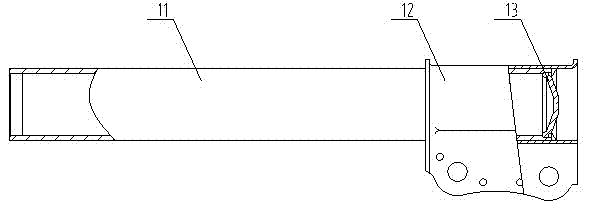

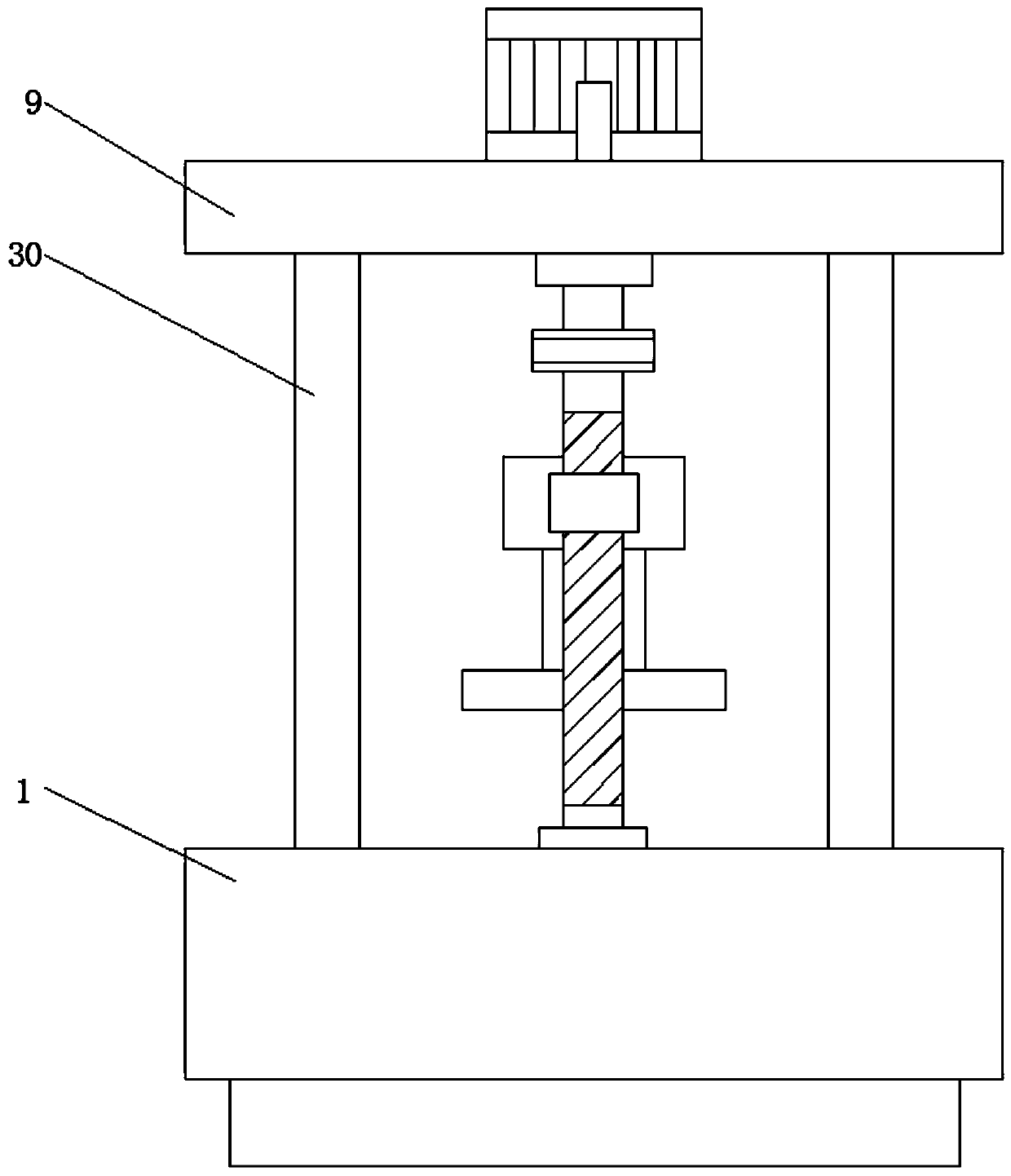

Liquid storage cylinder sub-assembly press fitting whole port assistive tool

ActiveCN103170844AMeet the requirements of the drawingImprove consistencyOther manufacturing equipments/toolsSEMI-CIRCLEEngineering

The invention discloses a liquid storage cylinder sub-assembly press fitting whole port assistive tool. A whole port pressure head sub-assembly comprises a linkage head, discharging bolts, a discharging rubber board and a discharging block. A notch for placing of the discharging rubber board is formed in the upper surface, opposite to the linkage head, of the discharging block, and the discharging rubber board is placed in the notch and is tightly pressed through the discharging bolts. A clamping block sub-assembly comprises a semi-circle enclasping block, clamping boards used for clamping the semi-circle enclasping block, a mounting board and a stand column. The clamping boards playing a role in fixing are arranged on outer side faces of the mounting board and the semi-circle enclasping block, and tightening adjusting screws with spiral retainer springs are arranged on outer sides of the clamping boards. A lower positioning seat sub-assembly comprises a positioning seat, a guide seat, a guide column and a guide sleeve. A compression spring is arranged on the guide column in a sleeved manner, and the guide sleeve is arranged on the external of the guide column. According to the liquid storage cylinder sub-assembly press fitting whole port assistive tool, dimensions of press-fit products meet requirements determined on a chart, consistency is good, material taking and discharging are easy, and production efficiency is greatly improved; and in the press fitting process, labor intensity of workers is greatly lightened.

Owner:隆昌山川机械有限责任公司

Injection molding equipment capable of realizing accurate shaping

The invention belongs to the field of injection molding equipment, in particular to injection molding equipment capable of realizing accurate shaping. Aiming at overcoming the defects of injection molding equipment in the current market that the descending height of an upper injection molding body cannot be accurately controlled, so that an injection mold is inconvenient to unload, and the injection molding equipment is not flexible enough, the following scheme is proposed. The injection molding equipment capable of achieving accurate shaping comprises a lower injection molding body, a lower injection molding groove is formed in the lower injection molding body, rectangular grooves are symmetrically formed in the lower surface of the lower injection molding groove, an injection molding pipe is arranged between the lower injection molding groove and the rectangular grooves, and the injection molding pipe is fixedly connected with the lower injection molding body. According to the injection molding equipment, the moving position of the upper injection molding body can be accurately controlled, the defects of the equipment are overcome, the injection molding equipment can be conveniently unloaded, the flexibility of the injection molding equipment is improved, a push plate and two push rods can be restored to the original state, and an injection molding object can be convenientlyunloaded next time.

Owner:深圳市人和智聚科技开发有限公司

Yarn length measuring instrument facilitating unloading of yarns

The invention provides a yarn length measuring instrument facilitating unloading of yarns, and relates to the field of textiles. The yarn length measuring instrument comprises a frame, and the bottomof one side of the frame is provided with a yarn tube frame. A part, located above the yarn tube frame, of the front surface of the frame is provided with a yarn guide frame and a tension rod. A side,far from the yarn tube frame, of the front surface of the frame is provided with a yarn frame, and the yarn frame is provided with a rotary drum in rotating connection with the frame. The outer frameof the rotary drum is in plugging connection with a connecting rod, and an end part of the connecting rod is connected with a winding rod. Before the length measurement, a twisting handle is rotatedto control an arc block to make contact with and press an end block, and bolts are inserted into two jacks, so as to fix the yarn length measuring instrument. The operation is quick. After the yarn measurement, only the twisting handle needs to be rotated to control the end block to be separated from the arc block during yarn unloading, and the connecting rod is driven by a spring to get close tothe rotary drum, thereby enabling the external diameter of the yarn frame to decrease, and facilitating the taking-down of the tensioned yarns. The operation is simple and convenient, and the practicality is good.

Owner:江苏腾旺化纤有限公司

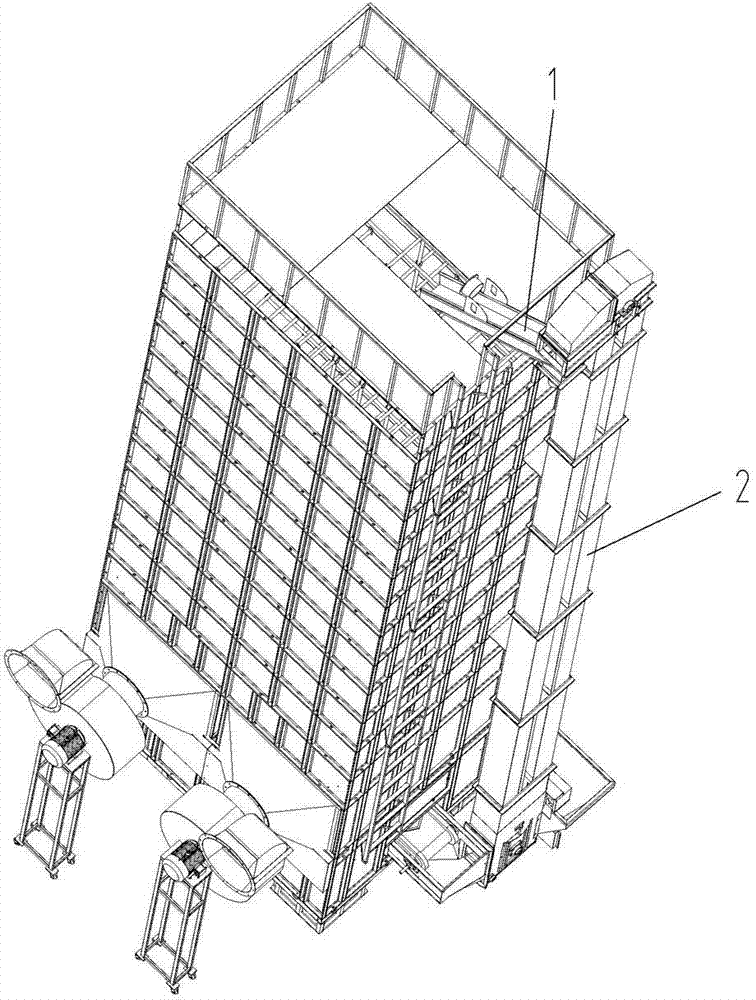

Blanking mechanism of circulating-type grain drying machine

InactiveCN103072827AEasy unloadingRealize the unloading functionLoading/unloadingEngineeringMechanical engineering

The invention relates to a blanking mechanism of a circulating-type grain drying machine. The circulating-type grain drying machine comprises a circulating conveying mechanism and a blanking mechanism arranged at a discharge port on the top of the circulating conveying mechanism. The blanking mechanism comprises a hopper and a blanking slope and is characterized in that the bottom of the hopper is further provided with a discharge opening; and a switching baffle plate is arranged between the hopper and the blanking slope. The blanking mechanism has a blanking function and a discharging function; and compared with discharging mechanisms, the blanking mechanism provided by the invention can be used for directly discharging grains onto a carriage, and is convenient, time-saving and labor-saving in discharging.

Owner:余继琅

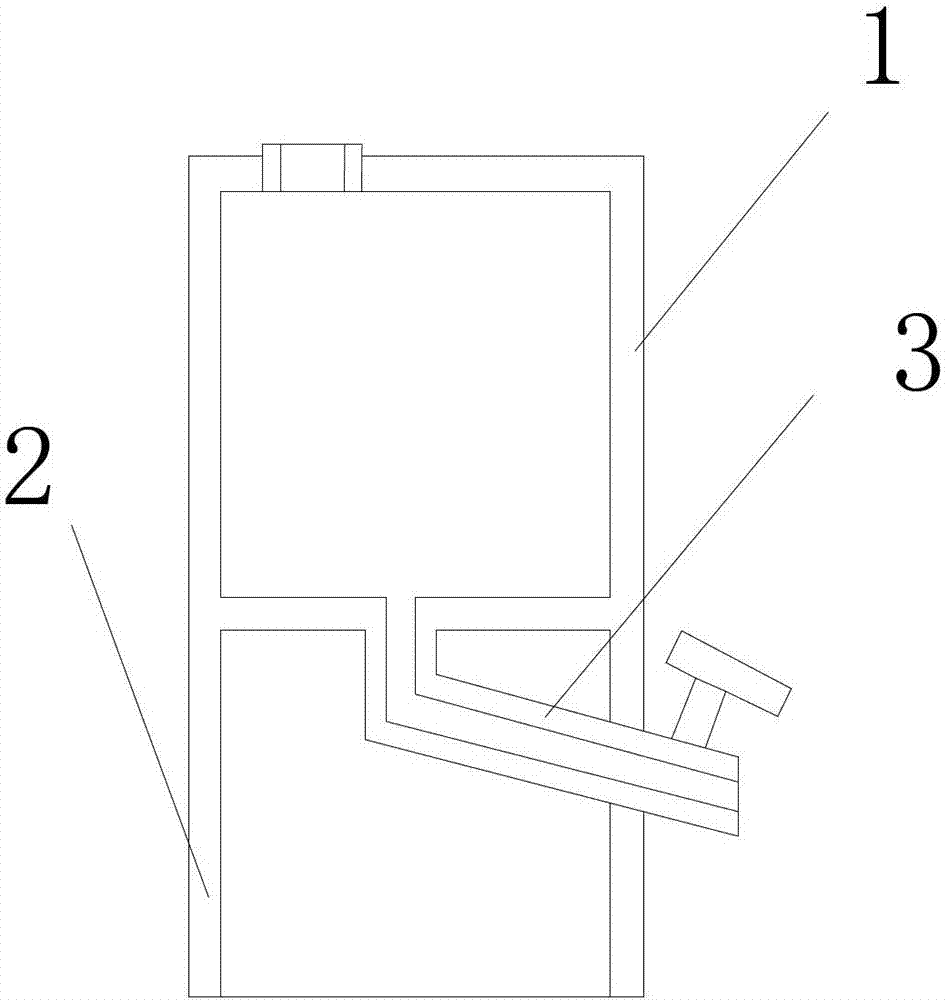

Cargo distribution device for logistics

InactiveCN112356902AEasy unloadingIncrease operating spaceHand carts with multiple axesHand cart accessoriesElectric machineryDrive motor

The invention discloses a cargo distribution device for logistics. The cargo distribution device comprises a distribution base, a pushing handle and a moving assembly. A cargo storage frame is arranged on the distribution base, a placing assembly is arranged in the cargo storage frame, and the placing assembly comprises a U-shaped placing plate, a power assembly and a transverse moving assembly; the transverse moving assembly comprises a transverse mounting frame and a transverse driving motor; and the power assembly comprises a fixing base fixedly installed on the driving sliding block and adriving air cylinder. By arranging the cargo storage frame, the transverse driving motor, the driving air cylinder and the U-shaped placing plate, when the whole device is in a standing state and cargoes need to be unloaded, the transverse driving motor drives the fixing base to extend out of the cargo storage frame under the mutual matching action of the rotating lead screw, the driving sliding block and the sliding groove; and under the action of the driving cylinder and the supporting connecting rod, the U-shaped placing plate is driven to incline around the fixed rotating seat so that cargoes are convenient to unload and transport.

Owner:费红英

Material barrel convenient for discharging for chemical engineering

InactiveCN102963582AEasy unloadingEasy to unloadCans/barrels/drumsExternal fittingsCompound (substance)Engineering

The invention relates to a material barrel convenient for discharging for chemical engineering. The material barrel is provided with a barrel body, wherein a feed opening is formed in the upper end of the barrel body; the outer wall of the barrel body downwards extends to form a barrel cover; a discharging pipe is connected to the lower end face of the barrel body and extends out of the side wall of the barrel cover; a valve is arranged on the discharging pipe positioned outside the barrel cover; and the discharging pipe is obliquely connected with the lower end face of the barrel body. According to the provided novel material barrel, the discharging pipe is arranged at the lower end of the barrel body and is convenient for discharging of the material barrel; discharging can be conveniently finished by opening the valve on the discharging pipe; and the barrel cover extending at the lower end of the barrel body can effectively protect the discharging pipe from being cracked by an foreign object.

Owner:ZHANGJIAGANG JINTENG CHEM MACHINERY MFG

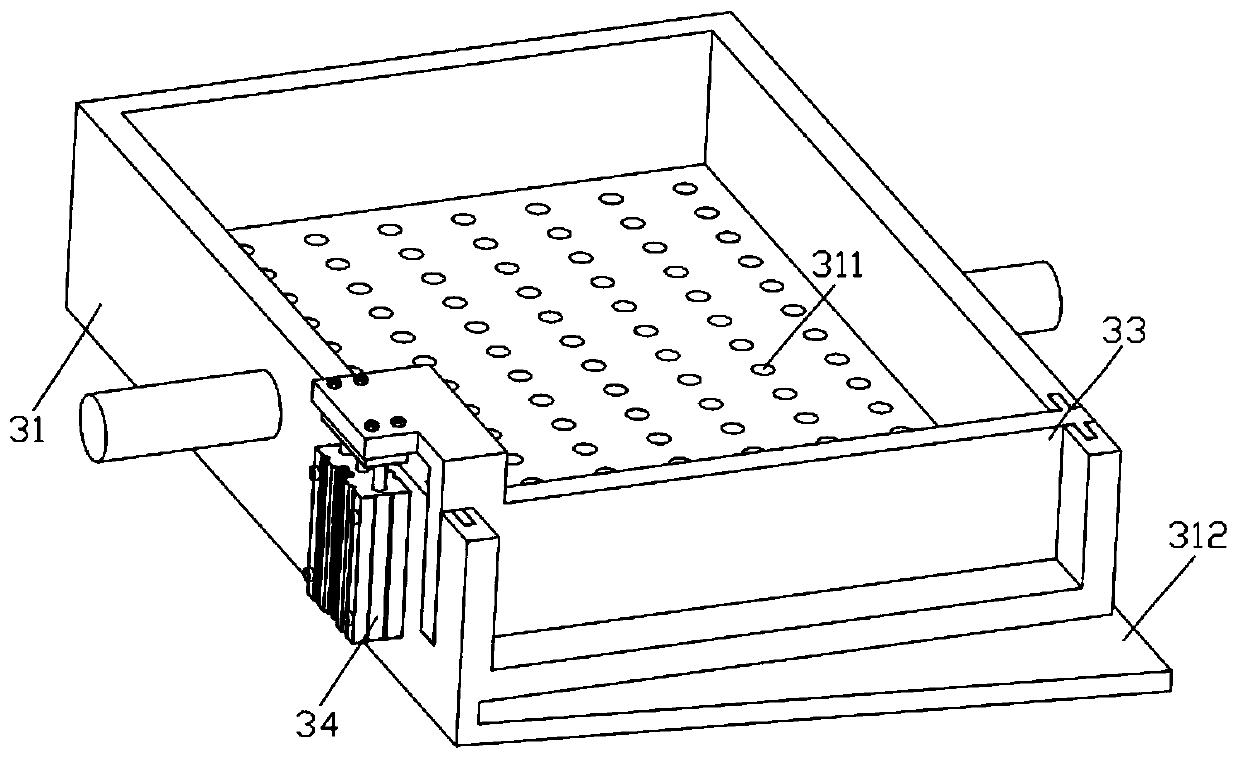

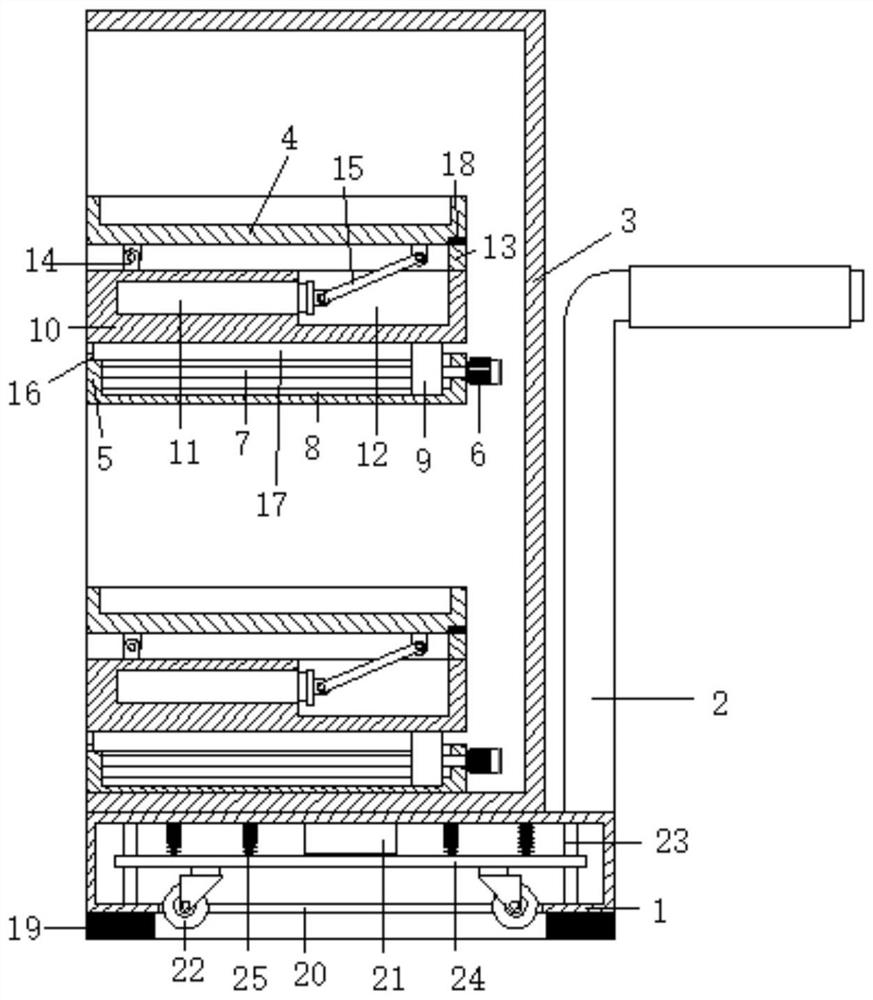

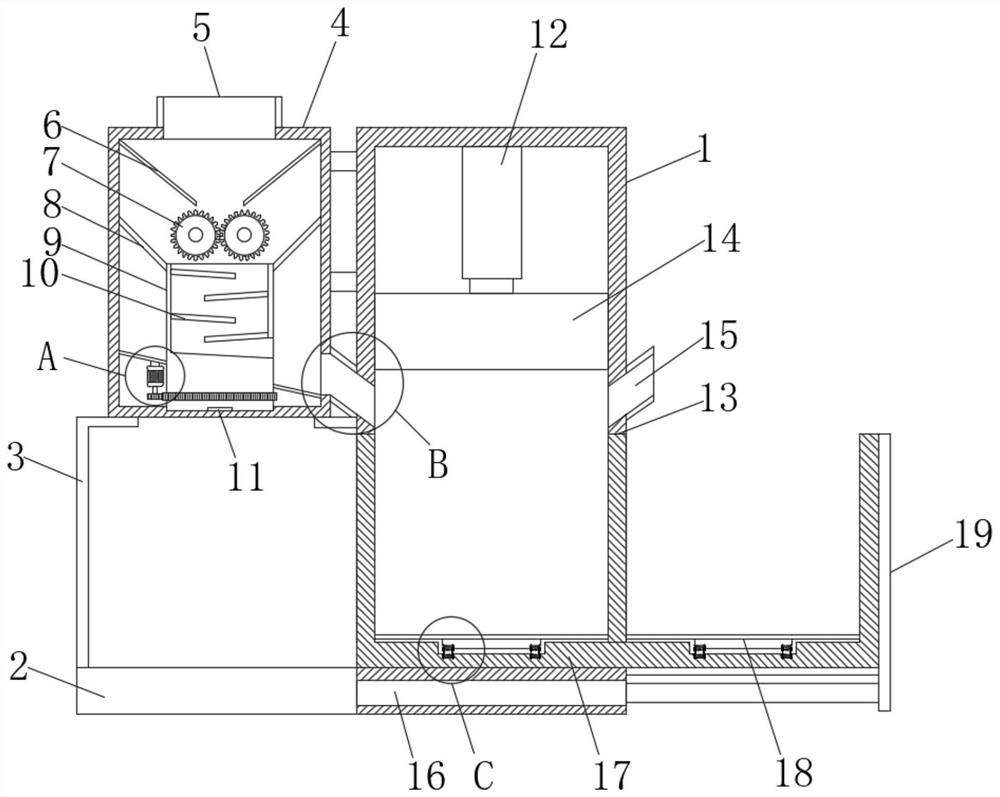

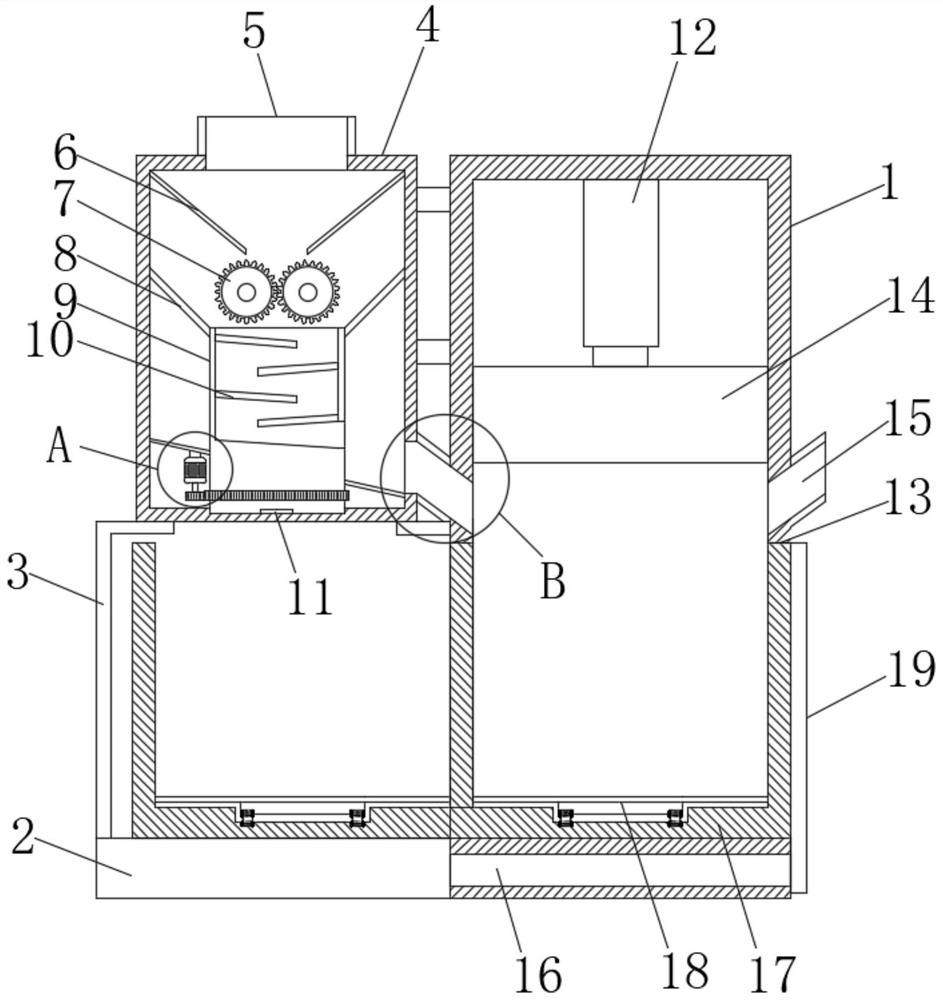

Industrial solid waste agglomeration device

InactiveCN112452423AEasy unloadingAchieve recyclingGrain treatmentsPressesProcess engineeringContinuous type

The invention discloses an industrial solid waste agglomeration device. The industrial solid waste agglomeration device comprises a machine body, a bottom plate and a smashing box. The machine body isof a hollow cuboid structure, a transversely-through discharging channel is formed in the lower end of one side face of the machine body, and the bottom plate is welded and fixed to the position, below the discharging channel, of the side face of the machine body. The upper end face of the bottom plate is flush with the bottom end face of the discharging channel, a sliding frame is arranged at the upper ends of the bottom plate and the discharging channel, a support is welded to the side, away from the machine body, of the upper end face of the bottom plate, a supporting plate is welded to the side face, close to the bottom plate, of the machine body and located above the discharging channel, and the smashing box is fixed to the top ends of the support and the supporting plate. One side surface of the smashing box is welded and fixed to the side surface of the machine body through supporting rods. According to the industrial solid waste agglomeration device, continuous agglomeration is achieved, shutdown for use is not needed, discharging is convenient after agglomeration is completed, meanwhile, iron-containing impurities in waste can be filtered out during agglomeration, and theagglomeration quality is prevented from being affected.

Owner:谢海胜

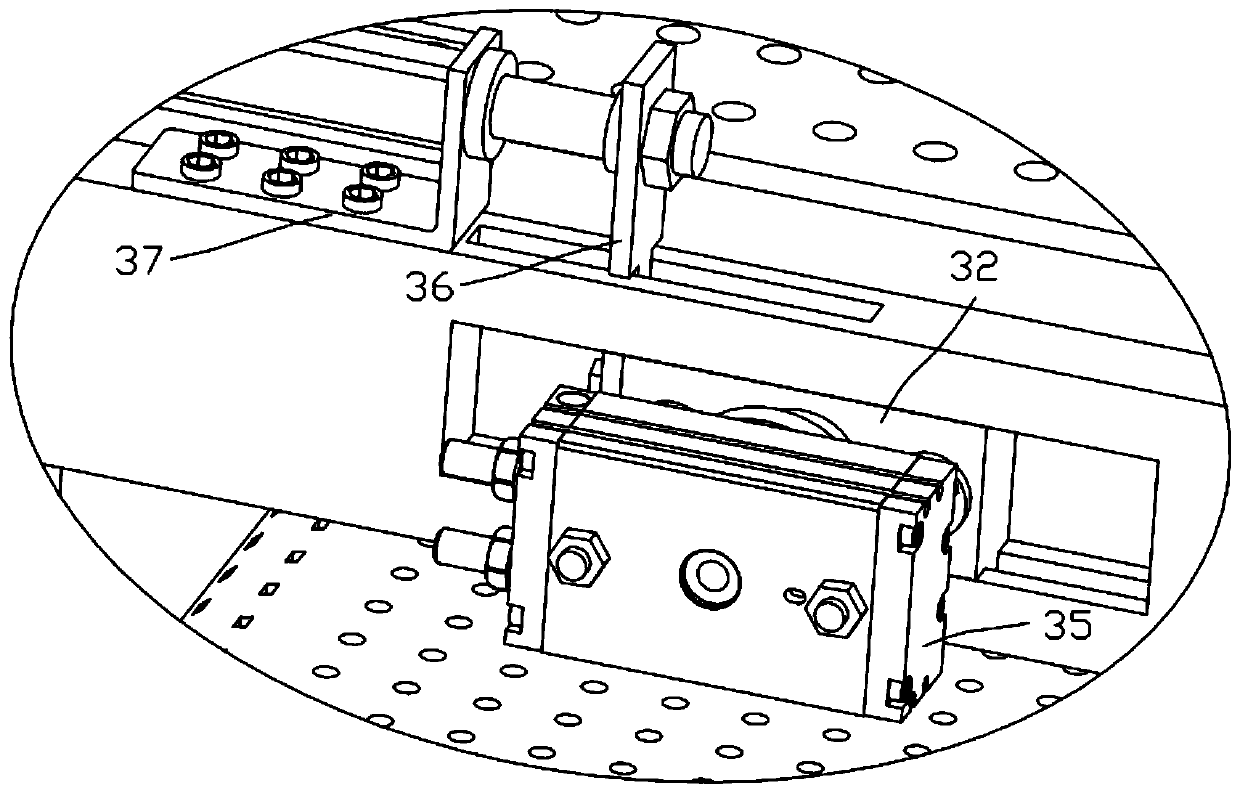

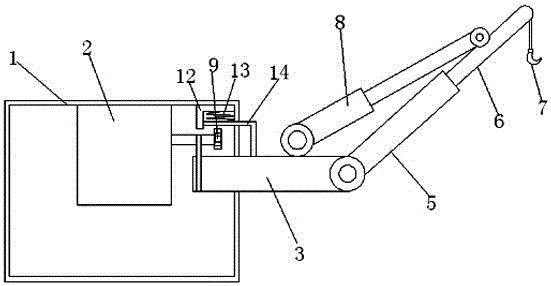

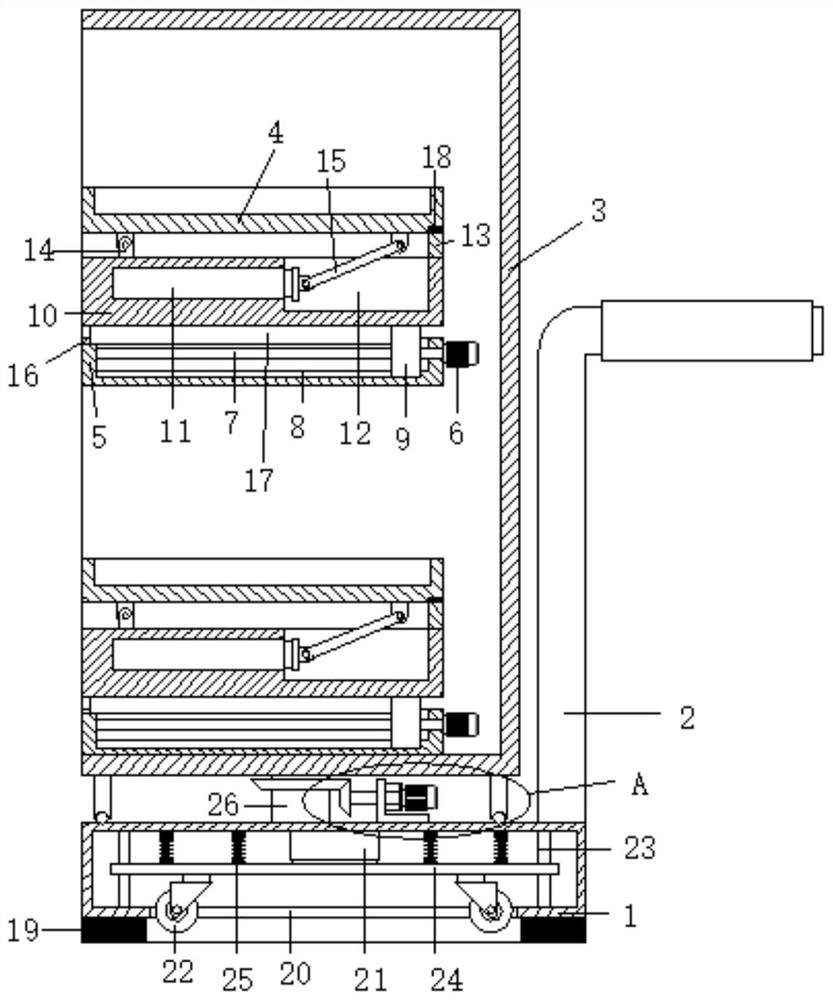

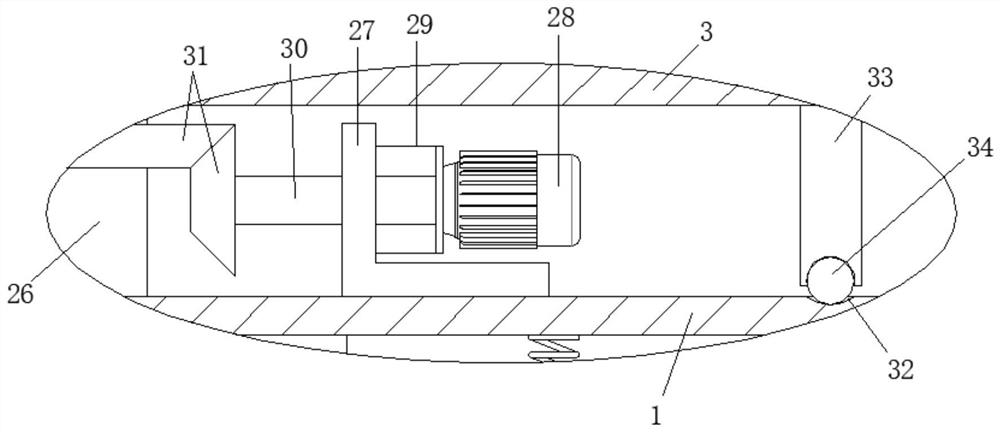

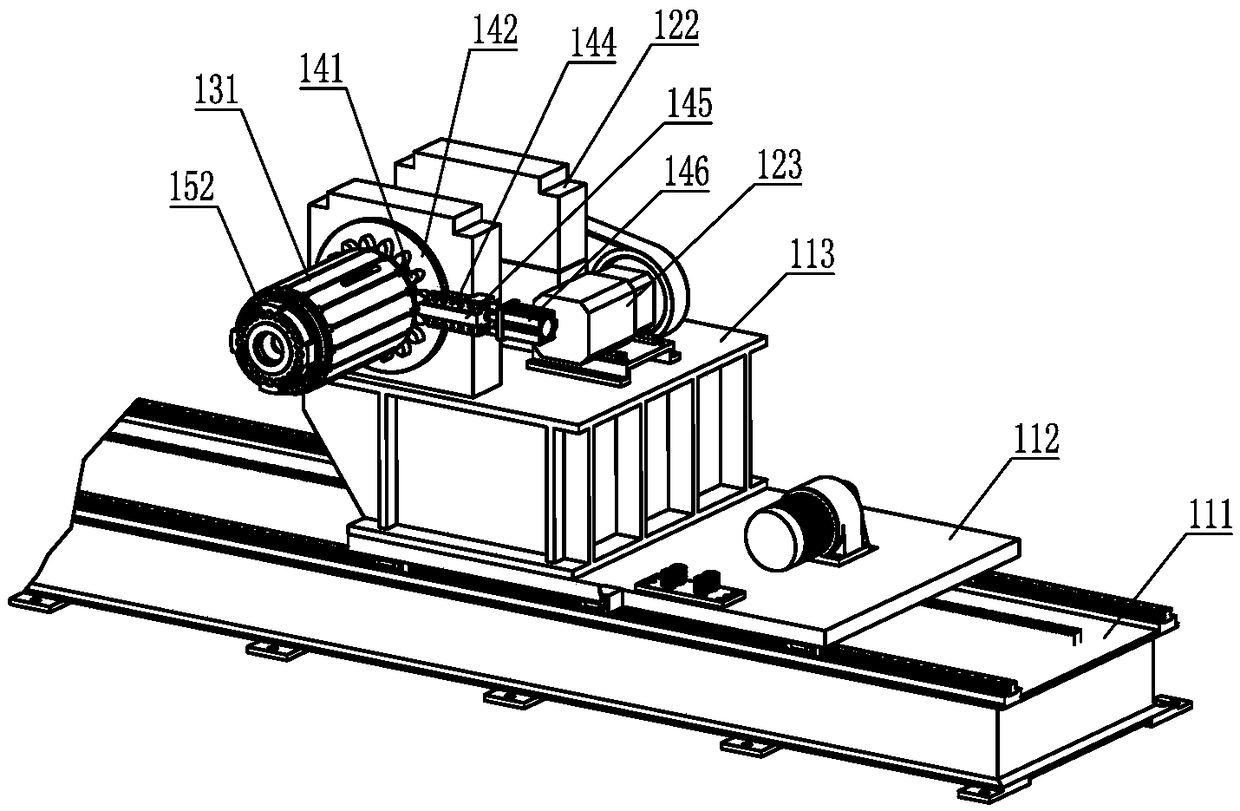

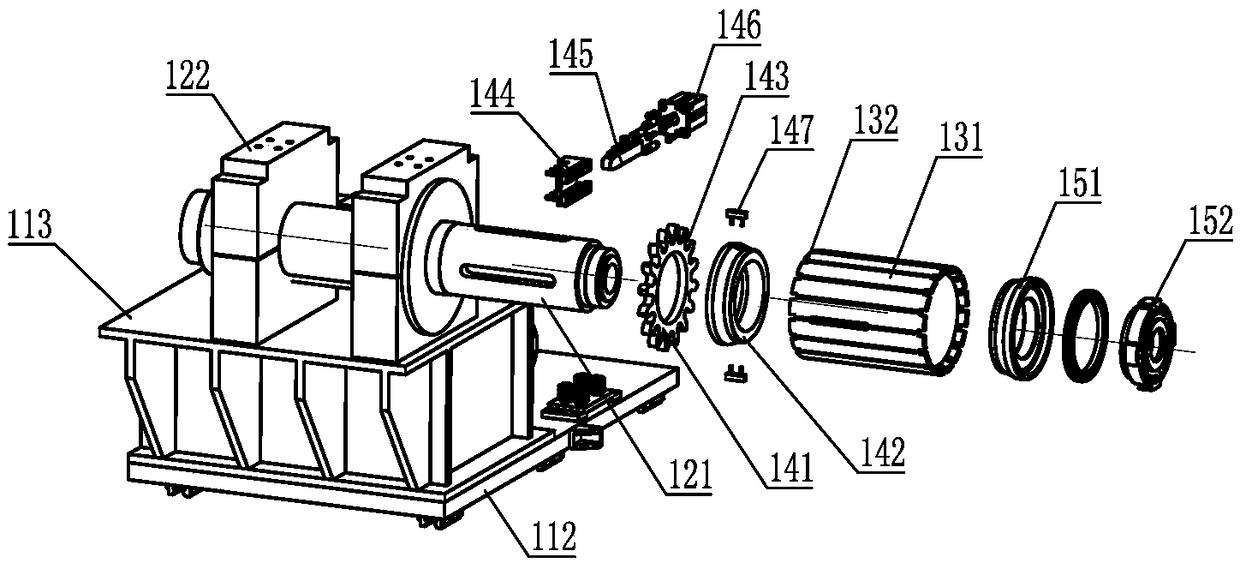

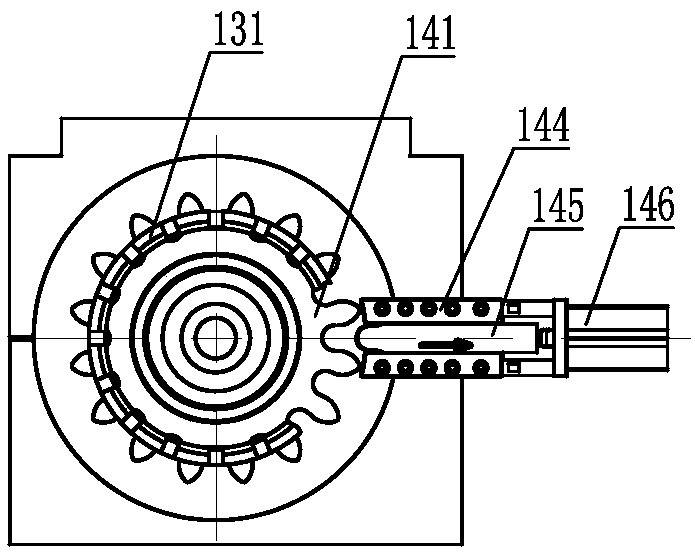

Amorphous thin strip winding machine

PendingCN109466952AImprove automatic work performanceEasy to unloadWebs handlingWinding machineEngineering

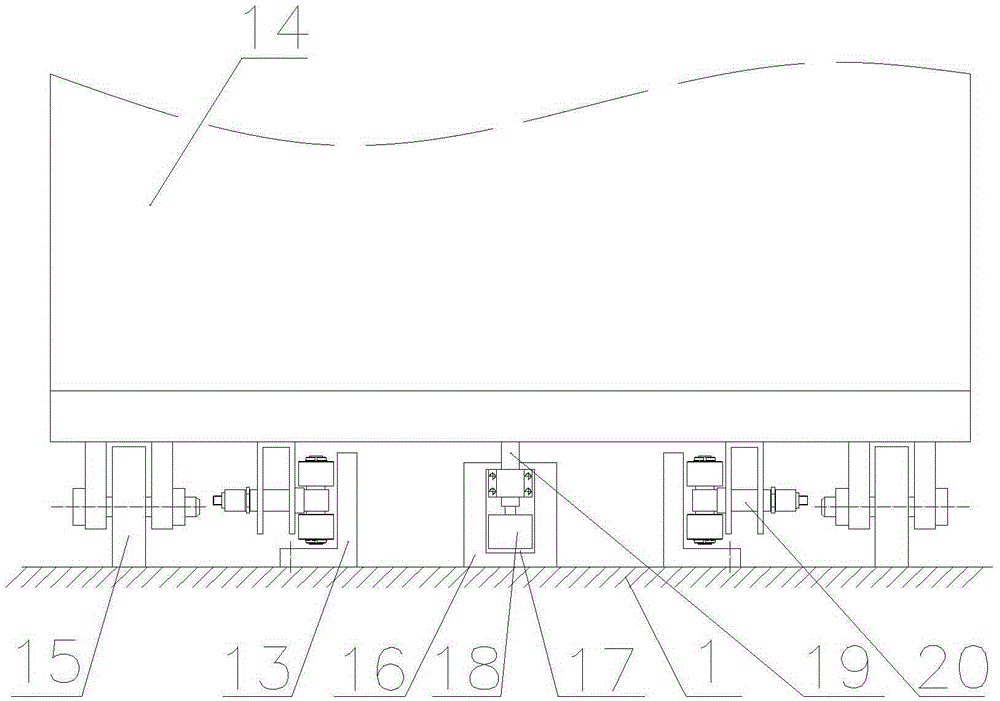

The invention discloses an amorphous thin strip winding machine. The amorphous thin strip winding machine comprises a winding guide rail base; a winding pedestal is slidably installed on the winding guide rail base; a winding base is installed on the winding pedestal; a winding main shaft seat is installed on the winding base; a winding main shaft is rotationally installed on the winding main shaft seat; one end of the winding main shaft is in transmission connection with a winding rotation driving device; a roll core is installed on the winding main shaft; an indexing positioning device is installed between one end of the roll core and the winding main shaft; a roll core locking device is installed between the other end of the roll core and the winding main shaft; the winding main shaft and the roll core can be used for automatically winding a strip roll; and after winding is ended, the indexing positioning device can be used for locking the strip roll, so the roll can be discharged conveniently. The amorphous thin strip winding machine disclosed by the invention can easily realize automatic winding, improves the automatic working performance of a winding machine and improves theproduction efficiency.

Owner:JIANGSU GUONENG ALLOY TECH CO LTD

Efficient and rapid gravel filter device

The invention discloses an efficient and rapid gravel filter device which comprises a strip-shaped bearing base. A rapid gravel filter mechanism is arranged on the upper surface of the strip-shaped bearing base, and a movement mechanism is arranged on the lower surface of the strip-shaped bearing base. The efficient and rapid gravel filter device has the advantages that the device is quite convenient to use, feeding can be carried out at multiple positions conveniently, filtering is carried out at multiple positions at the same time, the filter effect is good through stirring during filtering,the filter speed is increased, and discharging is also facilitated.

Owner:常熟梁方智能技术有限公司

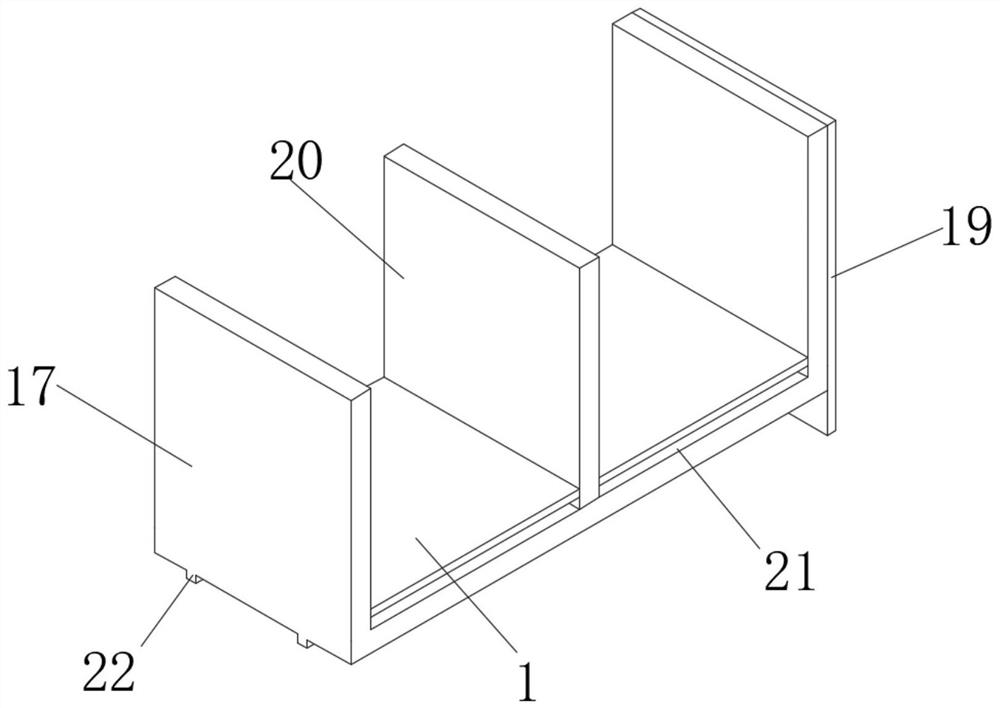

Loading and unloading structure of refrigeration carriage

InactiveCN105416153AGood positioning effectEasy unloadingRefrigerated goods vehicleVehicle with rollersEngineeringRefrigeration

The invention discloses a loading and unloading structure, facilitating loading and unloading, of a refrigeration carriage. The loading and unloading structure comprises a box body. One end, in the longitudinal direction, of the box body is provided with a goods feed-discharge opening. Rails extending in the longitudinal direction of the box body are arranged in the box body. The loading and unloading structure further comprises goods boxes corresponding to the rails. Support rolling wheels are arranged under the goods boxes. Two rows of limiting rolling wheel mechanisms are arranged under each goods box and located on the two sides of the corresponding rail. The loading and unloading structure further comprises pushing-puling air cylinders corresponding to the rails. The cylinder body ends of all the pushing-puling air cylinders are all located at the end, far away from the goods feed-discharge opening, of the box body. The piston rods of the pushing-puling air cylinders can extend out of the goods feed-discharge opening. Installation plates are fixed to the ends of the piston rods of all the pushing-puling air cylinders respectively. A locating air cylinder is fixed to each installation plate, and a piston rod of each locating air cylinder extends upwards. A locating rod is fixed to the end of each locating air cylinder piston rod. A guide sleeve used for guiding of the corresponding locating rod is fixed to each installation plate. The lower portions of the goods boxes are respectively provided with locating grooves corresponding to the locating rods.

Owner:CHONGQING SPEED COMPOSITE CO LTD

Electric power fitting storage device

InactiveCN111845892AGood storageEasy unloadingSupporting partsHand carts with multiple axesStructural engineeringMechanical engineering

The invention discloses an electric power fitting storage device, and relates to the technical field of electric power fitting production. The device comprises a supporting plate, a plurality of partition plates and a set of bolts, a set of fixing plates are fixed to one surface of the supporting plate, a round roller is rotationally connected between the two fixing plates through bearings, a setof fixing blocks are fixed to one surface of the supporting plate, the round roller is located between two fixing blocks, a set of sliding rods are fixed to one surface of each fixing block, and a cover plate is fixed to the other ends of the two sets of sliding rods. According to the invention, the plurality of electric power fitting assemblies are stacked in order from top to bottom through theplurality of equally-divided partition plates; the electric power fitting assembly is not easy to deform during storage; the problem that the electric power fitting assemblies are difficult to disassemble due to mutual lamination is solved so that the storage effect of the electric power fitting assemblies is better, unloading is more convenient in the subsequent use process, the storage safety ofthe electric power fitting assemblies is improved, and the electric power fitting assemblies are more convenient and trouble-saving in the subsequent use process.

Owner:邹龙龙

Logistics storage device for agricultural and sideline products

ActiveCN112373879AEasy unloadingRealize unloadingClimate change adaptationRigid containersAgricultural engineeringStructural engineering

Owner:王光文

Two-wheel cart

InactiveCN107215365AEasy unloadingImprove handling efficiencyHand carts with one axisCartEngineering

The invention discloses a two-wheel trolley, which relates to the technical field of carts, and comprises a vehicle frame, a vehicle bucket, and wheels, the vehicle bucket is installed on the vehicle frame, the wheels are installed under the vehicle frame, and the vehicle frame Outriggers and push rods are also installed on the vehicle body, the front part of the vehicle body and the vehicle frame are fixedly connected through a hinge support, and a movable connection device is installed at the rear of the vehicle body and the vehicle frame. The two-wheel trolley of the present invention is equipped with two wheels on the vehicle frame, which makes the material handling easier and more convenient; By opening the movable connection device, it is convenient to unload materials and effectively improve the efficiency of material handling; the two-wheel trolley has the characteristics of low cost, convenient operation, light weight and simple maintenance.

Owner:东至林野生态种植中心

Intelligent push-cart

InactiveCN108297912AInnovative designEasy unloadingHand carts with multiple axesHand cart accessoriesCartEngineering

The invention relates to the field of push-carts, more specifically to an intelligent push-cart. The intelligent push-cart comprises a cart body frame, a hand-held handle and a roller mechanism, wherein the hand-held handle is mounted on the cart body frame and the roller mechanism is fixed under the cart body frame; the intelligent push-cart further comprises an article filling basket and a multifunctional children device, wherein the article filling basket is hung on the cart body frame and the multifunctional children device is fixed on the hand-held handle; the multifunctional children device comprises a housing protective body, a child seat and an electronic control panel; the child seat is mounted in the housing protective body in a detachable manner; and the electronic control panelis mounted on the child seat. The intelligent push-cart has the advantages that the design is novel; the child seat is embedded in the push-cart to prevent a child from directly standing in the basket, and therefore, accidents such as rollover, falling, crush injury caused by storage racks and so on are avoided.

Owner:罗弟容

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com